DENTAL METALS AND ALLOYS Metals and alloys play an important role in dentistry. These materials are used in all aspects of dental practice including:1. direct dental restorations e.g. amalgam alloys, gold alloys.2. inlays and onlays. e.g. gold alloys.3. crowns and bridges. e.g. gold alloys, nickel-chromium alloys, palladium alloys, titanium alloys.4. denture base frameworks. e.g. gold alloys, cobalt-chromium alloys.5. implants. e.g. pure titanium and titanium alloys.

6. endodontic posts. e.g. nickel-chromium alloys.7. endodontic and general dental instruments. e.g. cobalt-chromium nickel, stainless steel, nickel-titanium alloys.8. orthodontic wires and brackets and surgical wires. e.g. stainless steel, titanium alloys.Alloy: is defined as any combination of two or more metals.

SHAPING OF DENTAL METALS AND ALLOYS:1.Casting: it involves heating the material until it becomes molten, then it can be forced into an investment mold which has been prepared. e.g. of casting alloys; cobalt-chromium, nickel-chromium, titanium alloys …..etc.2.Cold working: it involves mechanical shaping of the metal at relatively low temperature taking the benefits of the high values of ductility and malleability possessed by many metals. e.g. type 1 gold alloys.

3. amalgamation: some alloys can be mixed with mercury to form a solid mass which gradually hardens by a chemical reaction followed by crystallization. The material is shaped by packing it into tooth cavity. e.g. dental amalgam.

CLASSIFIACATION OF DENTAL CASTING ALLOYS 1. according to their use; crown and bridge alloys, denture base framework alloys, metal-ceramic restoration alloys ……… etc.2. according to their major element; gold alloys, palladium alloys, silver alloys, nickel alloys, titanium alloys, cobalt alloys, ……….etc.3. according to their principal three elements; cobalt-chromium-molybdenum, titanium-aluminum-vanadium, gold-palladium-silver, …….etc.4. according to their nobility; this classification is proposed by ADA in 1984 according to the noble contents of the alloys;

① high noble (HN) (precious): these alloys contain ≥ 60 wt% of the noble metal elements. ② noble (N) (semiprecious): these alloys contain ≥ 25 wt% of the noble metal elements.③ predominant base metal (PD) (non-precious): these alloys contain ˂ 25 wt% of the noble metal elements.Noble metal elements are gold and palladium group metals. Silver is not considered a noble metal because it is more reactive in the oral cavity.

Requirements of desirable dental casting metals and alloys:

1. biocompatibility.2. ease of melting, casting, brazing (soldering) and polishing.

3. little solidification shrinkage.

4. minimal reactivity with the mold material.

5. good wear resistance.

6. high strength

7. excellent tarnish and corrosion resistance.

GOLD ALLOYS

General composition: it is the gold and other elements (silver, copper, platinum, palladium and zinc) which are added to the gold to improve its physical properties. Traditionally, the gold content of dental alloys is indicated by:

1. Carat (Karat): refers to the parts of pure gold in 24 parts of an alloy. e.g.24 Karat gold contain pure gold, 22 Karat gold contain 22 parts pure gold and 2 parts of other elements.

2. Fineness: refers to the number of parts per 1000 of gold e.g. fineness of 1000 contain pure gold, fineness of 650 contain 65% gold.

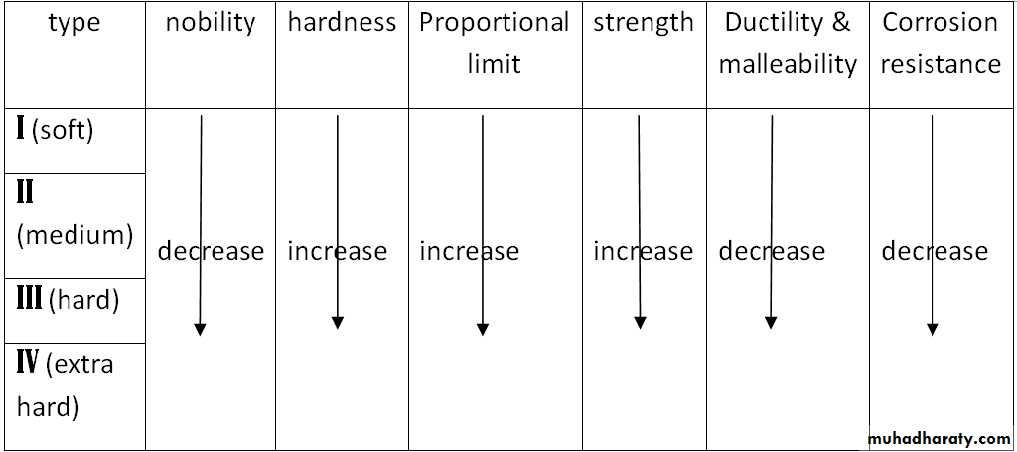

Types of gold alloys: there are 4 types of gold alloys that differ in their percentages of their composition. Accordingly they differ from each other in their physical properties.

Types of gold alloys: there are 4 types of gold alloys that differ in their percentages of their composition. Accordingly they differ from each other in their physical properties.

Uses of gold alloys:

Type I: small inlays, and direct dental restorations.Type II: medium inlays.

Type III: large inlays, onlays, crowns and bridges.

Type IV: crowns , bridges, and denture base frameworks.

Faults in casting

4 types of faults1. Finning and bubbling:

Finning (formation of fins on the casting surface) is due to cracking of the investment caused by its rapid heating. This fault can be avoided by slow heating of the mold to allow escapement of gases without cracking of the mold.

Bubbling (formation of spheres on the casting surface)is due to the presence of surface porosities in the investment. This fault can be avoided by vacuume investing.

These faults increase the time of finishing.

2. Incomplete casting : this type of faults can be avoided by:

A. convenient number and diameter of the sprues.

B. the balance between the molten alloy temperature and mold temperature is important to prevent solidification of the alloy before the mold can be properly filled.

C. sufficient thrust should be created by the rotational speed of the centrifugal casting machines to ensure proper flow of the alloy to all parts of the mold cavity.

D. gases and steam within the mold that cannot escape cause back pressure which leads to rounded edges of the casting and lacking in details. Therefore the metallic plate support the end of the ring must be perforated to allow escapement of gases and steam.

3. porosity: (pitting on the casting surface):

This is caused by broken pieces of investment or particles of dirt which have fallen down the sprue. This can be avoided by handling the molds with the sprue downwards.4. oversized or undersized castings:

These faults can be overcome by the following:A. the casting shrinkage of the alloy should be compensated for by the setting expansion, thermal expansion and inversion of the investment.

B. the proper choice of the impression material and impression technique influences the final results.