Piped gas supply

Description

Anaesthetists regularly use piped gas supply and suction in

different parts of the hospital. This session explores the

different components of the piped gas system, examines

safety procedures governing its usage, and describes how it

operates in conjunction with the anaesthetic machine.

Session introduction

Learning objectives:

• Recognize the key features and functionality

of the piped gas supply network and outlets.

• Demonstrate an awareness of the piped gas

supply safety features including how the

supply connects to the anaesthesia machine.

Introduction to piped gas

• This session explores the fundamental aspects of how

anaesthetists regularly use piped gas supply and

suction in different parts of the hospital for patient

care.

• The gases are supplied from central supply points of

hospital premises, such as cylinder main fold banks or

liquid oxygen storage tanks, which house large volumes

of gas.

• The gas is piped through special copper alloy piped

work, and out let valves control the flow of the gas

throughout the hospital, ensuring its instant availability

at the required locations.

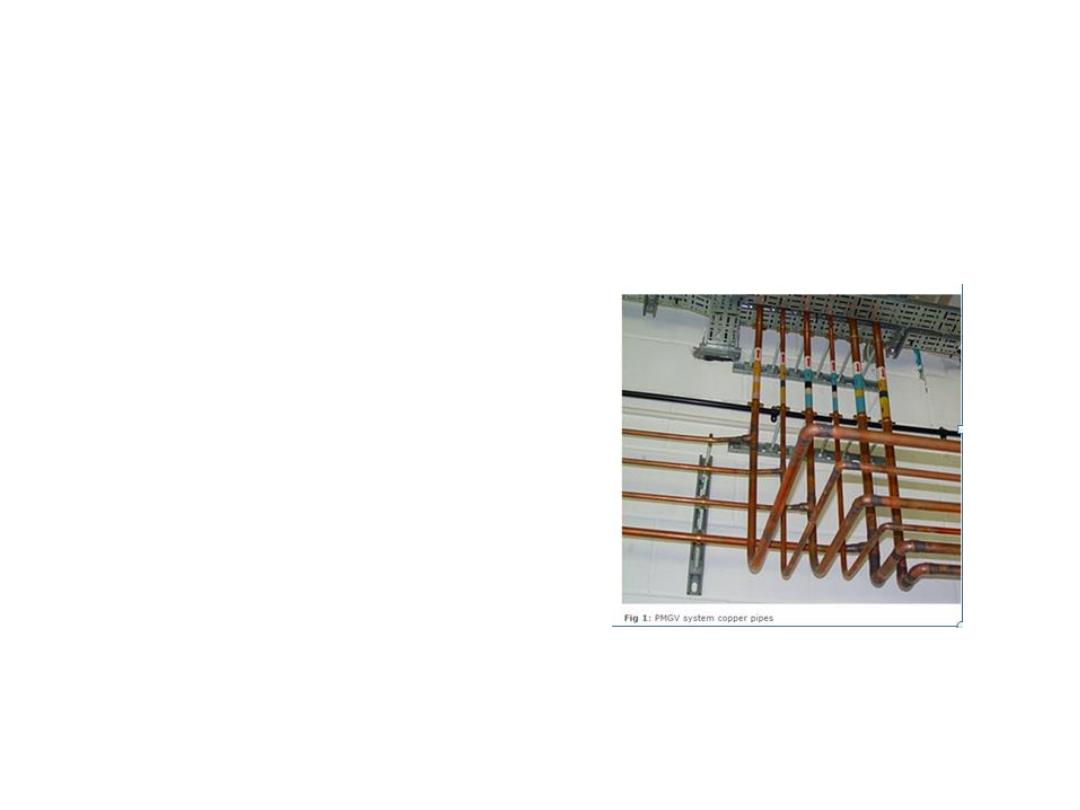

Piped medical gas and vacuum (PMGV)

system

•

Gases are delivered from central

supply points and distributed via a

copper pipework system with brass

fittings which ends in outlets.

•

Copper is used in these piped

medical gas and vacuum (PMGV)

systems because it prevents the

degradation of the gases.

•

Copper also has bacteriostatic

properties, which it important in a

sterile environment.

•

PMGV systems are grease free, and

the size of the pipes vary depending

on the demand they supply.

•

As a safety feature, the pipes are

labelled at regular intervals to avoid

misconnection.

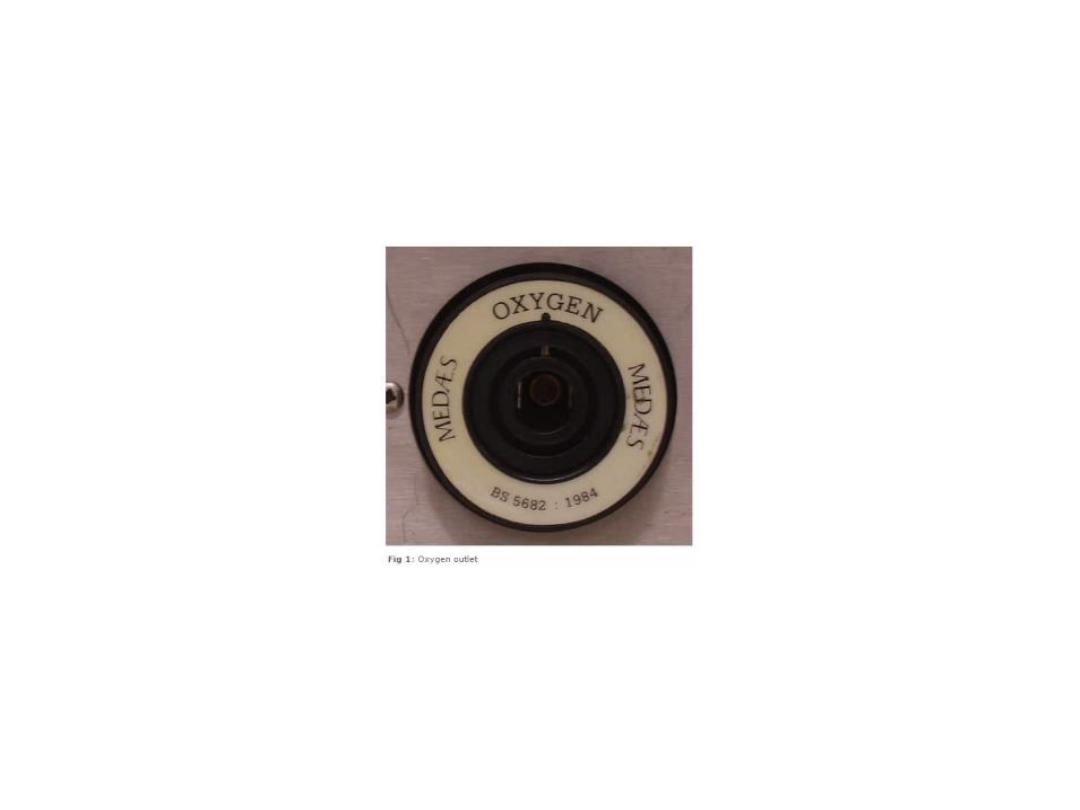

The piped supply outlets

The piped supply outlets are identified by:

• Gas colour coding.

• Gas name.

• Shape.

This provide a safety system that ensures a

patient can not be given an incorrect supply.

View the images to see the different colours

and shapes of the outlets.

Oxygen outlet

white

Nitrous oxide outlet

blue

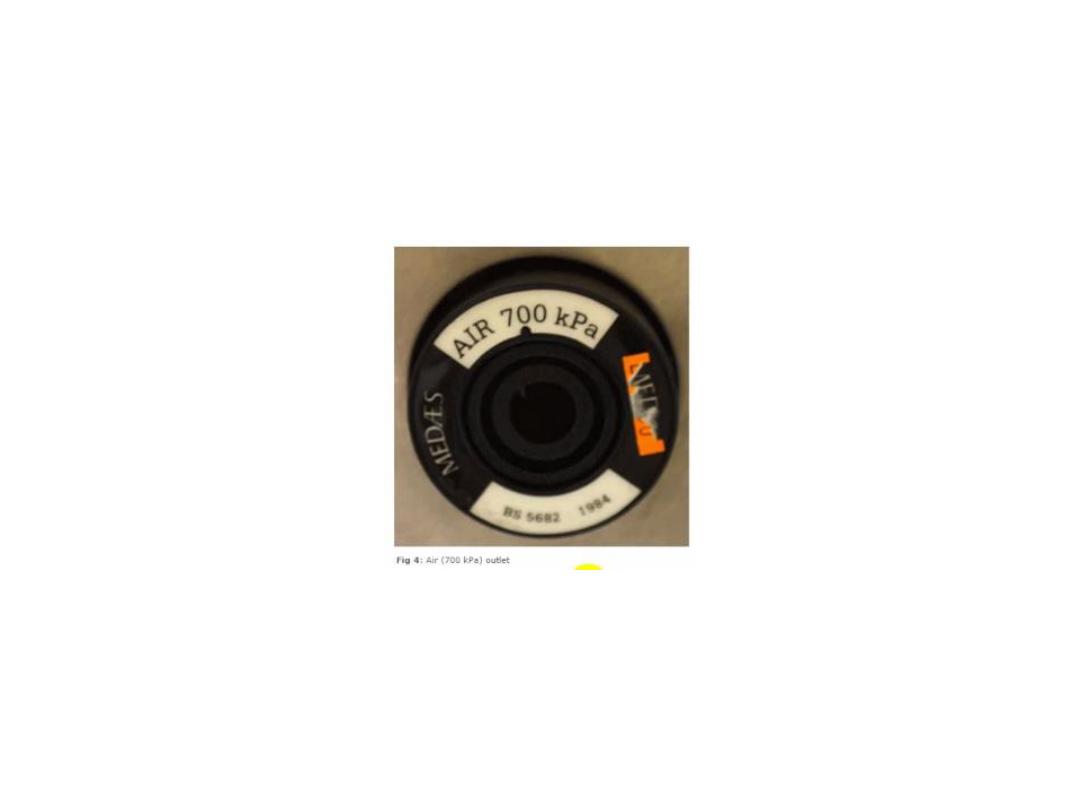

air (400 KPa) outlet

black

Air (700 KPa) outlet

black

Suction outlet

yellow

Scavenging outlet

yellow/blue

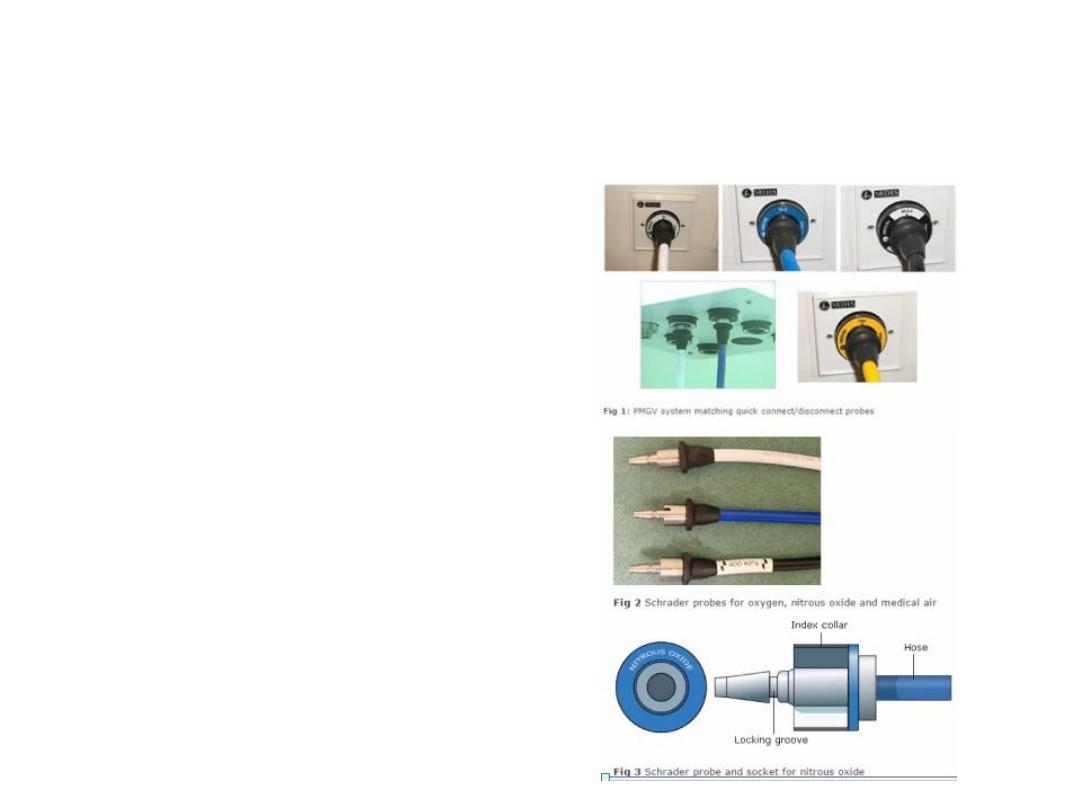

Piped gas outlets

The safety of the patients

is paramount. PMGV system

outlets are designed to

accepts matching quick

connect/ disconnect probes.

They will only accept the

correct connecter – none of

the others will fit.

The outlets have Schrader

sockets with an indexing

collar specific to each gas or

gas mixture.

Anaesthetic machine

In order to improve the safety of gas

delivery, the following design features

are incorporated.

The PMGV system outlets are

connected to the anaesthetic machine

via flexible colour – coded hoses.

•

White for oxygen.

•

Blue for nitrous oxide.

•

Black for air.

•

Yellow for vacuum/suction.

•

Brown for scavenging.

The British standard states that the

end of the hose connecting to the

anaesthetic machine should be

permanently fixed using a nut and liner

union and gas specific non

interchangeable screw threads (NISTs).

Safety features

•

The single hose test is performed to

detect cross – connection. This

ensures that the correct gas is

flowing via the correct flow meter on

the anaesthetic machine.

•

A reserve bank of cylinder is available

should be primary supply fail. Usually

the switched off cylinders are

attached to the anaesthetic machine

and can be turned on very quickly in

the case of a central supply failure.

•

The tug test is performed to detect

misconnection – it confirms that each

pipe line is correctly inserted in to

the appropriate gas supply terminal.

Inadequately inserted pipes can

appear to be attached to the terminal

even when hanging vertically, but

their will be no gas flow.

Compressed medical air

• Medical air is supplied either for

medical use, such as during

anaesthesia via the anaesthetic

machine, or drive power tools,

such as orthopedic surgical tools

or tourniquet equipment.

• For clinical use, medical air is

supplied at pressure of 400 KPa,

while for power tools it supplied

at 700 KPa.

• anaesthetic machines and most

intensive care ventilator blenders

accept a 400KPa supply.

• The terminal outlet of the two

pressures are different, to

prevent misconnection.

Session key points

• Piped gas is supplied by a network of copper pipelines throughout

the hospital from central supply points.

• The outlet are named, colour coded and shaped coded to accept

matching probes that are permanently fixed.

• Single hose and tug tests are performed to test for cross connection

and misconnection respectively.

• There is a risk of fire from worn and damaged hoses.

• Gases are supplied under pressure of 400KPa. In addition, air is also

supplied under pressure of 700KPa.

• A vacuum of -53KPa(-400mmHg) is generated. A pump should be

capable of creating a negative pressure of -53KPa . A unit should

take no longer than 10 seconds to generate a vacuum (500mmHg)

with a displacement of air of 25L/min.

Session summary

Learning objectives:

• Recognize the key features and functionality

of the piped gas supply network and outlets.

• Demonstrate an awareness of the piped gas

supplied safety features including how the

supply connects to the anaesthesia machine.