Pharmaceutical industry Mixing II

Page 1

Dr.Hussein

Al Qadisyiah College of pharmacy

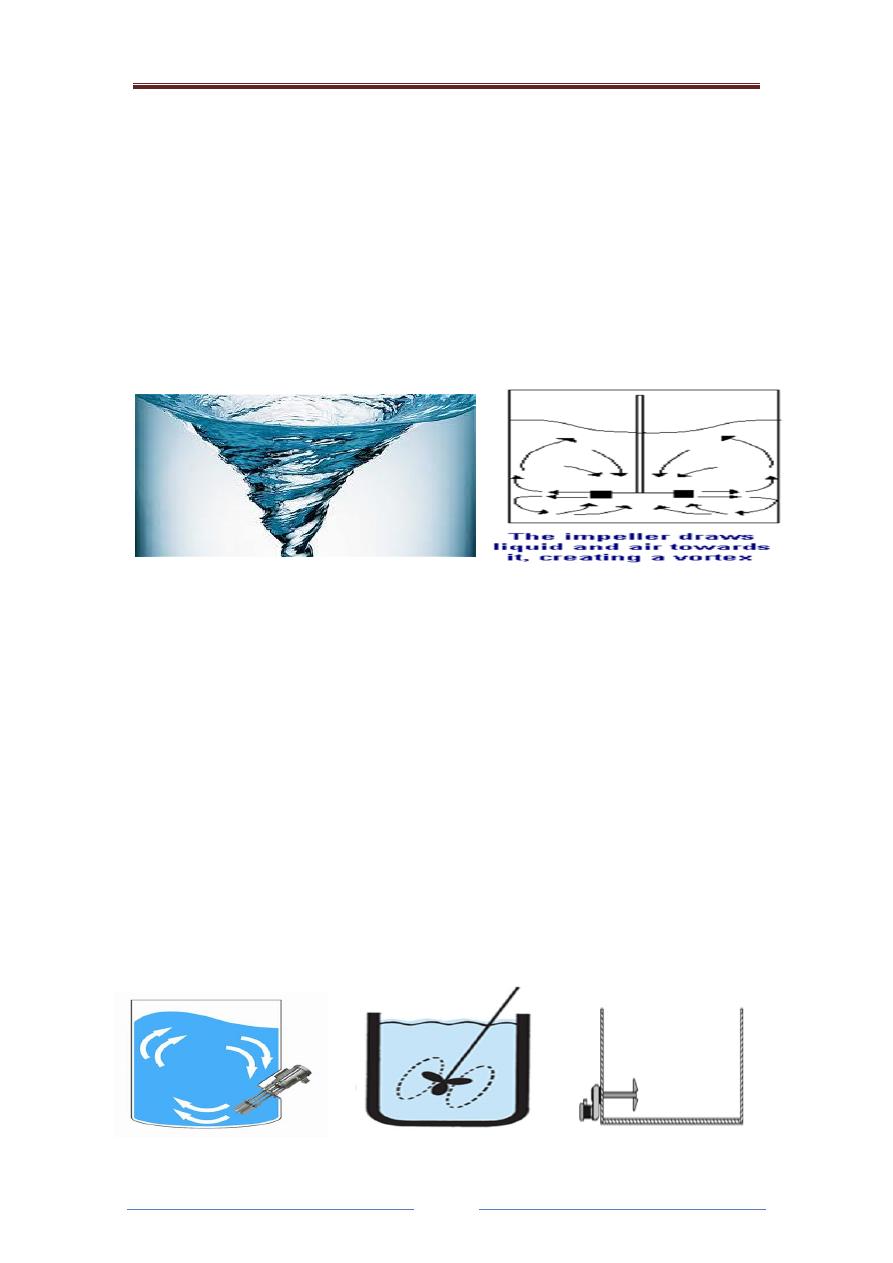

Vortex formation

A strong circulatory flow pattern sometimes manifests into formation of

a vortex near the impeller shaft. Vortex can be formed when

Shaft is placed symmetrically in the tank.

Blades in the turbines are arranged perpendicular to the central shaft.

At high impeller speeds

In unbaffled tanks

Vortex formation reduces mixing intensity by reducing velocity of

the impeller relative to the surrounding fluid.

When vortex reaches the impeller, air from the surface of the liquid

are drawn and air bubbles are produced.

Air bubbles in the fluid can create uneven loading of the impeller

blades.

Entrapped air causes oxidation of the substances in certain cases.

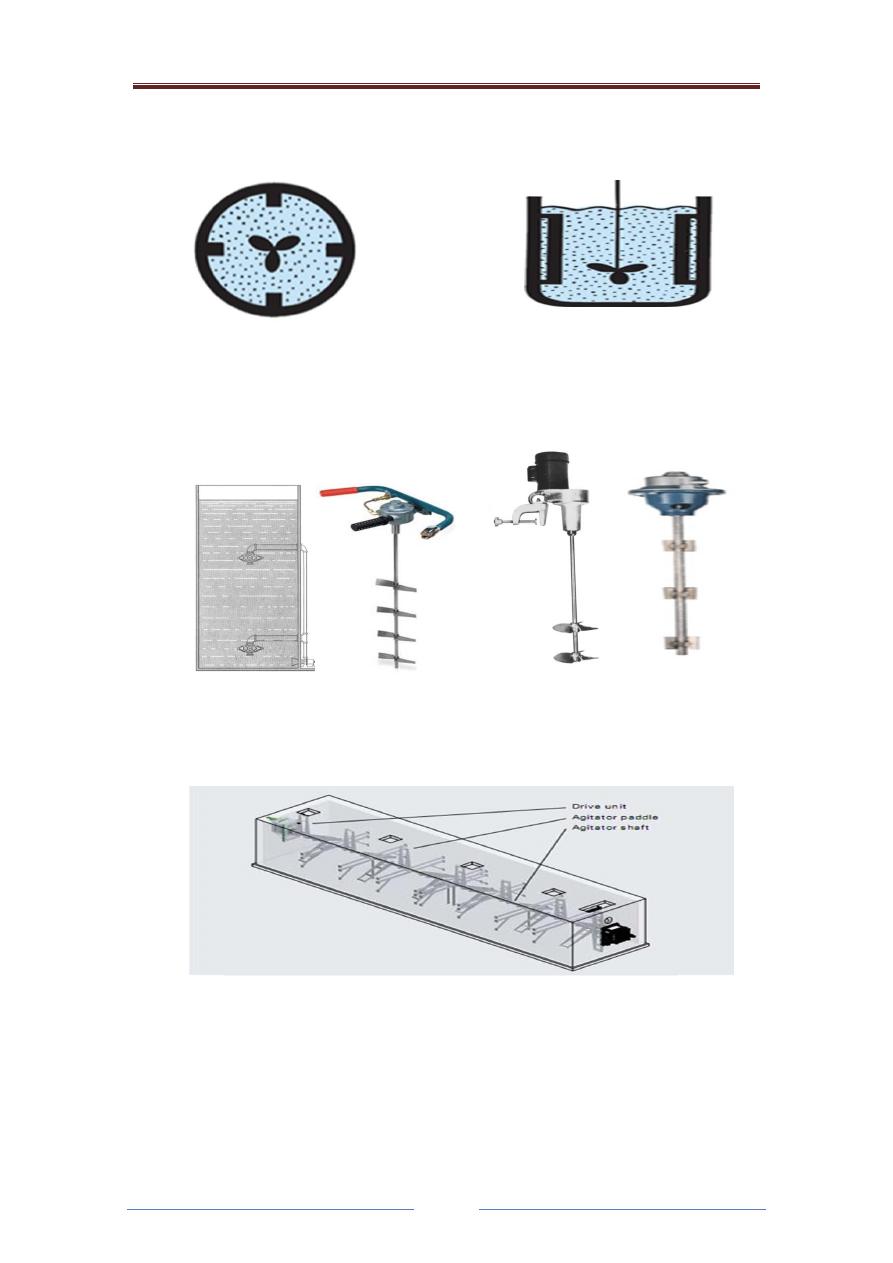

Prevention of vortex formation

1. Impeller should in in any one of the position that can avoid

symmetry such as off central, inclined, side entering, etc., and

should be deep in the liquid .

Pharmaceutical industry Mixing II

Page 2

Dr.Hussein

Al Qadisyiah College of pharmacy

2. Baffled containers should be used. In such case impeller can be

mounted vertically at the center

.

3. Two or more impellers are mounted on the same shaft where

greater depth is required. This system is known as push and pull

mechanism. The bottom impeller is placed about one impeller

diameter above the bottom of the tank. It creates zone of high

turbulence.

4. Tank other than cylindrical in shape are used to prevent vortex

formation. However, such shapes may facilitate the formation of

dead spots

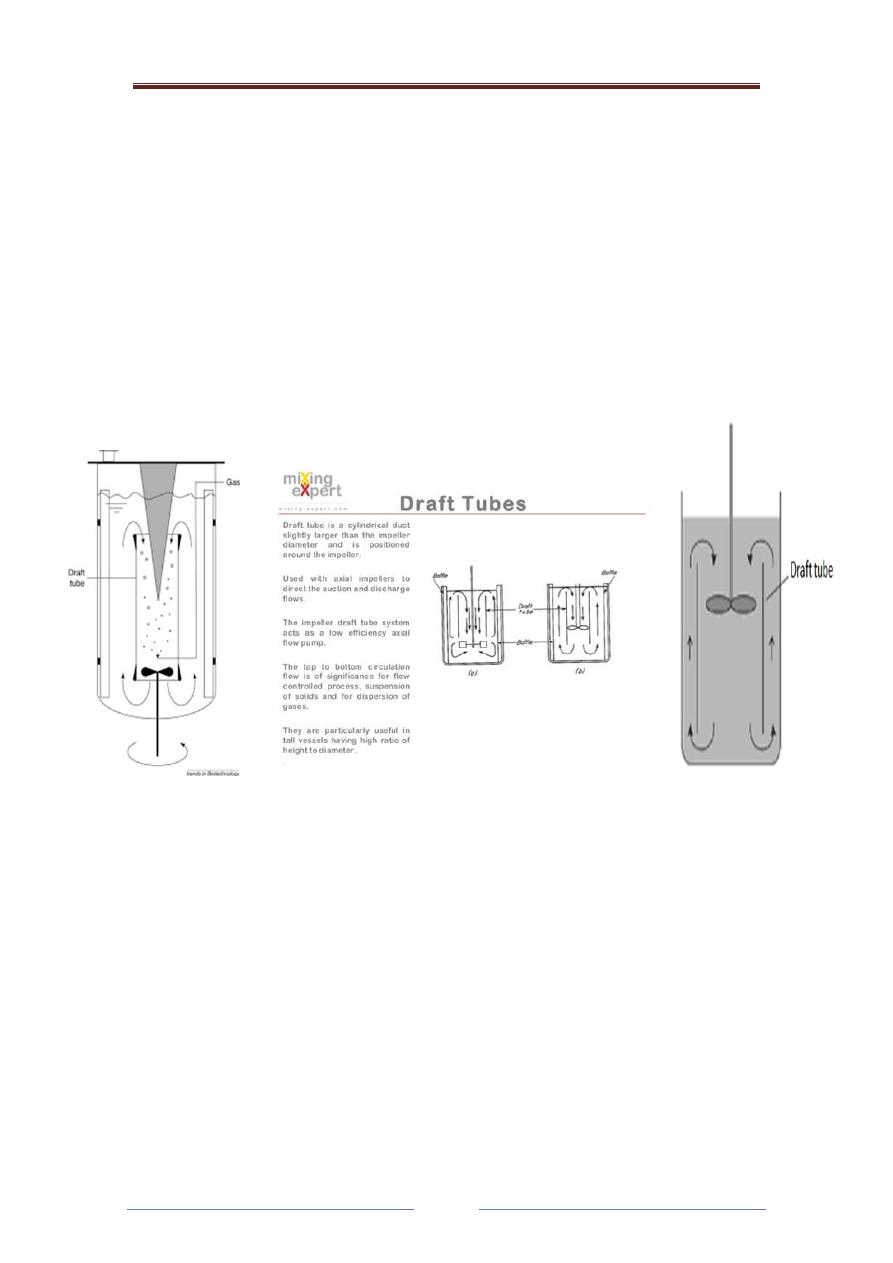

Return flow with Draft tubes

Draft tubes are placed to control the direction and velocity of the

flow to the impeller.

Pharmaceutical industry Mixing II

Page 3

Dr.Hussein

Al Qadisyiah College of pharmacy

These are mounted around the propeller. In case of turbines, draft

tubes are mounted immediately above the impeller.

Draft tubes are fitted to equipment used in the manufacture of certain

emulsions.

When solid particles tend to float on the surface of the liquid, they

are dispersed using draft tubes.

Air jet mixers of continuous mixing of liquids employ draft tubes.

Draft tubes add to the fluid friction in the system. These reduce rate

of flow.

Factors influencing mixing of liquids in tanks

1. Material related factors-

Properties of liquids: physical properties of materials to be mixed.

e.g.: Density, Viscosity and miscibility.

2. Equipment related factors-

Shape of impeller: Propeller type, straight, vertical, curved, or

pitched.

Position of impeller: Central, off-center, side entry, vertical or

inclined etc.,

Pharmaceutical industry Mixing II

Page 4

Dr.Hussein

Al Qadisyiah College of pharmacy

Shape and size of the container: cylindrical or other geometric

forms. Presence or absence of baffles.

Cost of equipment and its maintenance.

3. Process related factors

Speed of rotation of the impeller.

Time required for mixing.

Amount of power that can be expended.

Ease of operation.

Batch size.

Equipment for Liquid mixing

1. Air jet mixer

Principle:

When compressed air jets are passes from the bottom of a vessel, air

bubbles are formed in the liquid phase. The buoyancy of the bubbles lifts

the liquids, which are confines to the central portion due to the presence

of drat tubes. The liquids flow down from the periphery of the vessel and

enter from the bottom due to suction effect.

Construction:

Compresses air or suitable gas is allowed to pass at high pressure from

the inlet provided at the bottom of the tank. This causes buoyancy of the

bubbles which lifts the liquid rom bottom to the top of the vessel.

Pharmaceutical industry Mixing II

Page 5

Dr.Hussein

Al Qadisyiah College of pharmacy

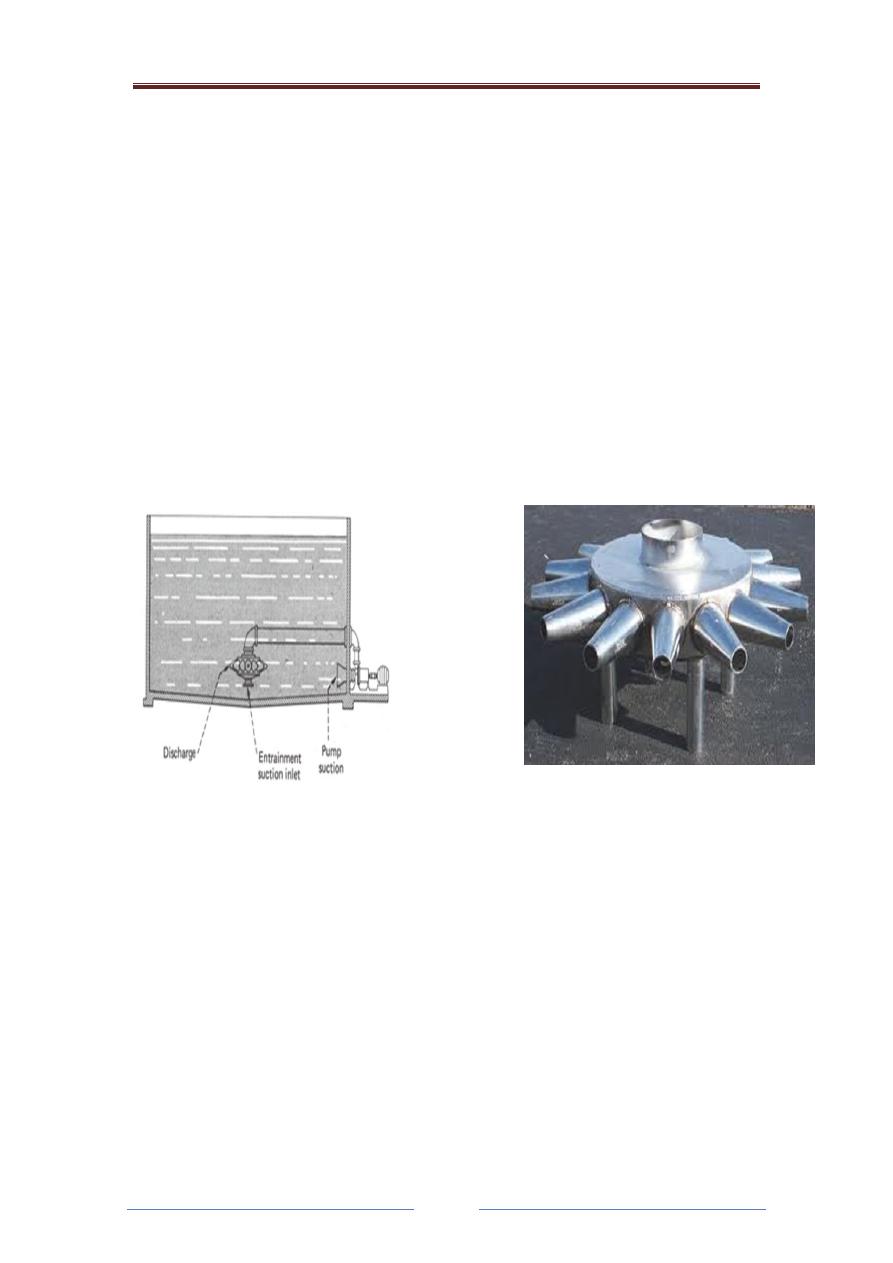

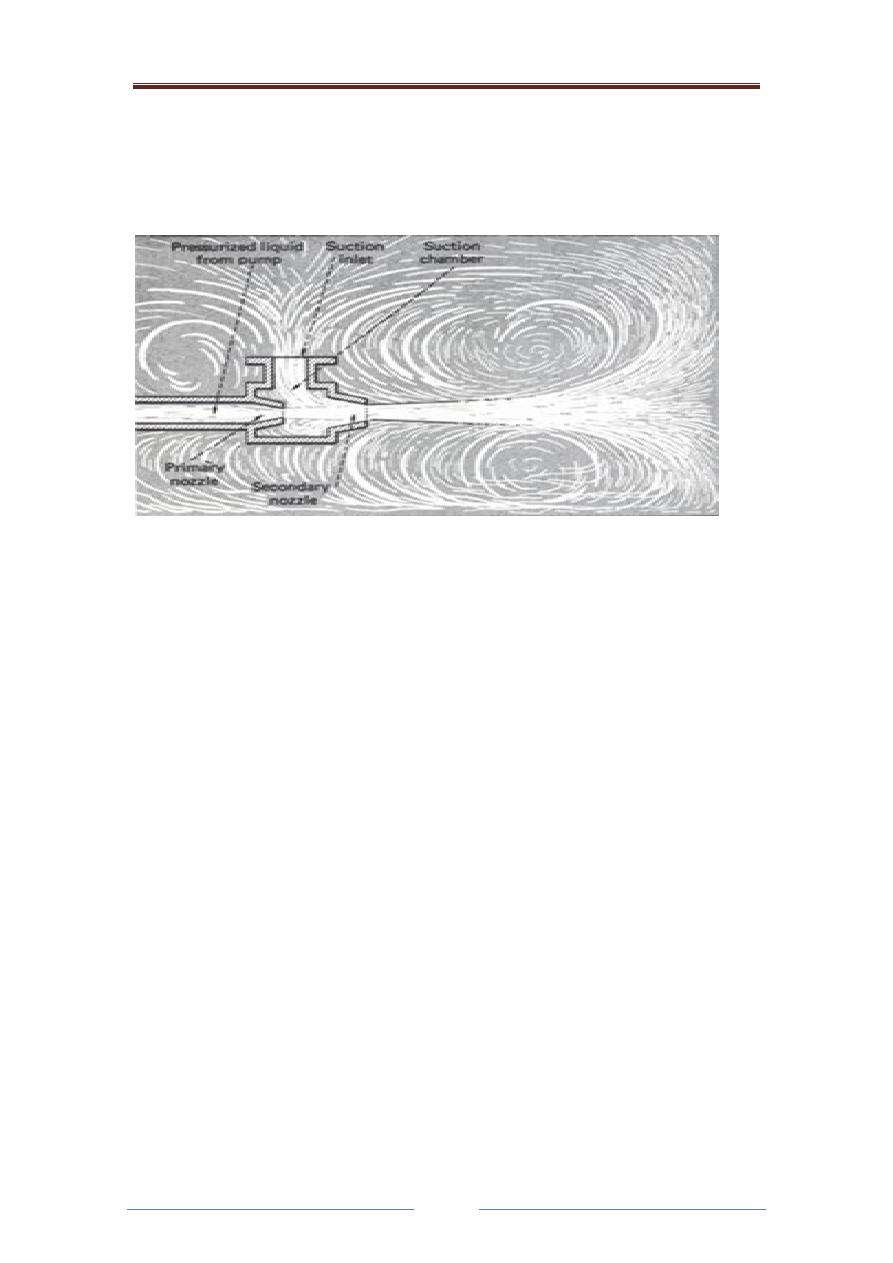

2.Jet mixer

It consists of a vessel and a mixing device known as Jet.

A typical jet-mixing system has 12 jets arranged radially in a cluster

in the centre of the mixing tank. The cluster of jets is called an eddy

jet mixer.

An individual jet has two concentric nozzles with a suction chamber

between them.

It consists of a vessel and a mixing device known as Jet.

A typical jet-mixing system has 12 jets arranged radially in a cluster

in the centre of the mixing tank. The cluster of jets is called an eddy

jet mixer.

An individual jet has two concentric nozzles with a suction chamber

between them.

The tank contents are pumped through the top of the mixer to the

primary nozzles. Then, after passing through the common suction

chamber, the 12 streams of fluid are discharged into the tank through

the secondary nozzles.

As the pressurized fluid flows through the primary nozzle and into

the chamber, it creates a suction because of its high velocity-typically

6-10 m/s for low-shear mixing and 10-20 m/s for high shear.

This suction draws fluid from the tank into the chamber, where the

large velocity difference causes intense mixing .

The mixed fluid is then expelled from the jet through the secondary

nozzle. This forms a cone that entrains the surrounding liquid, and a

Pharmaceutical industry Mixing II

Page 6

Dr.Hussein

Al Qadisyiah College of pharmacy

plume that spreads horizontally before rising to the surface. The

plume imparts most of its energy to the fluid in its path, causing

circulation and mixing throughout the tank. Mixing in the tank is less

intense than in the suction chamber.

Jet mixers tend to be used in situations that require turbulence, rapid

approach to homogeneity, and high local shear rates.

Jet mixing is normally used for liquids and slurries having viscosities

below 1,000 mp; a mechanical agitator is generally more efficient for

higher-viscosity fluids.

Mainly useful for processes of liquid blending. e.g., neutralization or

extraction.

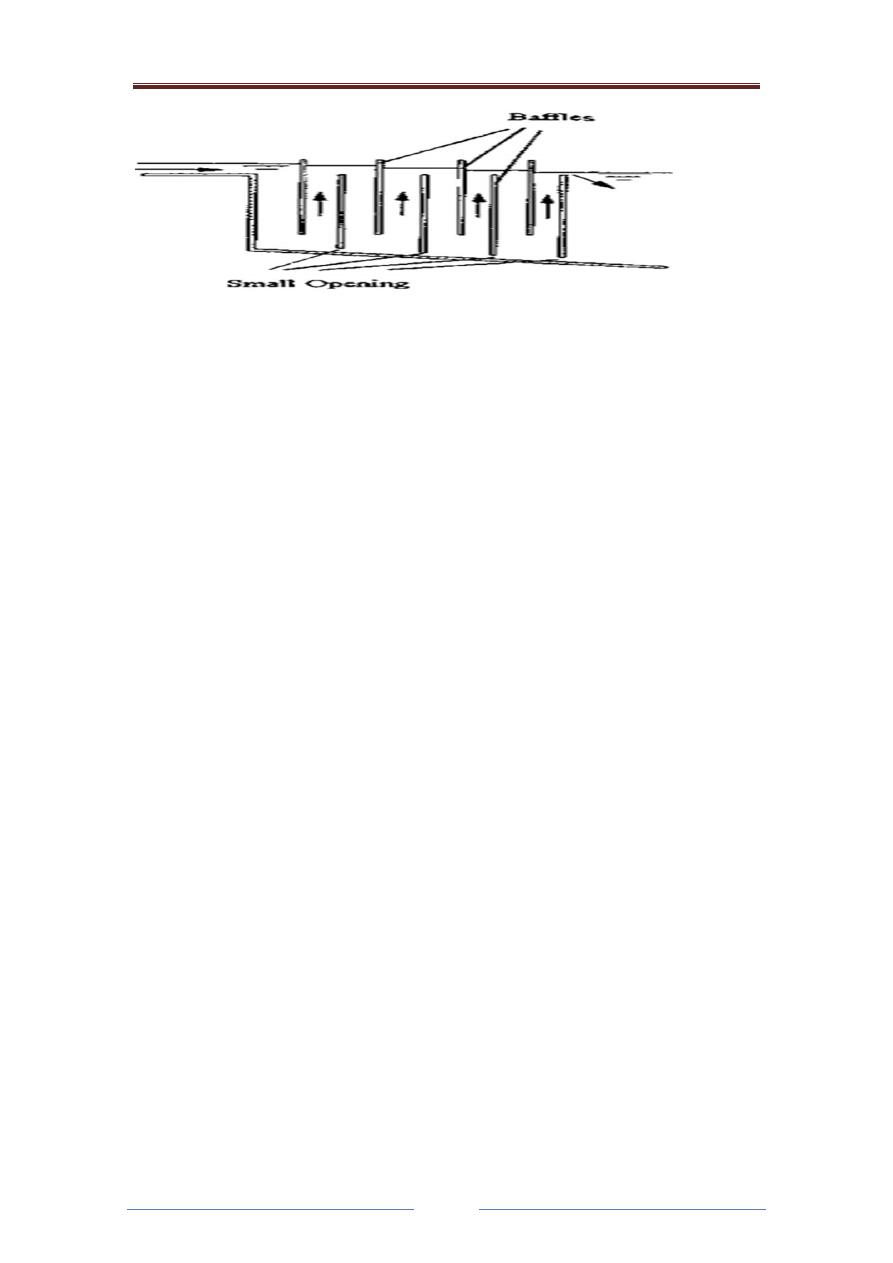

3.Flow mixer or line mixer or pipe mixer

It may consist a baffled pipe or an empty chamber.

Liquids to be mixed are passed through the pipe/ chamber.

Mixing takes place through bulk transport in the direction of flow.

The power supplied to pump the liquid itself accomplishes mixing.

For effective mixing controlling the feed rate is essential

Pharmaceutical industry Mixing II

Page 7

Dr.Hussein

Al Qadisyiah College of pharmacy

If the input rate is difficult to control and fluctuations in the added

proportions of the liquids are unavoidable, continuous mixing

equipment of tank type is preferable, because hold-up of the liquids

and back flow or recirculation is possible

.

Used when large volume of liquids are to be mixed.

Used for continuous mixing.

Mixing of immiscible Liquids

Carried mainly in the manufacture of emulsions, and the equipment

used for the preparation of an emulsion is known as emulsifier. Also

known as homogenizer as it results in fine emulsion. Fine emulsion is

prepared in 2 stages.

In 1

st

stage coarse emulsion is prepared by using one of the following

process:-

– Hand homogenizer

– Porcelain mortar and pestle

– Milk shake mixer

– Propeller in a baffled tank

Sometimes the above equipment directly gives fine emulsion.

Otherwise coarse emulsion is subjected to homogenizer in the 2

nd

stage to get fine emulsion by using following process:-

– Silverson emulsifier

– Colloidal mill

– Rapisonic homogenizer

Pharmaceutical industry Mixing II

Page 8

Dr.Hussein

Al Qadisyiah College of pharmacy

Silverson mixer –Emulsifier

Principle:

It produces intense shearing forces and turbulence by use of high

speed rotors.

Circulation of material takes place through the head by the suction

produced in the inlet at the bottom of the head.

Circulation of the material ensures rapid breakdown of the dispersed

liquid into smaller globules.

It consists of long supporting columns and a central portion. Central

portion consists of a shaft which is connected to motor at one end and

other to the head.

Head carries turbine blades.

Blades are surrounded by a mesh, which is further enclosed by a cover

having openings.

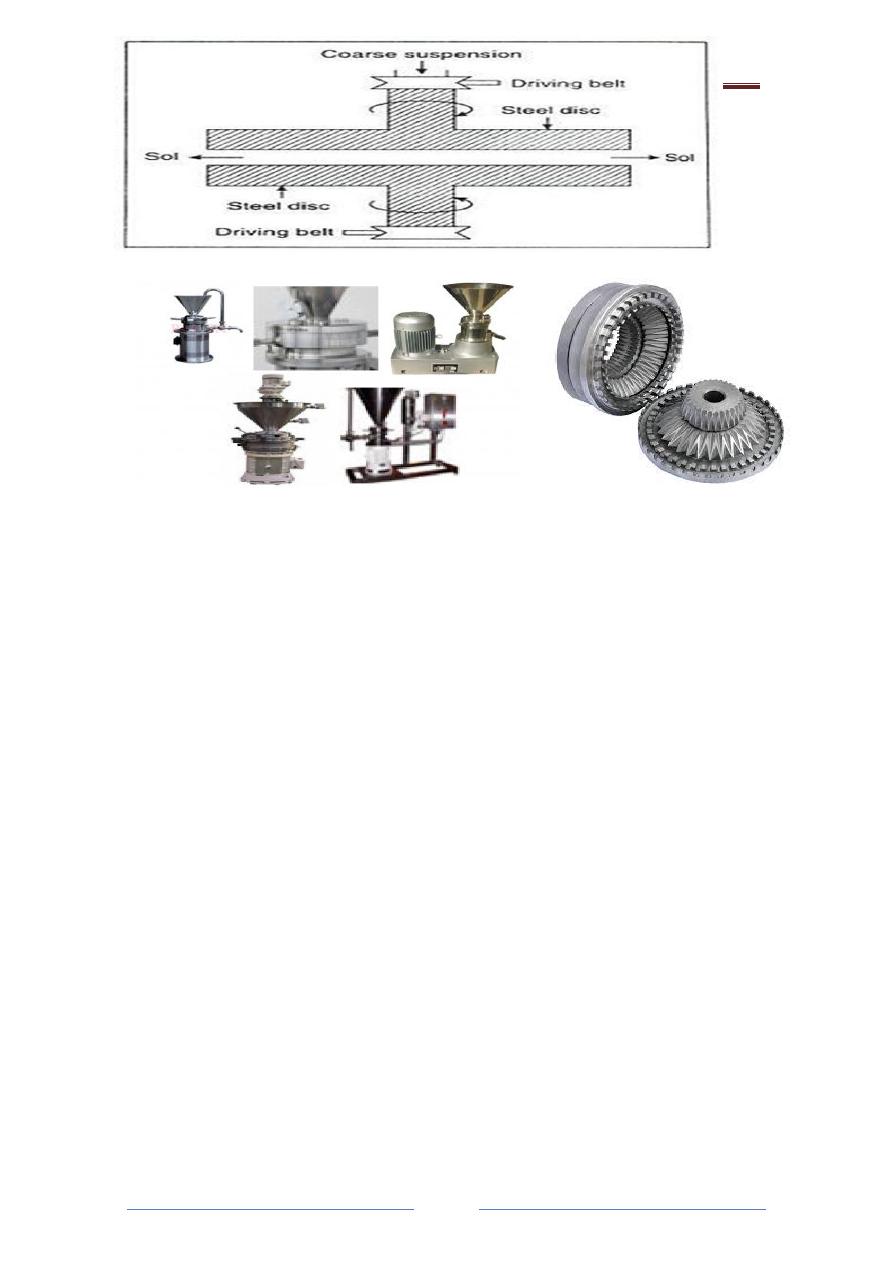

Colloid mill

Pharmaceutical industry Mixing II

Page 9

Dr.Hussein

Al Qadisyiah College of pharmacy

DESCRIPTION

The colloidal mill is used in the reduction of the particles or solid

materials which are present in the suspensions or emulsion. The shearing

is the mechanism in the colloidal mill. By the stator and the rotor present

in the cylindrical vessel of the colloidal mill the shearing take place and

the reduction of the particles takes place.

Basic parts

It consists of an inlet hopper which is used to feed the material into the

mill.

It consists of a rotor and stator which are used to reduce the particles

size by applying the shearing force.

It consists of an outlet which is used to discharge the reduced

particles.

Construction

A colloidal mill consist of a high speed rotor and a stator with a

conical milling surfaces between which is an adjustable clearance

ranging from 0.002 to 0.03 inches.

The rotor speed is 3000 to 20000rpm. The material to be ground

should be pre milled as finely as possible to prevent damage to the

colloidal mill.

Pharmaceutical industry Mixing II

Page

10

Dr.Hussein

Al Qadisyiah College of pharmacy

Rotors and the stator may be smooth surfaced or rough surface. With

the rotor and the stator there is a thin uniform film of material between

them and it is subjected to the maximum amount of shear.

Rough surfaced mill add intense eddy current, turbulence and the

impaction of the particles to the shearing action.

Principle

Colloidal mill works on the principle of rotor-stator.

The size reduction is affected due to shearing, when the material is

passed between the narrow gap of milling surfaces of rotor and stator.

A rotor turns at high speeds of 3000 - 20000rpm. The high levels of

hydraulic shear applied to the process liquid disrupt structures in the

fluid. Colloid mills are frequently used to increase the stability of

suspensions, emulsions and can also be used to reduce the particle size

of solids in suspensions.

Higher shear rates leads to smaller droplets of 1 micron. Based on a

rotor rotating at high speed and very close to a conical stator, the

particle size is done by modifying the gap between the rotor and the

stator.

ADVANTAGES

High throughput with excellent grinding result.

Infinitely adjustable gap settings between rotor/stator for control of

particle size reduction

Suitable for products of high viscosity range.

Capable of operation under pressures up to 16 bar.

High-value seal with wear-resistant materials.

High quality surface finishes for easy cleaning.

Other materials and finishes are available upon request

Machine is self-draining.

Low noise levels.

DISADVANTAGES

Requires high power for the running of the colloidal mill.

Using of wet materials.

Pharmaceutical industry Mixing II

Page

11

Dr.Hussein

Al Qadisyiah College of pharmacy

Ultrasonic Emulsifiers – Rapisonic homogenizer

Principle:

Application of intense vibration by causing equipment producing

sonic or ultrasonic frequencies, can affect vibration in some cases

causing emulsification and in others resulting in coalescence of an

emulsion. While sonic frequencies are from 15 to 20,000 /s,

ultrasonic frequencies are above 20,000 /s. ultrasonic frequencies

break up a liquid into globules by cavitation method i.e., when a

liquid is subjected to ultrasonic vibrations alternate regions of

compression and rarefaction are produced in the liquid.

Cavities are formed in the regions of rarefaction which subsequently

collapse in the regions of compression. Which results great forces for

emulsification.

Construction:

It consists of a pump driven by a motor. It is connected to inlet tube

and an out let tube.

Head consists of a flat jet for liquid inlet. Facing the jet, a thin blade

is present which vibrates at its natural frequency.

Can be used for batch process (by placing it in a tank) or for

continuous process (by placing it in a pipeline).

Pharmaceutical industry Mixing II

Page

12

Dr.Hussein

Al Qadisyiah College of pharmacy

It has the capacity to produce dispersed globules of one micron size.

As this method is highly efficient to decrease globule size, reduced

concentration of emulgents is sufficient.

Its capacity of mixing liquids ranges from 20 - 500 liters per minute.

It is suitable for thermolabile substances since heat is not generated

during mixing

It is useful only for low viscous liquids.

II-Solid-Solid Mixing (Powder mixing)

In pharmaceutical production when the formulation contains an active

ingredient, which is toxic or is present in a concentration of about 0.5%

of the total mass then the mixing of solids becomes a critically important

operation. Product with too low an active ingredient will be ineffective

and a product with too high active ingredient may be lethal.

To provide good solid mixing the phenomenon to be avoided or

overcome is the tendency of the particles to segregate. Segregation

occurs when a system contains particles with different sizes, densities,

etc. and motion can cause particles to preferentially accumulate into

one area over another.

Powder mixing is a process in which two or more than two solid

substances are intermingled in a mixer by continuous movement of the

particles. Mainly, the object of mixing operation is to produce a bulk

mixture which when divided into different doses, every unit of dose

must contain the correct proportion of each ingredient. The degree of

mixing will increase with the length of time for which mixing is done.

Powder mixing is a neutral type of mixing. It is one of the most

common operations employed in pharmaceutical industries for the

preparation of different types of formulations, e.g. powders, capsules

and tablets. When grinding and mixing of different substances is to be

done simultaneously then two or more than two substances are fed to

the mill one at the same time.

The ease with which different powders blend to a reasonably

homogeneous mix varies considerably, being dependent on various

physical properties of the individual components and on their relative

proportions. It is easier to mix equal weights of two powders of

similar fineness and density than to incorporate a small proportion of a

fine powder in a large mass of a coarse denser material.

Pharmaceutical industry Mixing II

Page

13

Dr.Hussein

Al Qadisyiah College of pharmacy

Apart from density and particle size, the stickiness of the components

to be mixed is also important. Prolonged mixing becomes necessary to

effectively distribute materials like lubricants and wetting agents into

tablet granules.

Also wide differences among properties such as particle size

distribution, shape and surface characteristics such as surface area and

electrostatic charges may take blending very difficult.

Flow characteristics such as angle of repose and ability to flow,

abrasiveness of one ingredient upon the other, state of agglomeration

of the ingredients, moisture or liquid content of the solids, density,

viscosity and surface tension at operating temperature of any liquid

added, are some other significant considerations in mixing and

selection of mixing equipments. In fact the properties of the blending

ingredients dominate the mixing operation.

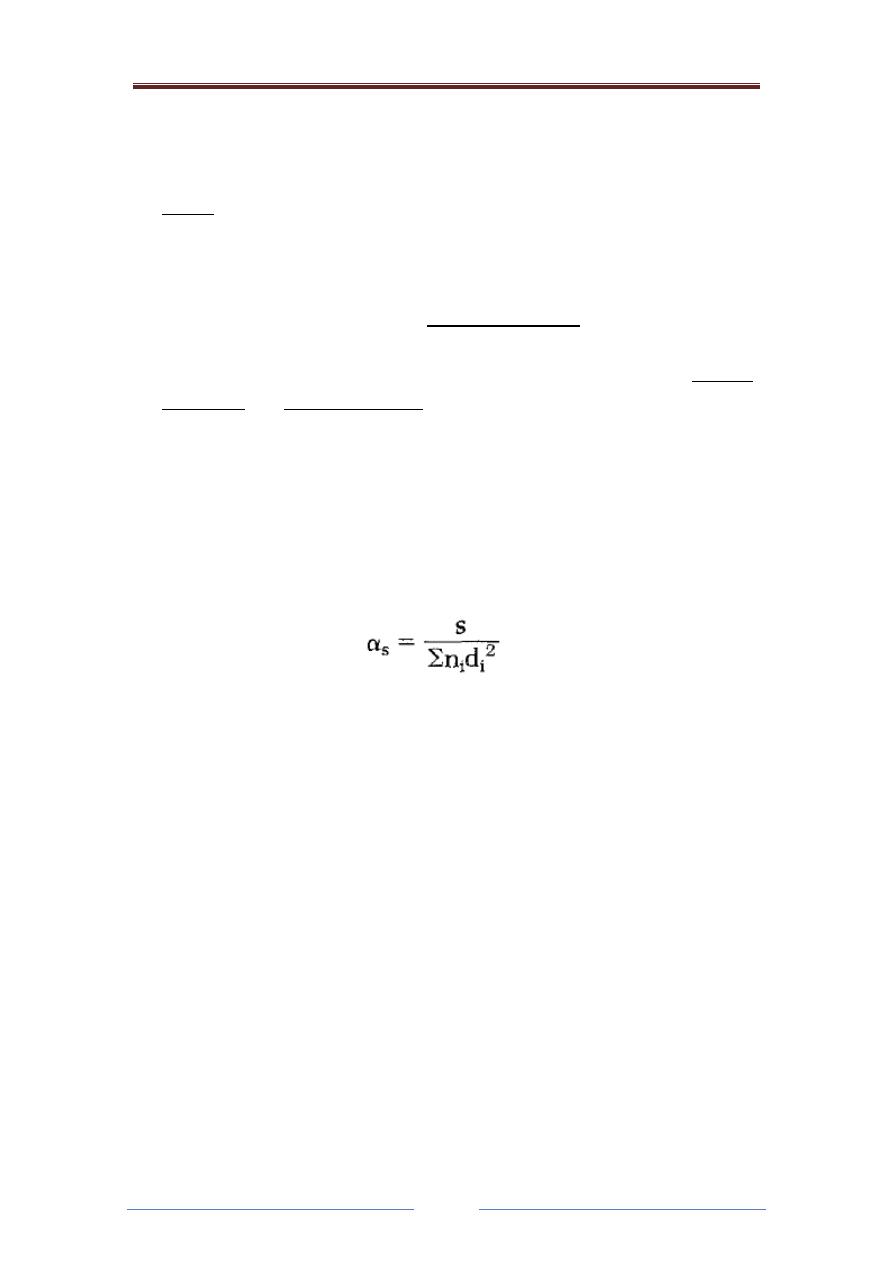

A large number of shape factors have been defined and used in studies

of multiparticulate solids systems. A typical example is that of a

surface shape factor, α

s

, defined by the expression:

The total surface area of the powder is S, having Ni particles of

projected diameter di. Powders whose particles are highly irregular in

shape generally exhibit large values of α

s

.

The value for α

s

can be seen

to increase substantially as the particles become more angular and

deviate from a spherical shape.

Forces Acting in Multiparticulate Solids Systems.

The forces that operate at a particulate level during the mixing process

are essentially of two types: (1) those that tend to result in movement of

two adjacent particles or groups of particles relative to each other and (2)

those that tend to hold neighboring particles in a fixed relative position.

In the first category are forces of acceleration produced by the

translational and rotational movements of single particles. or groups

of particles. Such motion can result either from contact with the

mixer surfaces or from contact with other particles. In either case, the

Pharmaceutical industry Mixing II

Page

14

Dr.Hussein

Al Qadisyiah College of pharmacy

efficiency of momentum transfer is highly dependent on the elasticity

of the collisions. In general, much more rapid and efficient

interchange of momentum would be expected if loss by inelasticity

was minimal.

Included in the second category of forces namely those that resist

particulate movement, are interparticulate interactions associated

with the size, shape, and surface characteristics of the particles

themselves. Powders that have high "cohesive" forces due to

interaction of their surfaces can be expected to be more resistant to

intimate mixing than those whose surfaces do not interact strongly.

Factors that influence this type of interaction are surface polarity,

surface charge, and adsorbed substances such as moisture.

Mixing Mechanisms.

It has been generally accepted that solids mixing proceeds by a

combination of one or more mechanisms.

1. Convective mixing. This mechanism may be regarded as analogous to

bulk transport as discussed in connection with fluids mixing. Depending

on the type of mixer employed, convective mixing can occur by an

inversion of the powder bed, by means of blades or paddles, by means of

a revolving screw, or by any other method of moving a relatively large

mass of material from one part of the powder bed to another.

2. Shear mixing. As a result of forces within the particulate mass, slip

planes are set up. Depending on the flow characteristics of the powder,

these can occur singly or in such a way as to give rise to laminar flow.

When shear occurs between regions of different composition and 'parallel

to their interface, it reduces the scale of segregation by thinning the

dissimilar layers. Shear occurring in a direction normal to the interface of

such layers is also effective since it too reduces the scale of segregation.

3. Diffusive mixing. Mixing by "diffusion" is said to occur when random

motion of particles within a powder bed causes them to change position

relative to one another. Such an exchange of positions by single particles

results in a reduction of the intensity of segregation. Diffusive mixing

occurs at the interfaces of dissimilar regions that are undergoing shear

and therefore results from shear mixing. It may also be produced by any

form of agitation that results in interparticulate motion.

Pharmaceutical industry Mixing II

Page

15

Dr.Hussein

Al Qadisyiah College of pharmacy

General notes

The mixing of particles whose surfaces are nonconducting

(electrically) often results in the generation of surface charges, as

evidenced by a tendency of the powder to clump following a period of

agitation. Surface charging of particles during mixing is undesirable,

for it tends to decrease the process of interparticulate "(diffusion.)"

Charging of powder beds and the undesirable effects it produces can

be prevented or reduced in many cases by surface treatment, which is

usually accomplished by adding small amounts of surfactants to the

powder, thereby increasing the conductivity of the surface. The

problem can also-be solved in some cases by mixing under conditions

of increased humidity (above 40%).

Segregation

particulate solids tend to segregate by virtue of differences in the size,

density, shape, and other properties of the particles of which they are

composed. The process of segregation occurs during mixing as well as

during subsequent handling of the completed mix, and it is most

pronounced with free-flowing powders.

Powders that are not free-flowing or that exhibit high forces of

cohesion or adhesion between particles of similar or dissimilar

composition are often difficult to mix owing to agglomeration. The

clumps of particles can be broken down in such cases by the use of

mixers that generate high shear forces or that subject the powder to

impact. When these powders have been mixed, however, they are

less susceptible to segregation because of the relatively high

interparticulate forces that resist interparticulate motion leading to

unmixing.

Physical properties affecting mixing

1. Material density: If the components are of different density, the

denser material will sink through the lighter one, the effect of which

will depend on the relative positions of the material in the mixer. If

the denser particles form the lower layer in a mixture at the start of a

mixing operation, the degree of mixing will increase gradually until

equilibrium is attained, not necessarily complete mixing. If the

Pharmaceutical industry Mixing II

Page

16

Dr.Hussein

Al Qadisyiah College of pharmacy

denser component is above, the degree of mixing increases to a

maximum, then dropping to equilibrium as the denser component

falls through the lighter one, so that segregation has started. This

factor is of practical significance in charging and operating a mixer.

2. Particle size: Variation in particle size can lead to segregation also

since smaller particles can fall through the voids between the larger

particles. There will be a critical particle size that can just be retained

in the mixed condition, which will depend upon the packing. When

the bed of the particles is disturbed, dilation occurs and the greater

porosity of open packing allows a large size of particle to slip

through the voids, leading to segregation.

3. Particle shape: The ideal particle is spherical in shape, and further

the particles depart from this theoretical form, the greater the

difficulty of mixing. If the particles are of irregular shapes, then they

can become interlocked leading to a decrease in the risk of

segregation once mixing has been achieved.

4. Particle attraction: Some particles exert attractive forces; this may

be due to adsorbed liquid films or electrostatic charges, such particles

tending to aggregate. Sine these are surface properties, the effect

increases as particle size decreases.

5. Proportions of materials to be mixed :The proportions of materials

to be mixed play a very important role in powder mixing. It is easy to

mix the powders if they are available in equal quantities but it is

difficult to mix small quantities of powders with large quantities of

other ingredients or diluents. The practical method for mixing such

quantities is that the component present in lesser amount is mixed

with an equal amount of the diluent, then a further amount of diluent

is incorporated which is almost equal to previous quantities and so on

until whole of the diluent has been added. This method is followed

for mixing potent substances with diluents. When more than two

components are to be mixed, they should always be mixed in

ascending order of their weights so as to ensure uniform mixing of

the ingredients.

Conditions for mixing

The theory of powder mixing shows four conditions that should be

observed in the mixing operation.

Pharmaceutical industry Mixing II

Page

17

Dr.Hussein

Al Qadisyiah College of pharmacy

1. Mixer volume: The mixer must allow sufficient space for dilation of

the bed. Overfilling reduces the efficiency and may prevent mixing

entirely.

2. Mixing mechanism: The mixer must apply suitable shear forces to

bring about local mixing and a convective movement to ensure that

the bulk of the material passes through this area.

3. Mixing time: Mixing must be carried out for an appropriate time,

since the degree of mixing will approach its limiting equilibrium

value asymptotically. Hence, there is an optimum time for mixing for

any particular situation, one should also note that the equilibrium

condition may not represent the best mixing if segregation has

occurred.

4. Handling the mixed powder :When the mixing operation is

completed, the mixer should stop and the powder should be handled

in such a way that segregation is minimized. The vibration caused by

subsequent manipulation, transport, handling or use is likely to cause

segregation. Therefore, a bulk powder that has been stored or

transported should be re-mixed before removing a part of the

contents.

Equipment

A wide variety of equipment is used in different industries. In some

machines the container rotates. In others a device rotates within a

stationary container. In some cases, a combination of rotating container

and rotating internal device is used. Sometimes baffles or blades are

present in the mixer.

For mixing of powders or a powder with a small quantity of a liquid

where a constituent is cohesive or sticky, the material tends to

agglomerate into balls. Under these conditions agitation mixers are

more satisfactory than tumbling mixers. They consist essentially of a

stationary shell with a horizontal or vertical agitator moving inside it.

The agitator may take the form of blades, paddles or screw.

Sometimes agglomerates are desired as in the case of some foods and

pharmaceuticals.

Mixing is sometimes achieved by feeding two or more materials

simultaneously to a mill, such as ball mill, if both require grinding.

For fine, dry powders the use of a screw conveyor often gives

Pharmaceutical industry Mixing II

Page

18

Dr.Hussein

Al Qadisyiah College of pharmacy

satisfactory mixing while transporting the material and hence no

additional equipment or power is needed for mixing.

Criteria:

1. Powder bed should not be filled for more than 60%

2. Particles should be subjected to movement in three directions

3. Shearing force should be sufficient to prevent aggregation.

4. There should be no centrifugal effect

5. Forces should not cause breakage of the particles.

6. The mixing process should be stopped abruptly.

Classification of equipment for solid mixing

Based on flow properties:

1. Free flowing solids: e.g.: V cone blend , Double cone blender

2. Cohesive solids: e.g.: Sigma blender, Planetary mixer

Based on scale of mixing:

1. Batch type(small scale):

e.g.: Mortar and pestle, V cone blender, Double cone blender,

Ribbon blender, Sigma blender, Planetary paddle, Fluidized mixer

2. Continuous type(large scale): e.g.: barrel type, zigzag type

Tumblers or cylindrical blenders with no mixing blade

Meant for dry powders

Equipment consists of a container of any geometric form.

Container is mounted on special roller so that it can be rotated about

any axis.

Edge of 27 degrees is good for mixing.

Efficiency of a tumbler mixer highly depends on the speed of

rotation. It should be critical and optimum.

Slow rotation- no intense tumbling, No cascade motion, Not enough

shear rates are applied.

Rapid rotation-sufficient centrifugal action to the powder to the side

of the mixer, more dusting and segregation of fines is possible.

Rate of rotation depends upon size , shape of the tumbler and nature

of the material to be mixed. Common range is 30-100rpm.

Pharmaceutical industry Mixing II

Page

19

Dr.Hussein

Al Qadisyiah College of pharmacy

Mixing is done by tumbling motion, which is accentuated by virtue

of the shape of the container.

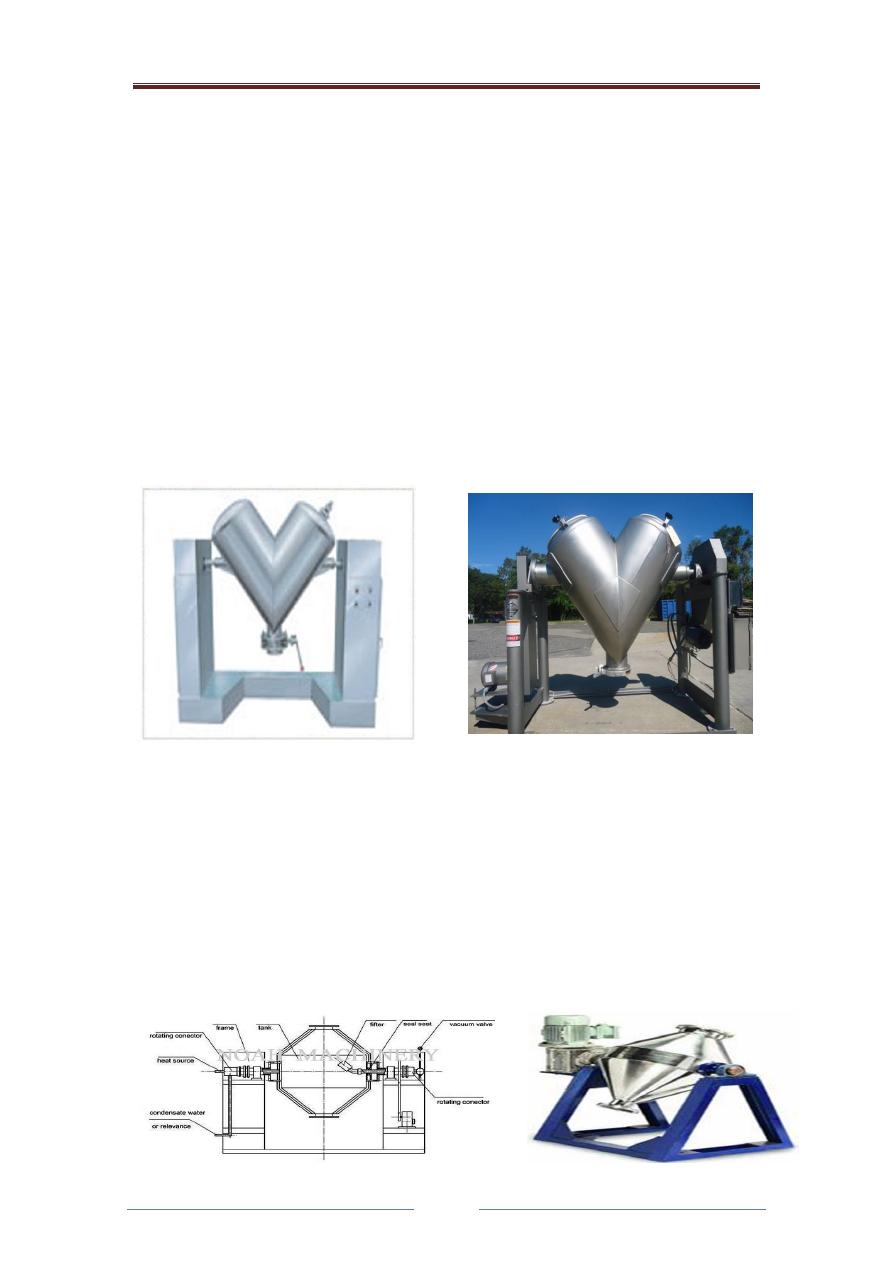

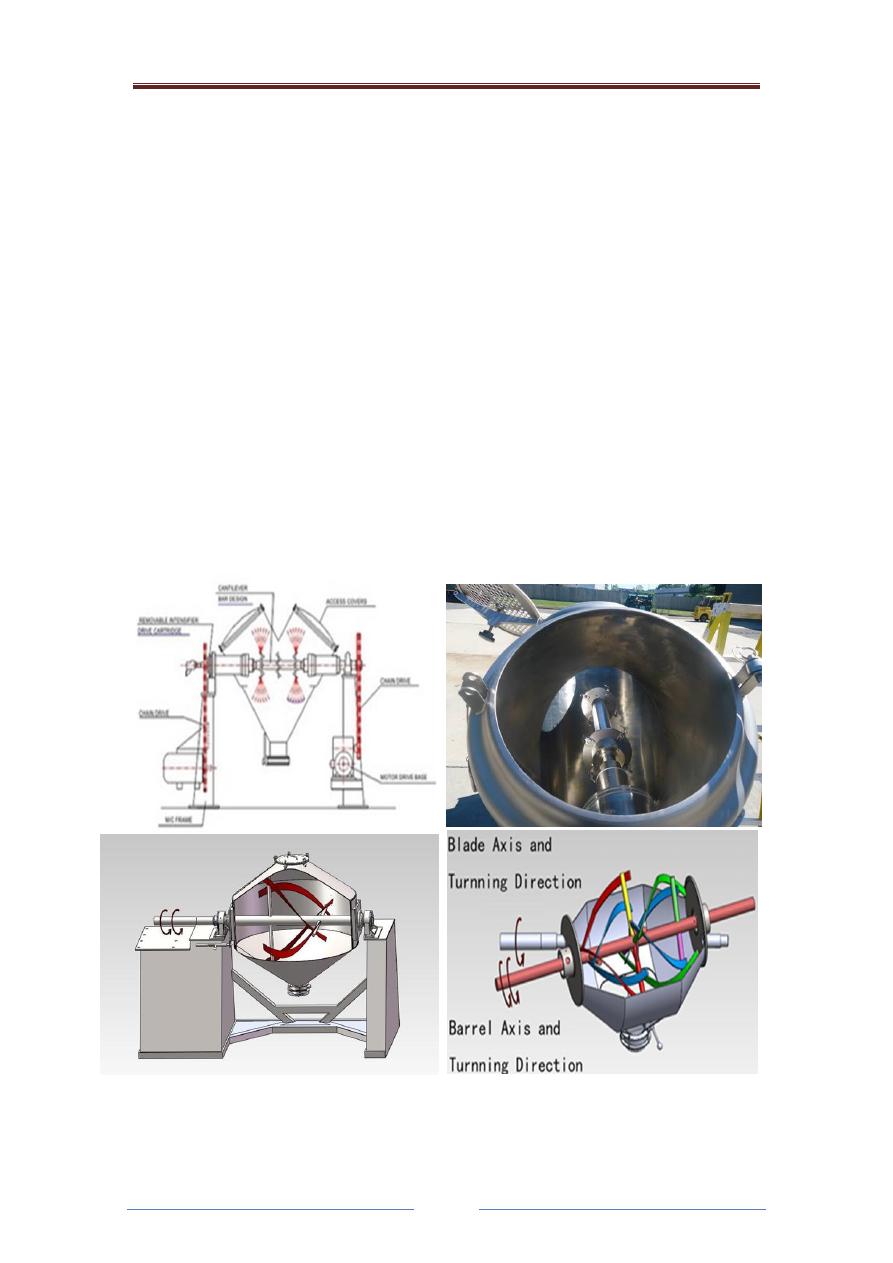

1. Twin shell blender or V cone blender

It is V shaped and made up of stainless steel or transparent plastic.

Material is loaded through shell hatches and emptying is normally

done through and apex port.

The material is loaded approximately 50-60% of the total volume.

Small models – 20 kg , rotate at 35rpm

Large models – 1 ton, rotate at 15rpm

As the blender rotates , the material undergoes tumbling motion.

When V is inverted, the material splits into two portions. This

process of dividing and recombining continuously yields ordered

mixing by mechanical means.

2. Double cone blender

It consists of double cone on rotating shaft.

It is usually used for small amount of powders.

It is efficient for mixing powders of different densities.

Material is loaded and emptying is done through the same port.

The rate of rotation should be optimum depending upon the size,

shape of the tumbler and nature of the material to be mixed.

The rate of rotation commonly ranges from 30-100rpm.

Mixing occurs due to tumbling motion.

Pharmaceutical industry Mixing II

Page

20

Dr.Hussein

Al Qadisyiah College of pharmacy

Advantages of V cone blender and double cone blenders:

If fragile granules are to be blended, V cone blender is suitable

because of minimum attrition.

They handle large capacities.

Easy to clean , load, and unload.

This equipment requires minimum maintenance.

Disadvantages of V cone blender and double cone blenders:

V cone blender needs high headspace for installation.

It is not suitable for fine particulate system or ingredients of large

differences in the particle size distribution, because not enough

shear is applied

If powders are free flowing, serial dilution is required for the

addition of low dose active ingredients.

Tumbling blenders with agitator mixing blades

Pharmaceutical industry Mixing II

Page

21

Dr.Hussein

Al Qadisyiah College of pharmacy

Advantages of tumblers with blades:

Baffles are useful for both wet and dry mixing.

Wide range of shearing force can be applied with agitator bars

permitting the intimate mixing of very fine as well as coarse

powders.

Serial dilution is not needed when incorporating low-dose active

ingredients.

Disadvantages of tumblers with blades:

Attrition is large, size reduction of friable particles results.

Cleaning may be a problem, because agitator assembly must be

removed and the packing should be replaced for a product

changeover

Potential packing (sealing) problems occur.

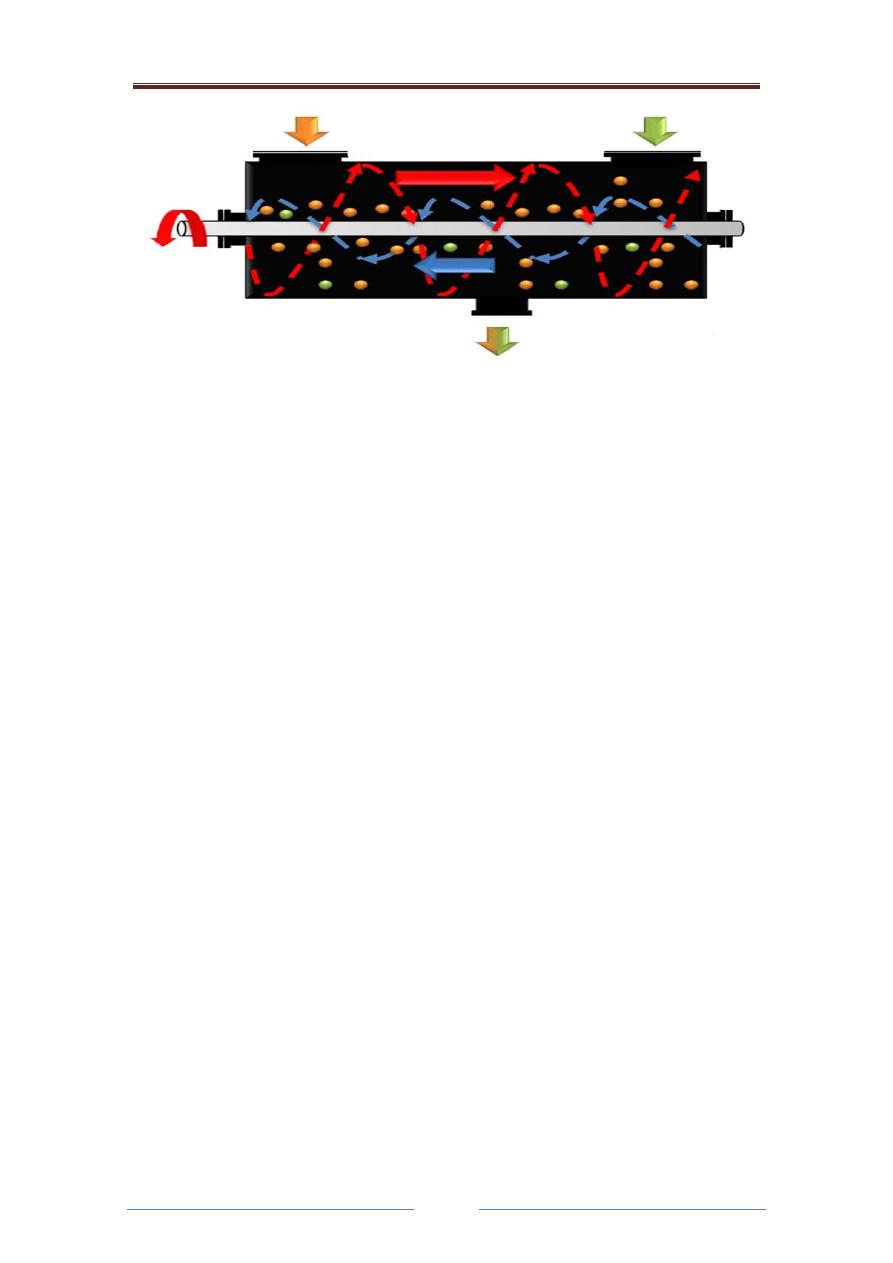

Ribbon blender

Principle:

Mechanism of mixing is shear. Shear is transferred by moving blades.

High shear rates are effective in breaking lumps and aggregates.

Convective mixing also occurs as the powder bed is lifted and allowed to

cascade to the bottom of the container. An equilibrium state of mixing

can be achieved.

Construction:

Consists of horizontal cylindrical trough usually open at the top. It is

fitted with two helical blades, which are mounted on the same shaft

through the long axis of the trough.

Blades have both right and left hand twists.

Blades are connected to fixed speed drive.

It can be loaded by top loading and emptying is done through bottom

Pharmaceutical industry Mixing II

Page

22

Dr.Hussein

Al Qadisyiah College of pharmacy

Uses:

Used for mixing of finely divided solids, wet solid mass, and plastic

solids.

Uniform size and density materials can be easily mixed.

Used for solid – solid and liquid – solid mixing.

Advantages of ribbon blender:

High shear can be applied by using perforated baffles, which bring

about a rubbing and breakdown aggregates.

Headroom requires less space.

Disadvantages of ribbon blender:

It is a poor mixer, because movement of particles is two dimensional.

Shearing action is less than in planetary mixer.

Dead spots are observed in the mixer, though they are minimum.

It has fixed speed drive.

Sigma blade mixer

Principle – shear. Inter meshing of sigma blades creates high shear and

kneading action.

Construction and working:

It consists of double tough shaped stationary bowl.

Two sigma shaped blades are fitted horizontally in each tough of the

bowl.

These blades are connected to a fixed speed drive.

Mixer is loaded from top and unloaded by tilting the entire bowl.

Pharmaceutical industry Mixing II

Page

23

Dr.Hussein

Al Qadisyiah College of pharmacy

The blades move at different speeds , one about twice than the other,

which allows movement of powder from sides to centers.

The material also moves top to downwards and gets sheared between

the blades and the wall of the tough resulting cascading action.

Perforated blades can be used to break lumps and aggregates which

creates high shear forces.

The final stage of mix represents an equilibrium state.

Uses of sigma blade mixer:

Used in the wet granulation process in the manufacture of tablets, pill

masses and ointments,

It is primarily used for liquid – solid mixing, although it can be used

for solid – solid mixing.

Advantages of sigma blade mixer:

Sigma blade mixer creates a minimum dead space during mixing.

it has close tolerances between the blades and the sidewalls as well

as bottom of the mixer shell.

Pharmaceutical industry Mixing II

Page

24

Dr.Hussein

Al Qadisyiah College of pharmacy

Planetary mixer

Principle:

Mechanism of mixing is shear. Shear is applied between moving

blade and stationary wall. Mixing arm moves around its own axis and

around the central axis so that it reaches every spot of the vessel. The

plates in the blades are sloped so that powder makes an upward

movement to achieve tumbling action also.

Construction:

Consists of vertical cylinder shell which can be removed.

The blade is mounted from the top of the bowl.

Mixing shaft is driven by planetary gear and it is normally built with

variable speed drive.

Uses :

Break down agglomerates rapidly.

Low speeds are used for dry blending and fast for wet granulation.

Advantages:

Speed of rotation can be varied at will.

More useful for wet granulation process.

Disadvantages:

Mechanical heat is buildup within the powder mix.

It requires high power.

It has limited size and is useful for batch work only.

Pharmaceutical industry Mixing II

Page

25

Dr.Hussein

Al Qadisyiah College of pharmacy

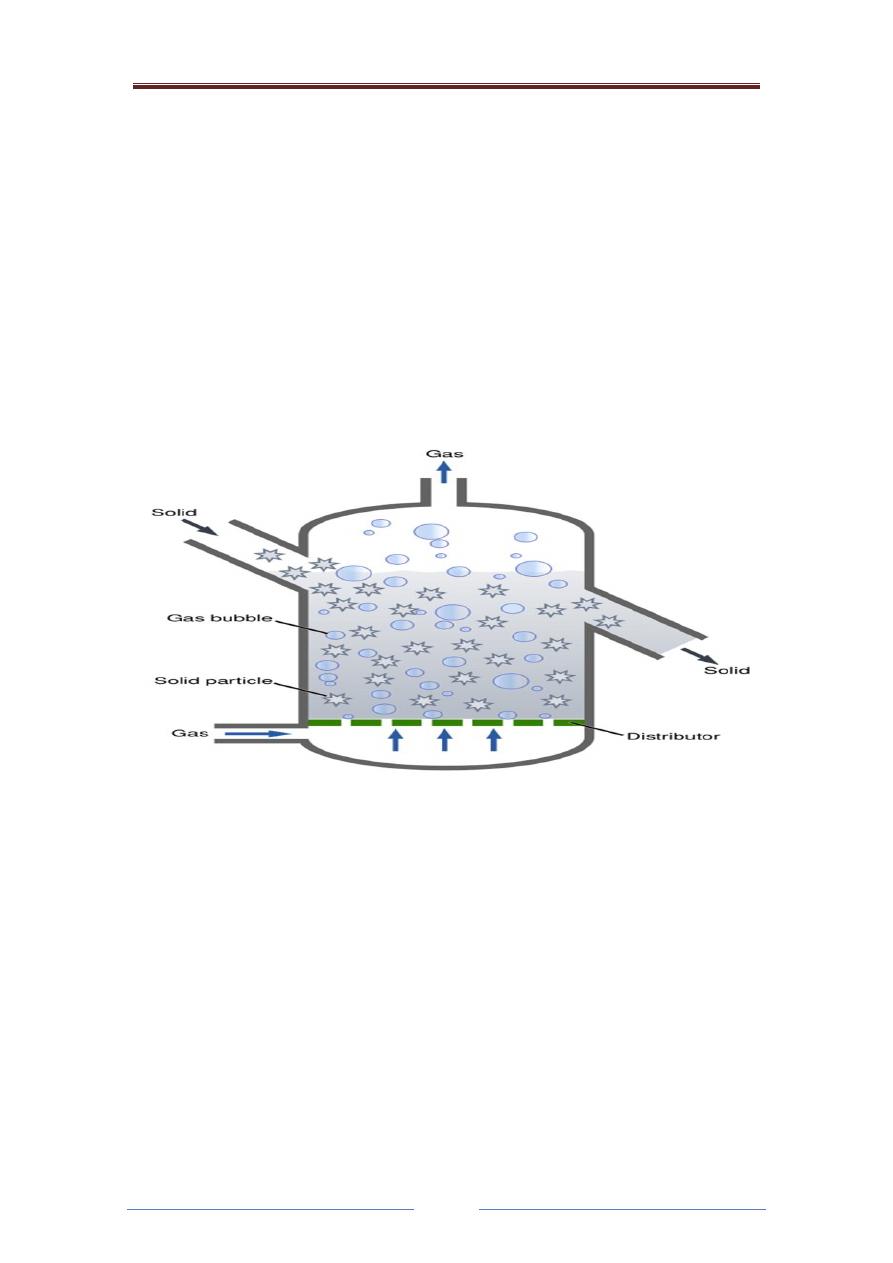

Air mixer or Fluidized mixer

Principle: The air movement is used for mixing powders. Air is admitted

at its base at an angle which gives tumbling action and spiral movements

to the powder. Thus mixing is achieved.

Construction:

It consists of stationary vessel which may be horizontal or vertical

which is made up of stainless steel.

A wire mesh is placed at the bottom of the vessel which acts as

support for placing the materials.

Air is allowed from beneath the mesh and circulated by using a fan.

Advantage

Reduced mixing time.

Mixing is intimate and efficient

Useful for drying and wet massing.

Also useful for coating with some modifications.

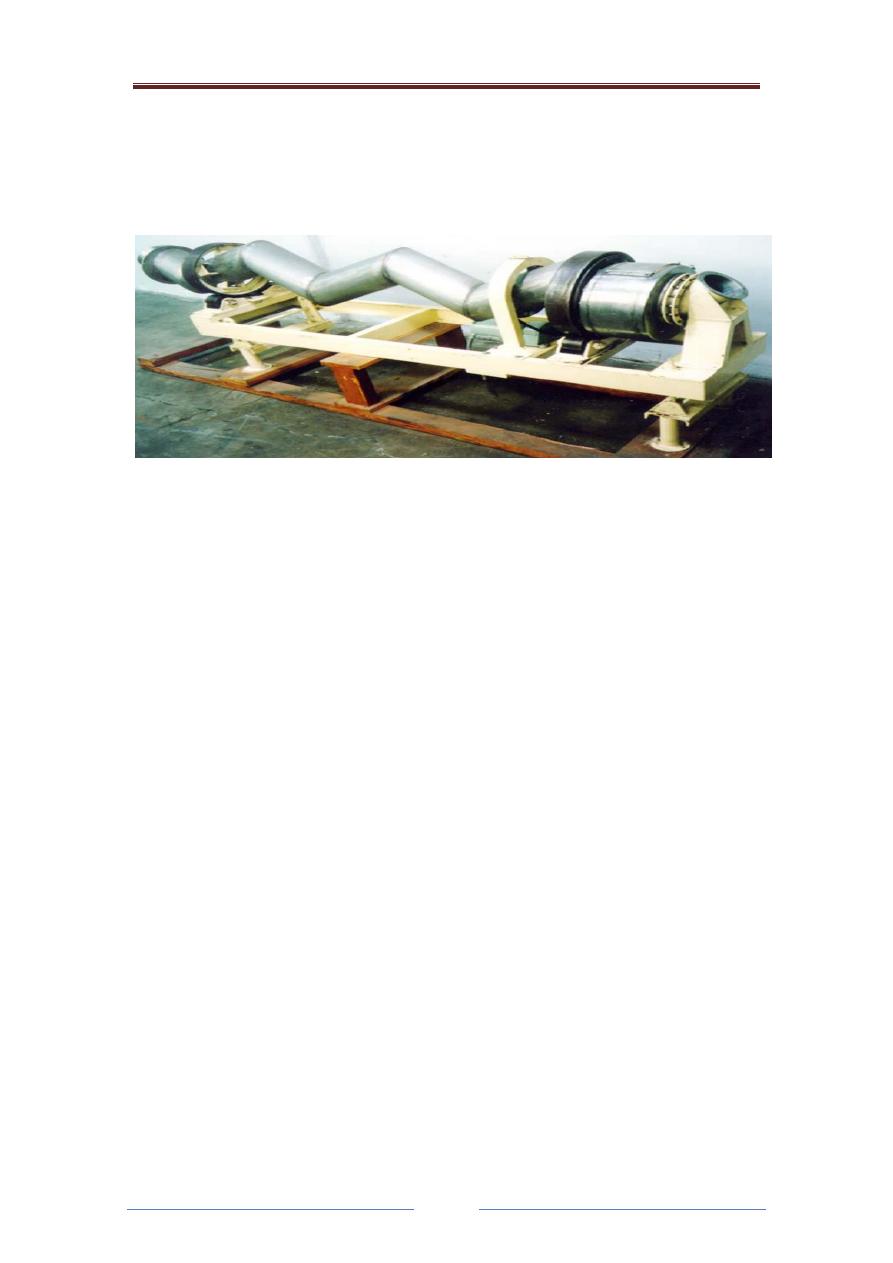

Zigzag continuous blender

Principle :

Material undergoes tumbling motion.

It is rotating shell type having several V shaped blenders connected in

series.

Pharmaceutical industry Mixing II

Page

26

Dr.Hussein

Al Qadisyiah College of pharmacy

When V section is inverted the material splits into two portions ; one

half moves backward while another half moves forward.

As the first V section clears the charge, a fresh feed enters, hence used

for continuous blending.

Mixing of semisolids

Semi solids dosage forms include ointments, pastes, creams, jellies,

etc., while mixing such dosage forms , the material must be brought to

the agitator or the agitator must move the material throughout the

mixer.

The mixing action include combination of low speed shear, smearing,

wiping, folding, stretching and compressing.

A large amount of mechanical energy is applied to the material by

moving parts. Sometimes a part of the supplied energy appears as

heat.

The forces required for efficient mixing are high and consumption of

power is also high. Hence the equipment must be rugged constructed

to tolerate these forces.

Some semisolids exhibit dilatant property i.e., viscosity increases with

increase in shear rates. Therefore, mixing must be done at lower

speeds.

The speed must be changed accordingly to thixotropic, plastic and

pseudo plastic materials.

Agitator mixers:

e.g.:- Sigma mixers and Planetary mixer.

Pharmaceutical industry Mixing II

Page

27

Dr.Hussein

Al Qadisyiah College of pharmacy

Shear mixers:

e.g.:- Triple roller mill and Colloidal mill.

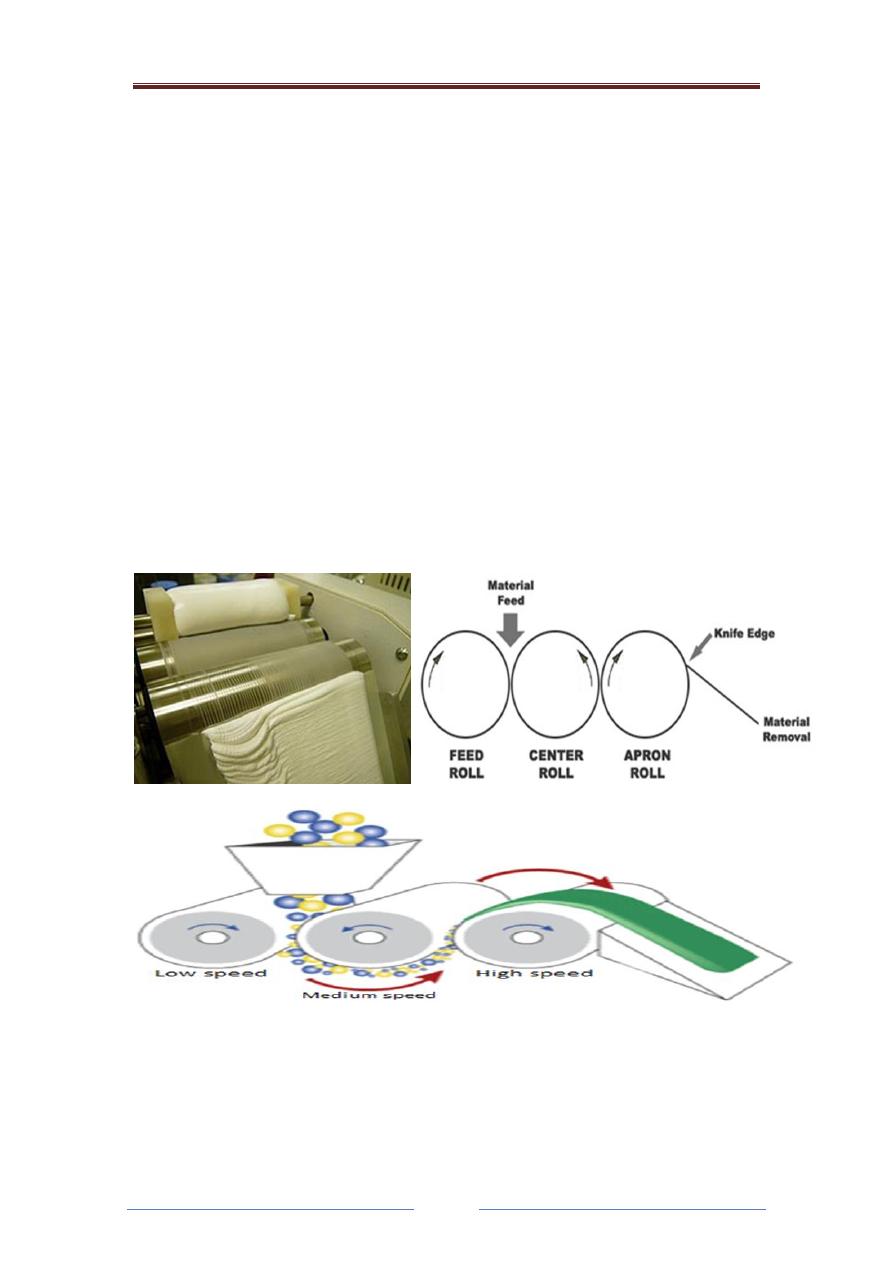

Triple roller mill

Principle:- High shear , which causes crushing of aggregates, particles

and also distributes the drug uniformly throughout the semi solid base.

It consists of 3 parallel rollers of equal diameters made up of stainless

steel.

These are mounted on rigid frame work horizontally.

The gap between the first 2 rollers is more than that of the gap

between the last two.

A hopper is placed in between the first two rollers.

A scrapper is attached to the last roller.

First roller rotates at lower speed compared to the 2

nd

similarly 2

nd

roller speed is less than the 3

rd

roller.