Dr.Samira Jameel J. Tarfa

Lecture 3Sterilization

Any process that eliminates or kills all forms of microbial life, includingFungi.

Bacteria.

Viruses.

Spores.

Since most instruments contact mucosa and or penetrate oral tissues.

• Disinfection

Process of destruction or removal of organism, capable of giving rise to infection.Antisepsis

Destruction or inhibition of microorganism in living tissues there by limiting or preventing harmful effects of infection.

Methods of Sterilization

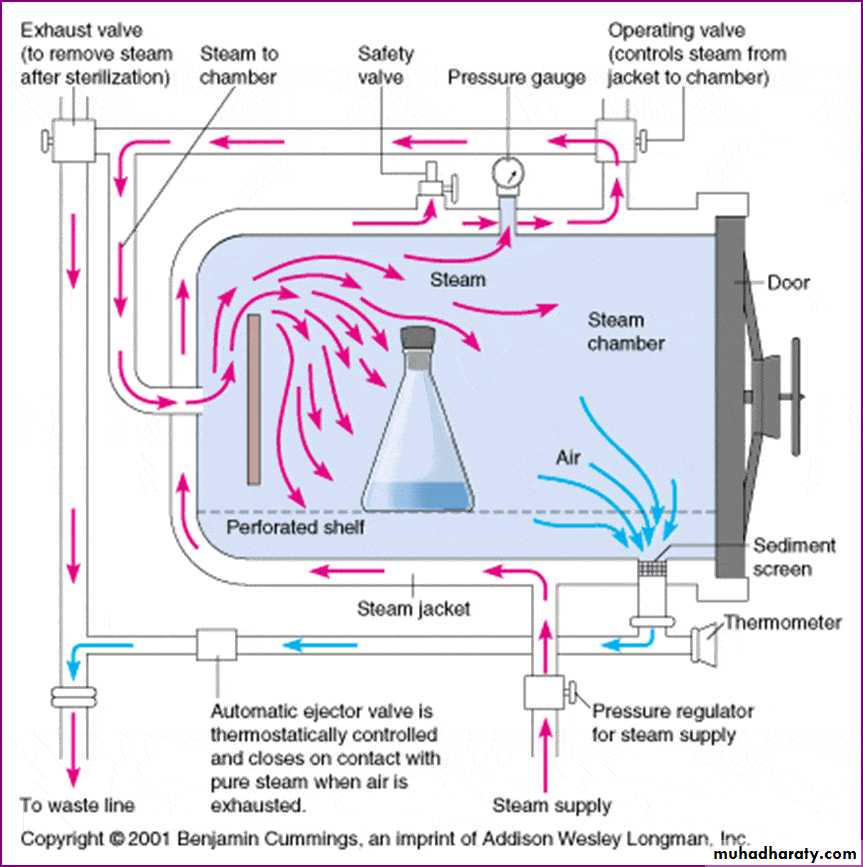

1-Steam pressure sterilization (autoclave).

2-Chemical vapor pressure sterilization (chemi-clave).

3-Dry heat sterilization (dryclave).

4-Ethylene oxide sterilization.

5-Hydrogen Peroxide Plasma.

Steam pressure sterilization (autoclave).

Sterilization with steam under pressure .For a light load of instrument. The time required at 250 °F (121° C) is a minimum of 15 Ibs pressure.

Time for wrapped instrument can be reduced to 7 minutes if the temperature is 273° F ( 134°C) to give 30 Ibs of pressure.

Advantages of Autoclaves

The most rapid and effective method for sterilization of cloth surgical packs and towel packs.Other methods are not suitable for processing cloth packs.

Autoclaves handle try and paper-bagged instruments.

Disadvantages of Autoclaves

Items sensitive to elevated temperature cannot be autoclaved.

Autoclaving tend to rust carbon steel instruments and burs.

Steam appears to corrode the steel neck and shank portions of some diamond instruments and burs.

2-Chemical vapor pressure Sterilization (chemi-clave).

Sterilization by chemical vapor under pressure.Its operate at 270°F (131°C) and 20 Ibs pressure.

They must be used with prescribed chemical by manufacture.

Advantages of Chemiclaves

Carbon steel and other corrosion- sensitive burs, instruments, and pliers are sterilized with out corrosion.Disadvantages of Chemiclaves

Items sensitive to elevated temperature will be damaged.Instruments must be lightly packed in bags obtained from the sterilizer manufacturer.

Towels and heavy cloth wrappings of surgical instruments may not be penetrated to provide sterilization.

• Dry Heat Sterilization

It is readily achieved at temperatures above 320° F( 160°C).

Packs of instruments must be placed at least 1 cm apart to allow heated air to circulate.

Individual instruments must actually be at160°Ctemperature for only 30 minutes.

Advantages of dry heat

Carbon steel instruments and burs do not rust, corrode, or loss their temper or cutting edges if they are well dried before processing.Rapid cycles are possible at high temperatures.

Disadvantages of dry heat

High temperatures may damage more heat- sensitive items, such as rubber or plastic goods.Sterilization cycles are prolonged at the lower temperatures.

Heavy loads of instruments, crowding of packs, easily defeat sterilization.

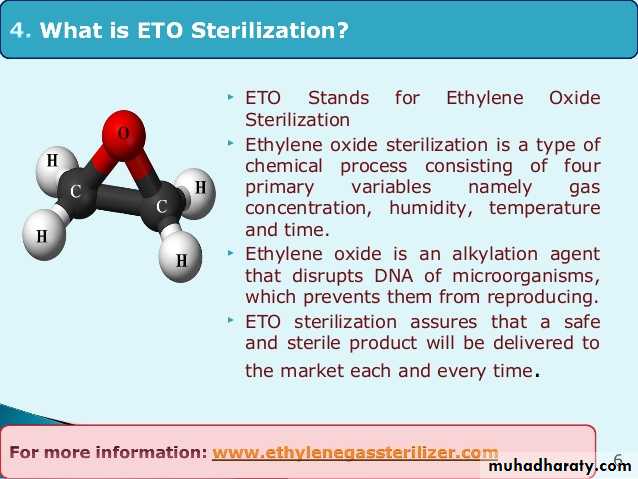

• Ethylene Oxide Sterilization

It is the most gentle method for sterilizing complex instruments and delicate materials.It sterilize items is several hours and operate at temperatures below 100° C.

Less expensive devices.

Units with large chamber sizes hold more instruments.

• Boiling Water

It is done for 10-30 minutes.Kill vegetative bacteria and spores but inactive against viruses.

It is not recommended for sterilization of instruments for surgical procedure.

It is useful for reducing viable levels if no better method is available.

New Methods of Sterilization

Microwave :has major limitations for sterilizing metal items.Peroxide vapor Sterilization.

Ultraviolet light : it is not highly effective against RNA viruses such as HIV.Liquid Sterilants

Liquid sterilants can kill bacterial spores in 6-10 hours.They are high-level disinfectants.

Glutaraldehydes at 2% to 3%.

Glutaraldehydes are irritating, sensitizing to skin and respiratory passages.

Do not use Glutaraldehydes at 2% solution to wipe dental unit and chair.

Most Glutaraldehydes required 20 minutes to kill tuberculosis bacteria.

Uses of High-Level Disinfection

According to the centers for disease control,

1-Instruments that penetrate tissues or contact mucosa are termed critical or semi-critical and require cleaning and heat or gas sterilization before reuse.

2-High-level disinfection is used mainly for plastic items that enter the mouth and that cannot withstand heat sterilization.

3-Disinfection for 20 to 90 minutes in glutaraldehyde germicides is not appropriate for instruments used in the mouth.

4-Most require 6 or more hours for sterilization.

Vaccines for dental health-care workers

Although the possibility of transmission of blood borne infections from dental workers to patients is considered to be small, it is recommends that all dental workers, who might be exposed to blood contaminated substances must be vaccinated forHBV, H5N1 influenza virus (bird flu virus), H1N1 influenza , measles, rubella, and tetanus.

Hand Washing and Care of HANDS

DHCWs should wash their hands before and after treating each patient.Hands should be washed after removal of gloves ,it may be contaminated with patient blood and saliva.

Methods of Sterilization

Before sterilization or high-level disinfection, instruments should be cleaned thoroughly to remove debris.Persons involved in cleaning and reprocessing instruments should wear heavy-duty gloves .

Placing instruments into a container of water or disinfectant as soon as possible after use .

Cleaning may be accomplished by thorough scrubbing with soap and water or a detergent solution.

All critical and semi critical dental instruments that are heat stable should be sterilized by autoclave, dry heat or chemical vapor.

Critical and semi critical instruments that will not be used immediately should be packaged before sterilization.

Cleaning and disinfection of dental unit and environmental surfaces

It should be cleaned with disposable towel, using an appropriate cleaning agent and water as necessary.Surface then should be disinfected with a suitable chemical germicide such as phenolics, iodophors, and chlorine.

Afresh solution of sodium hypochlorite prepared daily for surfaces disinfectants.

Disinfection and Dental laboratory

Dental materials and other items that have been used in the mouth should be cleaned and disinfected before being manipulated in the laboratory.These items also should be cleaned and disinfected after being manipulated in the laboratory.

High and low speed Handpieces sterilization

High speed dental hand pieces, low speed hand pieces used intraorally are sterilized by autoclave, dry heat, or heat/ chemical vapor.Manufacturers instructions for cleaning, lubrication, and sterilization procedures should be followed to ensure both effectiveness of the sterilization and the longevity of these instruments.

Internal surfaces of high and low speed hand piece may become contaminated with patient material during use . This material may expelled intraorally during subsequent uses.

Surface disinfection by wiping or soaking in liquid chemical germicides is not an acceptable method for reprocessing high and low speed hand piece used intraorally.

Other reusable intraoral instruments attached to, but removable from, the dental unit air or water lines such as ultrasonic scaler tips and component parts and air water syringe tips should be cleaned and sterilized after treatment of each patient in the same manner as hand pieces.

Disposal of Waste Materials

Blood, suctioned fluid, or other liquid waste may be poured carefully in to a drain connected to a sanitary sewer system.Disposable needles, scalpels, or other sharp items should be placed intact into puncture-resistant containers before disposal.

Solid waste contaminated wit blood or other body fluid should be placed in scaled, sturdy impervious bags to prevent leakage of the contained.