}

If a hazardous substance or work process

cannot be eliminated or substituted, then

enclosing it so workers are not exposed to

the hazard is the next best method of

control.

}

Many hazards can be controlled by partially

or totally enclosing the work process.

}

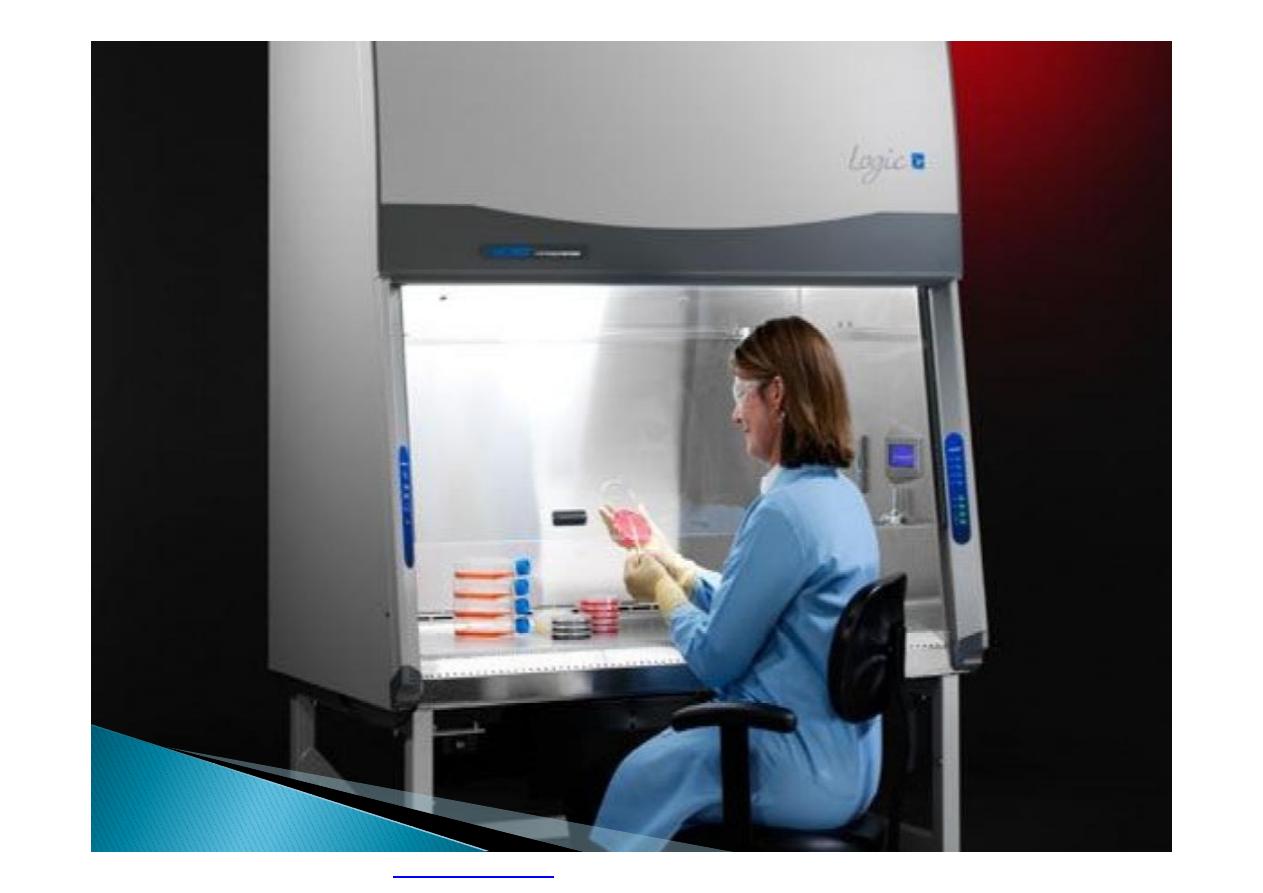

Highly toxic materials that can be released

into the air should be totally enclosed, usually

by using a mechanical handling device or a

closed glove system that can be operated

from the outside

PDF created with pdfFactory Pro trial version

}

Whole areas of a plant can be “enclosed” by

requiring workers to operate those areas

from a control room.

}

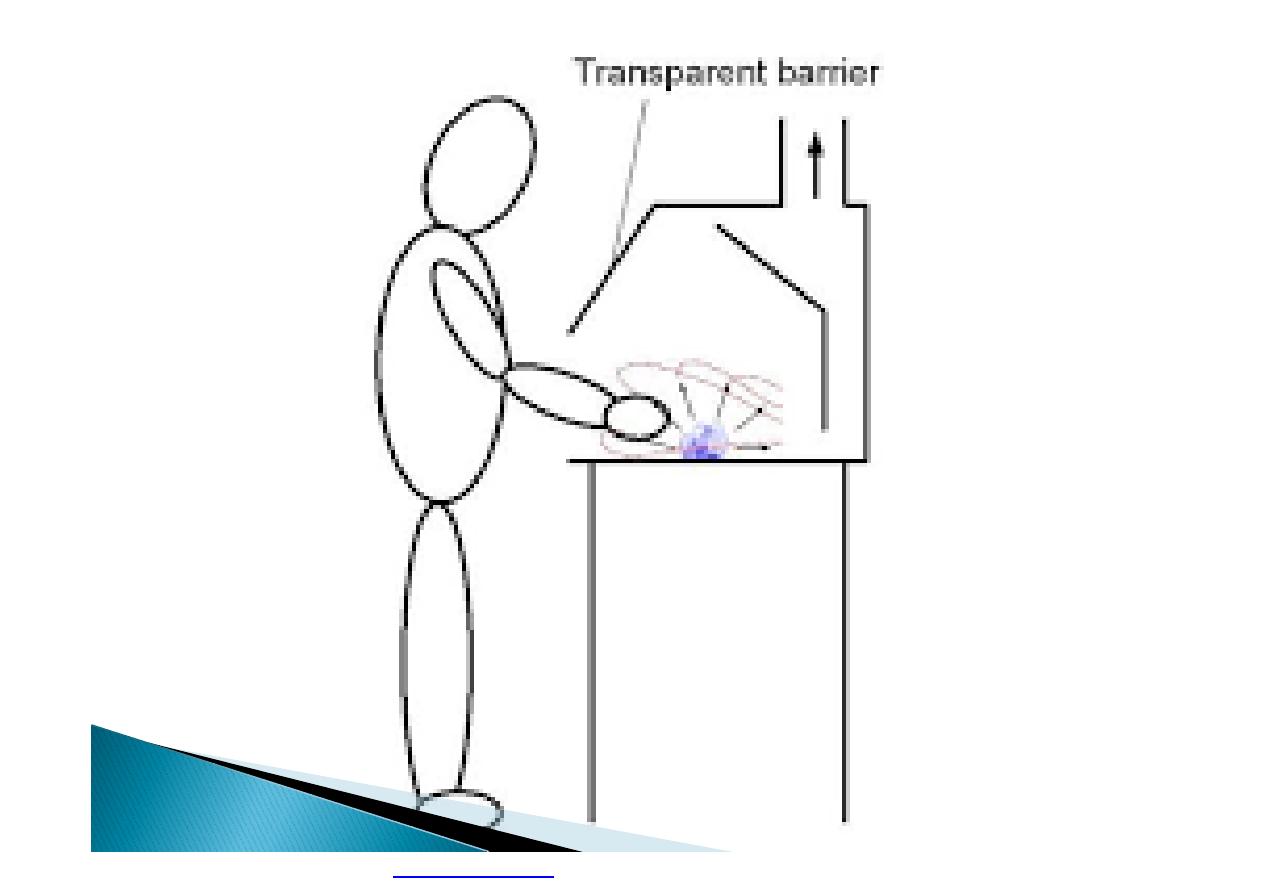

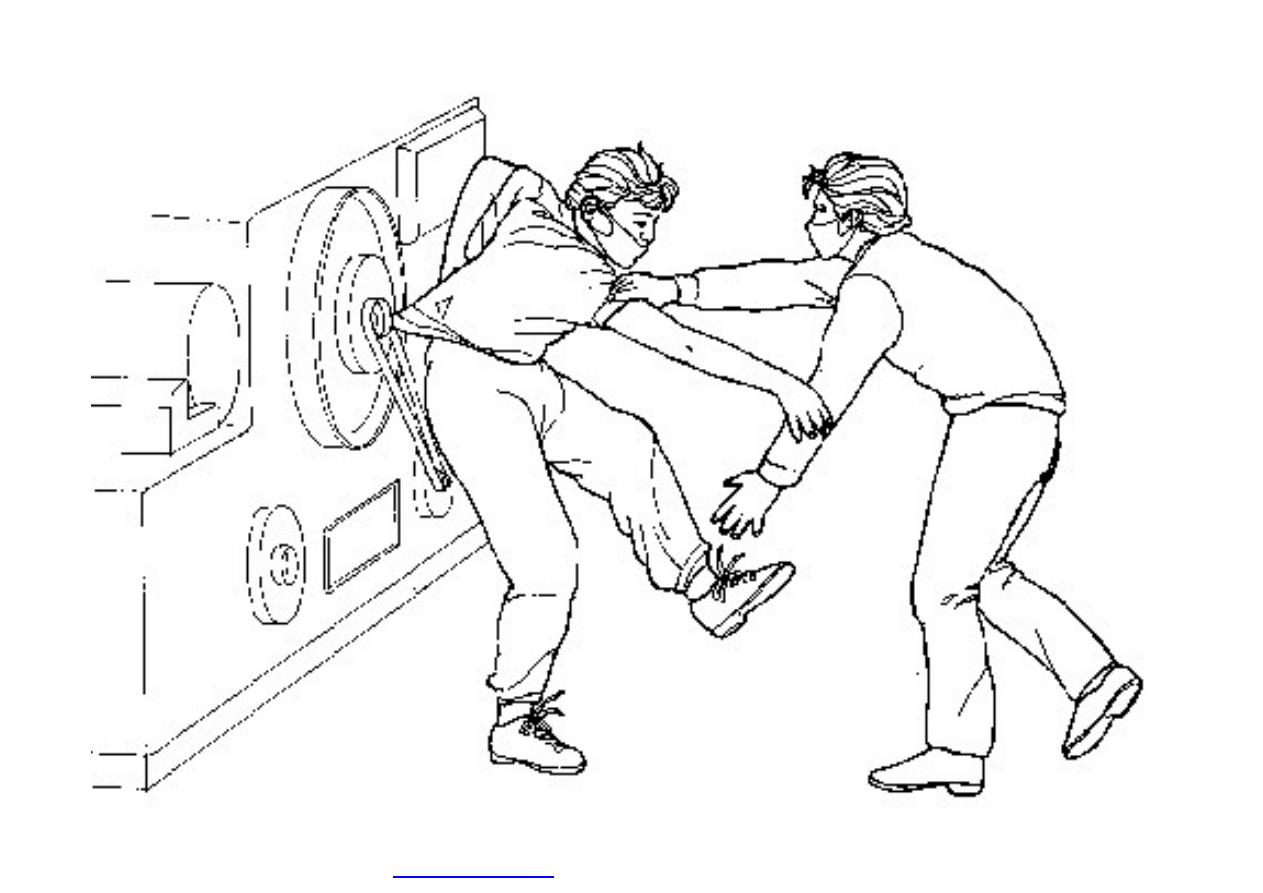

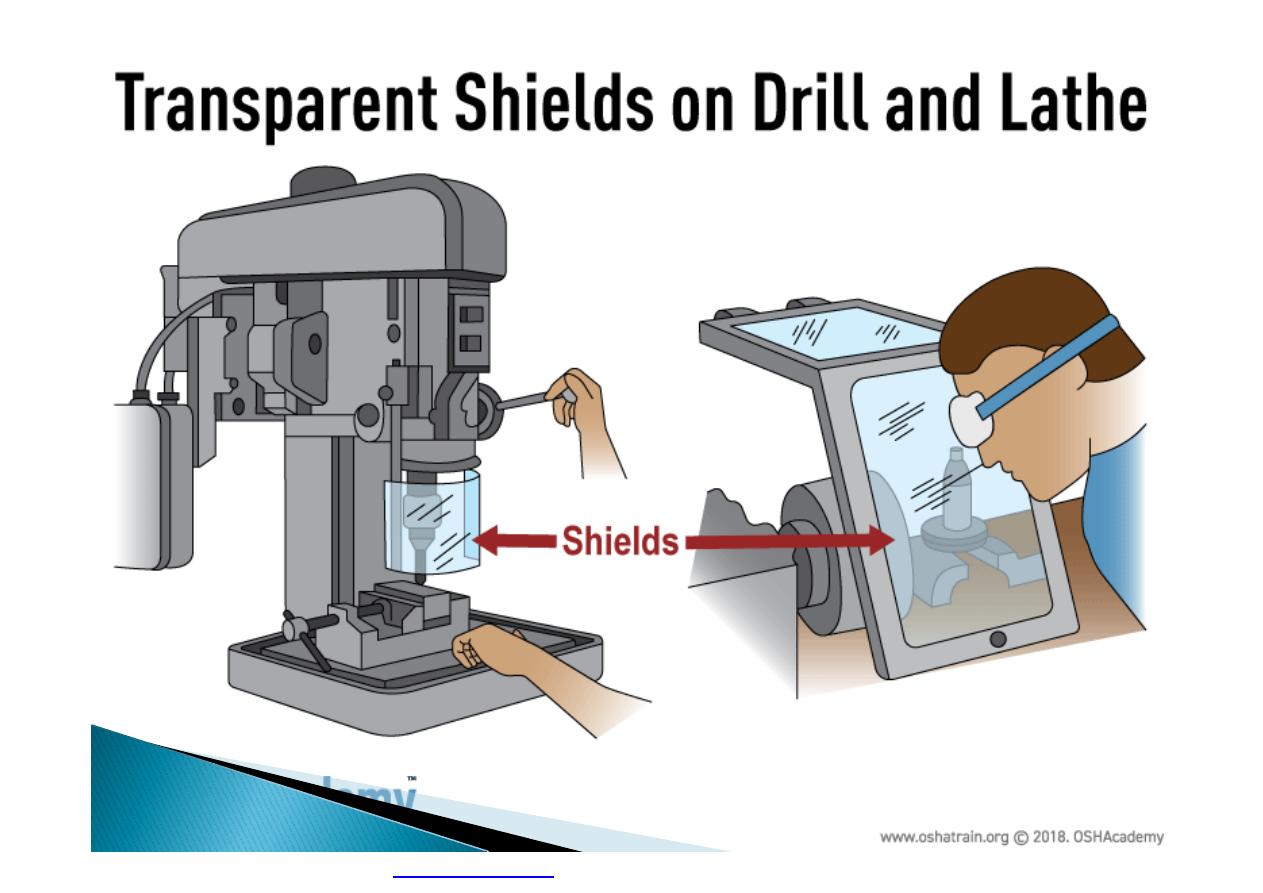

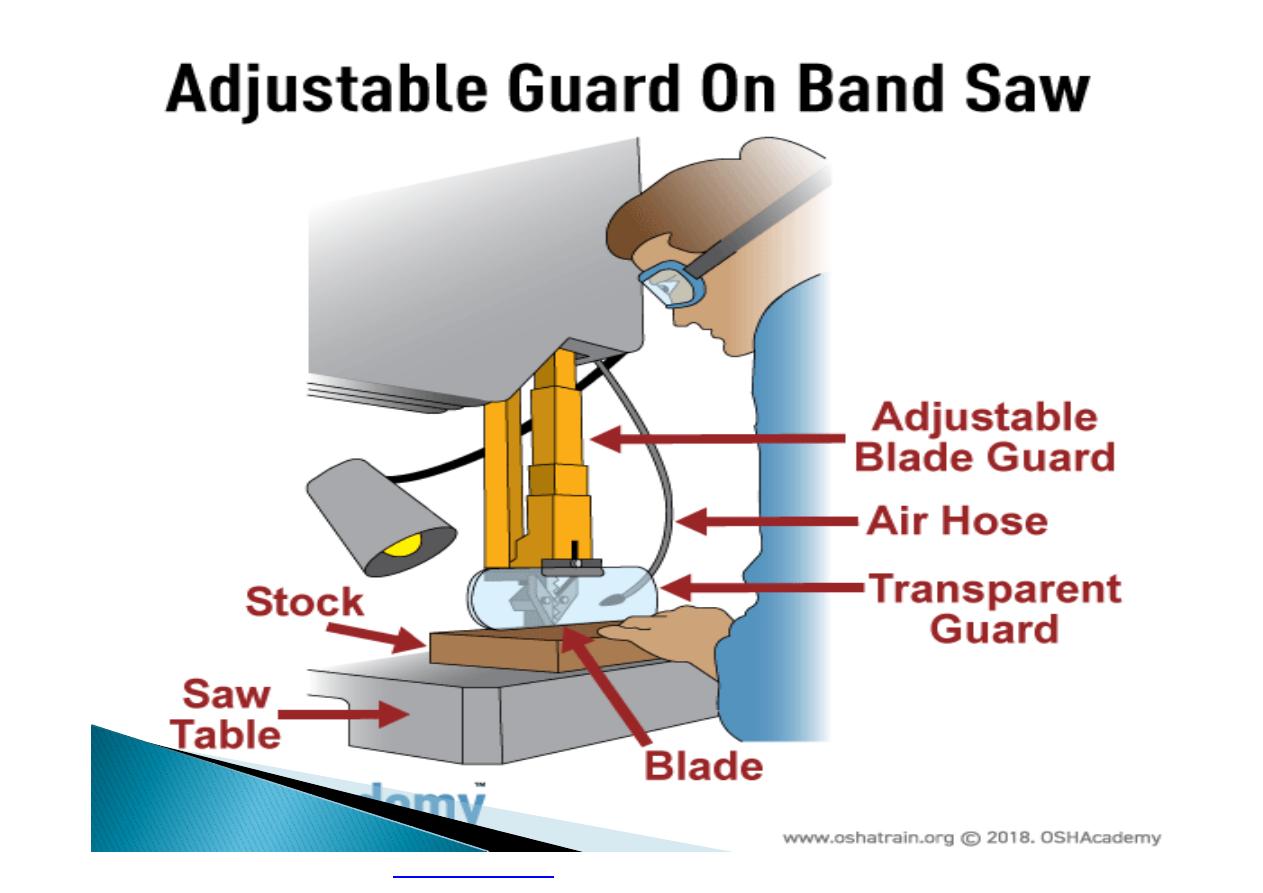

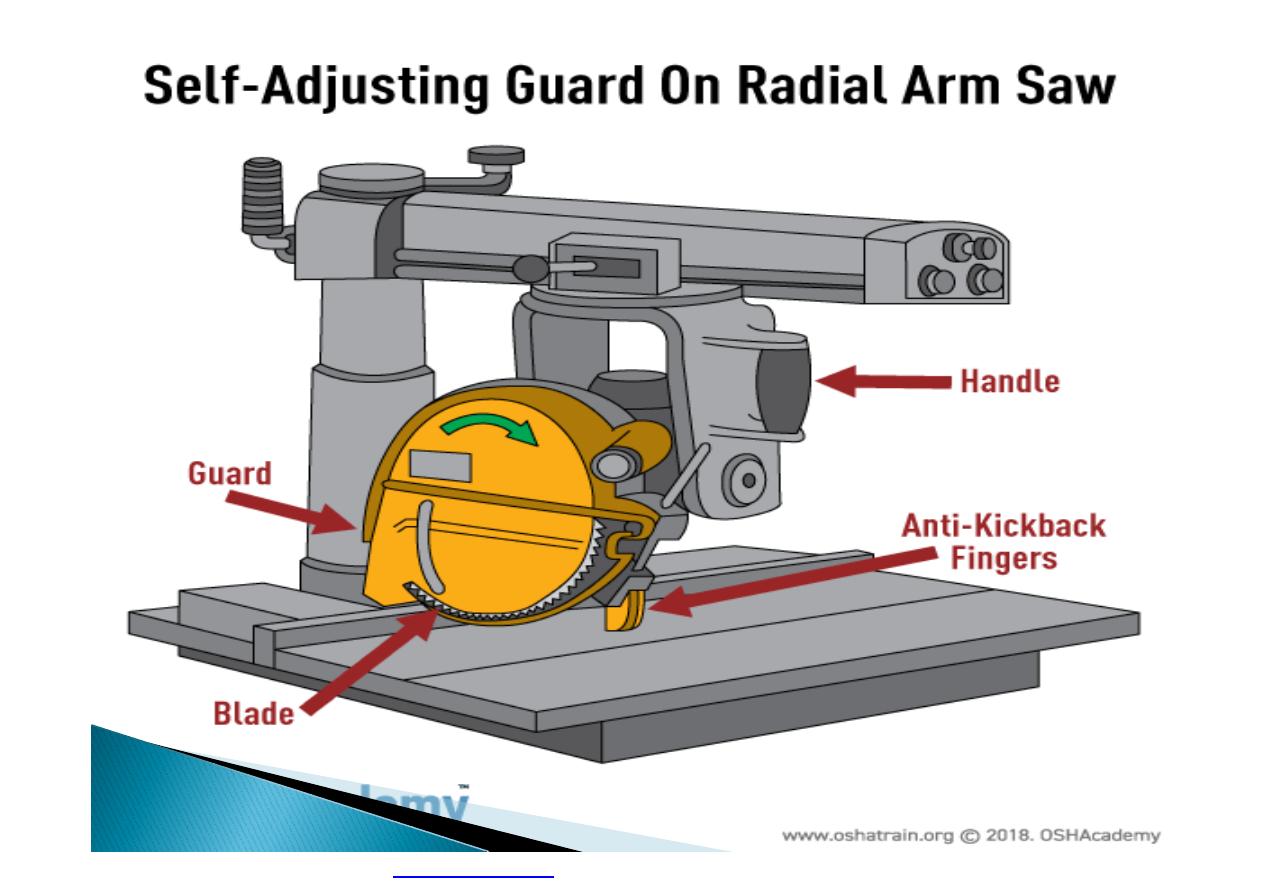

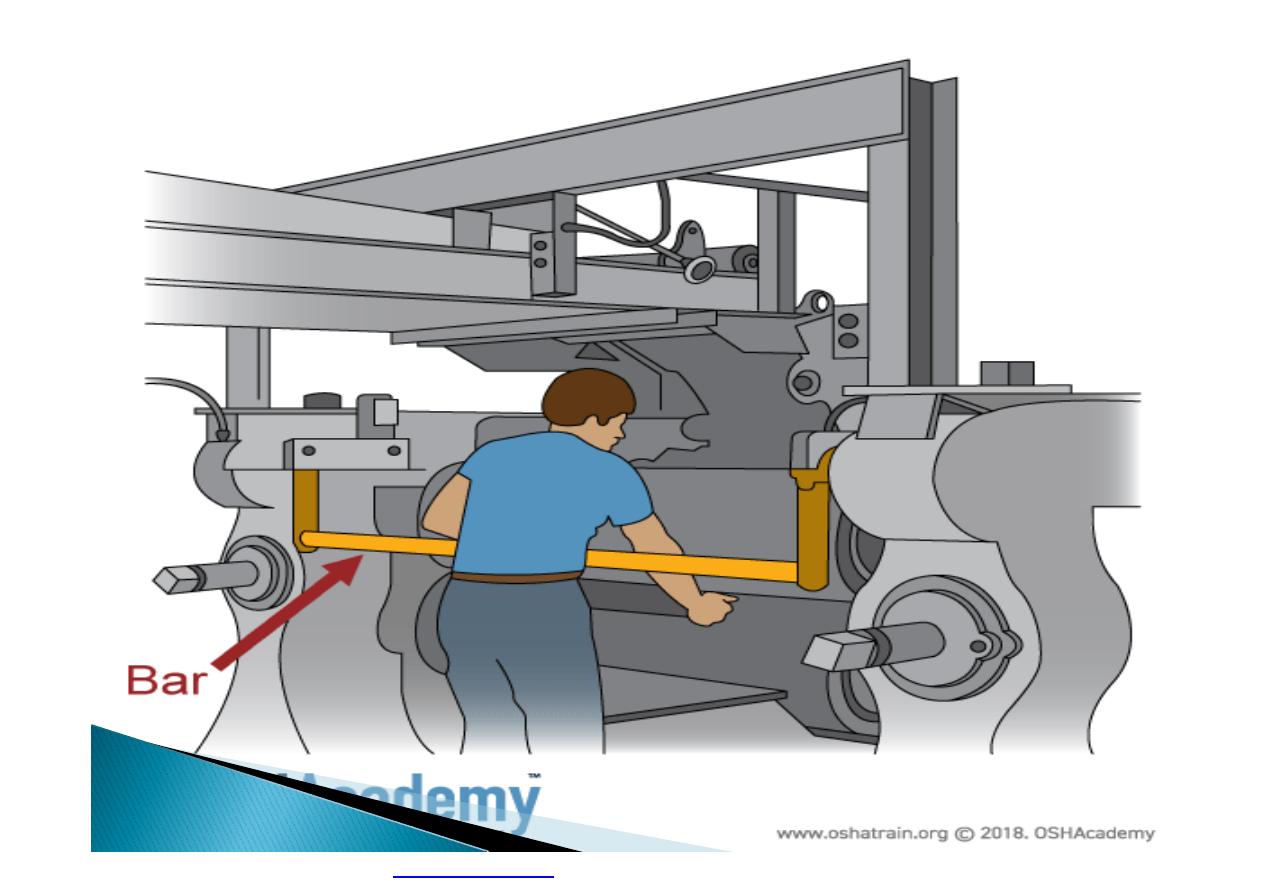

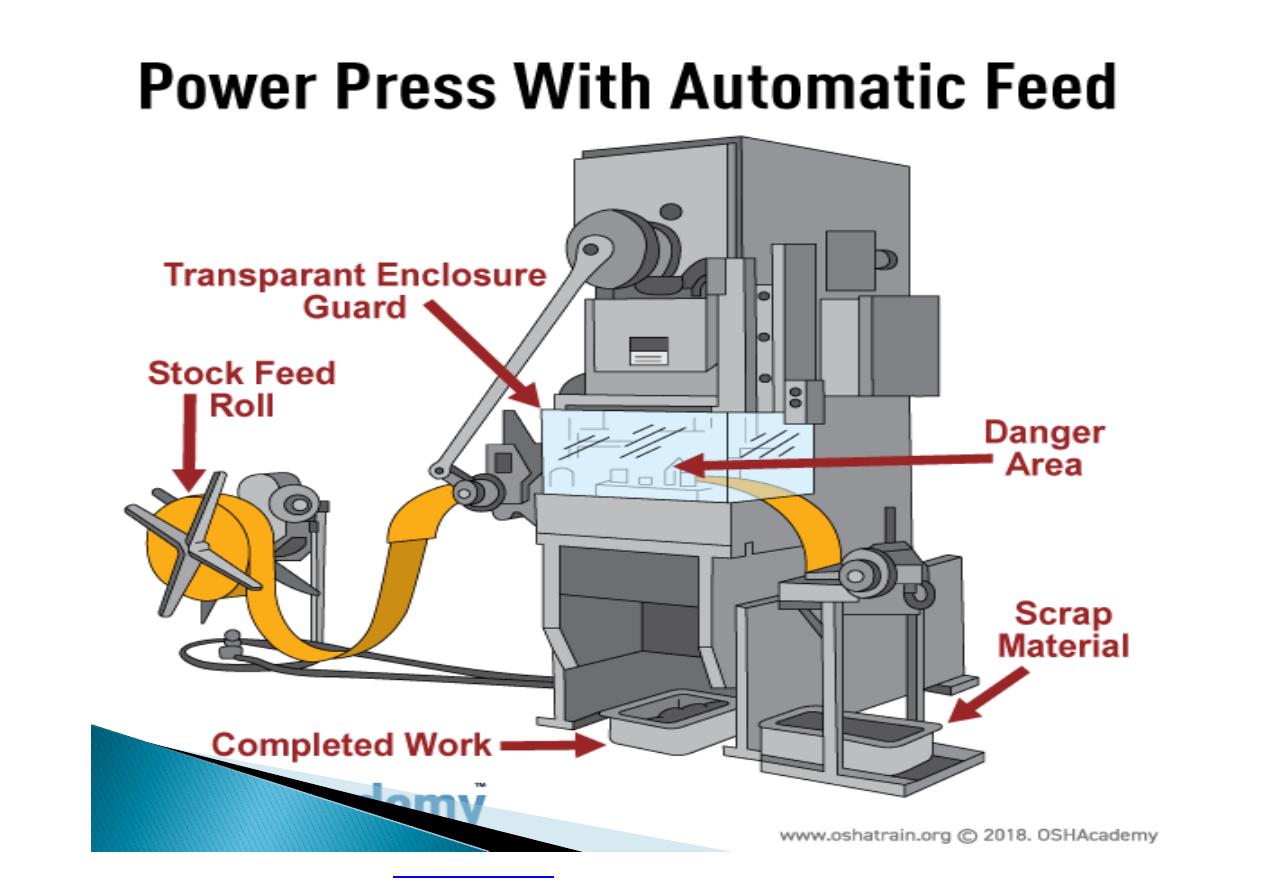

Machine guarding is another form of

enclosure that prevents workers from coming

into contact with dangerous parts of

machines.

}

Some of the areas of a machine that can

injure the worker are: the point of operation

pinch-points; sharp areas, such as blades;

exposed electrical components, which can

cause electrical shock or burns; presses,

which can crush; rotating parts; flying chips

and sparks.

PDF created with pdfFactory Pro trial version

}

Isolation can be an effective method of

control if a hazardous job can be moved to a

part of the workplace where fewer people will

be exposed,

}

or if a job can be changed to a shift when

fewer people are exposed (such as a weekend

or midnight shift).

}

The worker can also be isolated from a

hazardous job, for example by working in an

air-conditioned control booth.

}

isolating the work process or the worker does

not eliminate the hazard, which means

workers can still be exposed

PDF created with pdfFactory Pro trial version

}

Ventilation in the workplace can be used for

two reasons:

}

(1) to prevent the work environment from

being too hot, cold, dry or humid;

}

(2) to prevent contaminants in the air from

getting into the area where workers breathe.

PDF created with pdfFactory Pro trial version

}

Generally there are two categories of

ventilation:

1.

local exhaust ventilation

2.

general ventilation.

}

Ventilation should be used together with

other methods of control.

PDF created with pdfFactory Pro trial version

}

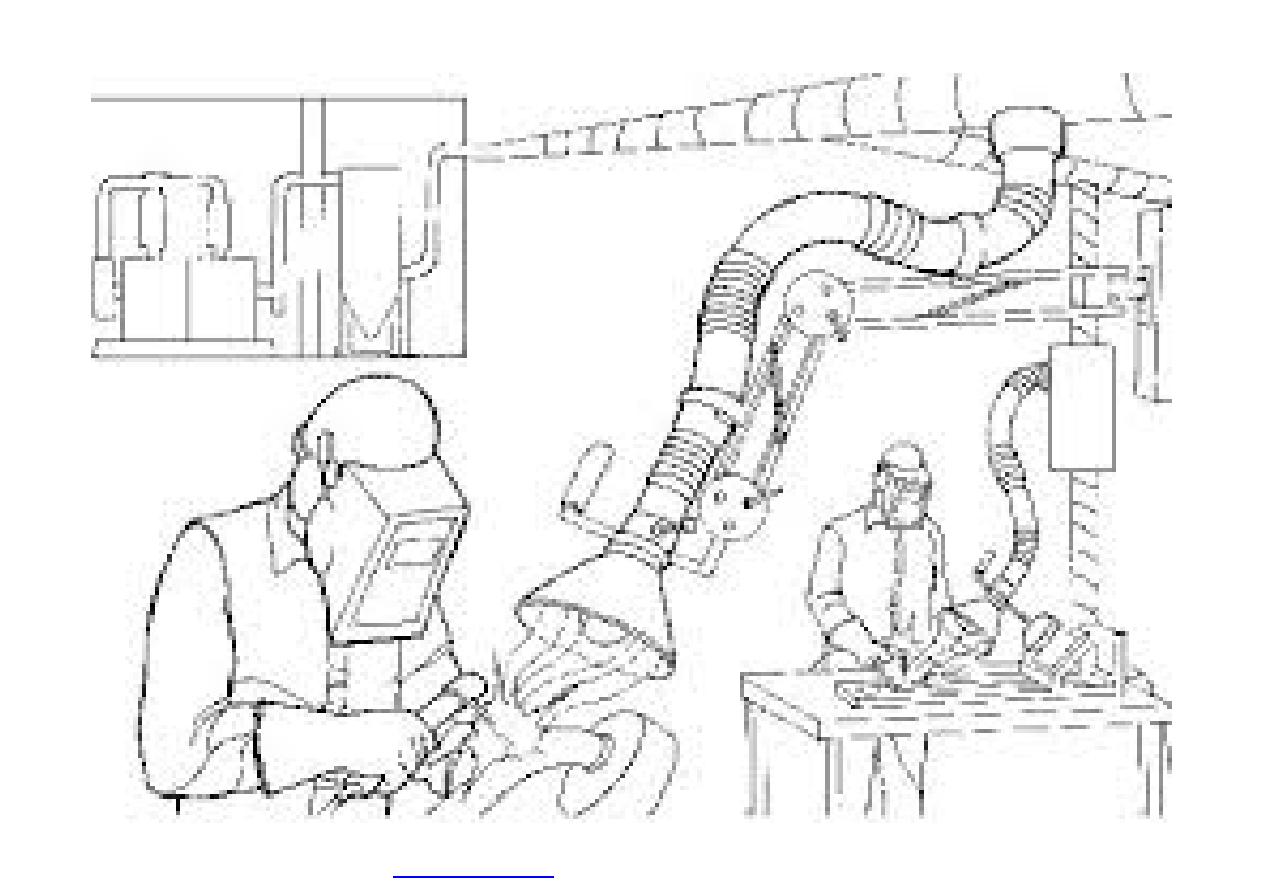

It usually uses suction, based on the principle of

a vacuum cleaner, to remove pollutants from the

air.

}

Exhaust ventilation can include the use of flexible

piping.

}

The end of the pipe that draws in the

contaminants (the inlet) must be placed as close

as possible to the source of the hazard in order

to be effective.

}

Flexible piping is often used to draw welding

fumes away from the worker and to draw away

contaminants in work areas that are hard to

reach.

PDF created with pdfFactory Pro trial version

}

Which is generally used for keeping the

workplace comfortable.

}

It is one of the least effective methods of

controlling hazards but one of the most

commonly used.

}

The purpose of any general ventilation

system is to remove contaminated air and

replace it with “fresh” air.

}

This system does not really remove

hazardous agents from the air; it simply

reduces the amounts in the air to levels that

are considered “safe” for breathing.

PDF created with pdfFactory Pro trial version

The effectiveness of a general ventilation

system depends on several things, including:

}

how quickly the hazardous agent is being

released into the air;

}

how much and how quickly fresh air is

coming in;

}

and how the contaminated air is being

removed.

PDF created with pdfFactory Pro trial version

}

Limiting the amount of time workers spend at

a hazardous job.

}

Used together with other methods of

control to reduce exposure to hazards.

}

changing work schedules (for example, two

people may be able to work for four hours

each at a job instead of one person working

for eight hours at that job);

}

giving workers longer rest periods or shorter

work shifts to reduce exposure time;

PDF created with pdfFactory Pro trial version

}

moving a hazardous work process to an area

where fewer people will be exposed;

}

changing a work process to a shift when

fewer people are working.

}

administrative controls only reduce the

amount of time workers are exposed to a

hazard and they do not eliminate exposures.

PDF created with pdfFactory Pro trial version

}

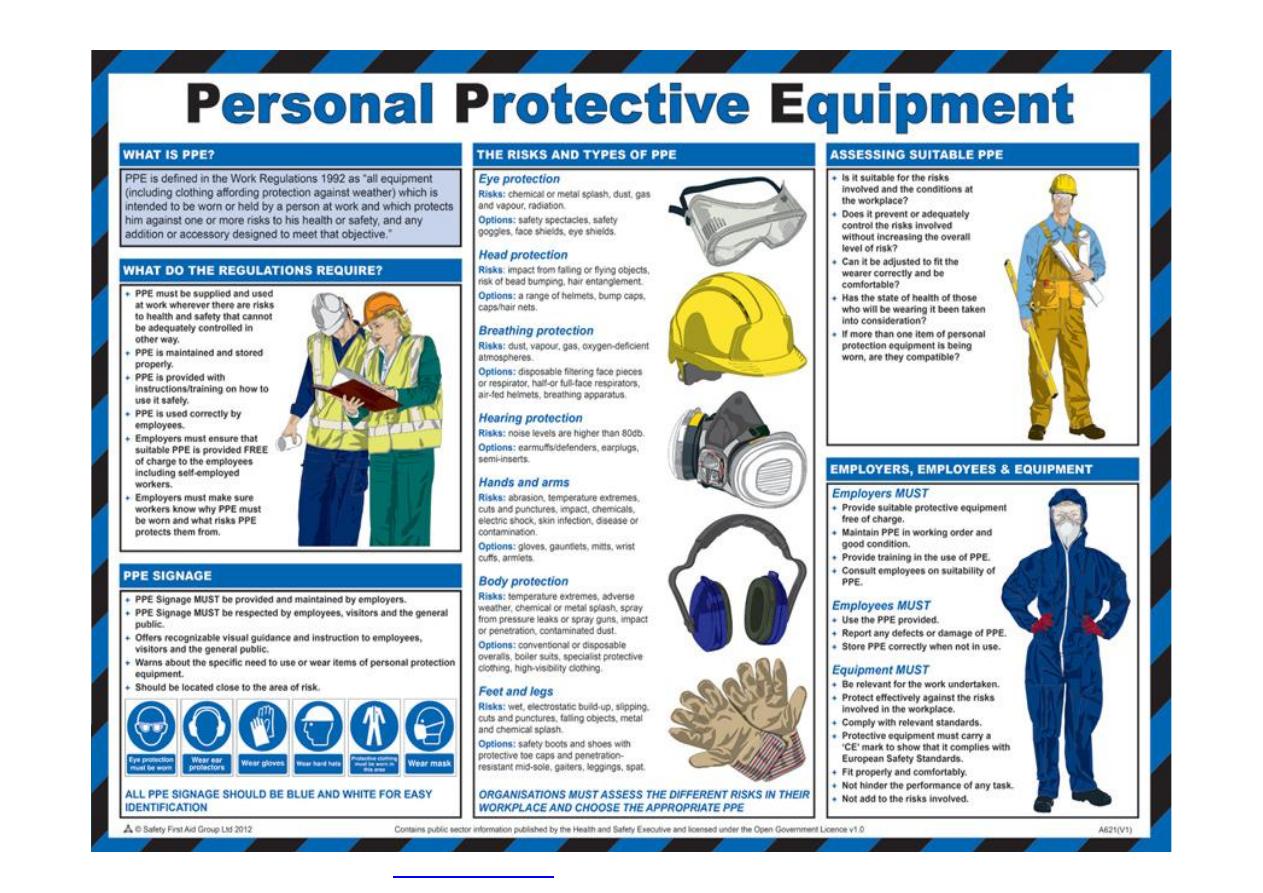

Personal protective equipment (PPE) is the least

effective method of controlling occupational

hazards and should be used only when other

methods cannot control hazards sufficiently.

}

PPE can be uncomfortable, can decrease work

performance and can create new health and

safety hazards.

}

For example, ear protectors can prevent the

worker from hearing warning signals, respirators

can make it harder to breathe, earplugs may

cause infection, and leaky gloves can trap

hazardous chemicals against the skin.

PDF created with pdfFactory Pro trial version

}

Hot or humid working conditions decrease

the effectiveness of PPE. Under these

conditions, workers should take frequent

breaks and drink plenty of fluids.

}

If PPE does not fit well it may not protect the

worker; this is particularly important with

respirators.

}

All workers using PPE should be trained on

the proper use, maintenance and limitations

of PPE.

PDF created with pdfFactory Pro trial version

a. General cleanliness

}

Keeping a clean and organized workplace

}

They will reduces the risk of fire and

accidents and cost effective.

}

At the same time, maintaining a pleasant

working environment can produce higher

productivity

PDF created with pdfFactory Pro trial version

b. Personal cleanliness

}

Personal hygiene (cleanliness) is also very

important as a method of controlling

hazards.

}

Employer should provide facilities so worker

can wash and/or take a shower every day at

the end of working shift

}

Eating and smoking away from the work area

help to prevent ingesting contaminants.

}

Worker should leave dirty clothes at work and

if necessary, washing work clothes done

separately not with the family wash.

}

So Worker does not take workplace hazards

home with him.

PDF created with pdfFactory Pro trial version

C. first-aid facility

}

Every workplace should have first-aid facility

}

Every workplace should have as well adequate

personnel trained to provide first aid.

}

First-aid facilities and trained personnel are

important components of a healthy and safe

workplace.

PDF created with pdfFactory Pro trial version

*

General control measures of occupational hazards :

1.

Elimination &/or substitution (most effective but

most difficult)

}

( substitute injections by administrating

medication through another route

}

(Usage of unleaded gasoline)

}

Replace flooring with more slip-resistant surface

2.

Isolation of the process . As in x ray room

3.

Total enclosure of the process.

4.

Shielding of the source or worker.

5.

Suppression of the emission .

6.

Locally applied exhausted ventilation.

7.

General ventilation .

10 October 2019

٩٢

PDF created with pdfFactory Pro trial version

6.

Reduce time of exposure (Work shift )

7.

Health education to the workers

(information, training and instruction) .

8.

Personal protective equipment.

9.

General cleanliness .

10.

Personal hygiene .

and

10 October 2019

٠٣

PDF created with pdfFactory Pro trial version

11. Maintaining control by:

a. pre employment exam

}

Provide a baseline data for further compare and

assessment.

}

to ensure that prospective employees can perform

their jobs safely and effectively.

}

No further deterioration of the health status of the

employee.

}

Adapt the work according to the capabilities of the

worker.

b. periodic medical exam

1.

Routine medical examination.

2.

After long absence medical examination.

3.

After any change in the process or the substances

used at the work

c. monitoring procedures .

PDF created with pdfFactory Pro trial version