C O N T E N T S

1. OILWELL CEMENTS

1.1 Functions of oilwell cement

1.2 Classification of cement powders

1.3 Mixwater Requirements

2. PROPERTIES OF CEMENT

3. CEMENT ADDITIVES

4. PRIMARY CEMENTING

4.1 Downhole cementing equipment

4.2 Surface cementing equipment

4.3 Single Stage Cementing Operation

4.4 Multi - Stage cementing Operation

4.5 Inner string cementing

4.6 Liner cementing

4.7 Recommendations for a good cement job

5. SQUEEZE CEMENTING

5.1 High Pressure Squeeze

5.2 Low pressure squeeze

5.3 Equipment used for squeeze cementing

5.4 Testing the squeeze job

6. CEMENT PLUGS

7. EVALUATION OF CEMENT JOBS

Cementing

LEarNiNg OBJECTiVES :

Having worked through this chapter the student will be able to:

General

• Describe the principal functions of cement.

Cement Slurries

• List and describe the major properties of a cement slurry.

• Describe the additives used in cement slurries and the way in which they affect

the properties of the slurry.

Cementing Operations

• Calculate the volume of : slurry, cement, mixwater, displacing fluid required for

a single stage and two-stage cementing operation.

• Calculate the bottomhole pressures generated during the above cementing

operations.

• Describe the surface and downhole equipment used in a single, two-stage and

liner cementation operation.

• Prepare a program for a single and two stage cementing operation and describe

the ways in which a good cement bond can be achieved.

Cement Plugs

• Describe the reasons for setting cement plugs.

• Describe the principal methods for placing a cement plug in casing or open

hole.

• Calculate the displacement volumes for an underbalanced cement plug.

Evaluation of Cementing Operations

• Describe the principles involved and the tools and techniques used to evaluate

the quality of a cementing operation.

• Discuss the limitations of the above techniques.

Cementing

Institute of Petroleum Engineering, Heriot-Watt University

1. iNTrOduCTiON

Cement is used primarily as an impermeable seal material in oil and gas well

drilling. It is most widely used as a seal between casing and the borehole, bonding

the casing to the formation and providing a barrier to the flow of fluids from, or into,

the formations behind the casing and from, and into, the subsequent hole section

(Figure 1). Cement is also used for remedial or repair work on producing wells.

It is used for instance to seal off perforated casing when a producing zone starts

to produce large amounts of water and/or to repair casing leaks. This chapter will

present: the reasons for using cement in oil and gas well drilling; the design of the

cement slurry; and the operations involved in the placement of the cement slurry.

The methods used to determine if the cementing operation has been successful will

also be discussed.

1.1 Functions of oilwell cement

There are many reasons for using cement in oil and gaswell operations. As stated

above, cement is most widely used as a seal between casing and the borehole,

bonding the casing to the formation and providing a barrier to the flow of fluids

from, or into, the formations behind the casing and from, and into, the subsequent

hole section (Figure 1). However, when placed between the casing and borehole the

cement may be required to perform some other tasks. The most important functions

of a cement sheath between the casing and borehole are:

• To prevent the movement of fluids from one formation to another or from the

formations to surface through the annulus between the casing and borehole.

• To support the casing string (specifically surface casing)

• To protect the casing from corrosive fluids in the formations.

However, the prevention of fluid migration is by far the most important function

of the cement sheath between the casing and borehole. Cement is only required

to support the casing in the case of the surface casing where the axial loads on

the casing, due to the weight of the wellhead and BOP connected to the top of

the casing string, are extremely high. The cement sheath in this case prevents the

casing from buckling.

The techniques used to place the cement in the annular space will be discussed

in detail later but basically the method of doing this is to pump cement down the

inside of the casing and through the casing shoe into the annulus (Figure 2). This

operation is known as a primary cement job. A successful primary cement job is

essential to allow further drilling and production operations to proceed.

Conductor pipe

Surface casing

Cement

Perforations

Production casing

Intermediate casing

Production tubing

Liner

Normally pressured

Abnormally pressured

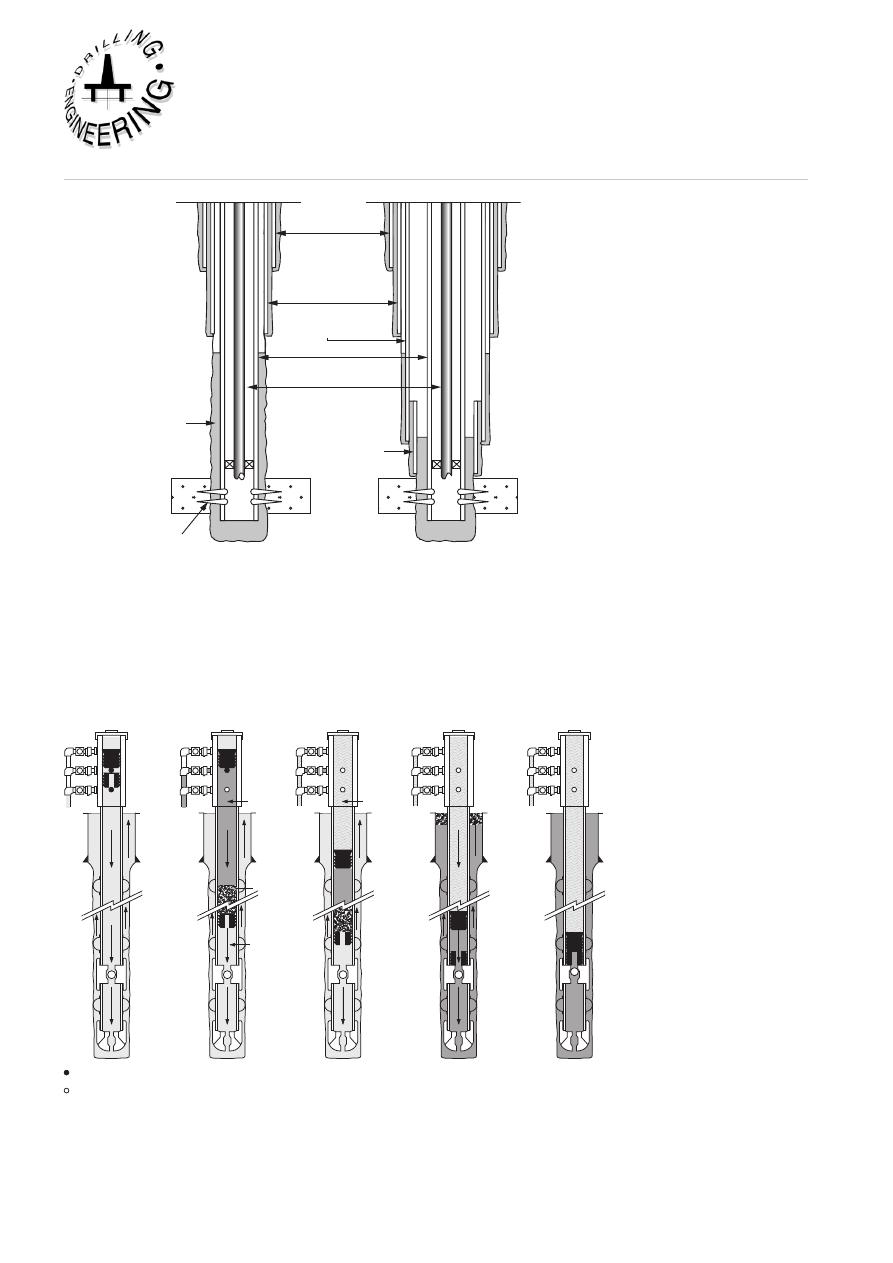

Figure 1

Functions of Primary Cementing

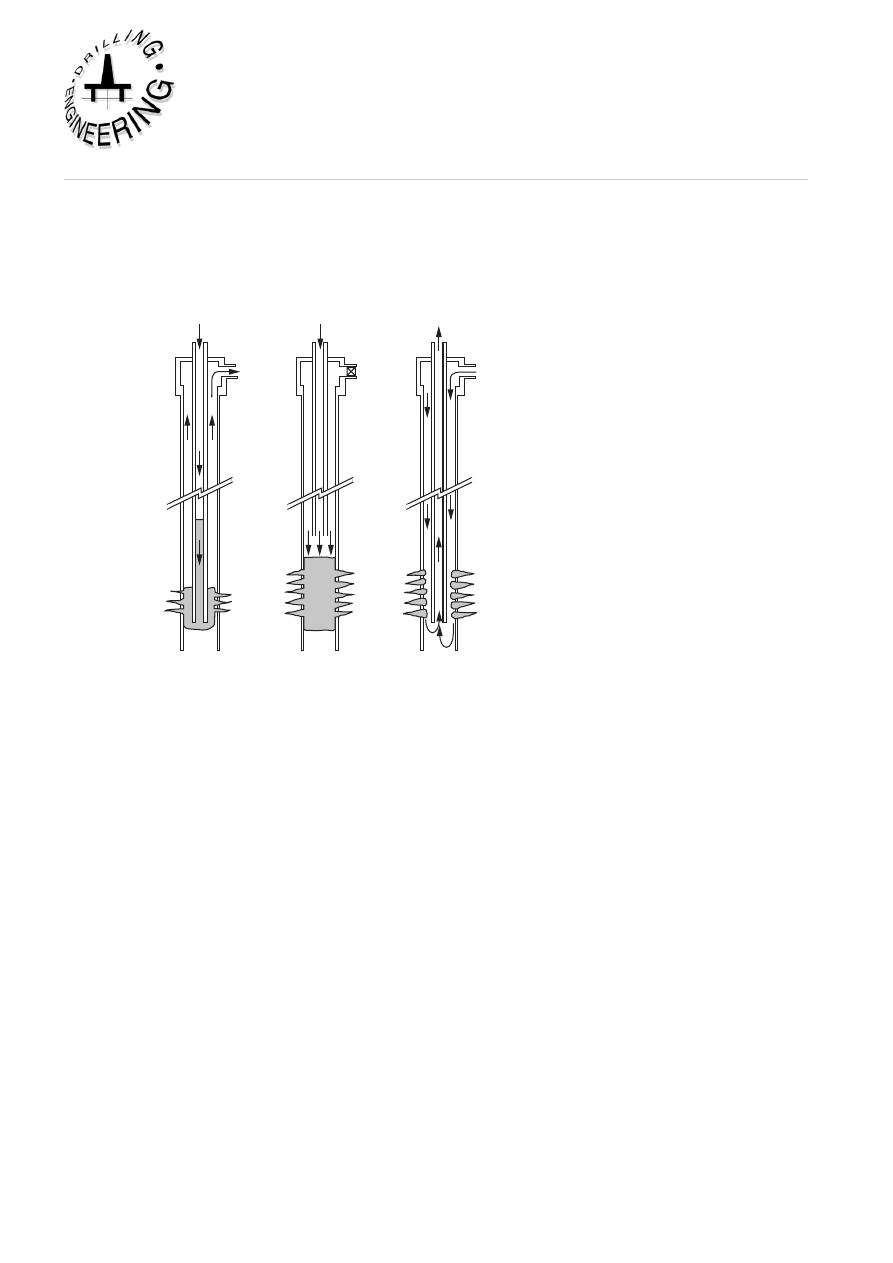

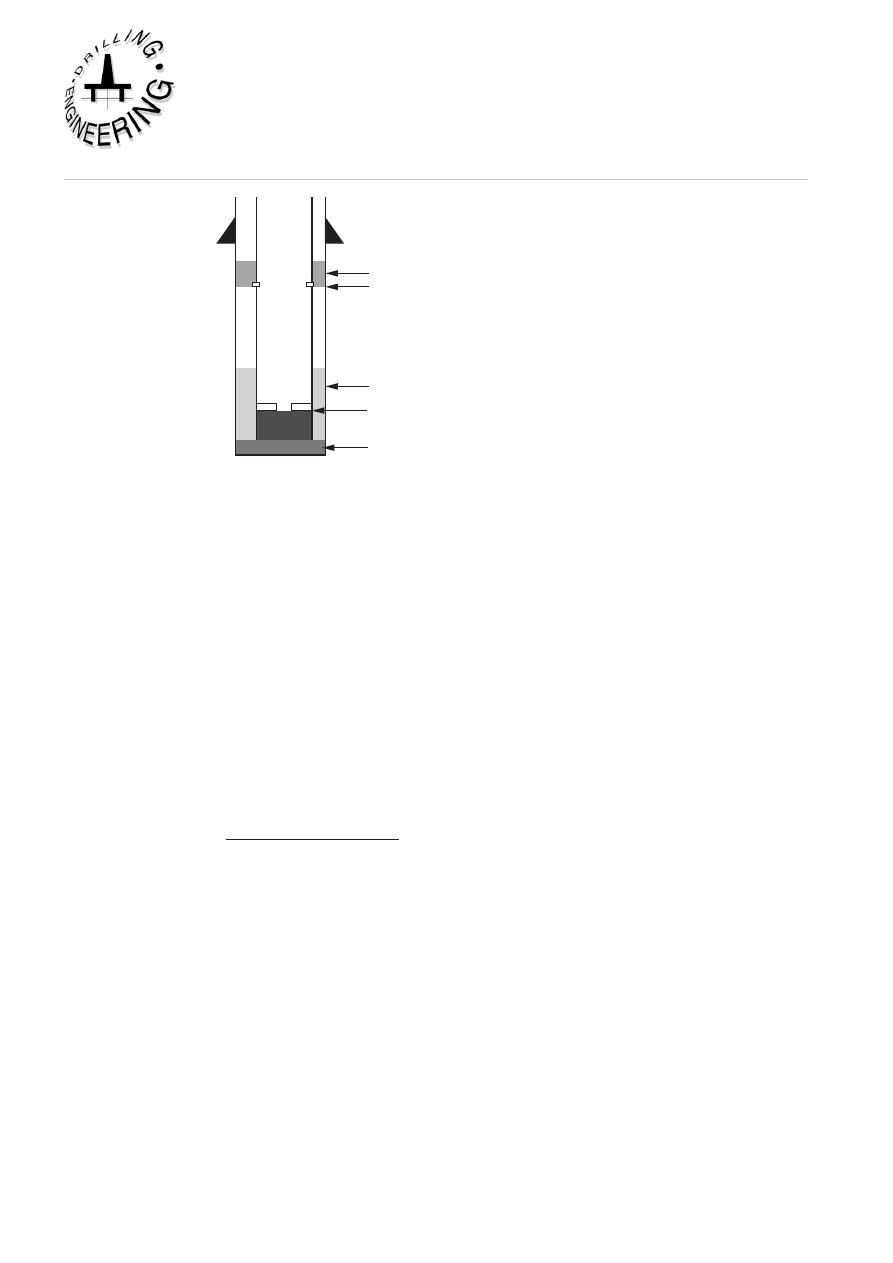

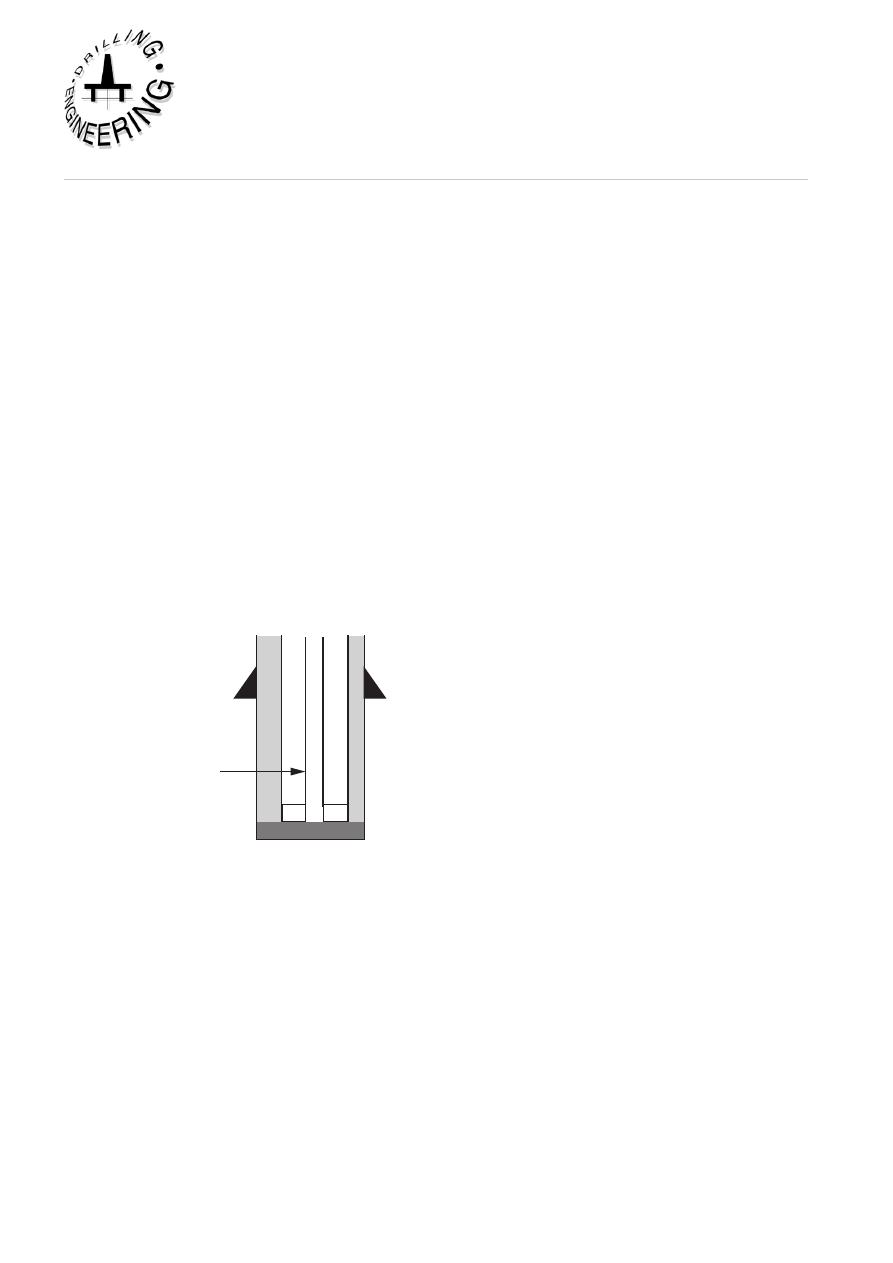

Circulating

mud

Pumping spacer

and slurry

Displacing

Displacing

End of job

Top

cementing

plug

Bottom

cementing

plug

Centralizers

Float

collar

Shoe

Spacer

Slurry

Displacing

Fluid

Original

mud

Plug release pin in

Plug release pin out

Figure 2

Primary Cementing Operations

Cementing

Institute of Petroleum Engineering, Heriot-Watt University

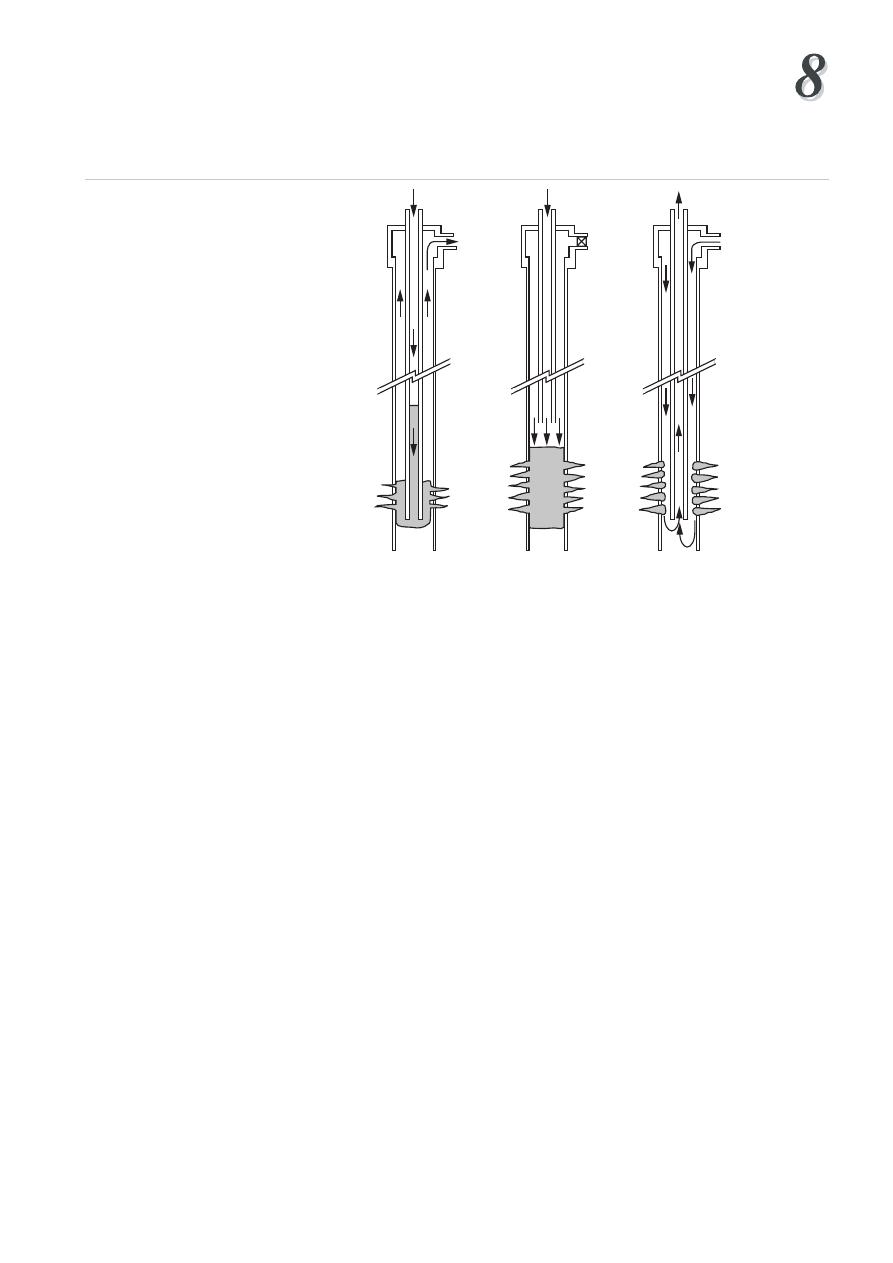

Spot cement Apply squeeze Reverse circulate

pressure

Schematic of Bradenhead squeeze technique normally used on low pressure

formations. Cement is circulated into place down drill pipe (left), then the wellhead,

or BOP, is closed (centre) and squeeze pressure is applied. Reverse circulating

through perforations (right) removes excess cement, or the plug can be drilled out.

Figure 3

Secondary or Squeeze Cementing Operation

Another type of cement job that is performed in oil and gas well operations is called

a secondary or squeeze cement job. This type of cement job may have to

be done at a later stage in the life of the well. A secondary cement job may be

performed for many reasons, but is usually carried out on wells which have been

producing for some time. They are generally part of remedial work on the well

(e.g. sealing off water producing zones or repairing casing leaks). These cement

jobs are often called squeeze cement jobs because they involve cement being forced

through holes or perforations in the casing into the annulus and/or the formation

(Figure 3).

The specific properties of the cement slurry which is used in the primary and

secondary cementing operations discussed above will depend on the particular

reason for using the cement (e.g. to plug off the entire wellbore or simply to plug

off perforations) and the conditions under which it will be used (e.g. the pressure

and temperature at the bottom of the well).

The cement slurry which is used in the above operations is made up from: cement

powder; water; and chemical additives. There are many different grades of cement

powder manufactured and each has particular attributes which make it suitable for

a particular type of operation. These grades of cement powder will be discussed

below. The water used may be fresh or salt water. The chemical additives (Figure

4) which are mixed into the cement slurry alter the properties of both the cement

slurry and the hardened cement and will be discussed at length in Section 3 below.

CEMENT SLURRY

Retarders;

Calcium lignosulphonate

CMHEC

Saturated salt solution

Extenders;

Bentonite

Pozzolan

Fluid loss additives;

Organic polymers

CMHEC

Mud contaminants;

Diesel

NaOH

Accelerators;

CaCI2

NaCI

Heavy weight material;

Barite

Haemitite

Friction reducers (dispersants);

Polymers

Calcium ligno sulphonate

Figure 4

Major cement additives

API Class

C3S

C2S C3A C4AF CaSO4

SQq. cm/Gram

A

53

24

8

8

3.5

1600-1900

B

44

32

5

12

2.9

1500-1900

C

58

16

8

8

4.1

2000-2400

D&E

50

26

5

13

3

1200-1500

G

52

27

3

12

3.2

1400-1600

H

52

25

5

12

3.3

1400-1600

*Plus free lime, alkali, (Na, K, Mg)

Compounds*

Fineness

Table 1

Composition of API Cements

Each cement job must be carefully planned to ensure that the correct cement and

additives are being used, and that a suitable placement technique is being employed

for that particular application. In planning the cement job the engineer must ensure

that:

• The cement can be placed correctly using the equipment available

• The cement will achieve adequate compressive strength soon after it is placed

• The cement will thereafter isolate zones and support the casing throughout the

life of the well

To assist the engineer in designing the cement slurry, the cement slurry is tested

in the laboratory under the conditions to which it will be exposed in he wellbore.

Theses tests are known as pilot tests and are carried out before the job goes ahead.

These tests must simulate downhole conditions as closely as possible. They will

Cementing

Institute of Petroleum Engineering, Heriot-Watt University

help to assess the effect of different amounts of additives on the properties of the

cement (e.g. thickening time, compressive strength development etc).

API Class

Mixwater

Slurry Weight

Gals/Sk.

Lbs/Gal.

A

5.2

15.6

B

5.2

15.6

C

6.3

14.8

D

4.3

16.4

E

4.3

16.4

F

4.3

16.2

G

5.0

15.8

H

4.3

16.4

Table 2

API Mixwater requirements for API cements

1.2 Classification of cement powders

There are several classes of cement powder which are approved for oilwell drilling

applications, by the American Petroleum Institute - API. Each of these cement

powders have different properties when mixed with water. The difference in

properties produced by the cement powders is caused by the differences in the

distribution of the four basic compounds which are used to make cement powder;

C

3

S, C

2

S, C

3

A, C

4

AF (Table 1).

Classes A and B

- These cements are generally cheaper than other classes of cement

and can only be used at shallow depths ,where there are no special requirements.

Class B has a higher resistance to sulphate than Class A.

Class C

- This cement has a high C

3

S content and therefore becomes hard relatively

quickly.

Classes D,E and F

- These are known as retarded cements since they take a much

longer time to set hard than the other classes of cement powder. This retardation is

due to a coarser grind. These cement powders are however more expensive than the

other classes of cement and their increased cost must be justified by their ability to

work satisfactorily in deep wells at higher temperatures and pressures.

Class G and H

- These are general purpose cement powders which are compatible

with most additives and can be used over a wide range of temperature and pressure.

Class G is the most common type of cement and is used in most areas . Class H has

a coarser grind than Class G and gives better retarding properties in deeper wells.

There are other, non-API, terms used to classify cement. These include the

following:

• Pozmix cement - This is formed by mixing Portland cement with pozzolan

(ground volcanic ash) and 2% bentonite. This is a very lightweight but durable

cement. Pozmix cement is less expensive than most other types of cement and due

to its light weight is often used for shallow well casing cementation operations.

Portland

API Class G

API ClassH

Water,

5.19

4.97

4.29

gal./sk.

Slurry Wt.

15.9

15.8

16.5

lb./gal.

Slurry Vol.

1.8

1.14

1.05

cuft./sk.

Temp. (deg. F) Pressure (psi) Typical comp. strength (psi) @ 12hrs

60

0

615

440

325

80

0

1470

1185

1065

95

800

2085

2540

2110

110

1600

2925

2915

2525

140

3000

5050

4200

3160

170

3000

5920

4380

4485

200

3000

-

5110

4575

Typical comp. strength (psi) @ 24hrs

60

0

2870

-

-

80

0

4130

-

-

95

800

4130

-

-

110

1600

5840

-

-

140

3000

6550

-

7125

170

3000

6210

5865

7310

200

3000

-

7360

9900

Table 3

Compressive strength of cements

• Gypsum Cement - This type of cement is formed by mixing Portland cement

with gypsum. These cements develop a high early strength and can be used for

remedial work. They expand on setting and deteriorate in the presence of water and

are therefore useful for sealing off lost circulation zones.

• Diesel oil cement - This is a mixture of one of the basic cement classes (A, B, G,

H ), diesel oil or kerosene and a surfactant. These cements have unlimited setting

times and will only set in the presence of water. Consequently they are often used

to seal off water producing zones, where they absorb and set to form a dense hard

cement.

1.3 Mixwater Requirements

The water which is used to make up the cement slurry is known as the mixwater.

The amount of mixwater used to make up the cement slurry is shown in Table 2.

These amounts are based on :

• The need to have a slurry that is easily pumped.

• The need to hydrate all of the cement powder so that a high quality hardened

cement is produced.

• The need to ensure that all of the free water is used to hydrate the cement

powder and that no free water is present in the hardened cement.

Cementing

Institute of Petroleum Engineering, Heriot-Watt University

The amount of mixwater that is used to make up the cement slurry is carefully

controlled. If too much mixwater is used the cement will not set into a strong,

impermeable cement barrier. If not enough mixwater is used :

• The slurry density and viscosity will increase.

• The pumpability will decrease

• Less volume of slurry will be obtained from each sack of cement

The quantities of mixwater quoted in Table 2 are average values for the different

classes of cement. Sometimes the amount of mixwater used will be changed to

meet the specific temperature and pressure conditions which will be experienced

during the cement job.

2. PrOPErTiES OF CEMENT

The properties of a specific cement slurry will depend on the particular reason for

using the cement, as discussed above. However, there are fundamental properties

which must be considered when designing any cement slurry.

(a) Compressive strength

The casing shoe should not be drilled out until the cement sheath has reached a

compressive strength of about 500 psi. This is generally considered to be enough

to support a casing string and to allow drilling to proceed without the hardened

cement sheath, disintegrating, due to vibration. If the operation is delayed whilst

waiting on the cement to set and develop this compressive strength the drilling rig

is said to be “waiting on cement” (WOC). The development of compressive

strength is a function of several variables, such as: temperature; pressure; amount

of mixwater added; and elapsed time since mixing.

The setting time of a cement slurry can be controlled with chemical additives, known

as accelerators. Table 3 shows the compressive strengths for different cements

under varying conditions.

(b) Thickening time (pumpability)

The thickening time of a cement slurry is the time during which the cement slurry

can be pumped and displaced into the annulus (i.e. the slurry is pumpable during

this time). The slurry should have sufficient thickening time to allow it to be:

• Mixed

• Pumped into the casing

• Displaced by drilling fluid until it is in the required place

Generally 2 - 3 hours thickening time is enough to allow the above operations to

be completed. This also allows enough time for any delays and interruptions in the

cementing operation. The thickening time that is required for a particular operation

will be carefully selected so that the following operational issues are satisfied:

• The cement slurry does not set whilst it is being pumped

• The cement slurry is not sitting in position as a slurry for long periods,

potentially being contaminated by the formation fluids or other contaminants

10

• The rig is not waiting on cement for long periods.

Wellbore conditions have a significant effect on thickening time. An increase in

temperature, pressure or fluid loss will each reduce the thickening time and these

conditions will be simulated when the cement slurry is being formulated and tested

in the laboratory before the operation is performed.

(c) Slurry density

The standard slurry densities shown in Table 2 may have to be altered to meet

specific operational requirements (e.g. a low strength formation may not be able

to support the hydrostatic pressure of a cement slurry whose density is around 15

ppg). The density can be altered by changing the amount of mixwater or using

additives to the cement slurry. Most slurry densities vary between 11 - 18.5 ppg.

It should be noted that these densities are relatively high when the normal formation

pore pressure gradient is generally considered to be equivalent to 8.9 ppg. It is

generally the case that cement slurries generally have a much higher density than

the drilling fluids which are being used to drill the well. The high slurry densities

are however unavoidable if a hardened cement with a high compressive strength

is to be achieved.

(d) Water loss

The slurry setting process is the result of the cement powder being hydrated by

the mixwater. If water is lost from the cement slurry before it reaches its intended

position in the annulus its pumpability will decrease and water sensitive formations

may be adversely affected. The amount of water loss that can be tolerated depends

on the type of cement job and the cement slurry formulation.

Squeeze cementing requires a low water loss since the cement must be squeezed

before the filter cake builds up and blocks the perforations. Primary cementing is

not so critically dependent on fluid loss. The amount of fluid loss from a particular

slurry should be determined from laboratory tests. Under standard laboratory

conditions (1000 psi filter pressure, with a 325 mesh filter) a slurry for a squeeze

job should give a fluid loss of 50 - 200 cc. For a primary cement job 250 - 400 cc

is adequate.

(e) Corrosion resistance

Formation water contains certain corrosive elements which may cause deterioration

of the cement sheath. Two compounds which are commonly found in formation

waters are sodium sulphate and magnesium sulphate. These will react with lime

and C

3

S to form large crystals of calcium sulphoaluminate. These crystals expand

and cause cracks to develop in the cement structure. Lowering the C

3

A content of

the cement increases the sulphate resistance. For high sulphate resistant cement

the C

3

A content should be 0 - 3%

(f) Permeability

After the cement has hardened the permeability is very low (<0.1 millidarcy). This

is much lower than most producing formations. However if the cement is disturbed

during setting (e.g. by gas intrusion) higher permeability channels (5 - 10 darcies)

may be created during the placement operation.

Cementing

11

Institute of Petroleum Engineering, Heriot-Watt University

Cement

Gel

Mixwater

Slurry Density Slurry Volume

Class

%

%

gal/sk.

cu. ft/sk

ppg

pcf

cu. ft/sk

G

0

44.0

4.96

0.663

15.9

118.70

1.14

G

4

65.2

7.35

0.982

14.3

107.00

1.49

G

8

88.4

9.74

1.302

13.3

99.77

1.83

G

12

107.2

12.10

1.621

12.7

94.83

2.18

G

16

128.8

14.50

1.940

12.2

91.24

2.52

SLURRY COMPOSITION

Cement

Gel

Time

Class

%

hrs.

80 deg F 100 deg F

120 deg F 140 deg F

160 deg F

G

0

24

1800

3050

4150

5020

6700

G

4

24

860

1250

1830

1950

2210

G

8

24

410

670

890

1090

1340

COMPRESSIVE STRENGTH, psi

Cement

Gel Casing Schedules, Hrs; mins.

Class

%

2000 ft

4000ft

6000ft

8000ft

10000ft

91 deg F 103 deg F 113 deg F

126 deg F 144 deg F

G

0

4:30

2:50

2:24

1:50

1:20

G

4

4:10

2:18

1:51

1:27

0:57

G

8

5:00

2:43

2:06

1:38

1:04

THICKENING TIME

Table 4

Cements with bentonite

3. CEMENT addiTiVES

Most cement slurries will contain some additives, to modify the properties of the

slurry and optimise the cement job. Most additives are known by the trade-names

used by the cement service companies. Cement additives can be used to:

• Vary the slurry density

• Change the compressive strength

• Accelerate or retard the setting time

• Control filtration and fluid loss

• Reduce slurry viscosity

Additives may be delivered to the rig in granular or liquid form and may be blended

with the cement powder or added to the mixwater before the slurry is mixed. The

amount of additive used is usually given in terms of a percentage by weight of the

cement powder (based on each sack of cement weighing 94 lb). Several additives

will affect more than one property and so care must be taken as to how they are used

(Figure 4).

1

It should be remembered that the slurry is mixed up and tested in the laboratory

before the actual cement job.

(a) Accelerators

Accelerators are added to the cement slurry to shorten the time taken for the cement

to set. These are used when the setting time for the cement would be much longer

than that required to mix and place the slurry, and the drilling rig would incur WOC

time. Accelerators are especially important in shallow wells where temperatures are

low and therefore the slurry may take a long time to set. In deeper wells the higher

temperatures promote the setting process, and accelerators may not be necessary.

The most common types of accelerator are:

• Calcium chloride (CaCl

2

) 1.5 - 2.0%

• Sodium chloride (NaCl) 2.0 - 2.5%

• Seawater

It should be noted that at higher concentrations these additives will act as

retarders.

(b) Retarders

In deep wells the higher temperatures will reduce the cement slurry’s thickening

time. Retarders are used to prolong the thickening time and avoid the risk of the

cement setting in the casing prematurely. The bottom hole temperature is the

critical factor which influences slurry setting times and therefore for determining

the need for retarders. Above a static temperature of 260 - 275 degrees F the effect

of retarders should be measured in pilot tests.

The most common types of retarders are:

• Calcium lignosulphanate (sometimes with organic acids) 0.1 - 1.5%

• Saturated Salt Solutions

(c) Lightweight additives (Extenders)

Extenders are used to reduce slurry density for jobs where the hydrostatic head

of the cement slurry may exceed the fracture strength of certain formations. In

reducing the slurry density the ultimate compressive strength is also reduced and

the thickening time increased. The use of these additives allows more mixwater

to be added, and hence increases the amount of slurry which is produced by each

sack of cement powder (the yield of the slurry). Such additives are therefore

sometimes called extenders.

The most common types of lightweight additives are:

• Bentonite (2 - 16%) - This is by far the most common type of additive used to

lower slurry density. The bentonite material absorbs water, and therefore allows

more mixwater to be added. Bentonite will also however reduce compressive

strength and sulphate resistance. The increased yield due to the bentonite added is

shown in Table 4.

Cementing

1

Institute of Petroleum Engineering, Heriot-Watt University

• Pozzolan - This may be used in a 50/50 mix with the Portland cement. The result

is a slight decrease in compressive strength, and increased sulphate resistance.

• Diatomaceous earth (10 - 40%) - The large surface area of diatomaceous earth

allows more water absorption, and produces low density slurries (down to 11

ppg).

(d) Heavyweight additives

Heavyweight additives are used when cementing through overpressured zones. The

most common types of additive are:

• Barite (barium sulphate) - this can be used to attain slurry densities of up to

18ppg. It also causes a reduction in strength and pumpability.

• Hematite (Fe

2

O

3

) - The high specific gravity of hematite can be used to raise slurry

densities to 22 ppg. Hematite significantly reduces the pumpability of slurries and

therefore friction reducing additives may be required when using hematite.

• Sand - graded sand (40 - 60 mesh) can give a 2 ppg increase in slurry density.

(e) Fluid loss additives

Fluid loss additives are used to prevent dehydration of the cement slurry and

premature setting. The most common additives are:

• Organic polymers (cellulose) 0.5 - 1.5%

• Carboxymethyl hydroxyethyl cellulose (CMHEC) 0.3 - 1.0%

(CMHEC will also act as a retarder)

(f) Friction reducing additives (Dispersants)

Dispersants are added to improve the flow properties of the slurry. In particular

they will lower the viscosity of the slurry so that turbulence will occur at a lower

circulating pressure, thereby reducing the risk of breaking down formations. The

most commonly used are:

• Polymers 0.3 - 0.5 lb/sx of cement

• Salt 1 - 16 lb/sx

• Calcium lignosulphanate 0.5 - 1.5 lb/sxg)

(g) Mud contaminates

As well as the compounds deliberately added to the slurry on surface, to improve

the slurry properties, the cement slurry will also come into contact with, and be

contaminated by, drilling mud when it is pumped downhole. The chemicals in the

mud may react with the cement to give undesirable side effects. Some of these

are listed below:

Mud additive

Effect on cement

barite

increases density and reduces

compressive strength

caustic

acts as an accelerator

1

calcium compounds

decrease density

diesel oil

decrease density

thinners

act as retarders

The mixture of mud and cement causes a sharp increase in viscosity. The major

effect of a highly viscous fluid in the annulus is that it forms channels which are

not easily displaced. These channels prevent a good cement bond all round the

casing.

To prevent mud contamination of the cement a spacer fluid is pumped ahead of the

cement slurry.

4. PriMarY CEMENTiNg

The objective of a primary cement job is to place the cement slurry in the annulus

behind the casing. In most cases this can be done in a single operation, by pumping

cement down the casing, through the casing shoe and up into the annulus. However,

in longer casing strings and in particular where the formations are weak and may

not be able to support the hydrostatic pressure generated by a very long colom of

cement slurry, the cement job may be carried out in two stages. The first stage is

completed in the manner described above, with the exception that the cement slurry

does not fill the entire annulus, but reaches only a pre-determined height above the

shoe. The second stage is carried out by including a special tool in the casing

string which can be opened, allowing cement to be pumped from the casing and into

the annulus. This tool is called a multi stage cementing tool and is placed in the

casing string at the point at which the bottom of the second stage is required. When

the second stage slurry is ready to be pumped the multi stage tool is opened and

the second stage slurry is pumped down the casing, through the stage cementing

tool and into the annulus, as in the first stage. When the required amount of slurry

has been pumped, the multi stage tool is closed. This is known as a two stage

cementing operation

and will be discussed in more detail later.

The height of the cement sheath, above the casing shoe, in the annulus depends

on the particular objectives of the cementing operations. In the case of conductor

and surface casing the whole annulus is generally cemented so that the casing is

prevented from buckling under the very high axial loads produced by the weight

of the wellhead and BOP. In the case of the intermediate and production casing

the top of the cement sheath (Top of Cement - TOC) is generally selected to be

approximately 300-500 ft. above any formation that could cause problems in the

annulus of the casing string being cemented. For instance, formations that contain

gas which could migrate to surface in the annulus would be covered by the cement.

Liners are generally cemented over their entire length, all the way from the liner

shoe to the liner hanger.

4.1 Downhole cementing equipment

In order to carry out a conventional primary cement job some special equipment

must be included in the casing string as it is run.

Cementing

1

Institute of Petroleum Engineering, Heriot-Watt University

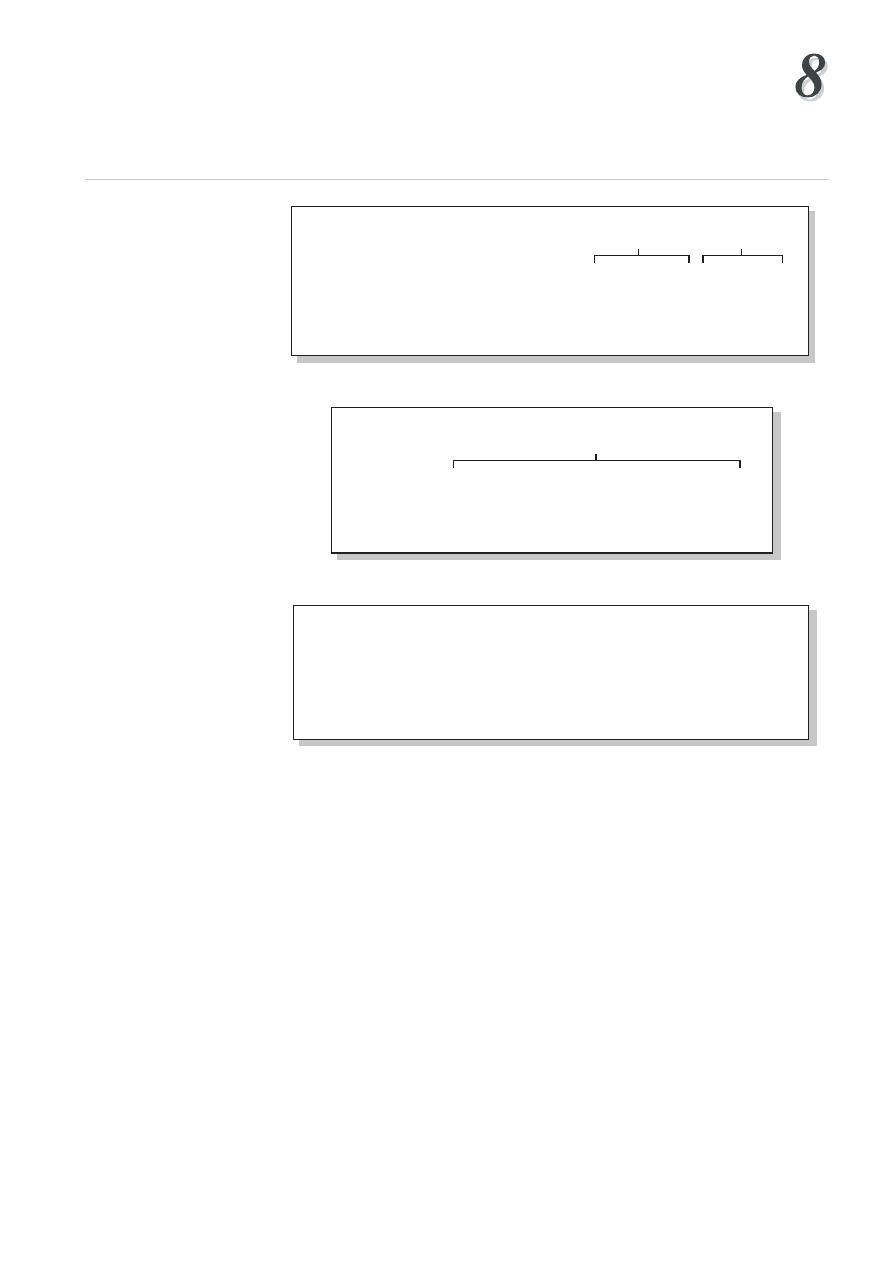

• Guide shoe - A guide (Figure 5) shoe is run on the bottom of the first joint of

casing. It has a rounded nose to guide the casing past any ledges or other irregularities

in the hole .

.

Drillable

material

Float valve

Float shoe

Guide shoe

Figure 5

Guide shoe and float shoe

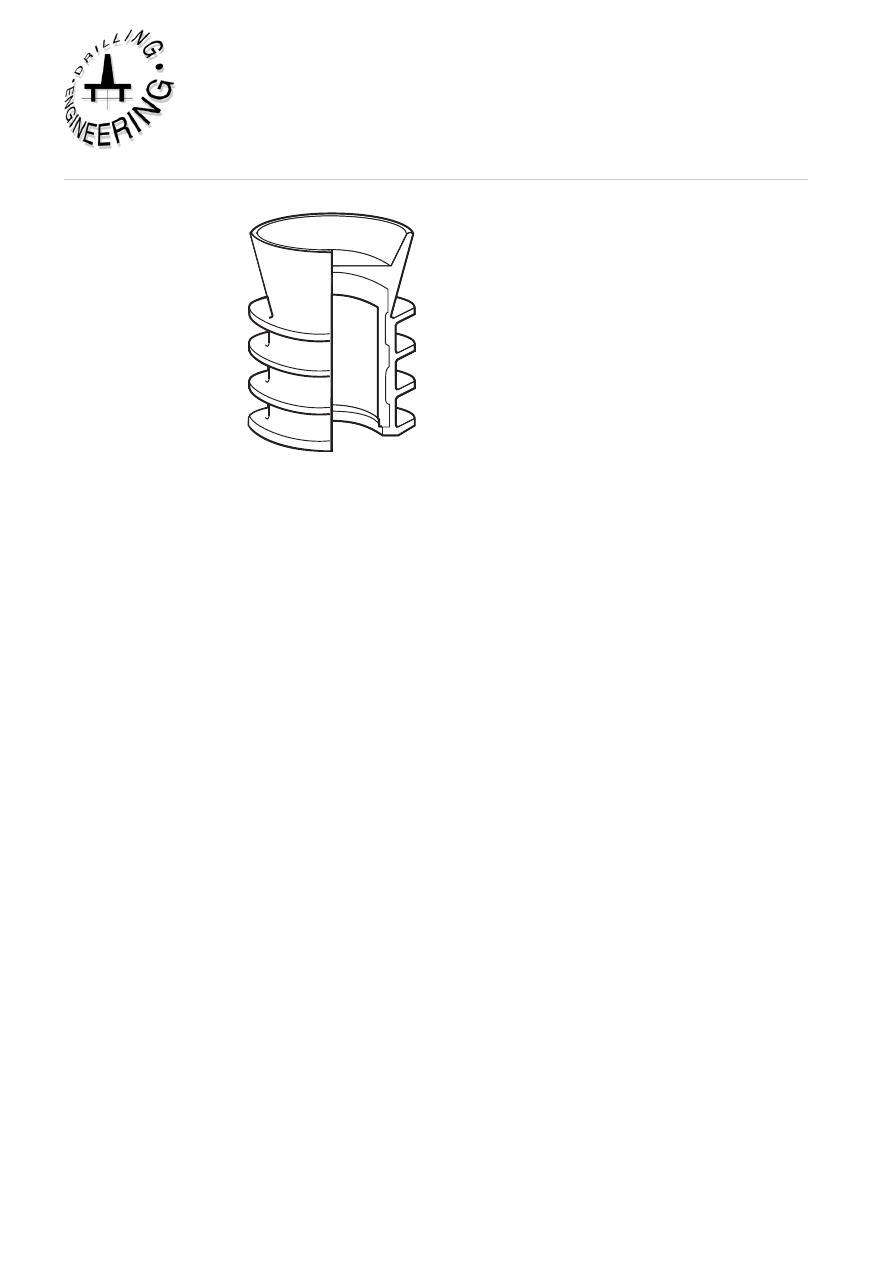

• Float collar - A float collar (Figure 6) is positioned 1 or 2 joints above the guide

shoe. It acts as a seat for the cement plugs used in the pumping and displacement

of the cement slurry. This means that at the end of the cement job there will be

some cement left in the casing between the float collar and the guide shoe which

must be drilled out.

The float collar also contains a non-return valve so that the cement slurry cannot

flow back up the casing. This is necessary because the cement slurry in the annulus

generally has a higher density than the displacing fluid in the casing, therefore a

U-tube effect is created when the cement is in position and the pumps are stopped.

Sometimes the guide shoe also has a non-return valve as an extra precaution. It is

essential that the non-return valves are effective in holding back the cement slurry.

1

Drillable

material

Float valve

Figure 6

Float collar

The use of a non-return valve means that as the casing is being run into the borehole

the fluid in the hole cannot enter the casing from below. This creates a buoyancy

effect which can be reduced by filling up the casing from the surface at regular

intervals while the casing is being run (every 5 - 20 joints). This filling up process

increases the running in time and can be avoided by the use of automatic or

differential fill up devices fitted to the float collar or shoe. These devices allow a

controlled amount of fluid to enter the casing at the bottom of the string. The ports

through which the fluid enters are blocked off before the cement job begins. The

use of a differential fill-up device also reduces the effect of surge pressures on the

formation .

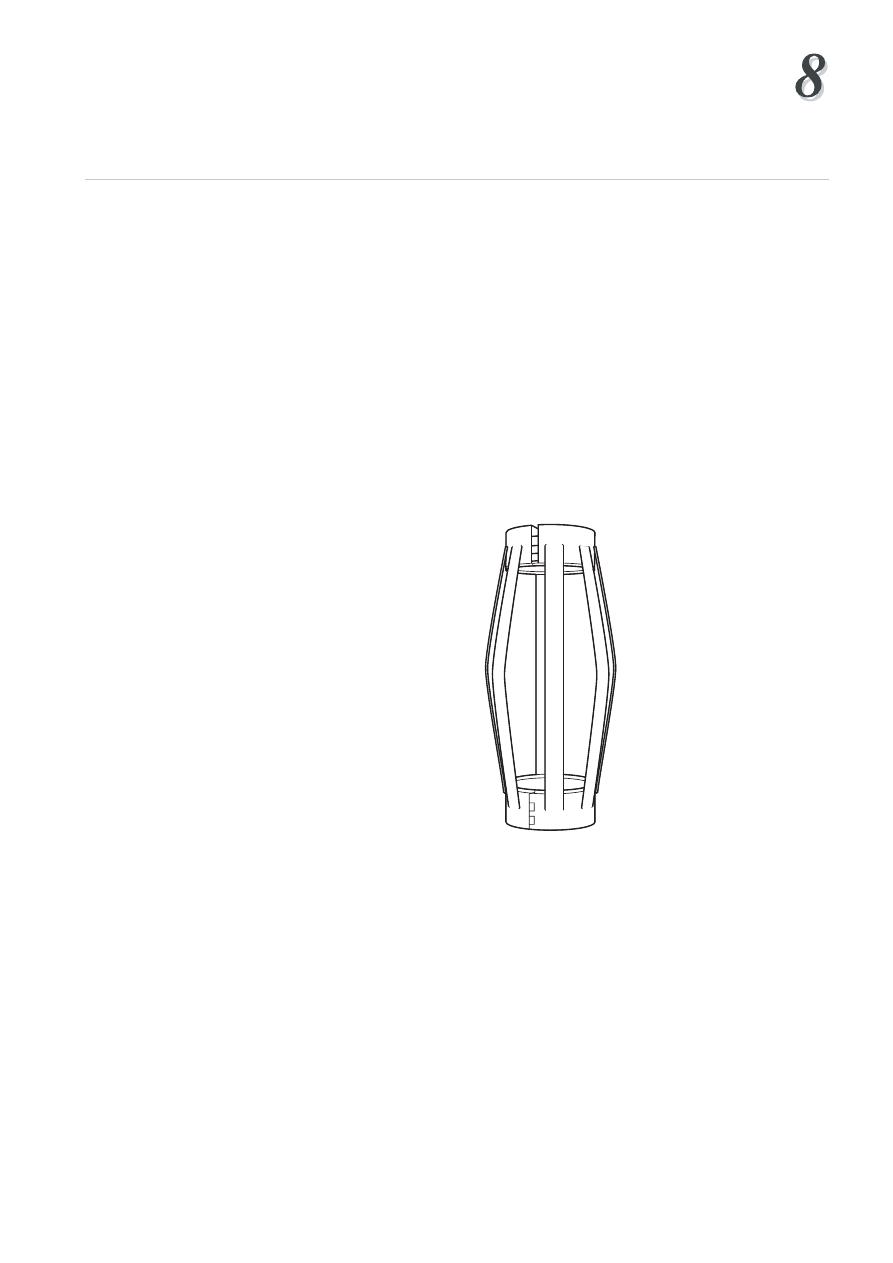

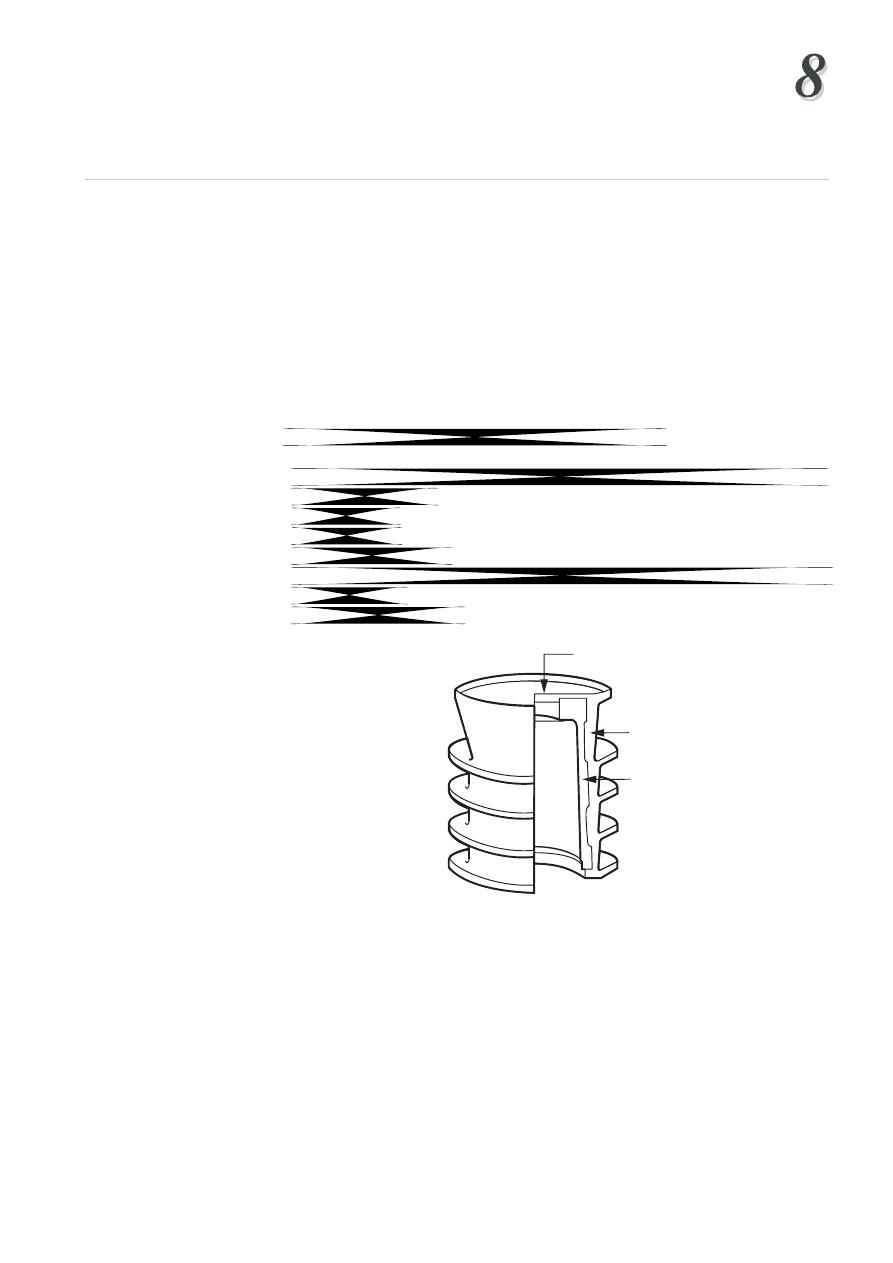

• Centralisers - these are hinged metal ribs which are installed on the casing

string as it is run (Figure 7). Their function is to keep the casing away from the

borehole so that there is some annular clearance around the entire circumference

of the casing

The proper use of centralisers will help to:

• Improve displacement efficiency (i.e. place cement all the way around the

casing)

• Prevent differential sticking

• Keep casing out of keyseats

Cementing

1

Institute of Petroleum Engineering, Heriot-Watt University

Centralisers are particularly required in deviated wells where the casing tends to lie

on the low side of the hole. On the high side there will be little resistance to flow,

and so cement placement will tend to flow up the high side annular space. Mud

channels will tend to form on the low side of the hole, preventing a good cement

job. Each centraliser is hinged so that it can be easily clamped onto the outside of

the casing and secured by a retaining pin. The centraliser is prevented from moving

up and down the casing by positioning the centraliser across a casing coupling or a

collar known as a stop collar. The spacing of centralisers will vary depending on

the requirements of each cement job. In critical zones, and in highly deviated parts

of the well, they are closely spaced, while on other parts of the casing string they

may not be necessary at all. A typical programme might be:

1 centraliser immediately above the shoe

1 every joint on the bottom 3 joints

1 every joint through the production zone

1 every 3 joints elsewhere

Figure 7

Casing Centraliser

• Wipers/scratchers - these are devices run on the outside of the casing to remove

mud cake and break up gelled mud. They are sometimes used through the

production zone.

1

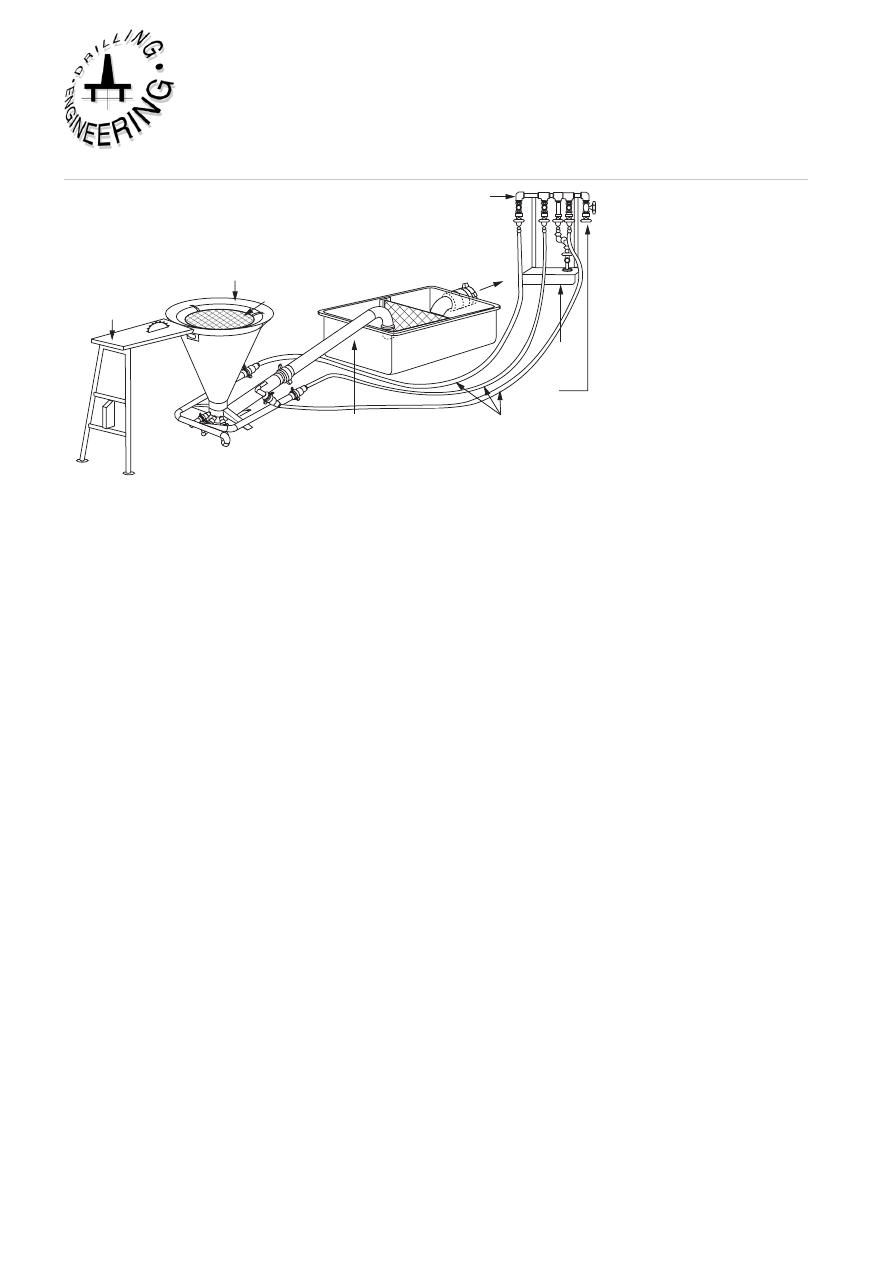

Cutting table

Hopper

Screen

Slurry tub

Mixing manifold

To triplex pump

slurry suction

Fluid end

HP hoses

To centrifugal

pump

Discharge gooseneck

Jet mixer

Figure 8

Cement unit showing jet mixer

4.2 Surface cementing equipment

Mixing and pumping facilities:

On most rigs cement powder and additives are handled in bulk, which makes

blending and mixing much easier. For large volume cement jobs several bulk

storage bins may be required on the rig. On offshore rigs the cement is transferred

pneumatically from supply boats to the storage bins.

For any cement job there must be sufficient water available to mix the slurry at the

desired water/cement ratio when required. The mix water must also be free of all

contaminants.

The water is added to the cement in a jet mixer (Figure 8). The mixer consists of

a funnel shaped hopper, a mixing bowl, a water supply line and an outlet for the

slurry. As the mixwater is pumped across the lower end of the hopper a venturi

effect is created and cement powder is drawn down into the flow of mixwater and

a slurry is created. The slurry flows into a slurry tub where its density is measured.

The density of the slurry should be regularly checked during the cement job since

this is the primary means by which the quality of the slurry is determined. If the

density of the slurry is correct then the correct amount of mixwater has been mixed

with the cement powder. Samples can be taken directly from the mixer and weighed

in a standard mud balance or automatic devices (densometers) can also be used.

Various types of cement pumping units are available. For land based jobs they

can be mounted on a truck, while skid mounted units are used offshore. The unit

normally has twin pumps (triplex, positive displacement) which may be diesel

powered or driven by electric motors. These units can operate at high pressures

(up to 20,000 psi) but are generally limited to low pumping rates. Most units are

capable of mixing and displacing 50 - 70 cubic feet of slurry per minute. In order

to minimise contamination by the mud in the annulus a preflush or spacer fluid is

pumped ahead of the cement slurry. The actual composition of the spacer depends

Cementing

1

Institute of Petroleum Engineering, Heriot-Watt University

on the type of mud being used. For water based muds the spacer fluid is often just

water, but specially designed fluids are available. The volume of spacer is based on

the need to provide sufficient separation of mud and cement in the annulus (20 - 50

bbls of spacer is common).

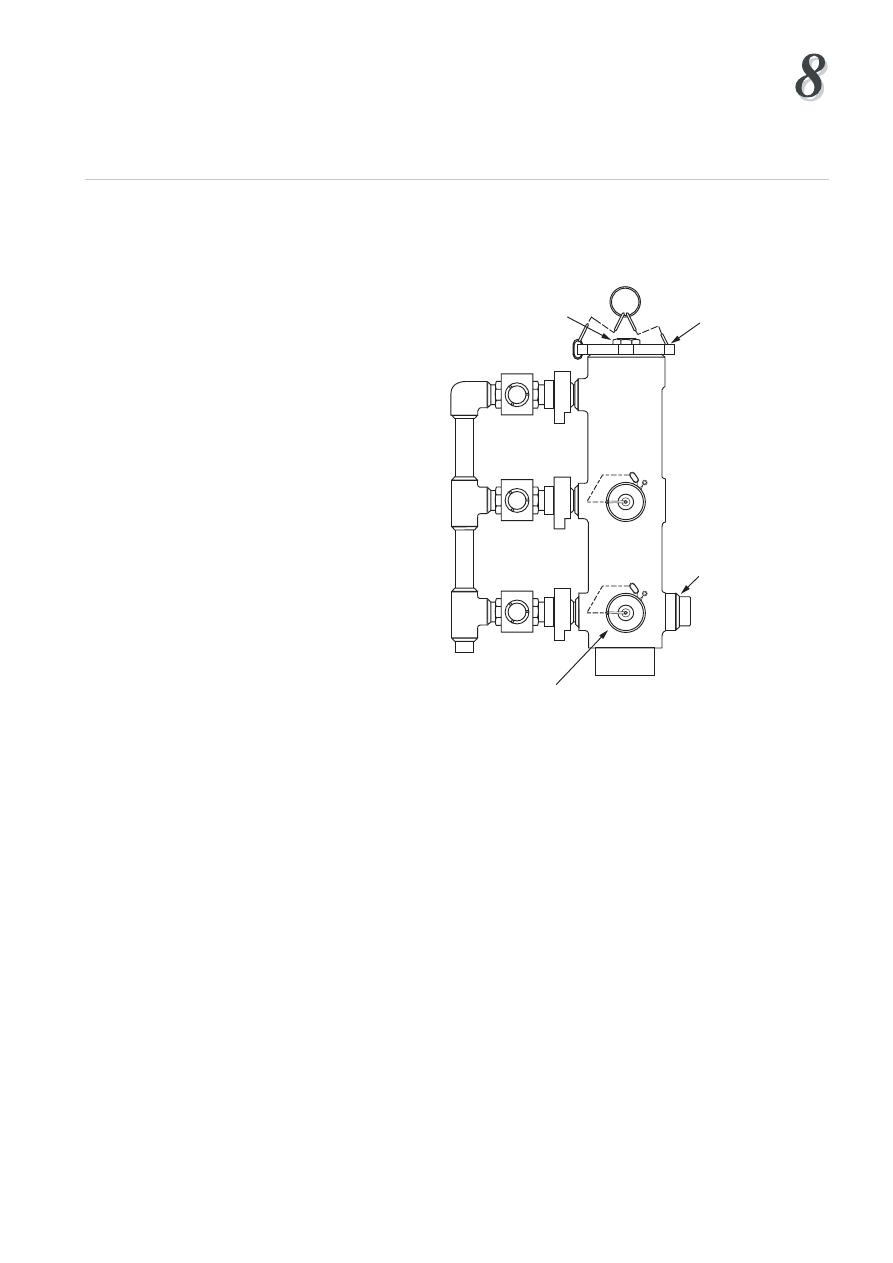

Hex plug

Cap

Body

Bull plug

Bail assy.

w/lock bolt

Manifold

assembly:

2" pipe

fittings

Figure 9

Cement Head

Cementing heads:

The cement head provides the connection between the discharge line from the

cement unit and the top of the casing (Figure 9). This piece of equipment is

designed to hold the cement plugs used in the conventional primary cement job.

The cement head makes it possible to release the bottom plug, mix and pump down

the cement slurry, release the top plug and displace the cement without making or

breaking the connection to the top of the casing. For ease of operation the cement

head should be installed as close to rig floor level as possible. The cement jobs will

be unsuccessful if the cement plugs are installed in the correct sequence or are not

released from the cementing head.

Mud is normally used to displace the cement slurry. The cement pumps or the rig

pumps may be used for the displacement. It is recommended that the cement slurry

is displaced at as high a rate as possible. High rate displacement will aid efficient

mud displacement. It is highly unlikely that it will be possible to achieve turbulence

in the cement slurry since it is so viscous and has such a high density. However, it

may be possible to generate turbulence in the spacer and this will result in a more

efficient displacement of the mud.

0

4.3 Single Stage Cementing Operation

The single stage primary cementing operation is the most common type of cementing

operation that is conducted when drilling a well. The procedure for performing a

single stage cementing operation (Figure 10) will be discussed first and then the

procedure for conducting a multiple stage and stinger cementing operations

will be discussed.

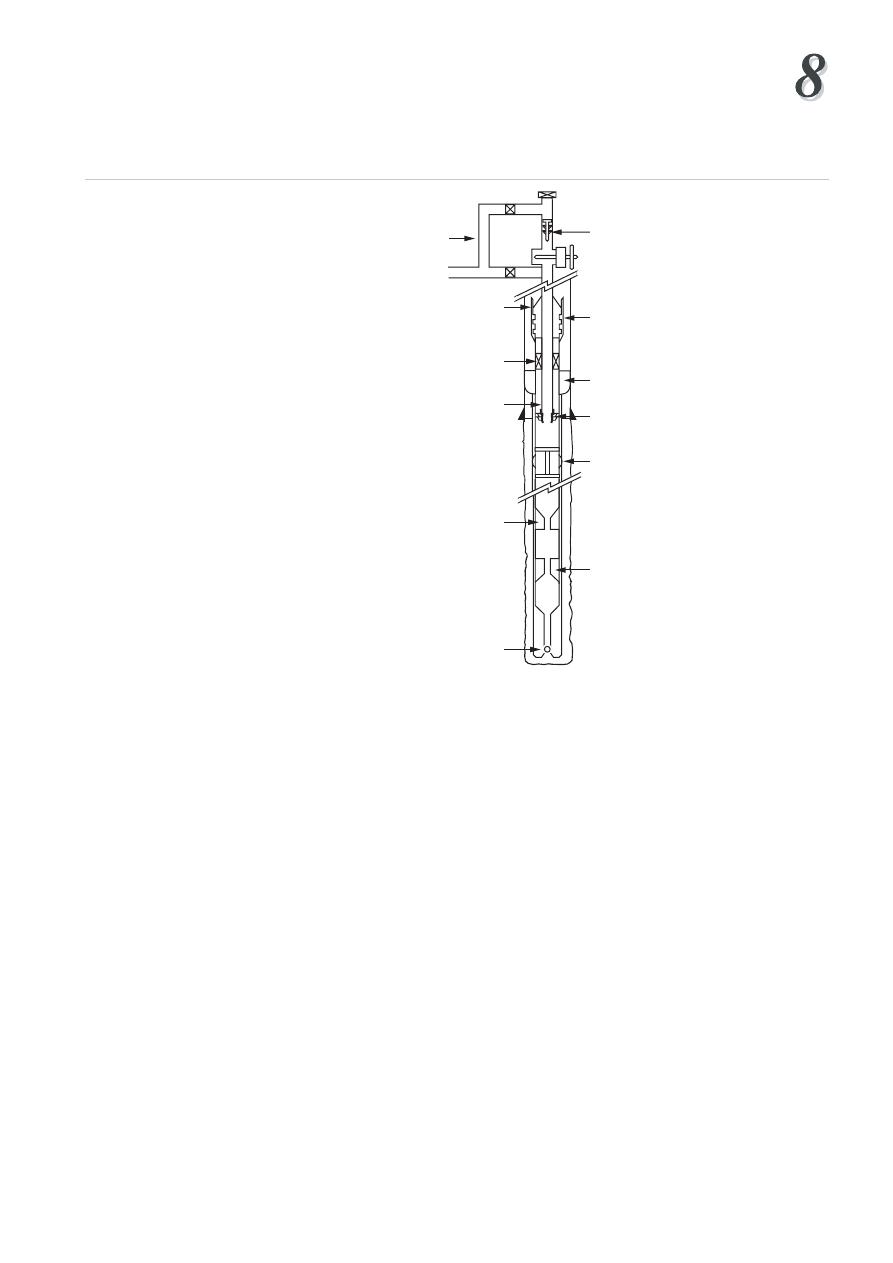

Circulating

mud

Pumping spacer

and slurry

Displacing

Displacing

End of job

Top

cementing

plug

Bottom

cementing

plug

Centralizers

Float

collar

Shoe

Spacer

Slurry

Displacing

Fluid

Original

mud

Plug release pin in

Plug release pin out

Figure 10

Single Stage Cementing Operation

In the case of the single stage operation, the casing with all of the required cementing

accessories such as the float collar, centralisers etc. is run in the hole until the shoe is

just a few feet off the bottom of the hole and the casing head is connected to the top

of the casing. It is essential that the cement plugs are correctly placed in the cement

head. The casing is then circulated clean before the cementing operation begins (at

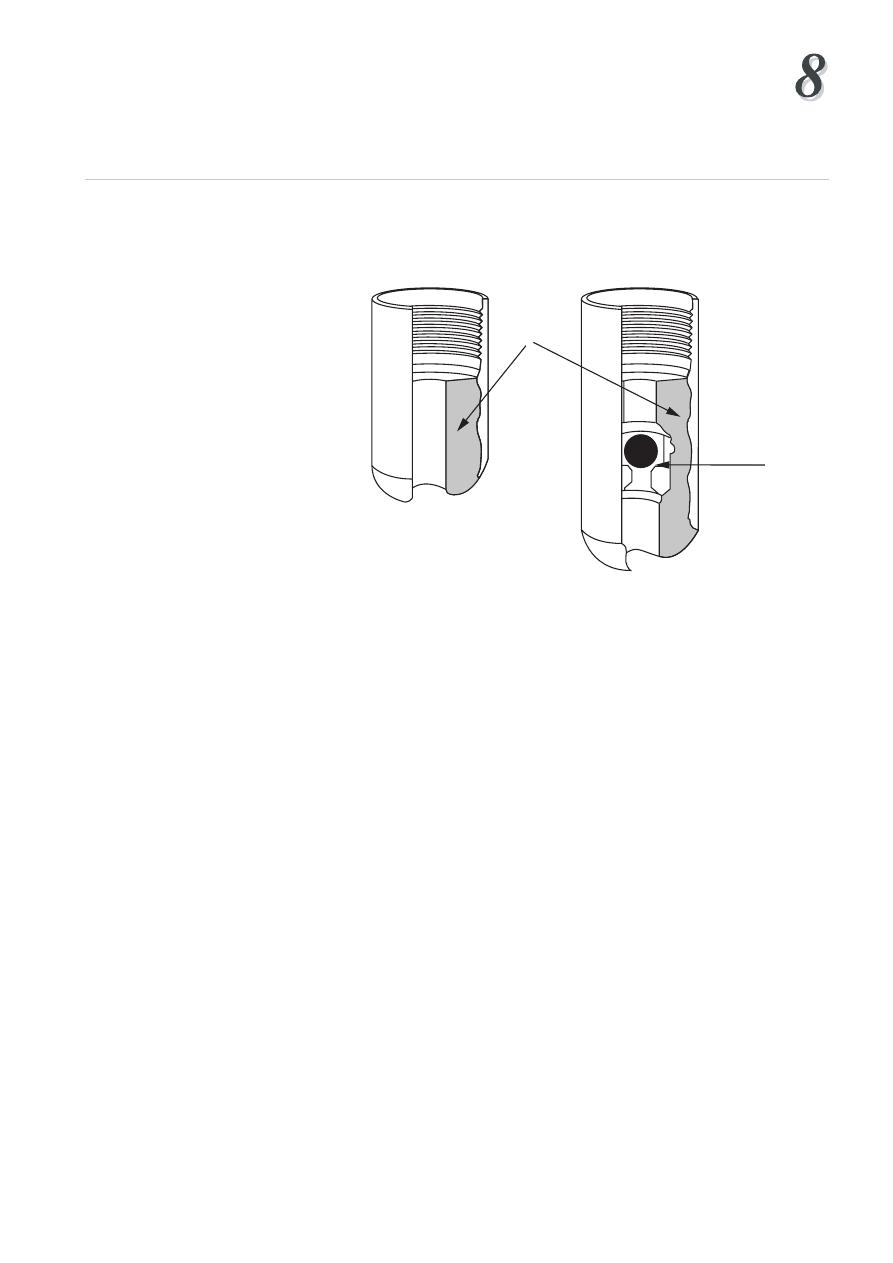

least one casing volume should be circulated). The first cement plug (wiper plug)

shown in Figure 11, is pumped down ahead of the cement to wipe the inside of the

casing clean. The spacer is then pumped into the casing. The spacer is followed by

the cement slurry and this is followed by the second plug (shut-off plug) shown

in Figure 12. When the wiper plug reaches the float collar its rubber diaphragm is

ruptured, allowing the cement slurry to flow through the plug, around the shoe, and

up into the annulus. At this stage the spacer is providing a barrier to mixing of the

cement and mud. When the solid, shut-off plug reaches the float collar it lands on

the wiper plug and stops the displacement process. The pumping rate should be

slowed down as the shut-off plug approaches the float collar and the shut-off plug

should be gently bumped into the bottom, wiper plug. The casing is often pressure

tested at this point in the operation. The pressure is then bled off slowly to ensure

that the float valves, in the float collar and/or casing shoe, are holding.

Cementing

1

Institute of Petroleum Engineering, Heriot-Watt University

The displacement of the top plug is closely monitored. The volume of displacing

fluid necessary to bump the plug should be calculated before the job begins. When

the pre-determined volume has almost been completely pumped, the pumps should

be slowed down to avoid excessive pressure when the plug is bumped. If the top

plug does not bump at the calculated volume (allowing for compression of the mud)

this may be because the top, shut-off plug has not been released. If this is the case,

no more fluid should be pumped, since this would displace the cement around the

casing shoe and up the annulus. Throughout the cement job the mud returns from

the annulus should be monitored to ensure that the formation has not been broken

down. If formation breakdown does occur then mud returns would slow down or

stop during the displacement operation.

The single stage procedure can be summarised as follows:

1. Circulate the casing and annulus clean with mud (one casing volume pumped)

2. Release wiper plug

3. Pump spacer

4. Pump cement

5. Release shut-off plug

6. Displace with displacing fluid (generally mud) until the shut-off plug lands on

the float collar

7. Pressure test the casing

Rupture Disk

Moulded

Elastomer

Aluminium

Core

Figure 11

Bottom Plug (wiper plug)

Figure 12

Top Plug (shut off plug)

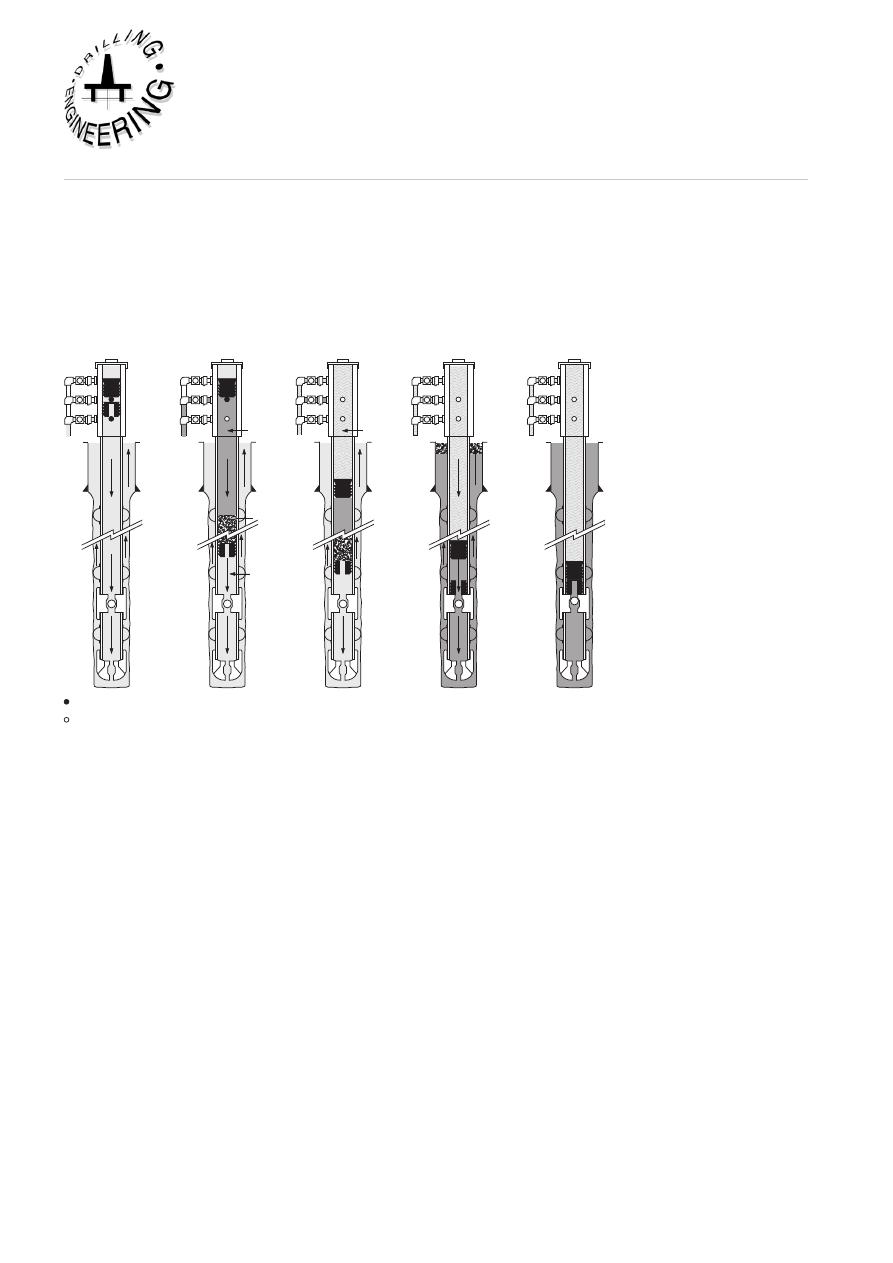

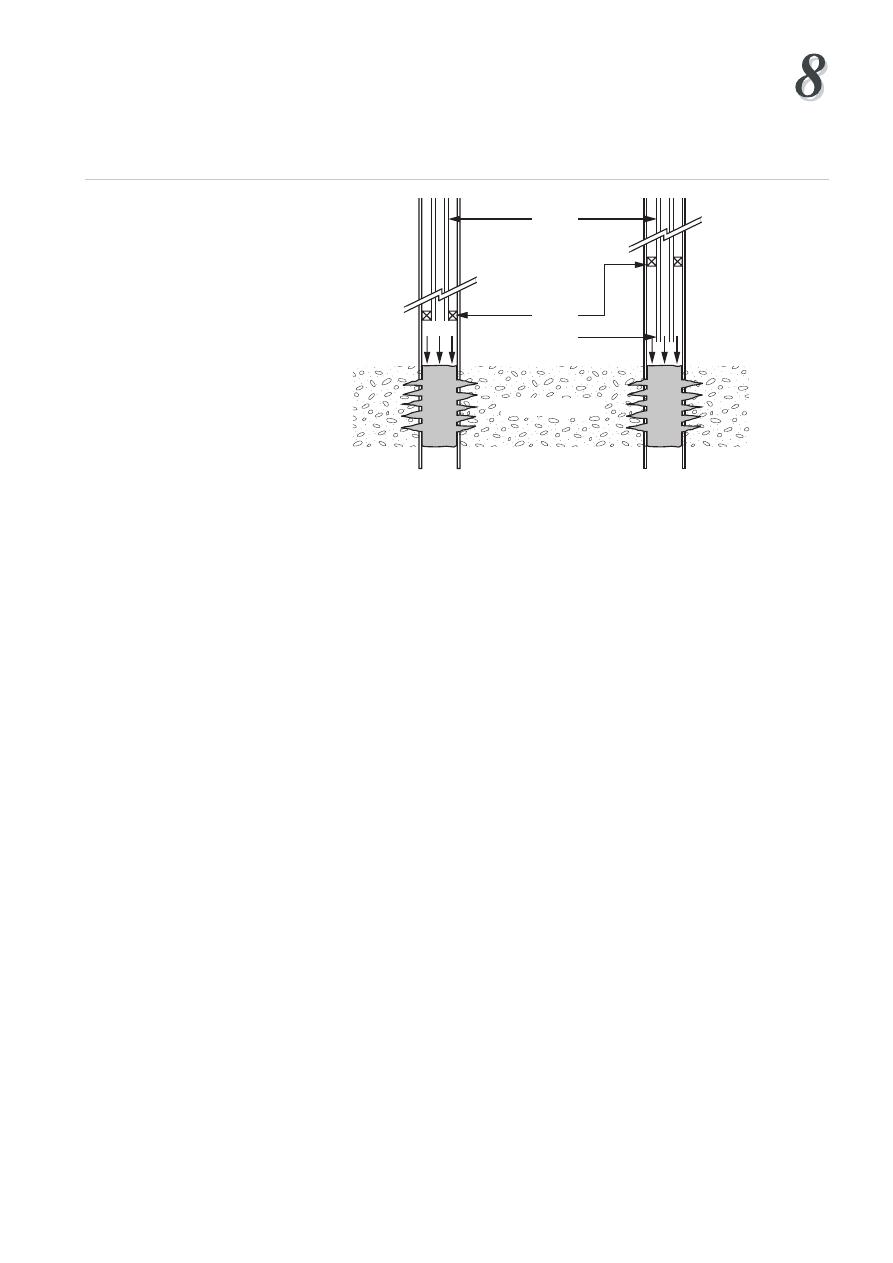

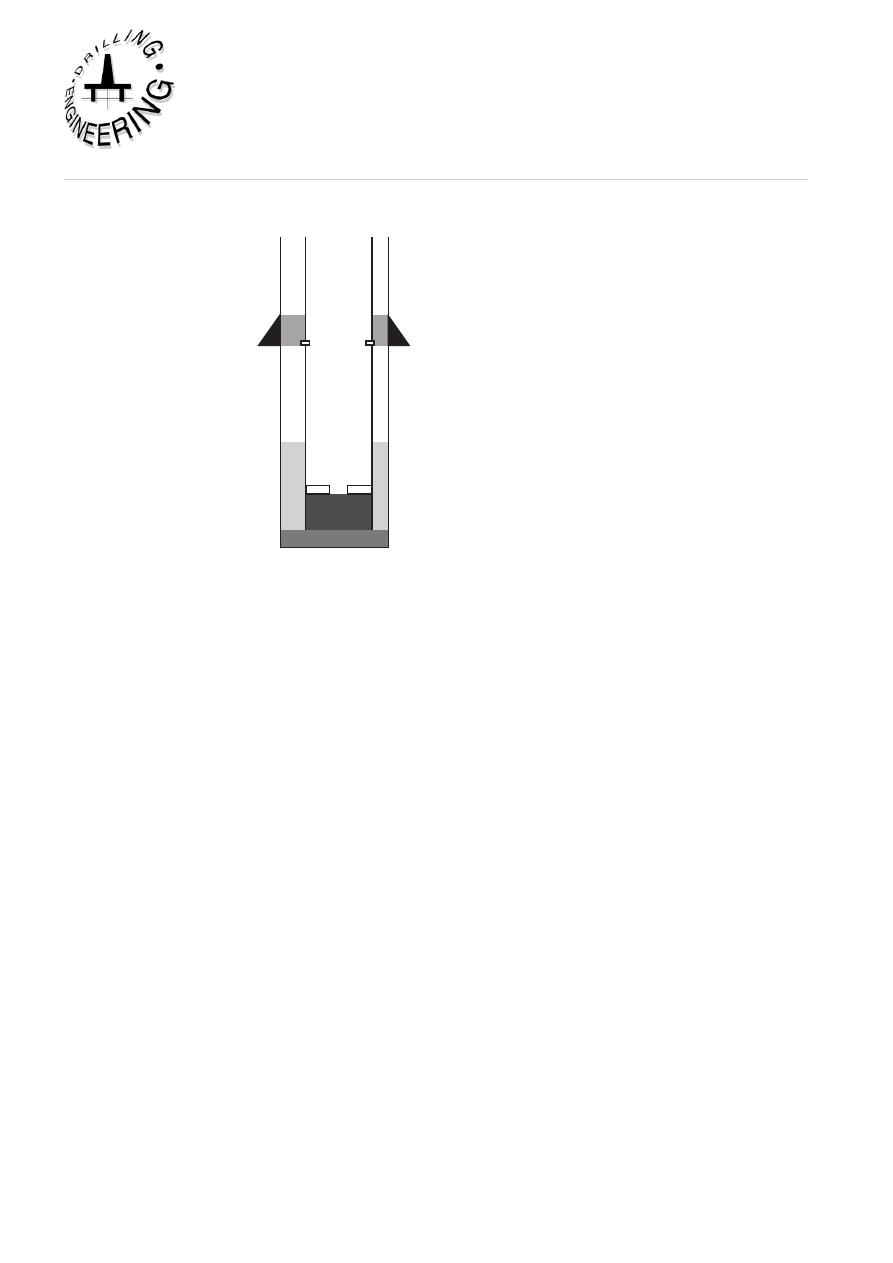

4.4 Multi - Stage Cementing Operation

When a long intermediate string of casing is to be cemented it is sometimes necessary

to split the cement sheath in the annulus into two, with one sheath extending from the

casing shoe to some point above potentially troublesome formations at the bottom

of the hole, and the second sheath covering shallower troublesome formations. The

placement of these cement sheaths is known as a multi-stage cementing operation

(Figure 13). The reasons for using a multi-stage operation are to reduce:

• Long pumping times

• High pump pressures

• Excessive hydrostatic pressure on weak formations due to the relatively high

density of cement slurries.

Cementing

Institute of Petroleum Engineering, Heriot-Watt University

Figure 13

Multi-Stage Cementing Operation

The procedure for conducting a multi-stage operation is as follows:

First stage

The procedure for the first stage of the operation is similar to that described in

Section 4.3 above, except that a wiper plug is not used and only a liquid spacer is

pumped ahead of the cement slurry. The conventional shut-off plug is replaced by

a plug with flexible blades. This type of shut-off plug is used because

it has to pass through the stage cementing collar which will be discussed below. It

is worth noting that a smaller volume of cement slurry is used, since only the lower

part of the annulus is to be cemented. The height of this cemented part of the

annulus will depend on the fracture gradient of the formations which are exposed in

the annulus (a height of 3000' - 4000' above the shoe is common).

Second stage

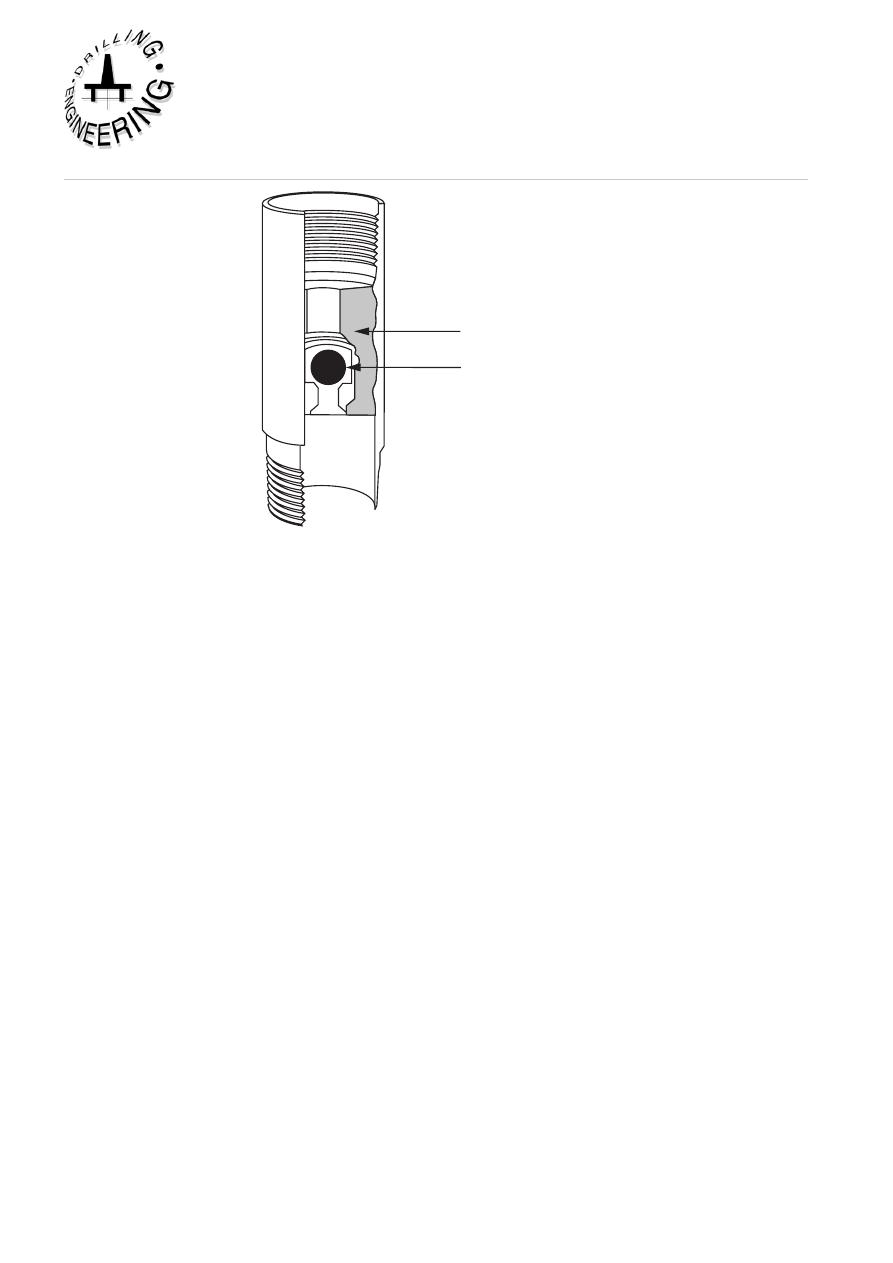

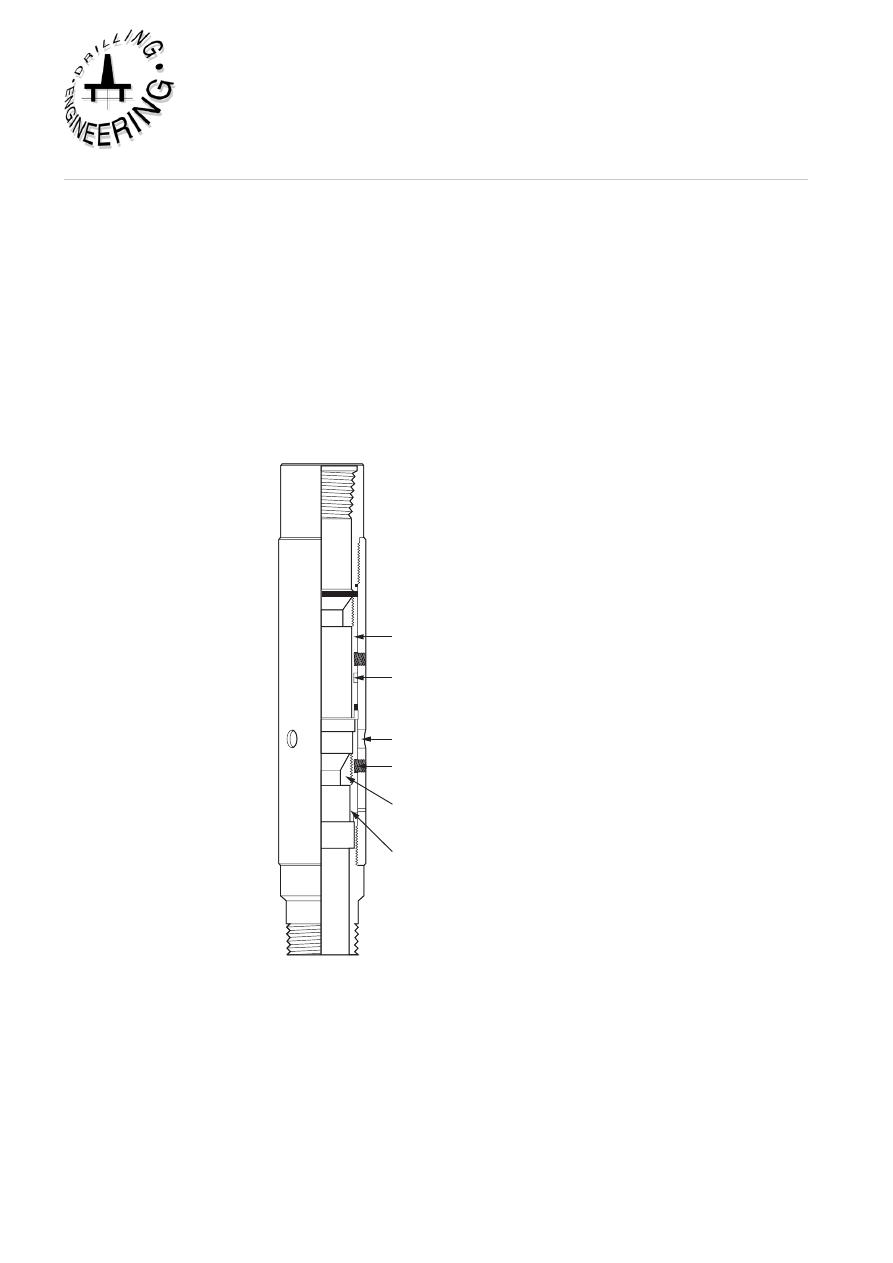

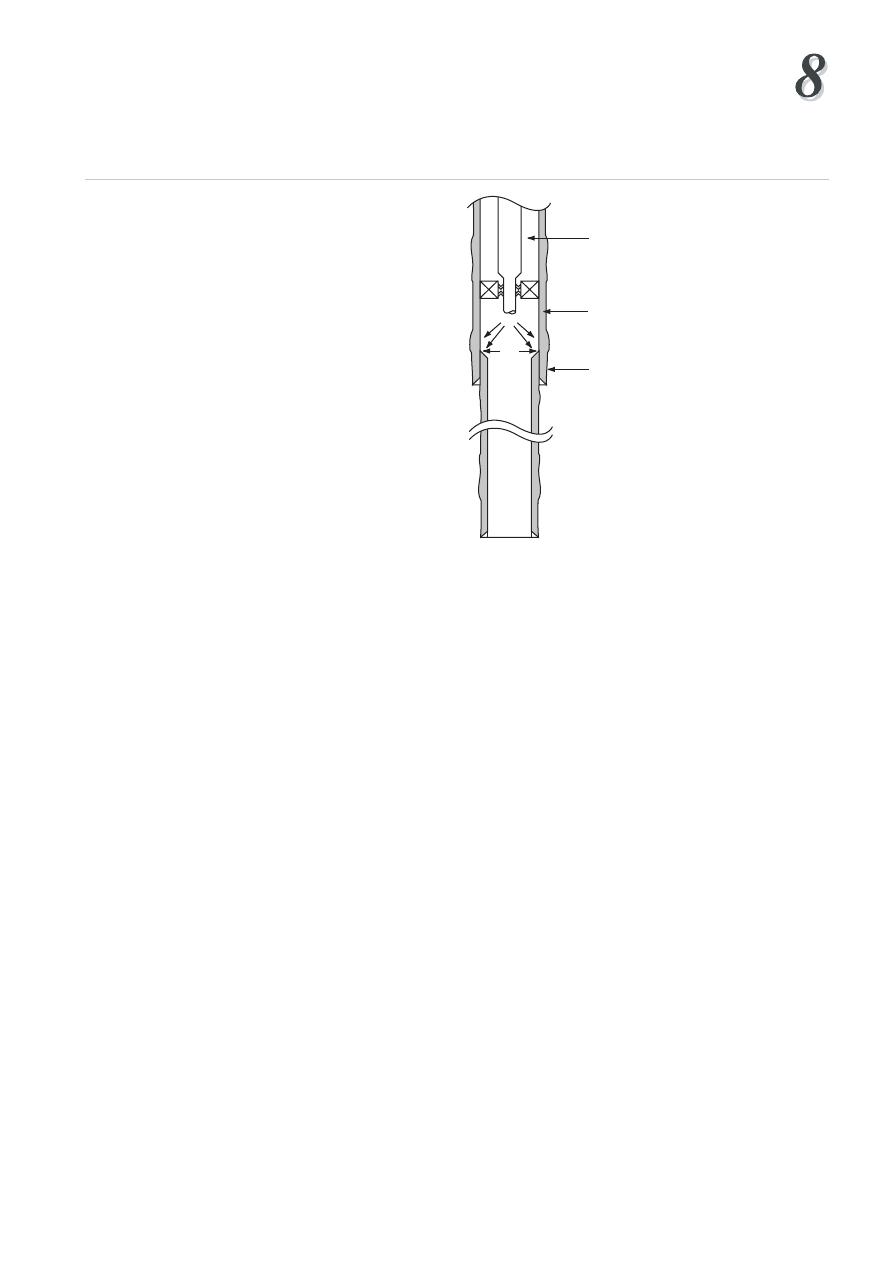

The second stage of the operation involves the use of a special tool known as a

stage collar (Figure 14), which is made up into the casing string at a pre-determined

position. The position often corresponds to the depth of the previous casing shoe.

The ports in the stage collar are initially sealed off by the inner sleeve. This sleeve

is held in place by retaining pins. After the first stage is complete a special dart is

released form surface which lands in the inner sleeve of the stage collar. When a

pressure of 1000 - 1500 psi is applied to the casing above the dart, and therefore

to the dart, the retaining pins on the inner sleeve are sheared and the sleeve moves

down, uncovering the ports in the outer mandrel. Circulation is established through

the stage collar before the second stage slurry is pumped.

The normal procedure for the second stage of a two stage operation is as follows:

1 Drop opening dart

2 Pressure up to shear pins

3 Circulate though stage collar whilst the first stage cement is setting

4 Pump spacer

5 Pump second stage slurry

6 Release closing plug

7 Displace plug and cement with mud

8 Pressure up on plug to close ports in stage collar and pressure test the casing.

Closing

sleeve

Lock

ring

Shear

pin

Drillable

opening

seat

Opening

sleeve

Ports

Figure 14

Multi-Stage Cementing Collar

To prevent cement falling down the annulus a cement basket or packer may be run

on the casing below the stage collar. If necessary, more than one stage collar can

be run on the casing so that various sections of the annulus can be cemented. One

disadvantage of stage cementing is that the casing cannot be moved after the first

stage cement has set in the lower part of the annulus. This increases the risk of

channelling and a poor cement bond.

Cementing

Institute of Petroleum Engineering, Heriot-Watt University

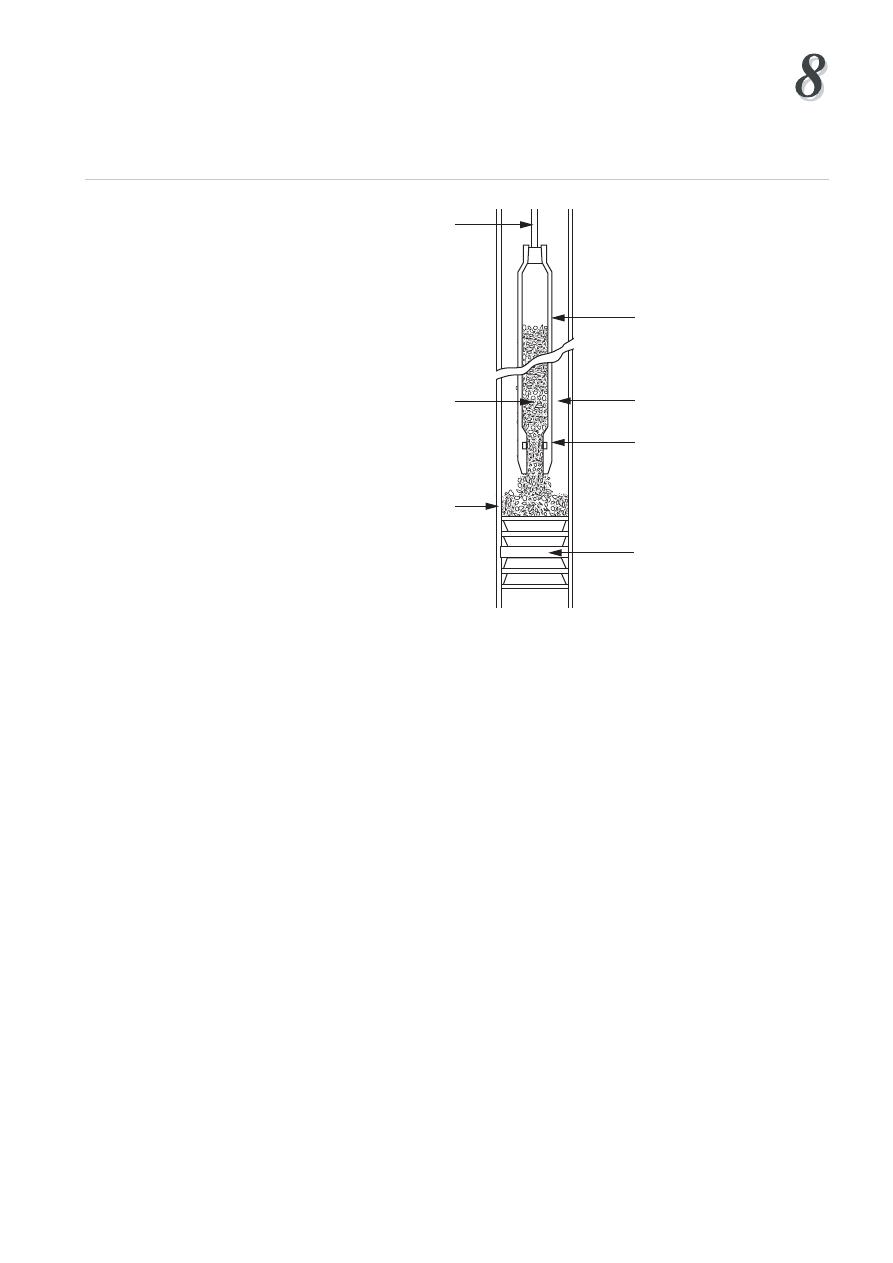

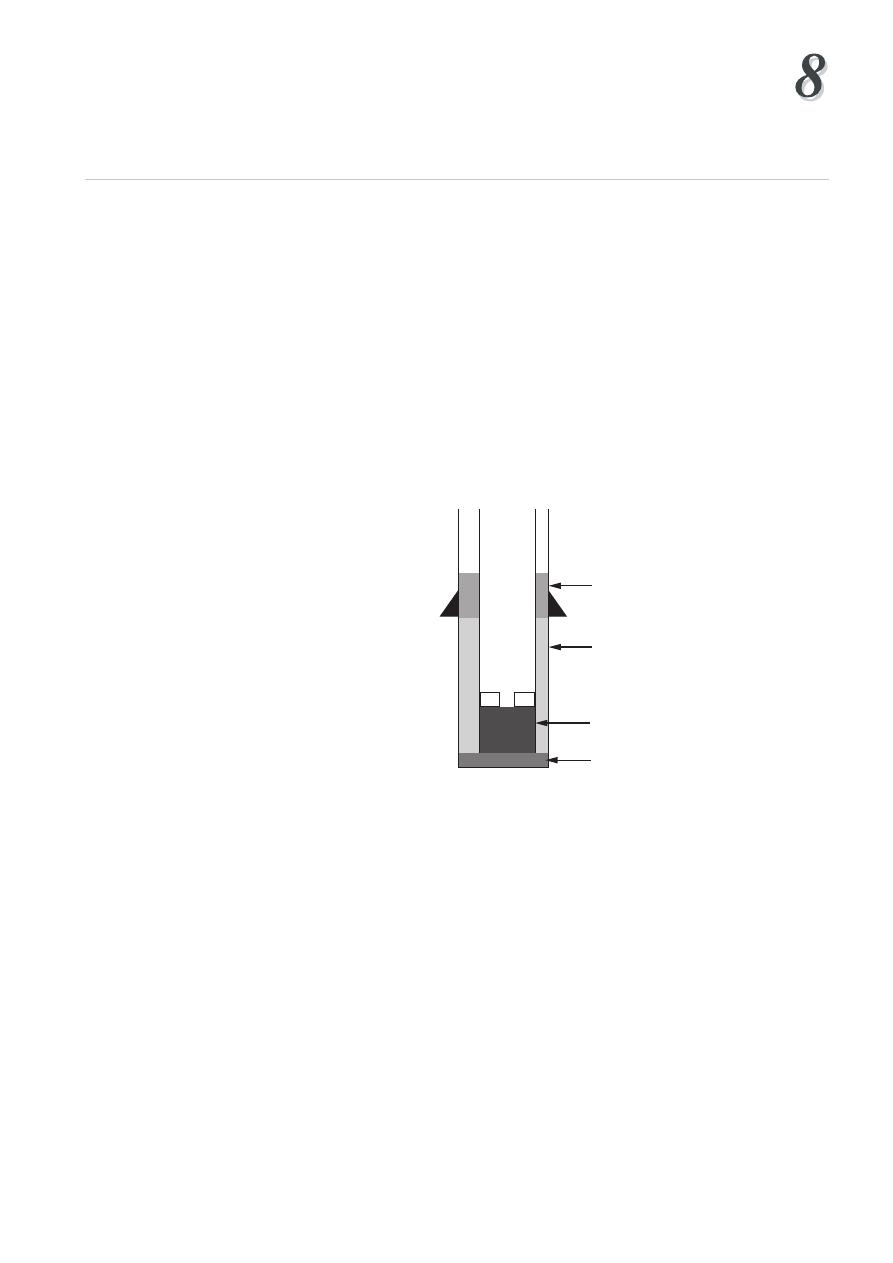

4.5 Inner string cementing

For large diameter casing, such as conductors and surface casing, conventional

cementing techniques result in:

• The potential for cement contamination during pumping and displacement

• The use of large cement plugs which can get stuck in the casing

• Large displacement volumes

• Long pumping times

• Large volume of cement left inside the casing between float collar and shoe.

An alternative technique, known as a stinger cement job, is to cement the casing

through a tubing or drillpipe string, known as a cement stinger, rather than through

the casing itself.

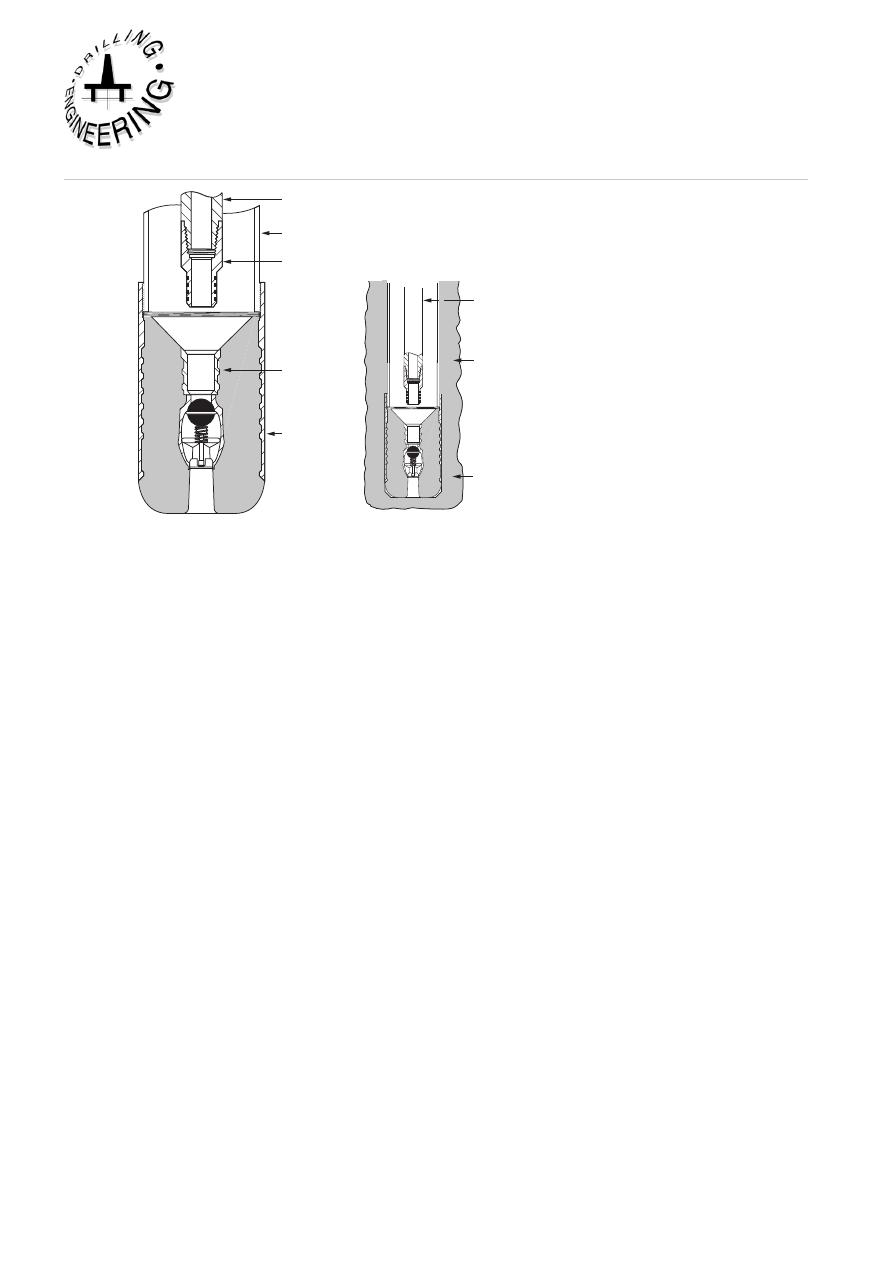

In the case of a stinger cement job the casing is run as before, but with a special

float shoe (Figure 15) rather than the conventional shoe and float collar. A special

sealing adapter, which can seal in the seal bore of the seal float shoe, is attached to

the cement stinger. Once the casing has been run, the cementing string (generally

tubing or drillpipe), with the seal adapter attached, is run and stabbed into the float

shoe. Drilling mud is then circulated around the system to ensure that the stinger

and annulus are clear of any debris. The cement slurry is then pumped with liquid

spacers ahead and behind the cement slurry. No plugs are used in this type of

cementing operation since the diameter of the stinger is generally so small that

contamination of the cement is unlikely if a large enough liquid spacer is used.

The cement slurry is generally under-displaced so that when the seal adapter on

the stinger is pulled from the shoe the excess cement falls down on top of the shoe.

This can be subsequently drilled out when the next hole section is being drilled.

Under-displacement however ensures that the cement slurry is not displaced up

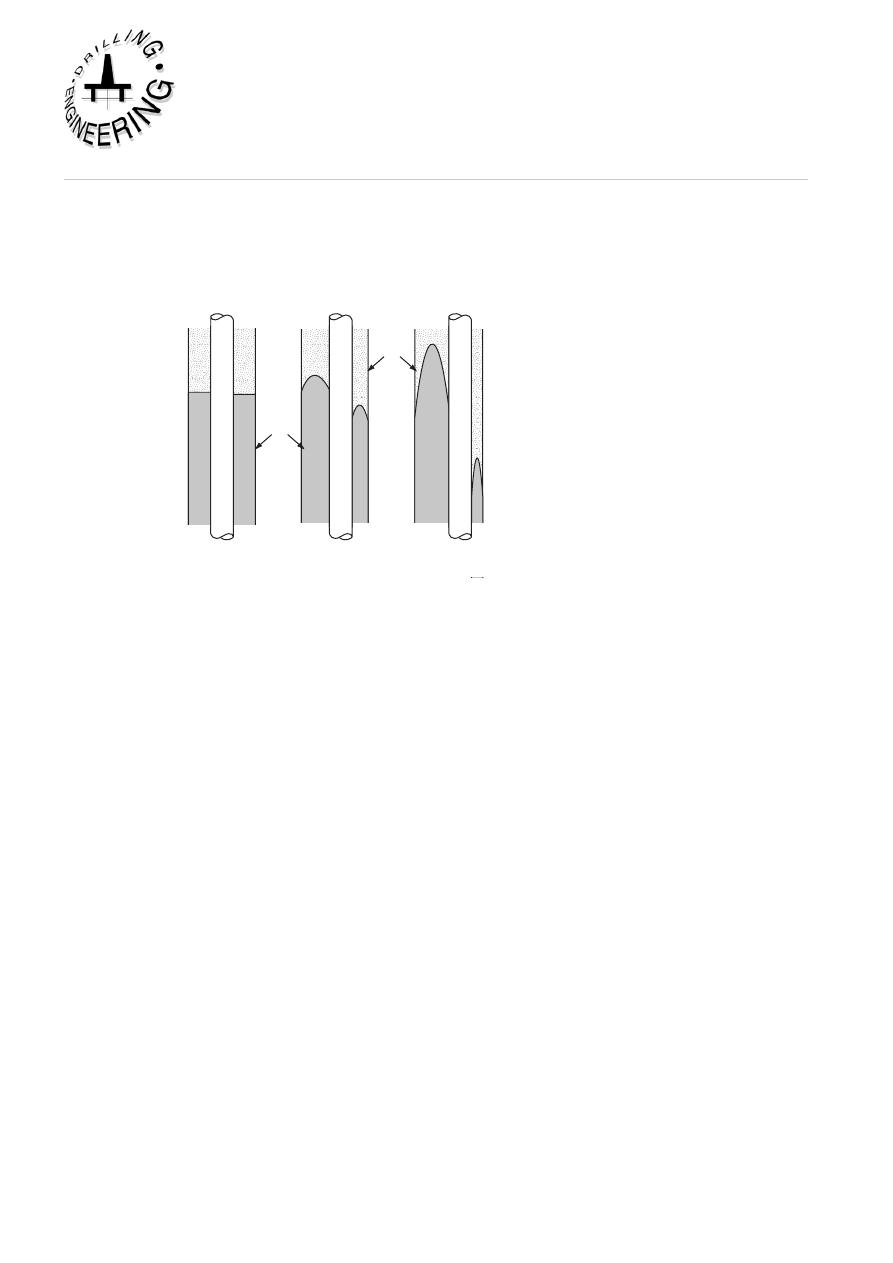

above the casing shoe, leaving spacer and drilling mud across the shoe. After the

cement has been displaced, and the float has been checked for backflow, the cement

stinger can be retrieved. This method is suitable for casing diameters of 13 3/8" and

larger. The main disadvantage of this method is that for long casing strings rig time

is lost in running and retrieving the inner string.

Tool joint

adapter

Sealing

adapter

Sealing

sleeve

Super seal

float shoe

Special

float shoe

Casing

Cement

Drillpipe

or tubing

Figure 15

Stinger Cementing Operation

4.6 Liner cementing

Liners are run on drillpipe and therefore the conventional cementing techniques

cannot be used for cementing a liner. Special equipment must be used for cementing

these liners.

As with a full string of casing the liner has a float collar and shoe installed. In

addition there is a landing collar, positioned about two joints above the float collar

(Figure 16). A wiper plug is held on the end of the tailpipe of the running string by

shear pins.

Cementing

Institute of Petroleum Engineering, Heriot-Watt University

Float shoe

Cementing

head

Setting tool

Hanger slips

Centralizers

Float collar

Landing collar

Wiper plug

Slick joint

Packoff

Tie- back

sleeve

Cementing

manifold

Figure 16

Liner Cementing Equipment

The liner is run on drillpipe and the hanger is set at the correct point inside the

previous casing string. Mud is circulated to ensure that the liner and the annulus is

free from debris, and to condition the mud. Before the cementing operation begins

the liner setting tool is backed off to ensure that it can be recovered at the end of the

cement job. The cementing procedure is as follows:

1 Pump spacer ahead of cement slurry

2 Pump slurry

3 Release pump down plug

4 Displace cement down the running string and out of the liner into the annulus

5 Continue pumping until the pump down plug lands on the wiper plug.

6 Apply pressure to the pump down plug and shear out the pins on the wiper

plug. This releases the wiper plug

7 Both plugs move down the liner until they latch onto landing collar

8 Bump the plugs with 1000 psi pressure

9 Bleed off pressure and check for back flow

Since there is no bottom plug in front of the slurry the wiper plug cleans off debris

and mud from the inside of the liner. This material will contaminate the cement

immediately ahead of the wiper plug. The spacing between the landing collar and

the shoe should be adequate to accommodate this contaminated cement, and thus

prevent it from reaching the annulus where it would create a poor cement job

around the shoe.

To promote a good cement job, cement in excess of that required to fill the annulus

between the liner and the borehole is used. This excess cement will pass up around

the liner top and settle on top of the liner running assembly. Once the cement is in

place the liner setting tool is quickly picked up out of the liner. With the tail pipe

above the liner top the excess cement can be reverse circulated out. The setting tool

can then be retrieved.

In practice it is very difficult to obtain a good cement job on a liner. The main

reasons for this are:

(a) Minimal annular clearances

A 7" OD liner run in an 8 1/2" hole gives a clearance of only 3/4" (assuming the

liner is perfectly centred). This small clearance means that:

• It is difficult to run the liner (surge pressure)

• High pressure drops occur during circulation (lost circulation problems)

• It is difficult to centralise the liner

• Cement placement is poor (channeling)

(b) Mud contamination

When the cement comes in contact with mud or mud cake it may develop high

viscosity. The increased pump pressure required to move this contaminated cement

up the annulus may cause formation breakdown. Fluid loss additives must be used

to prevent dehydration of the cement which may cause bridging in the annulus.

(c) Lack of pipe movement

Due to risk of sticking the setting tool, most operators want to be free of the liner

before cementing begins. By disconnecting the setting tool the liner cannot be moved

during the cement job. This lack of movement reduces the efficiency of cement

placement. Due to these problems it is often necessary to carry out a remedial

squeeze job at the top of the liner (Figure17). It is becoming more common these

days to remain latched on top of the liner and rotate the liner whilst the cement is

being displaced into position. A special piece of liner running equipment, known

as a rotating liner assembly, is used for this purpose.

Cementing

Institute of Petroleum Engineering, Heriot-Watt University

Tubing

Retainer or

retrievable packer

Top of liner

Cement

Figure 17

Remedial squeeze job on a liner

4.7 Recommendations for a good cement job

The main cause for poor isolation after a cement job is the presence of mud channels

in the cement sheath in the annulus. These channels of gelled mud exist because

the mud in the annulus has not been displaced by the cement slurry. This can occur

for many reasons. The main reason for this is poor centralisation of the casing in

the borehole, during the cementing operation. When mud is being displaced from

the annulus the cement will follow the least path of resistance. If the pipe is not

properly centralised the highest resistance to flow occurs where the clearance is

least. This is where mud channels are most likely to occur (Figure 18).

In addition, field tests have shown that for a good cement bond to develop the

formation should be in contact with the cement slurry for a certain time period

while the cement is being displaced. The recommended contact time (pump past

time) is about 10 minutes for most cement jobs. To improve mud displacement and

obtain a good cement bond the following practices are recommended:

• Use centralisers, especially at critical points in the casing string

• Move the casing during the cement job. In general, rotation is preferred to

reciprocation, since the latter may cause surging against the formation. A specially

designed swivel may be installed between the cementing head and the casing to

allow rotation. (Centralisers remain static and allow the casing to rotate within

them.)

• Before doing the cement job, condition the mud (low PV, low YP) to ensure

good flow properties, so that it can be easily displaced.

0

• Displace the spacer is in turbulent flow. This may not be practicable in large

diameter casing where the high pump rates and pressures may cause erosion or

formation breakdown.

• Use spacers to prevent mud contamination in the annulus.

Cement

100% Standoff

Mud

75% Standoff

50% Standoff

Figure 18

Effect of centralisation on channeling

5. SQuEEZE CEMENTiNg

Squeeze cementing is the process by which hydraulic pressure is used to force

cement slurry through holes in the casing and into the annulus and/or the formation.

Squeeze cement jobs are often used to carry out remedial operations during a

workover on the well (Figure 3). The main applications of squeeze cementing are:

• To seal off gas or water producing zones, and thus maximise oil production

from the completion interval

• To repair casing failures by squeezing cement through leaking joints or

corrosion hole

• To seal off lost circulation zones

• To carry out remedial work on a poor primary cement job (e.g. to fill up the

annulus)

• To prevent vertical reservoir fluid migration into producing zones (block

squeeze)

• To prevent fluids escaping from abandoned zones.

Cementing

1

Institute of Petroleum Engineering, Heriot-Watt University

During squeeze cementing the pores in the rock rarely allow whole cement to enter

the formation since a permeability of about 500 darcies would be required for this

to happen. There are two processes by which cement can be squeezed:

• High pressure squeeze - This technique requires that the formation be fractured.

which then allows the cement slurry to be pumped into the fractured zone.

• Low pressure squeeze - During this technique the fracture gradient of the formation

is not exceeded. Cement slurry is placed against the formation, and when pressure

is applied the fluid content (filtrate) of the cement is squeezed into the rock, while

the solid cement material (filter cake) builds up on the face of the formation.

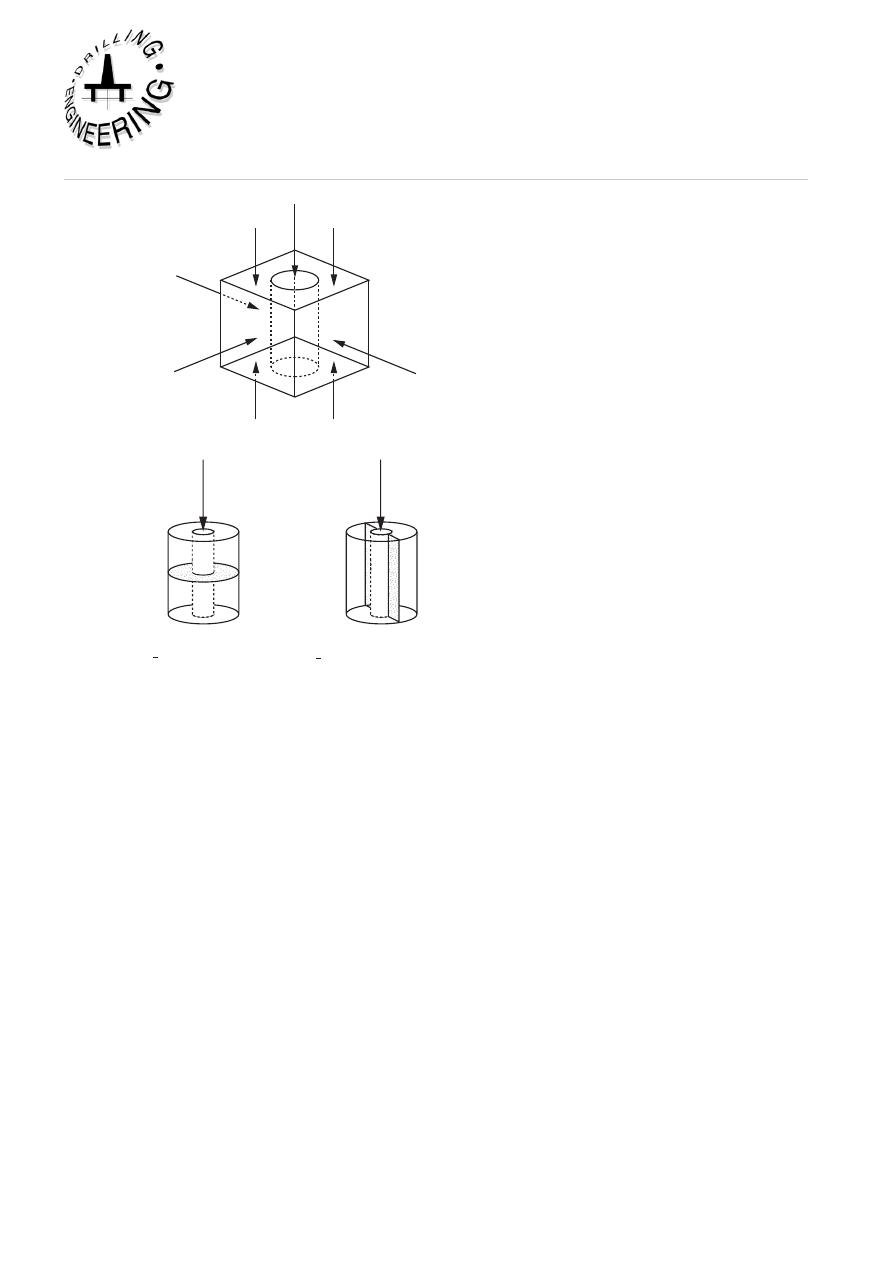

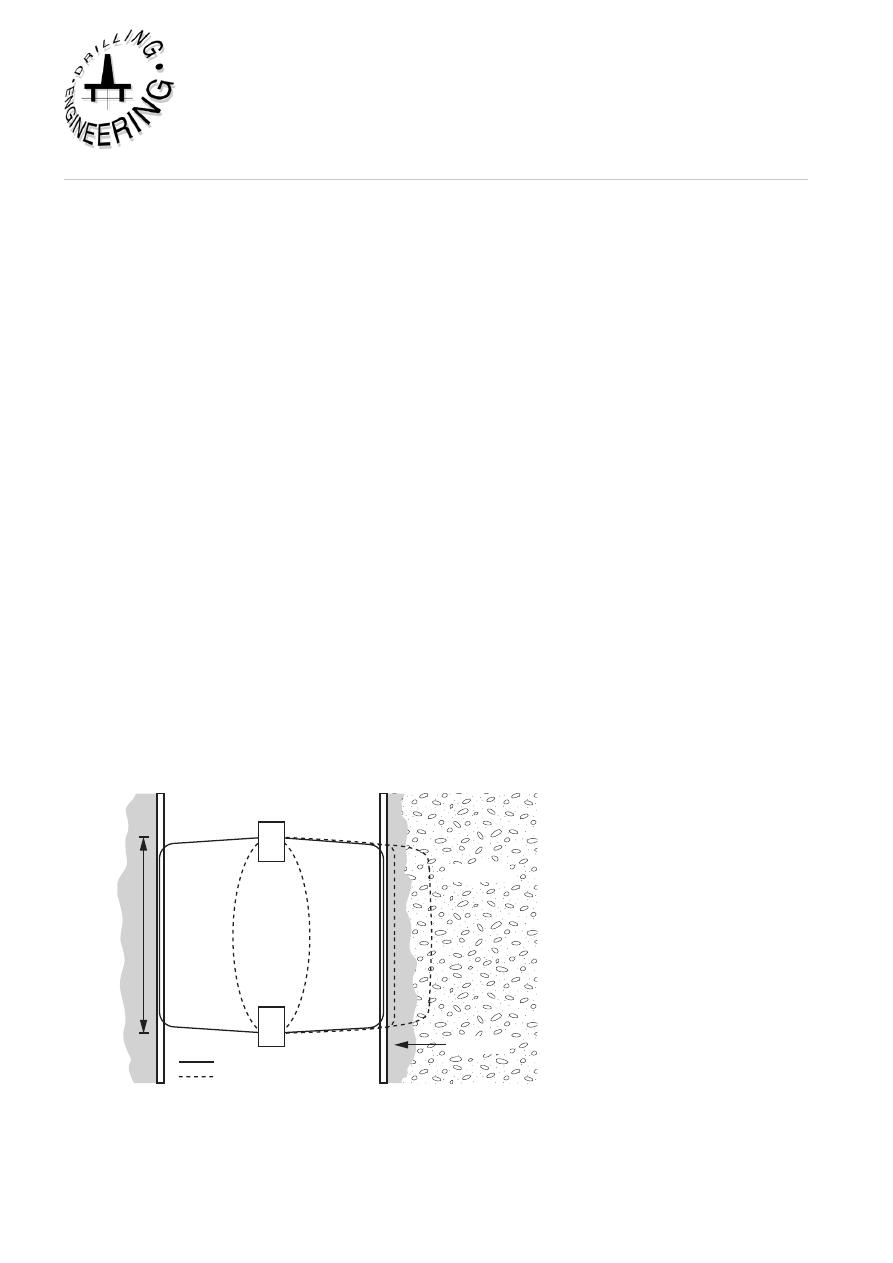

5.1 High Pressure Squeeze

In a high pressure squeeze the formation is initially fractured (broken down) by

a solids free breakdown fluid. A solids free fluid is used because a solids laiden

fluid such as drilling mud will build up a filter cake and prevent injection into the

formation. Solids free fluids such as water or brine are recommended. The direction

of the fracture depends on the rock stresses present in the formation. The fracture

will occur along a plane perpendicular to the direction of the least compressive

stress (Figure 19). In general, the vertical stress, due to the overburden, will be

greater than the horizontal stresses. A vertical fracture is therefore more likely.

In practice the fracture direction is difficult to predict since it may follow natural

fractures in the formation. Since squeeze cementing is often used to isolate various

horizontal zones a vertical fracture is of little use (vertical fluid movement is not

prevented).

Effect of well depth and vertical-horizontal formation stresses on type of hydraulic fracture

induced by injected fluid. Horizontal fracture pressure is less than overburden pressure,

this is usually the case at depths greater than 3,000 feet.

Wellbore fracture pressure PF

PF

PF

Vertical stress

σv

Horizont

al stress

σh1

Induced horizontal fracture

Induced vertical fracture

PF>σv ; σv<σH1 or σH2

PF>σH1or σH2 ; σH1or σH2< σv

Figure 19

Horizontal and vertical fracturing

After the formation is broken down a slurry of cement is spotted adjacent to the

formation, and then pumped into the zone at a slow rate. The injection pressure

should gradually build up as the cement fills up the fractured zone. After the cement

has been squeezed the pressure is released to check for back flow. The disadvantages

of this technique are:

• No control over the orientation of the fracture

• Large volumes of cement may be necessary to seal off the fracture

• Mud filled perforations may not be opened up by fracturing, so the cement

may not seal them off effectively.

5.2 Low Pressure Squeeze

It is generally accepted that a low pressure squeeze is a more efficient method of

sealing off unwanted perforated zones. In a low pressure squeeze the formation is

not fractured. Instead a cement slurry is gently squeezed against the formation. A

cement slurry consists of finely divided solids dispersed in a liquid. The solids are

too large to be displaced into the formation. As pressure is applied, the liquid phase

Cementing

Institute of Petroleum Engineering, Heriot-Watt University

is forced into the pores, leaving a deposit of solid material or filter cake behind. As

the filter cake of dehydrated cement begins to build up, the impermeable barrier

prevents further filtrate invasion. The filtrate must then be diverted to other parts of

the perforated interval. This technique therefore creates an impermeable seal across

the perforated zone. Fluid loss additives are important to perform this technique

successfully. Neat cement has a high fluid loss, resulting in rapid dehydration which

causes bridging before the other perforations are sealed off. Conversely a very low

fluid loss means a slow filter cake build up and long cement placement time. Key

factors which affect the build up of cement filter cake are:

• Fluid loss (generally 50 - 200 cc)

• Water to solids ratio (0.4 by weight)

• Formation characteristics (permeability, pore pressure)

• Squeeze pressure

Only a small volume of cement is required for a low pressure squeeze. Perforations

must be free from mud or other plugging material. If the well has been producing

for some time these perforations have to be washed out, sometimes with an acid

solution. The general procedure for a low pressure squeeze job is:

1 Water is pumped into the zone to establish whether the formation can be squeezed

(injectivity test). If water cannot be injected the squeeze job cannot be done without

fracturing the formation

2 Spot the cement slurry at the required depth

3 Apply moderate squeeze pressure

4 Stop pumping and check for bleed off

5 Continue pumping until bleed off ceases for about 30 mins

6 Stop displacement of cement and hold pressure

7 Reverse circulate out excess cement from casing

A properly designed slurry will leave only a small cement node inside the casing

after removing the excess cement. Throughout the procedure squeeze pressure

is kept below the fracture gradient. A running squeeze is where the cement is

pumped slowly and continuously until the final squeeze pressure is obtained. This

is often used for repairing a primary cement job. A hesitation squeeze is where

pumping is stopped at regular intervals to allow time for the slurry to dehydrate and

form a filter cake. Small volumes of cement (1/4 - 1/2 bbl) are pumped each time

separated by a delay of 10 - 15 mins. This technique is dangerous if the cement is

still in contact with the drillpipe or packer.

5.3 Equipment Used for Squeeze Cementing

The high pressure and low pressure squeeze operations can be conducted with or

without packers.

(a) Bradenhead squeeze

This technique involves pumping cement through drill pipe without the use of a

packer (Figure 20). The cement is spotted at the required depth. The BOPs and the

annulus are closed in and displacing fluid is pumped down, forcing the cement into

the perforations, since it cannot move up the annulus. This is the simplest method

of placing and squeezing cement, but has certain disadvantages:

• It is difficult to place the cement accurately against the target zone

• It cannot be used for squeezing off one set of perforations if other

perforations are to remain open

• Casing is pressured up, and so squeeze pressure is limited by burst resistance

A Bradenhead squeeze is only generally used for a low-pressure squeeze job.

Spot cement Apply squeeze Reverse circulate

pressure

Schematic of Bradenhead squeeze technique normally used on low pressure formations.

Cement is circulated into place down drill pipe (left), then the wellhead, or BOP, is closed

(centre) and squeeze pressure is applied. Reverse circulating through perforations (right)

removes excess cement, or the plug can be drilled out.

Figure 20

Bradenhead technique

(b) Squeeze using a packer

The use of a packer makes it possible to place the cement more accurately, and apply

higher squeeze pressures. The packer seals off the annulus, but allows communication

between drill pipe and the wellbore beneath the packer. (Figure 21)

Cementing

Institute of Petroleum Engineering, Heriot-Watt University

Tubing

Tailpipe

Perforated Zone

Packer

Figure 21

Squeeze cementing using a packer with or without a tailpipe

Two types of packer may be used in this type of operation:

(i) Drillable packer (cement retainer)

This type of packer contains a back pressure valve which will prevent the cement

flowing back after the squeeze. These are mainly used for remedial work on primary

cement jobs, or to close off water producing zones. The packer is run on drill pipe

or wireline and set just above or between sets of perforations. When the cement

has been squeezed successfully the drill pipe can be removed, closing the back

pressure valve. The advantages of these packers are:

• Good depth control

• Back pressure valve prevents cement back flowing

• Drill pipe recovered without disturbing cement

The major disadvantage is that they can only be used once then drilled out.

(ii) Retrievable packer (cement retainer)

These can be set and released many times on one trip. This makes them suitable for

repairing a series of casing leaks or selectively squeezing off sets of perforations.

By-pass ports in the packer allow annular communication, but these ports are closed

during the squeeze job. When the packer is released there may be some backflow,

and the cement filter cake may be disturbed. If this happens the packer should be

re-set and the squeeze pressure applied until the cement sets.

The basic procedure for squeezing with a retrieveable packer is:

1. run the packer on drillpipe and set it at required depth with by-pass open

2. pump the cement slurry (keep back pressure on annulus to prevent cement falling

The packer setting depth should be considered carefully. If positioned too high

above the perforations the slurry will be contaminated by the wellbore fluids and

large volumes of fluid from below the packer will be pumped into the formation

ahead of the cement. If the packer is set too low it may become stuck in the cement.

Generally the packer is set 30 - 50 ft above the perforations.

Sometimes a tail pipe is used below the packer to ensure that only cement is squeezed

into the perforations, and there is less chance of getting stuck (Figure 21). Bridge

plugs

are often set in the wellbore, to isolate zones which are not to be treated.

They seal off the entire wellbore, and hold pressure from above and below. Bridge

plugs can either be drillable or retrievable.

Condition mud

rotation pipe

Displace cement

and fluids

Spot balanced

plug

Pull pipe

slowly

Drill

pipe

Scratch

centralizer

Spacer

Spacer

and

preflush

Cement

Cement

plug

Preflush

Figure 22

Balanced Plug Cementation

5.4 Testing the Squeeze Job

After the cement has hardened it must be pressure tested. The tests should include

both positive and negative differential pressure. The following should be considered

when making a test:

• A positive pressure test can be performed by closing the BOPs and pressuring

up on the casing. (Do not exceed formation fracture gradient.)

• A negative pressure test (or inflow test) can be performed by reducing the

hydrostatic pressure inside the casing. This can be done using a DST tool or

displacing with the well to diesel. This test is more meaningful since mud filled

perforations may hold pressure from the casing, but may become unblocked

when pressure from the formation is applied.

Cementing

Institute of Petroleum Engineering, Heriot-Watt University

Wire line

Cement

Casing

Dump bailer

Dump release

Mud

Bridge plug

or obstuction

Figure 23

Dump Bailer Plug Cementation

6. CEMENT PLugS

At some stage during the life of a well a cement plug may have to be placed in

the wellbore. A cement plug is designed to fill a length of casing or open hole to

prevent vertical fluid movement. Cement plugs may be used for:

• Abandoning depleted zones

• Seal off lost circulation zones

• Providing a kick off point for directional drilling (eg side- tracking around

fish)

• Isolating a zone for formation testing

• Abandoning an entire well (government regulations usually insist on leaving

a series of cement plugs in the well prior to moving off location).

The major problem when setting cement plugs is avoiding mud contamination

during placement of the cement. Certain precautions should be taken to reduce

contamination.

• Select a section of clean hole which is in gauge, and calculate the volume required

(add on a certain amount of excess). The plug should be long enough to allow

for some contamination (500' plugs are common). The top of the plug should

be 250' above the productive zone

• Condition the mud prior to placing the plug

• Use a preflush fluid ahead of the cement

• Use densified cement slurry (ie less mixwater than normal)

After the cement has hardened the final position of the plug should be checked by

running in and tagging the cement. There are three commonly used techniques for

placing a cement plug:

(a) Balanced plug (Figure 22)

This method is aimed at achieving an equal level of cement in the drillpipe and

annulus. Preflush, cement slurry and spacer fluid are pumped down the drillpipe

and displaced with mud. The displacement continues until the level of cement

inside and outside the drillpipe is the same (hence balanced). If the levels are not

the same then a U-tube effect will take pace. The drillpipe can then be retrieved

leaving the plug in place.

(b) Dump bailer (Figure 23)

A dump bailer is an electrically operated device which is run on wireline. A

permanent bridge plug is set below the required plug back depth. A cement bailer

containing the slurry is then lowered down the well on wireline. When the bailer

reaches the bridge plug the slurry is released and sits on top of the bridge plug. The

advantages of this method are:

• High accuracy of depth control

• Reduced risk of contamination of the cement

the disadvantages are:

• Only a small volume of cement can be dumped at a time - several runs may be

necessary

• It is not suitable for deep wells, unless retarders used.

7. EVaLuaTiON OF CEMENT JOBS

A primary cement job can be considered a failure if the cement does not isolate

undesirable zones. This will occur if:

• The cement does not fill the annulus to the required height between the casing

and the borehole.

• The cement does not provide a good seal between the casing and borehole and

fluids leak through the cement sheath to surface.

• The cement does not provide a good seal at the casing shoe and a poor leak off

test is achieved

When any such failures occur some remedial work must be carried out. A number of

methods can be used to assess the effectiveness of the cement job. These include:

Cementing

Institute of Petroleum Engineering, Heriot-Watt University

90ºF

100ºF 110º

120ºF

700'

800'

900'

1000'

1100'

1200'

1300'

1400'

PROBABLE CEMENT

TOP

Figure 24

Estimating top of cement in annulus by running a temperature log

Radiation Intensity Increases

5800'

5900'

6000'

6100'

Cement top

Base Run

After Run

Figure 25

Estimating top of cement by running radioactivity log

0

detecting Top of Cement (TOC)

(a) Temperature surveys (Figure 24)

This involves running a thermometer inside the casing just after the cement job.

The thermometer responds to the heat generated by the cement hydration, and so

can be used to detect the top of the cement column in the annulus.

(b) Radioactive surveys (Figure 25)

Radioactive tracers can be added to the cement slurry before it is pumped (Carnolite

is commonly used). A logging tool is then run when the cement job is complete.

This tool detects the top of the cement in the annulus, by identifying where the

radioactivity decreases to the background natural radioactivity of the formation.

detecting Top of Cement (TOC) and the Measuring the Quality of

the Cement Bond

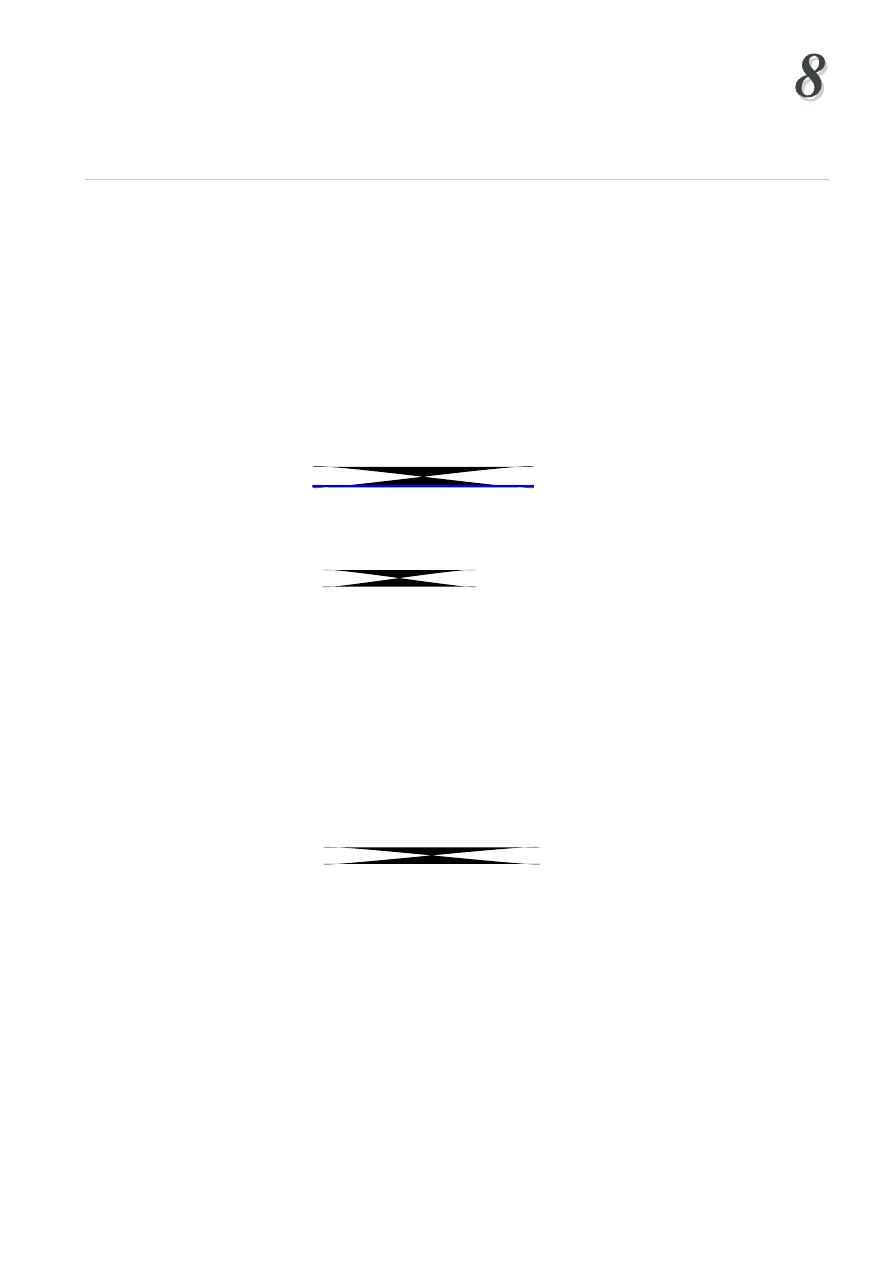

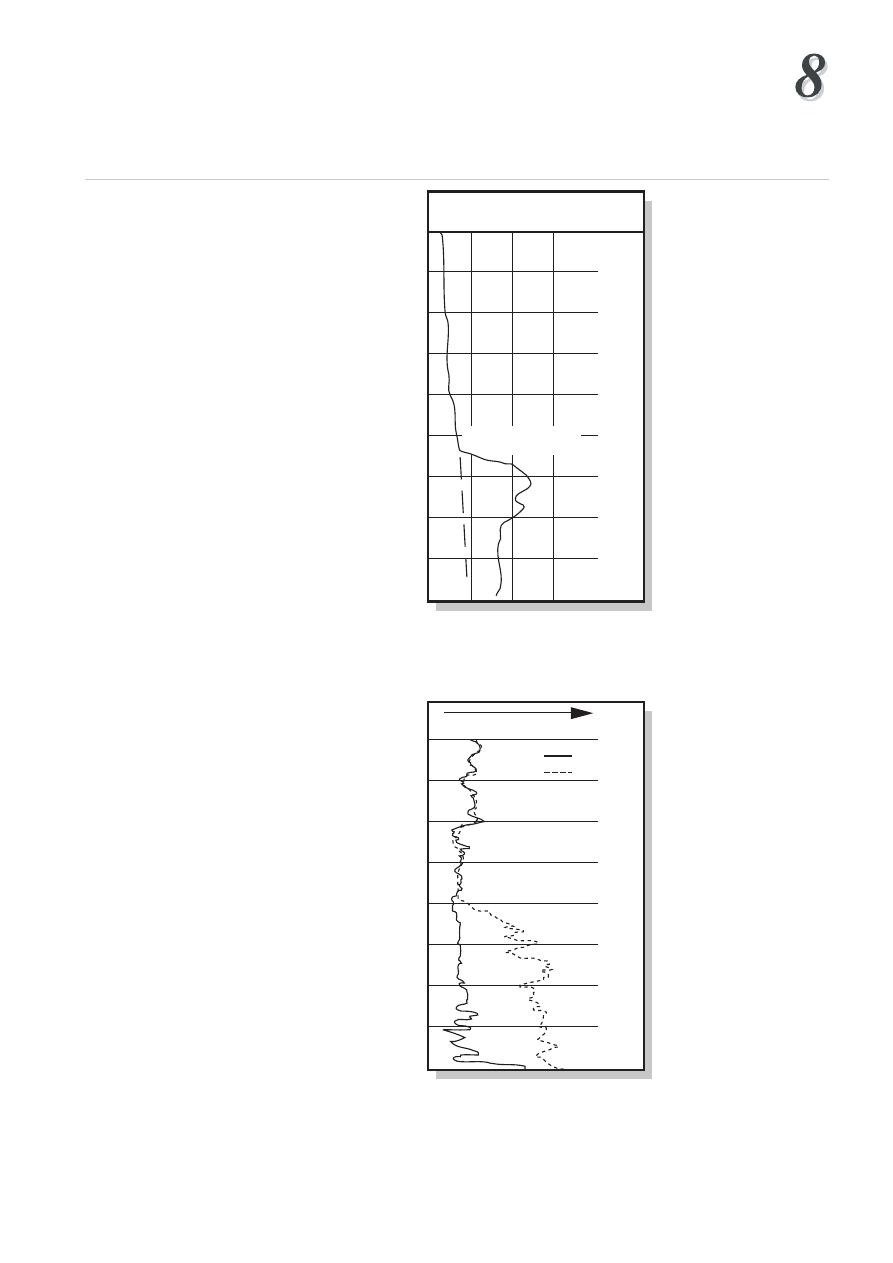

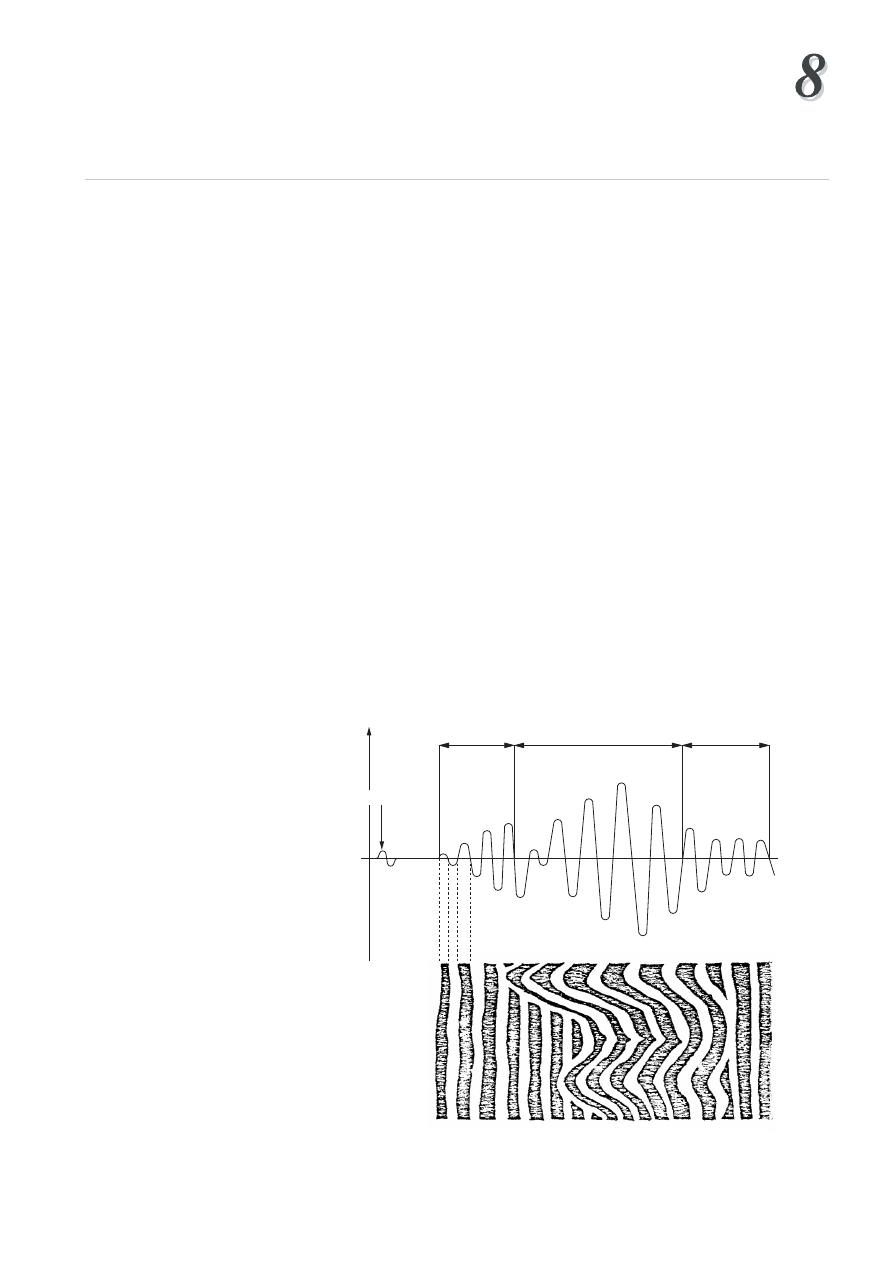

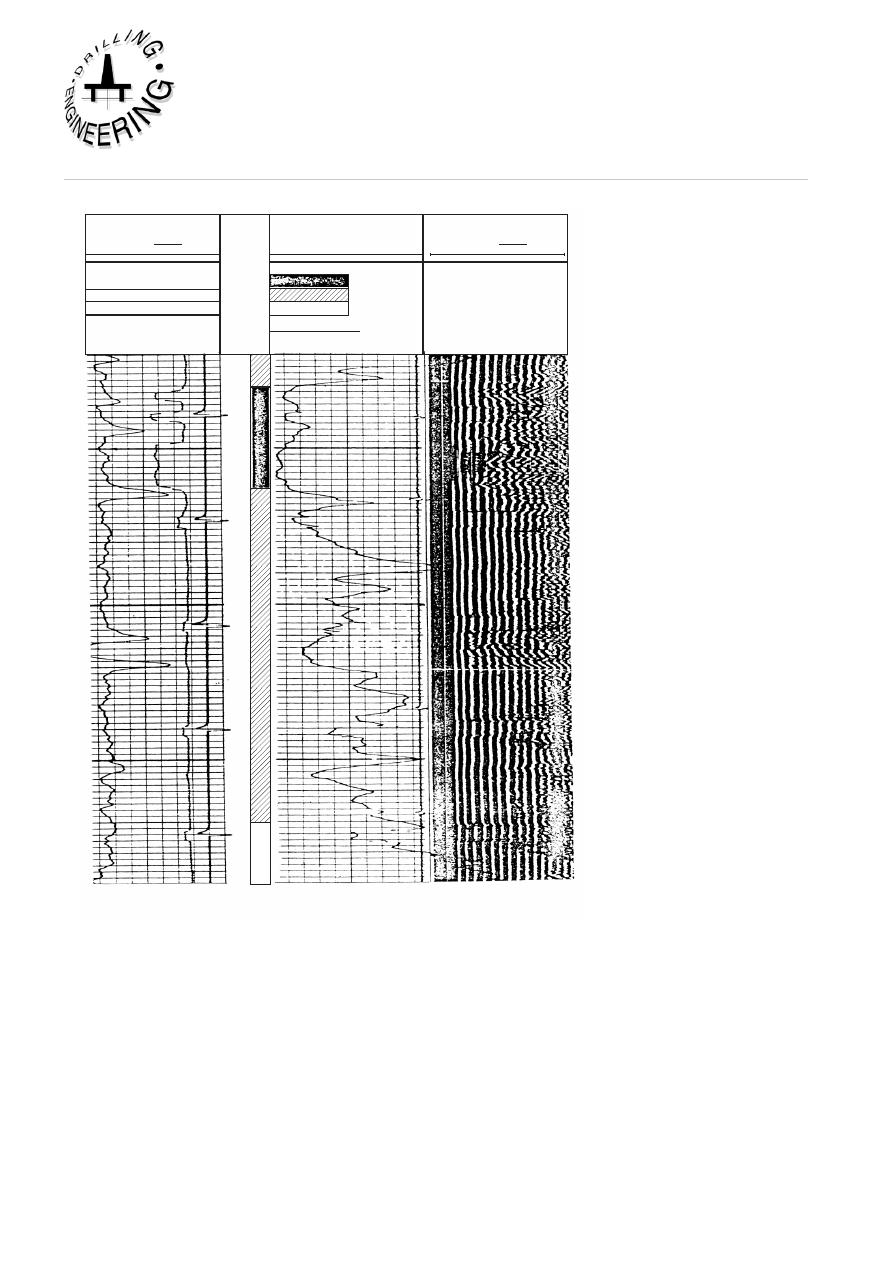

(a) Cement bond logs (CBL)

The cement bond logging tools have become the standard method of evaluating

cement jobs since they not only detect the top of cement, but also indicate how

good the cement bond is. The CBL tool is basically a sonic tool which is run on

wireline. The distance between transmitter and receiver is about 3 ft (Figure 26).

The logging tool must be centralised in the hole to give accurate results. Both the

time taken for the signal to reach the receiver, and the amplitude of the returning

signal, give an indication of the cement bond. Since the speed of sound is greater

in casing than in the formation or mud the first signals which are received at the

receiver are those which travelled through the casing (Figure 27). If the amplitude

(E

1

) is large (strong signal) this indicates that the pipe is free (poor bond). When

cement is firmly bonded to the casing and the formation the signal is attenuated,

and is characteristic of the formation behind the casing.

3 feet

Formation

Cement

Mud

T

R

Shortest path

Longest path

Figure 26

Schematic of CBL tool

Cementing

1

Institute of Petroleum Engineering, Heriot-Watt University

(b) the Variable Density Log (VDL)

The CBL log usually gives an amplitude curve and provides an indication of the

quality of the bond between the casing and cement. A VDL (variable density log),

provides the wavetrain of the received signal (Figure 28), and can indicate the

quality of the cement bond between the casing and cement, and the cement and

the formation. The signals which pass directly through the casing show up as

parallel, straight lines to the left of the VDL plot. A good bond between the casing

and cement and cement and formation is shown by wavy lines to the right of the

VDL plot. The wavy lines correspond to those signals which have passed into and

through the formation before passing back through the cement sheath and casing

to the receiver. If the bonding is poor the signals will not reach the formation and

parallel lines will be recorded all across the VDL plot.

The interpretation of CBL logs is still controversial. There is no standard API scale

to measure the effectiveness of the cement bond. There are many factors which can

lead to false interpretation:

• During the setting process the velocity and amplitude of the signals varies

significantly. It is recommended that the CBL log is not run until 24 - 36 hours

after the cement job to give realistic results.

• Cement composition affects signal transmission

• The thickness of the cement sheath will cause changes in the attenuation of the signal

• The CBL will react to the presence of a microannulus (a small gap between

casing and cement). The microannulus usually heals with time and is not a critical

factor. Some operators recommend running the CBL under pressure to eliminate

the microannulus effect

Transmitter

Amplitude

mV

Casing

arrivals

Formation arrivals Mud arrivals

E1

t (µ sec)

Figure 27

Signals picked up by receiver

TRANSIT TIME

GAMMA RAY

API UNITS

CASING BOND

BONDING CODE

VARIABLE DENSITY

MICROSECONDS

SPACING

3'

200

100

200

100

MICROSECONDS

SPACING

5'

1200

200

50

0

GOOD BOND

POOR BOND

GOOD

FAIR

POOR

Casing Collars

Corrected Depth

DEPTH

2200

2250

2300

Figure 28

Example of CBL/VDL