• Prestressed concrete: in general can be defined as the preloading of a structure before application of the serves load, so as to improve its performance in specific way, the preloading of a structure involves introducing sufficient axial pre compression in beam so as the tension in the concrete was eliminated at serves load, the deflections may be limited to an acceptable value, in fact, members can be designed to have zero deflection under the combined effects of service load and prestress force.

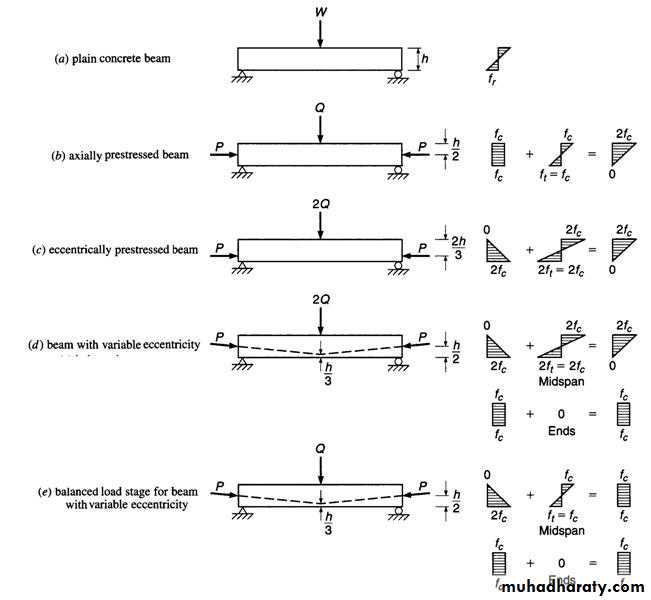

• Concrete stress control by prestressing

• For plain unreinforced concrete beam with a rectangular cross section shown in figure 1a. It carries a single concentrated load at the center of its span. (Self weight is ignored). After loading by load W, the tensile stress in the concrete at the bottom of the beam will reach the tensile strength of the concrete fr, and a crack will form and the beam will collapse without further increase of load.In figure 1b, an axial force P is introduced to the vertical loading, the longitudinal prestressing force will produce a uiform axial compression fc=P/Ac, where Ac is the cross sectional area of the concrete. When load Q is applied, the superposition of stresses due to P and Q will result in zero tensile stress at the bottom of the beam. Tensile stress in the concrete may be eliminated in this way or reduced to a specified amount.

• In figures 1c, 1d and 1e, the force P, with the same value as before, but applied with eccentricity e=h/6 relative to the concrete centroid, and compressive stress distribution varying from zero at the top surface to a maximum of 2fc=P/Ac + Pec2/Ic at the bottom, where fc is the concrete stress at the concrete centroid, c2 is the distance from the concrete centroid to the bottom of the beam, and Ic is the moment of inertia of the cross section. The load can be twice as great as before or 2Q and still cause no tensile stress.

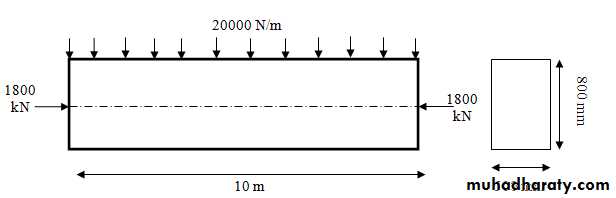

• Ex: A simply supported prestressed beam of cross section 500 mm wide and 800mm deep is loaded with a uniformly distributed load 20000 N/m on a span 10 m. Obtain the distribution of stresses at mid – span, at quarter span and at ends , if the prestressing force is 180 ton and the tendon is concentric.

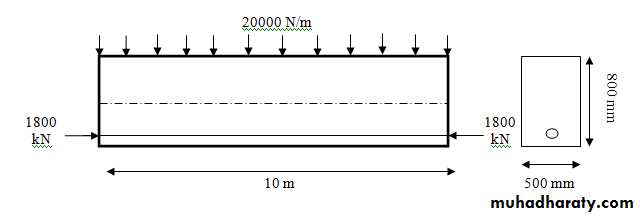

• Ex:Obtain stresses at midspan and at ends of the beam in previous example if it issubjected to an external load of 20000 N/m and a prestress of 180 ton applied eccentrically all along is 100mm from bottom.

•

• METHODS OF PRESTRESSING

• Pre-tensioning method pre-stressed concrete members: There are produced by stretching the tendon between external anchorages before the fresh concrete is placed and hardened, Then the concrete is placed around the tensioned tendon, and after the concrete has attained sufficient strength, the jacking pressure is released. This transfers the pre-stressing force to the concrete by bond and friction along the tendon.• Post-tension method pre-stressed concrete members: the tendon is placed unstressed in hollow conduit and placed in the beam form before pouring the fresh concrete, The tendons are stressed after the concrete has hardened and achieved sufficient strength, by jacking against the concrete member itself.

• Type of pre-stressing steel:

• Tendons

• There are three types of pre-stressing steel

• Round wires: wires are available in four diameters ranging between (4.89-7.01)mm with a minimum ultimate tensile strength ( 1325-1655) N/mm2. Tendons are composite from a number of wires ranging between (8-52) wires.

• Stranded cables: is consist of 6 wires of equal diameters bounded tightly on the 7th of slightly larger diameters, the available diameters are in the range of (6.34-16)mm with a minimum ultimate tensile strength (1728-1860) N/mm2.

Allays steel bars: this type is available in diameter of (16-36)mm with tensile strength (1000-1100) N/mm2.

2.Ordinary reinforcing steel

As a non pre-stressing steel used in pre-stress concrete members at high local compressive stress area, anchorages, also its required as a longitudinal reinforcement to control shrinkage and temperature cracking of concrete members, as well as reinforcing to increase the ultimate stress of the beams, reinforcing the overhanging flanges of beams, its also required as stirrups for diagonal tension shear.• The strength of concrete:

• It is required to used a higher concrete strength to reduce the member dimension, weight and moment for larger spans to obtain and economic design.• Also using high concrete strength (HCS) in design will give a higher modulus of elasticity Ec result a small amount of elastic shortening and creep losses.

• Concrete of higher strength gives a higher bearing stress, a higher diagonal shearing stress and a higher bound with the pre-stressing steel.

• Permissible stresses in pre-stressing steel:

• Due to pre-stressing at jacking force 0.94 fpy but not greater than o.8 fpu , or the value recommended by the manufacturer.• Immediately after pre-stress transfer 0.82 fpy but not greater than o.74 fpu .

• Post-tension at anchorage device 0.7 fpu .

• fpy: yielding stress of pre-stress steel.

• fpu: ultimate stress of pre-stress steel.