Introduction to rotary instrument techniques

Introduction to rotary instrument techniquesUNIVERSITY OF MOSUL

COLLEGE OF DENTISTRYUNIVERSITY OF MOSUL

COLLEGE OF DENTISTRY

2020-2021

2020-2021By:

Dr.Ashraf Salim5th. YEAR

5th. YEAR

REFERENCE:

Ingle’s ENDODONTICS 7th Edition, 2019.

Hartys Endodontics in Clinical Practice 7th.

Department of

Conservative

Dentistry

Department of

Conservative

Dentistry

Introduction

Since most hand preparation techniques are time consuming and may lead to iatrogenic errors (i.e. ledging, zipping, canal transportation and apical blockage), much attention has been directed toward root canal preparation techniques with Ni-Ti rotary instruments. Numerous studies have reported that they could efficiently create smooth, predetermined funnel-form shapes, with minimal risk of ledging and transportation. Rotary instrumentation in curved molar root canals of permanent teeth has been shown to be time efficient, with increased patient comfort lower risk of flare-up.Engine-Driven Instruments

Gates-Glidden DrillsGates-Glidden drills are suited for straight-line access modification. A No. 2 Gates (approximately size No. 70) is often used first, followed by the No. 3 (approximately size No. 90) and perhaps the No. 4 (approximately size No. 110). In very narrow canals, a No. 1 Gates (approximately size No. 50) may be needed. It is important to remember the size of the Gates-Glidden drills. If the canal orifice cannot accommodate a No. 50 file, careful hand instrumentation should be performed to provide adequate initial coronal space; alternatively, a tapered NiTi orifice shaper may be used in such a case. To prevent stripping perforations, Gates-Glidden drills should not be placed apical to canal curvatures (Figure1).

Figure (1): Gates-Glidden use in coronal portion of root preparation.

Conventional Rotary Systems with Stainless steel files:The group of conventional rotary systems for root canal preparation comprises a number of endodontic handpieces differing in their working motion and using stainless steel instruments. These endodontic working motions include:

Rotation.

Partial rotation.

Reciprocal rotation.

Vertical movement.

A combination of rotation and up and down movement.

In most of these handpieces, the motion of the file is rigid and cannot be influenced by the operator. All these conventional handpieces were designed for use with stainless steel instruments.

Problems associated with stainless steel instruments include:

Straightening of curved root canals

Insufficient cleanliness.

Apical blockages.

Loss of working length.

Perforations.

Instrument fractures.

These systems lost popularity after the introduction of rotary NiTi systems.

NiTi systems

Nickel-titanium alloys were developed in US Navy laboratories in the 1970s. His first application in dentistry, was for the use of orthodontic wires, due to its great resistance to fatigue. Dental alloys range from 56% nickel to 44% titanium, as is the case with Endodontics.

Advantages of NiTi files

Shape memory.

Superelasticity.

Low modulus of elasticity.

Good resiliency.

Corrosion resistance.

Softer than stainless steel.

Ability to prepare more curved canals more evenly and to a greater taper.

Shorter preparation time, as fewer instruments are required.

Disadvantages of NiTi files

Poor cutting efficiency.

NiTi files do not show signs of fatigue before they fracture, potentially unpredictable instrument fracture.

Less tactile feedback during canal preparation.

Not suitable for helping bypass ledges as most.

Greater cost compared with stainless steel instruments.

Regarding the treatment concept, three approaches can be identified:

Crowndown.Single length techniques.

Recently, single file systems have been introduced.

Single File Systems:

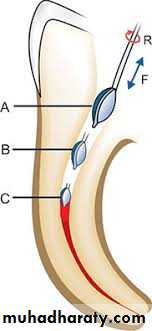

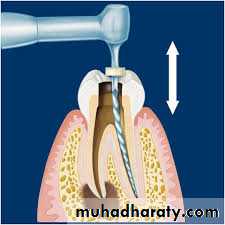

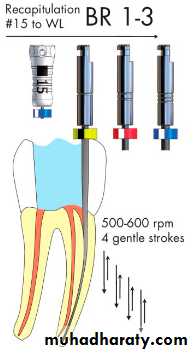

Systems, with a single instrument designed to prepare the entire root canal. The currently available Single-File systems can be subdivided into those used in full rotary motion, e.g. F360 and OneShape, and those used in reciprocating motion, e.g. Reciproc and WaveOne. Regarding reciprocating motion for a better control of these instruments, to avoid instrument fractures and to reduce the stress generated, they should be used in a gentle up-and-down movement to maximum amplitude of 3 mm (Figure2). One up-and-down movement is defined as one ‘peck’, and after three ‘pecks’ the instrument should be withdrawn and the canal copiously irrigated. The flutes of the instrument should be cleaned and small hand instruments should be used to ensure that the canal is not blocked with debris or dentine chips.Figure (2): Up-and-down movement (Peck) during instrumentation.

Advantages of the Single-File system include:

Considerably faster preparation; up to 60% reduction compared with the Single-Length technique.

Excellent shaping ability.

Reduced number of instruments.

Simplifying preparation.

Reducing costs.

Disadvantages of the Single-File system include:

Inconclusive evidence regarding the increased risk of apical debris extrusion and creation of dentinal cracks associated with the use of reciprocating Single-File systems.Reduced time for irrigation; special measures needed to improve canal cleanliness and disinfection, e.g. the use of passive ultrasonic activation (PUI) of the irrigant.

Reduced selection of available instrument sizes; as it is dependent on canal anatomy, further instruments might be required.

Single Length Systems

Single length systems uses multiple files where each file is introduced to the full working length, after preparation of the glide path. Each instrument is used to working length starting with small instruments and followed by files of higher taper or increasing diameter eg: Mtwo and BioRaCe (Figure3).Figure (3): Using multiple files at full working length.

Crown-Down Systems:

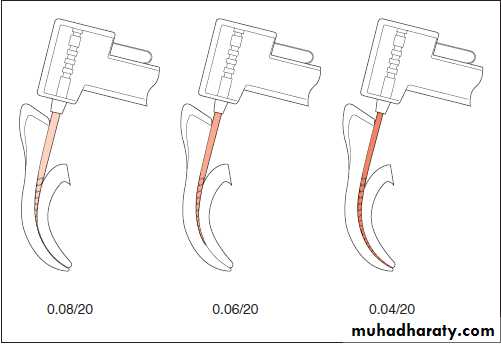

Crown-down systems use a different preparation approach. Instead of inserting each instrument to working length at the beginning of the preparation, instruments with large diameter and high taper are used first. The following instruments gradually get smaller in taper and/or diameter (Figure4) .

Figure (4): Larger instruments used coronally then smaller ones apically.

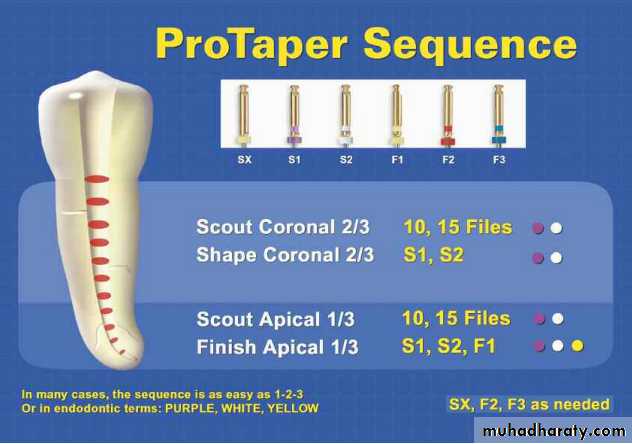

This technique, already known from manual root canal preparation, reduces the friction of the instruments inside the root canal. Each instrument has to enlarge only small parts of the root canal, resulting in reduced stress on the file and reduced risk of instrument fracture. Typical systems of this group are ProFile 04 and ProTaper (Figure5).Figure (5): The sequence of protaper files.

It should be noted that there is no evidence indicating that crown-down techniques, using NiTi instruments are superior, compared to single length techniques, with regard to relevant clinical parameters (shaping quality, safety of use, extrusion of debris, post-operative pain, clinical success).General rules when using engine-driven NiTi root canal instruments:

Instruments should be used with torque-controlled electric motors or handpieces to reduce the risk of instrument separation.A glide path should be created using either hand or engine-driven files.

Most systems include orifice shapers/openers that are shorter, more tapered instruments designed for coronal flaring of the root canal before preparation of the rest of the canal.

Instruments should never be forced apically, so excessive pressure on the instruments during preparation must be avoided.

Instruments should be kept moving inside the canal.

The predefined values of the motor with regard to torque and rotational speed should not be changed.

Regular inspection should be carried out, when the instruments are withdrawn from the canal, to check for damages or signs of potential instrument separation.

Newer NiTi instruments

To improve the properties of engine-driven NiTi root canal instruments, newer NiTi instruments were manufactured using electro-erosion to improve surface hardness of the instruments; it is claimed that this results in increased cutting efficiency and reduced risk of instrument separation.

Another innovation involves special heat treatment after grinding of the NiTi instruments; examples of NiTi instruments subjected to this heat treatment process are Pro- Taper NEXT Gold and WaveOne Gold. It is claimed that this additional special heat treatment increases the flexibility and resistance to cyclic fatigue of the resultant NiTi instruments.

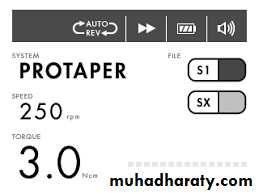

Motors and torque controlled handpieces

Electric motors usually have an auto-reverse function to loose locked instruments to minimize the risk of instrument separation, in some systems an acoustic warning tone can be adjusted by the operator when a critical torque limit is reached. In the library of these motors, pre-settings of optimal rotational speed and maximum torque values are stored and for most motors (Figure6), these values can be updated for newly introduced system by an interface. For most rotary NiTi systems, the recommended rotational speed is in the range of 150 r.p.m - 600 r.p.m.Figure (6): Presetting of protaper system with auto reverse function.

The EndThe End

GoodLuck

Dr. Ashraf Salim AlchalabiGoodLuck

Dr. Ashraf Salim Alchalabi