1

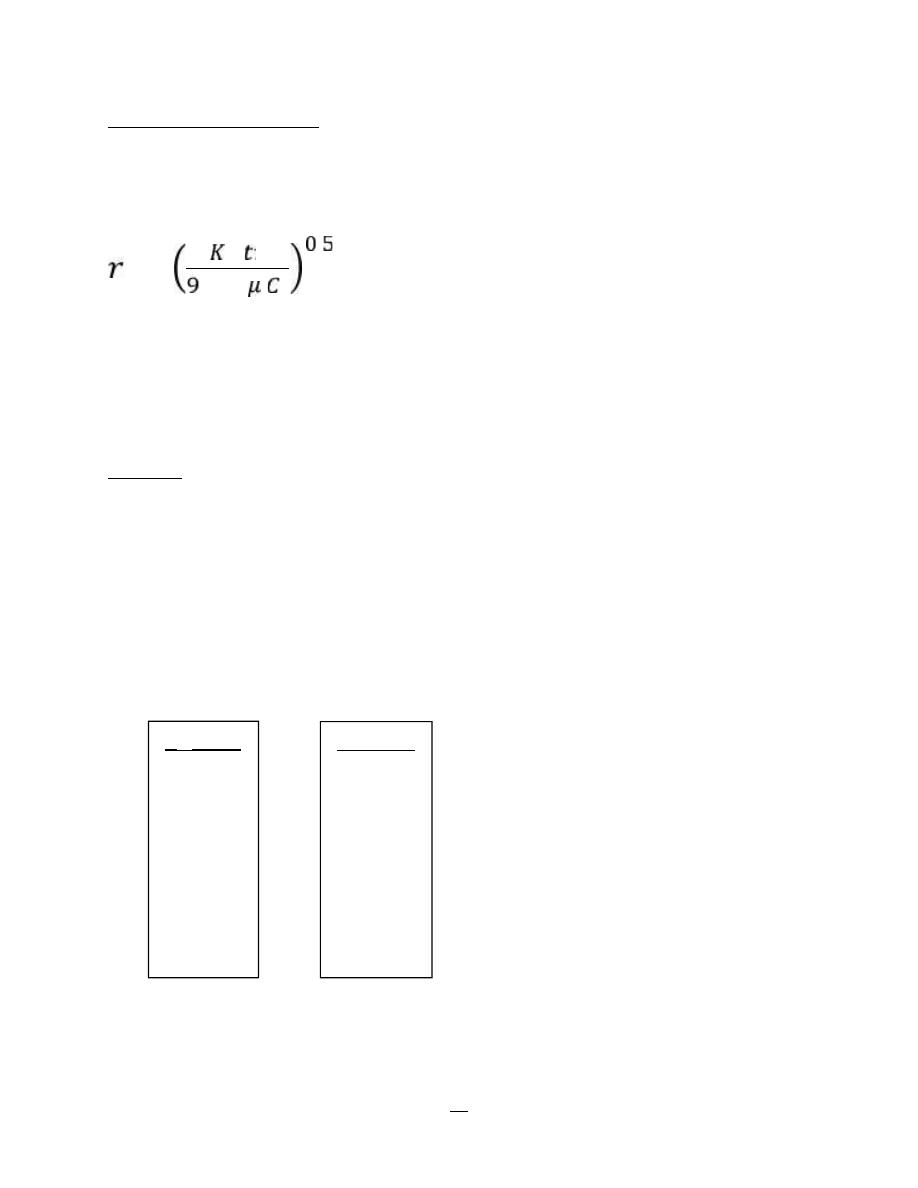

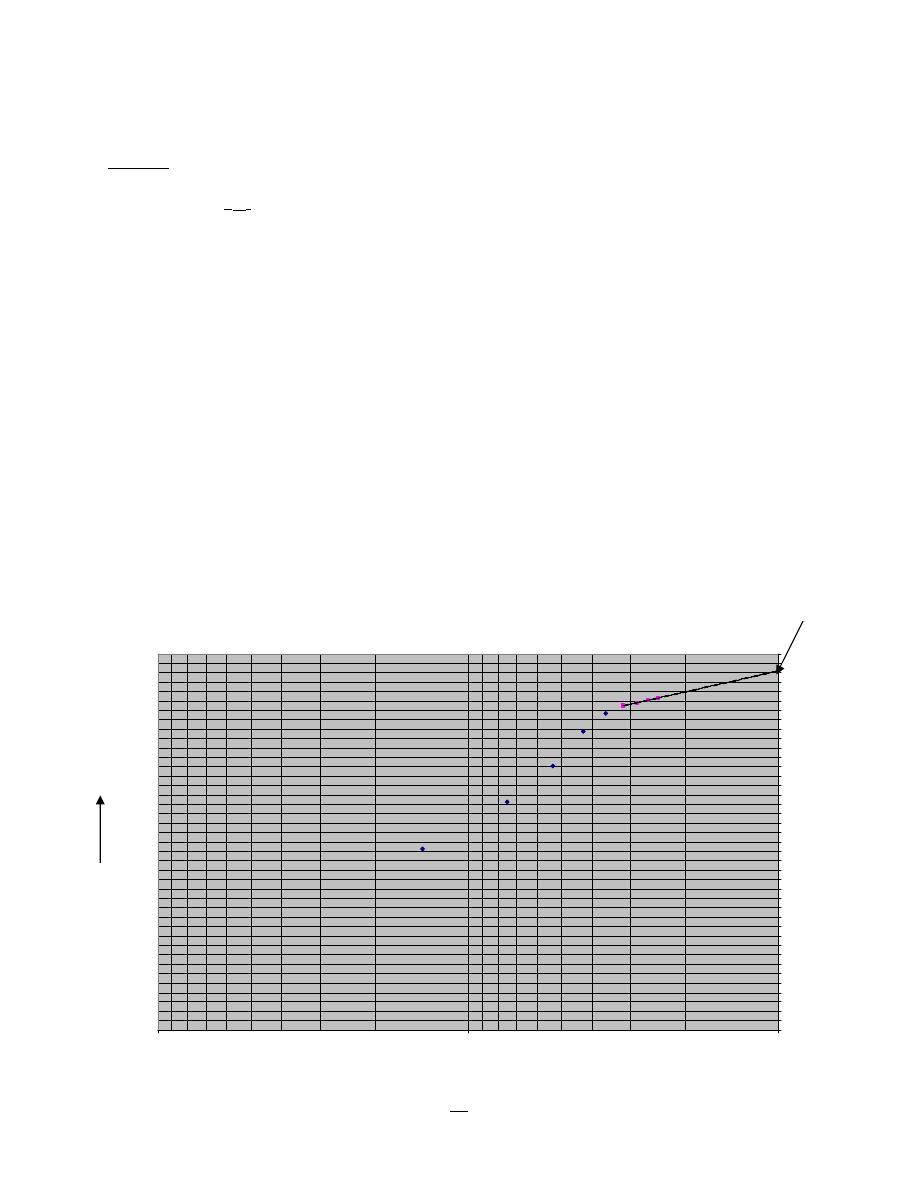

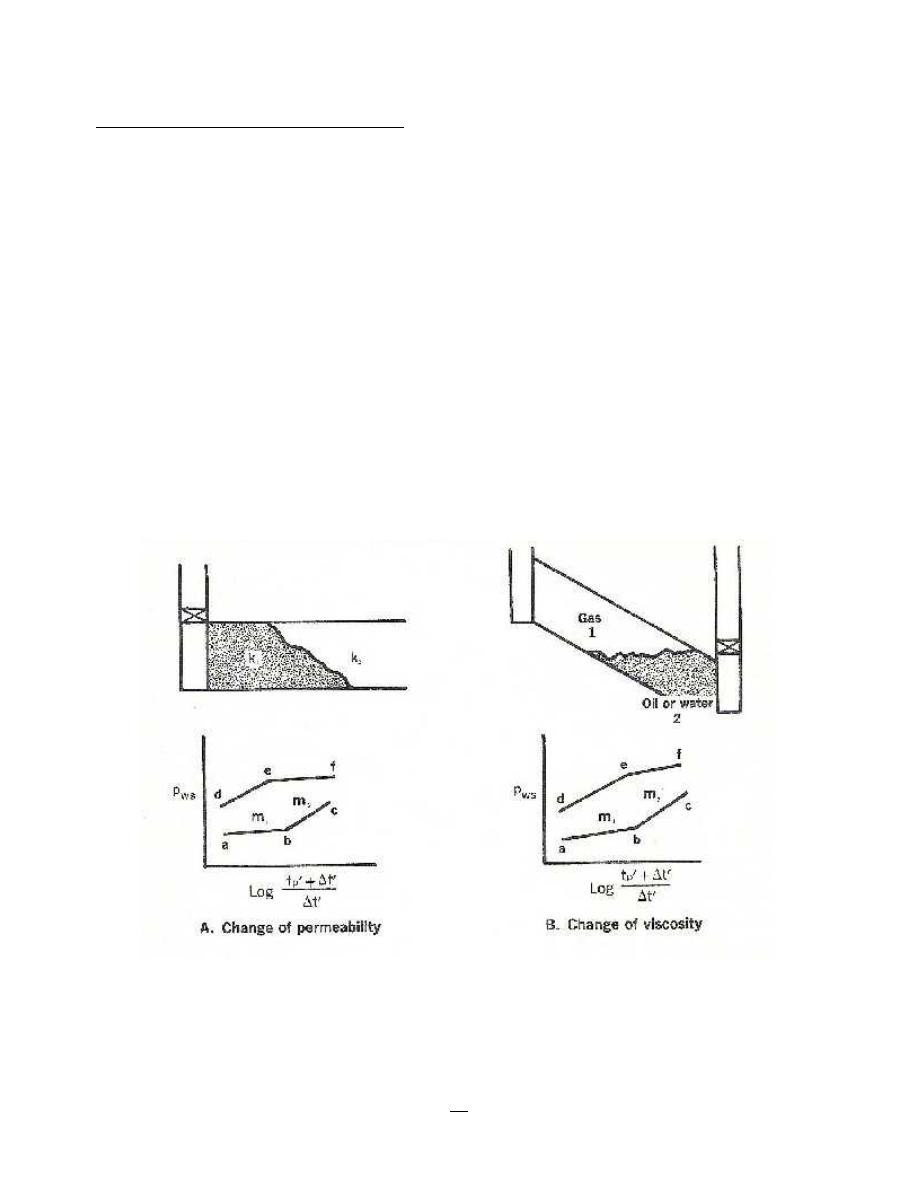

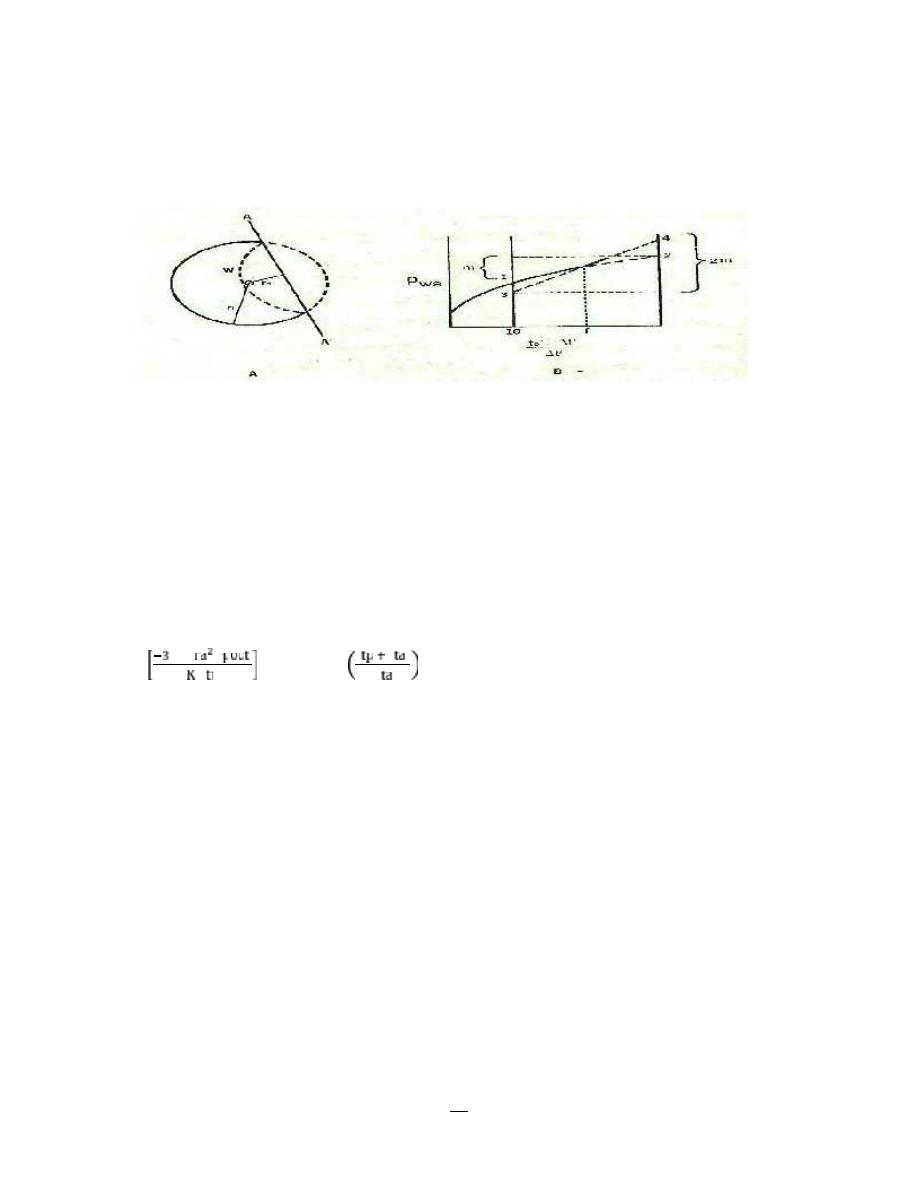

Production Engineering – I Herish N. Hamarash

PRODUCTION

ENGINEERING –I

2

Production Engineering – I Herish N. Hamarash

Introduction to Production Technology

The production engineering is that part of Petroleum Engineering which attempts to maximize

production (or injection) in a cost manner.

The appreciation of production engineering and methods of application are related directly and

interpedently with other major areas of petroleum engineering such as Formation Evaluation,

Drilling engineering and Reservoir Engineering.

The role of the Production Technologist is extremely broad. Currently within the operating

companies in the petroleum industry, the role and responsibility does vary between companies but

can be broadly said to be responsible for the production system.

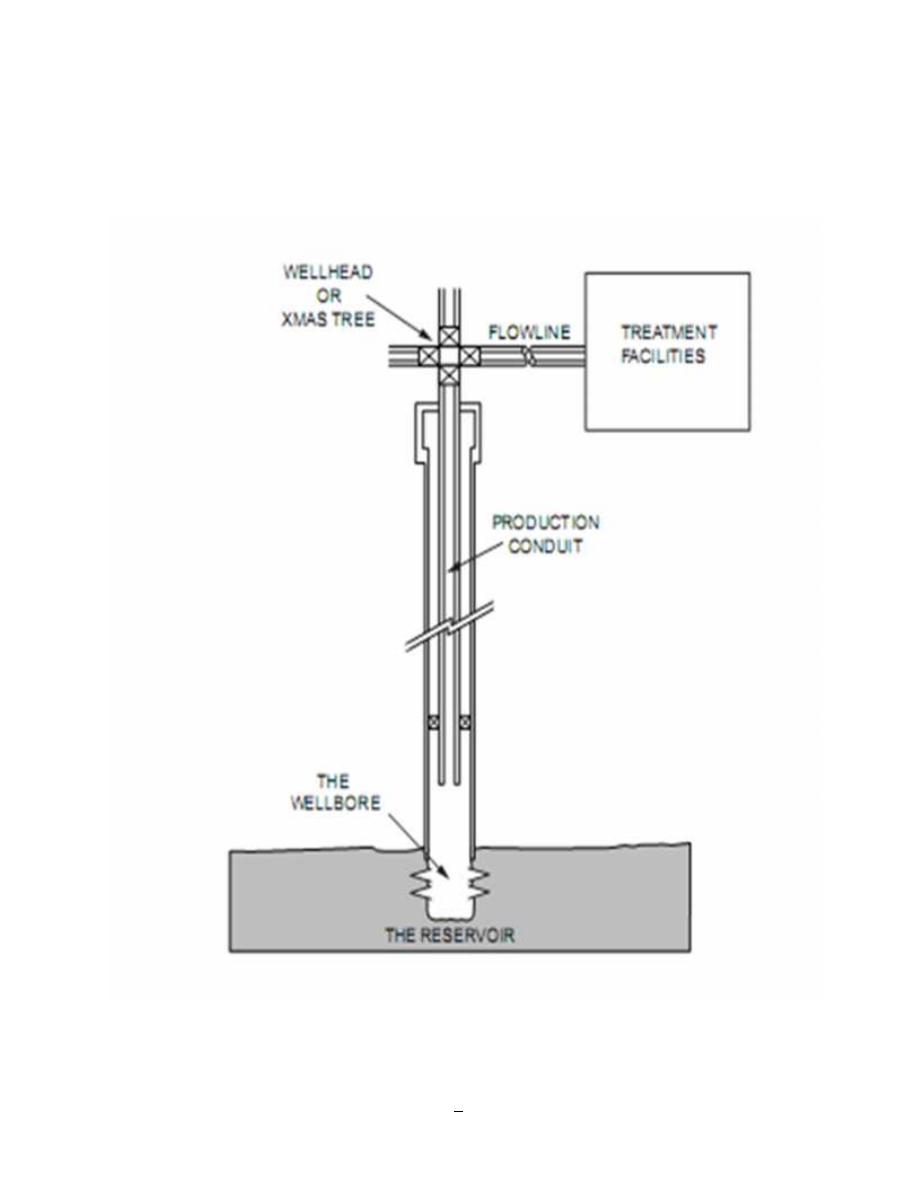

The production system is a composite term describing the entire production process and includes

the following principal components:-

1- The reservoir - it productive capacity and dynamic production characteristics over the

envisaged life of the development.

2- The wellbore - the production interval, the sump and the fluids in the wellbor

3- Production Conduit - comprising the tubing and the tubing components

4- Wellhead, Xmas Tree and Flow Lines

5- Treatment Facilities.

In simple terms, the term "well completion" refers to the methods by which a newly drilled well

can be finalized so that reservoir fluids can be produced to surface production facilities efficiently

and safely. In general, the process of completing a well includes the following:

A method of providing satisfactory communication between the reservoir and the borehole.

The design of the tubulars (casing and tubing) which will be installed in the well.

An appropriate method of raising reservoir fluids to the surface.

The design and the installation in the well of various components used to allow efficient

production, pressure integrity testing, emergency containment of reservoir fluids, reservoir

monitoring, barrier placement, well maintenance and well kill.

The installation of safety devises and equipment, which will automatically shut a well in

the event of a disaster.

In general, a well is the communication link between the surface and the reservoir and it represents

a large percentage of the expenditure in the development of an oil or gas field. It is of utmost

importance that the well be "completed" correctly at the onset, in order that maximum overall

productivity of the field may be obtained. The ideal completion is the lowest cost completion which

will meet the demands placed on it during its producing lifetime.

3

Production Engineering – I Herish N. Hamarash

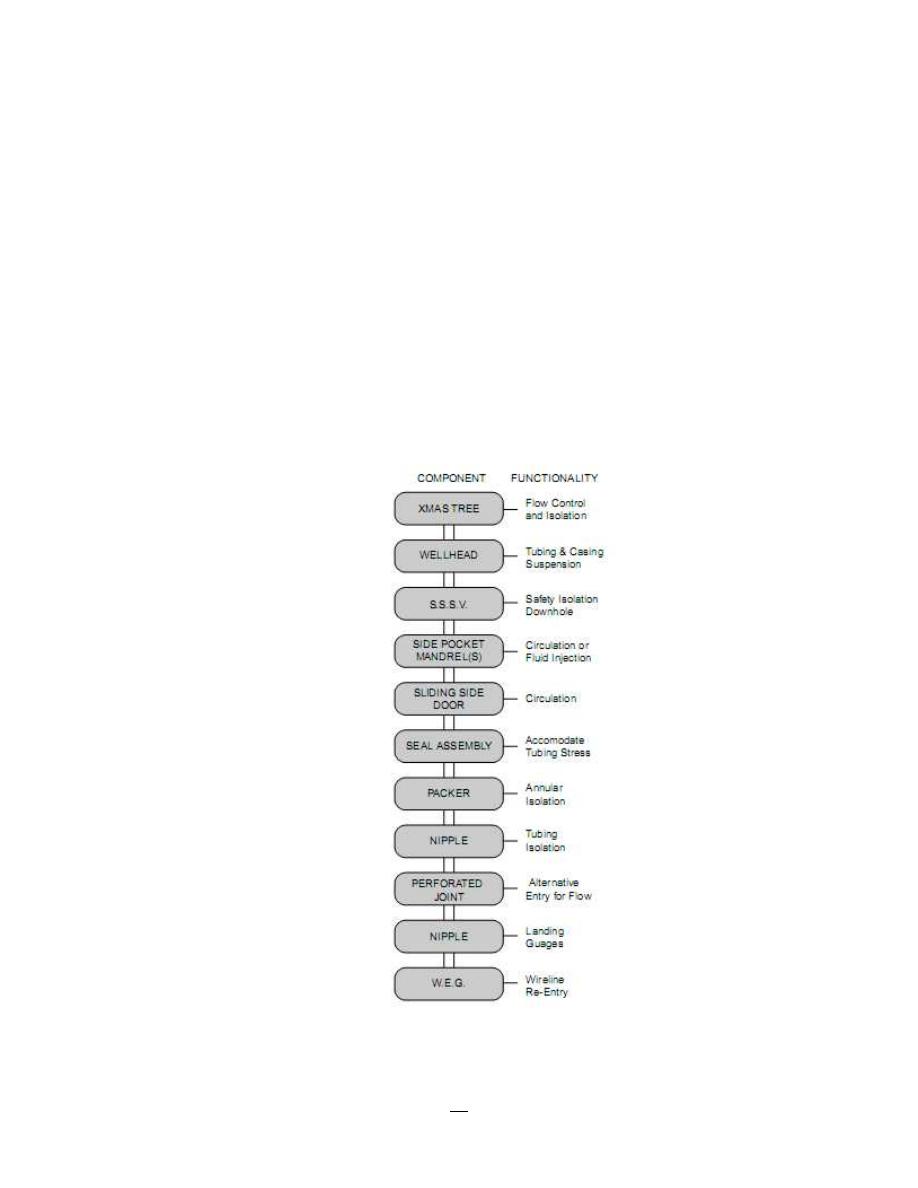

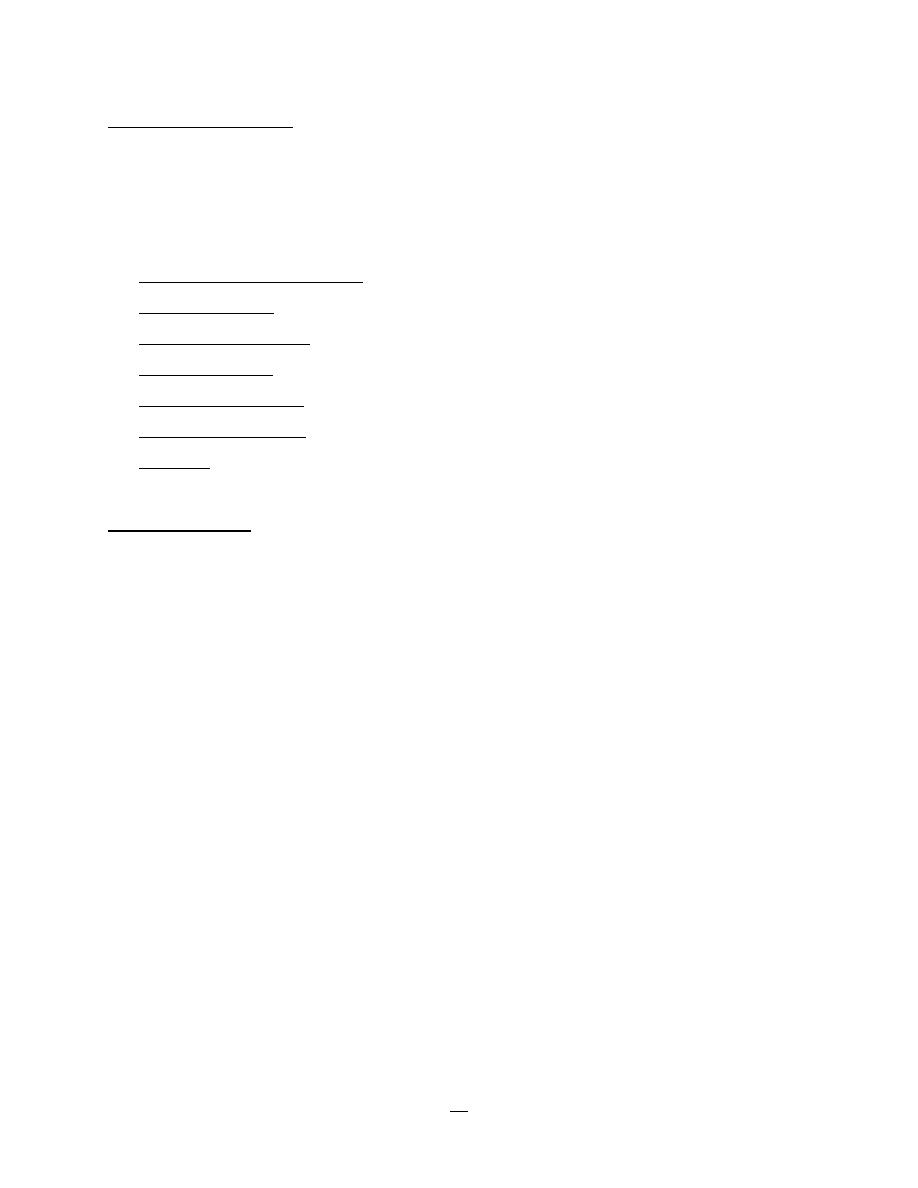

Figure (1) shows the Elements of the production technology system:

Figure (1): Elements of the production technology system

4

Production Engineering – I Herish N. Hamarash

Before knowing the classification of completion, must know the main objective from wells drilling

as following:

-

Exploration and evaluation wells: This type of wells is drill for exploration and

evaluation.

-

Production wells: The wells are drilled and completed for produce oil, gas and

sometime water produce.

-

Injection wells: The wells are drilled and completed for inject water or gas or

chemical material and sometimes petroleum products.

-

Measurement and observation wells: The wells are drilled and completed for

observation the reservoir (reservoir fluid behavior, reservoir pressure, etc...).

-

Special operation wells: The wells are drilled and completed for special operation

such as to kill the below out well.

From the above definition it can be seen that the responsibilities of Production Technology cover

primarily subsurface aspects of the system but they can also extend to some of the surface facilities

and treatment capabilities, depending on the operating company. The role of the Production

Technologist is one of achieving optimum performance from the production system and to achieve

this the technologist must understand fully the chemical and physical characteristics of the fluids

which are to be produced and also the engineering systems which will be utilized to control the

efficient and safe production/injection of fluids. The importance of the production chemistry input

has only recently been widely acknowledged. It is clear that the physico-chemical processes which

take place in the production of fluids can have a tremendous impact on project economics and on

both the production capacity and safety of the well. The main disciplines which are involved in

Production Technology are:

I.

Fluid flow

II.

Reservoir dynamics

III.

Equipment design, installation, operation and fault diagnosis

5

Production Engineering – I Herish N. Hamarash

Reservoir Drive Mechanisms

Ideally the hydrocarbons are recovered from the reservoir porous media by the assistance of the

drive mechanisms weather it was natural or artificial. Drive mechanisms have two

classifications:

Internal drive: Using the internal energy of the reservoir configuration.

External drive: Which involves the invasion of the pore spaces by a replacement fluid, this type

of drive called "Secondary recovery or Enhanced oil recovery".

Internal drive:

This is known as primary recovery, which includes three drive mechanisms:

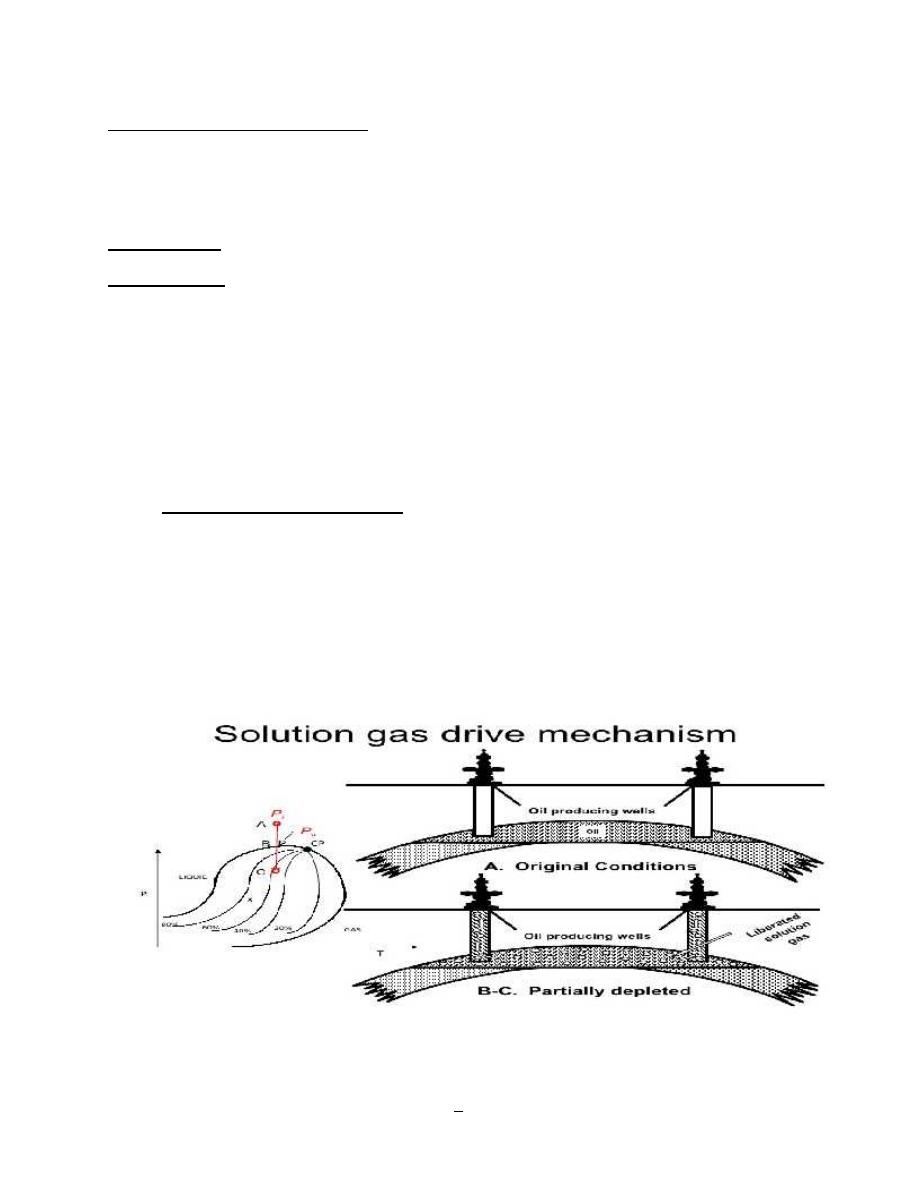

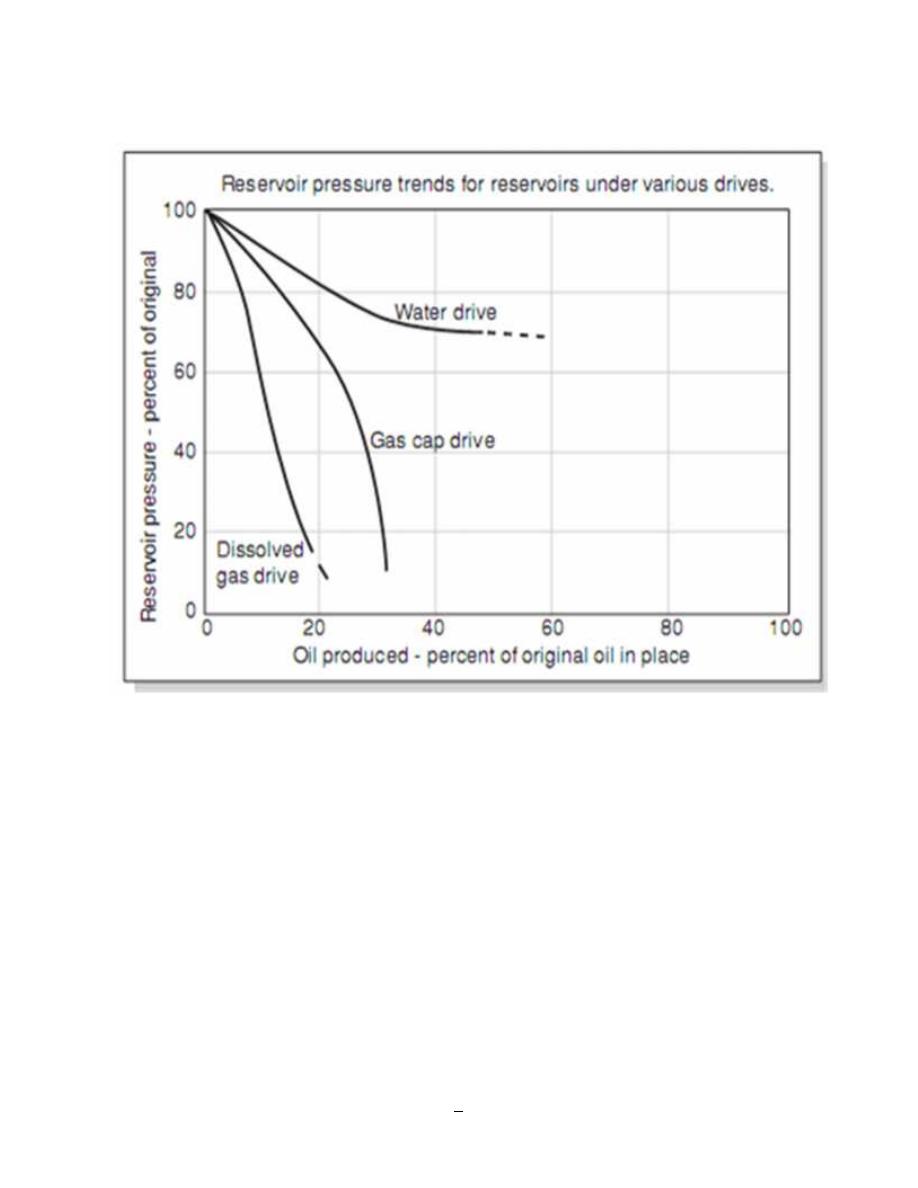

A. Depletion or internal gas drive (See Figure -2)

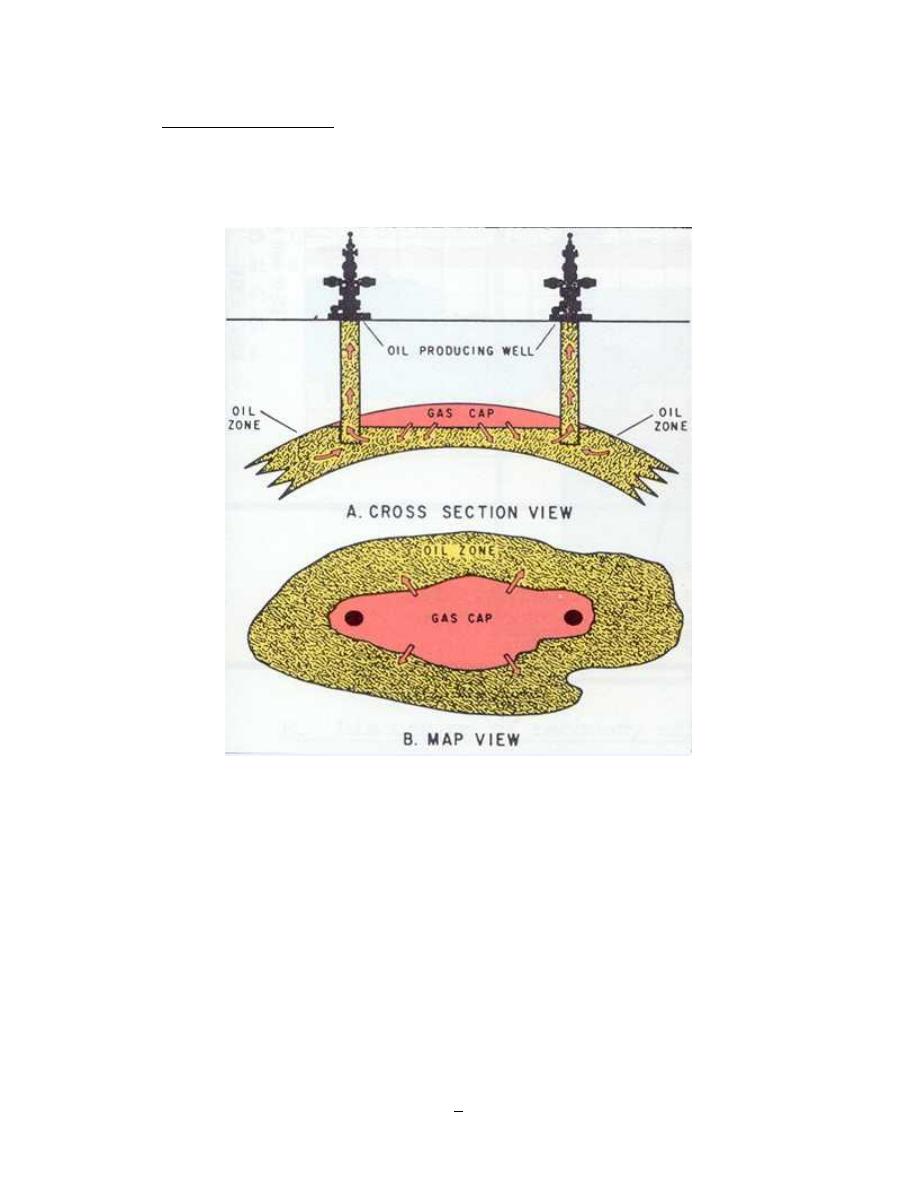

B. External gas cap drive (See Figure – 3)

C. Water drive (See Figure – 4)

A- Depletion or internal gas drive:

The compressibility of oil and water is relatively small. As soon as production commences, it

is accompanied by a rapid drop of pressure in the producing zone which soon reaches the

bubble point of entrained gas. Initially, this gas is dispersed, but it rapidly expands and assists

in dispelling the oil. Eventually, however, the gas will start to form a gas front, which, having

more mobility than the oil, will increase the production gas to oil ratios. This depletion or

dissolved gas drive is characterized by a rapid decline in reservoir pressure and by the recovery

of only a small percentage of the oil in situation, e.g. 5 to 20% maximum see figure - 5

Figure – 2: Internal Gas Drive

6

Production Engineering – I Herish N. Hamarash

B- External gas cap drive

Where the oil has a gas cap, the gas cap pressure together with the pressure of gas in solution

tends to maintain pressure in the reservoir much longer than depletion drive. Therefore, gas cap

reservoirs have higher recovery rates e.g. 20 to 40% see figure - 5

Figure – 3: Gas Cap Drive

7

Production Engineering – I Herish N. Hamarash

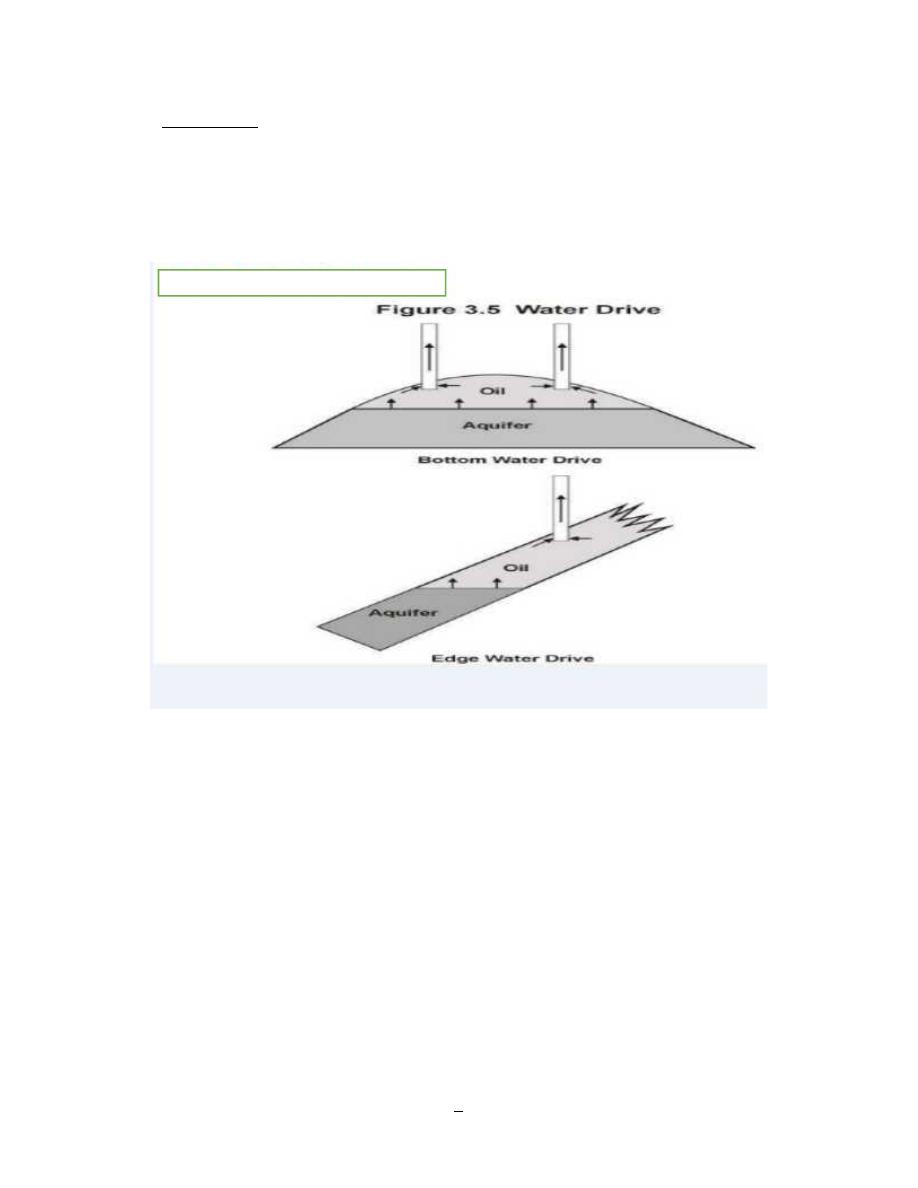

C- Water Drive

Water drive is characterized by large local deposits of water which expand as pressure is

reduced in the reservoir. Eventually, recovery will decrease due to the greater mobility of

the water front which eventually breaks through to the well-bore with increased water to

oil ratios. Nonetheless, water drive is the most efficient of all the drive mechanisms and

can produce recovery rates as high as 60% see figure - 5

Figure – 4: Water Drive

8

Production Engineering – I Herish N. Hamarash

Figure – 5: Expected recovery from different drives

9

Production Engineering – I Herish N. Hamarash

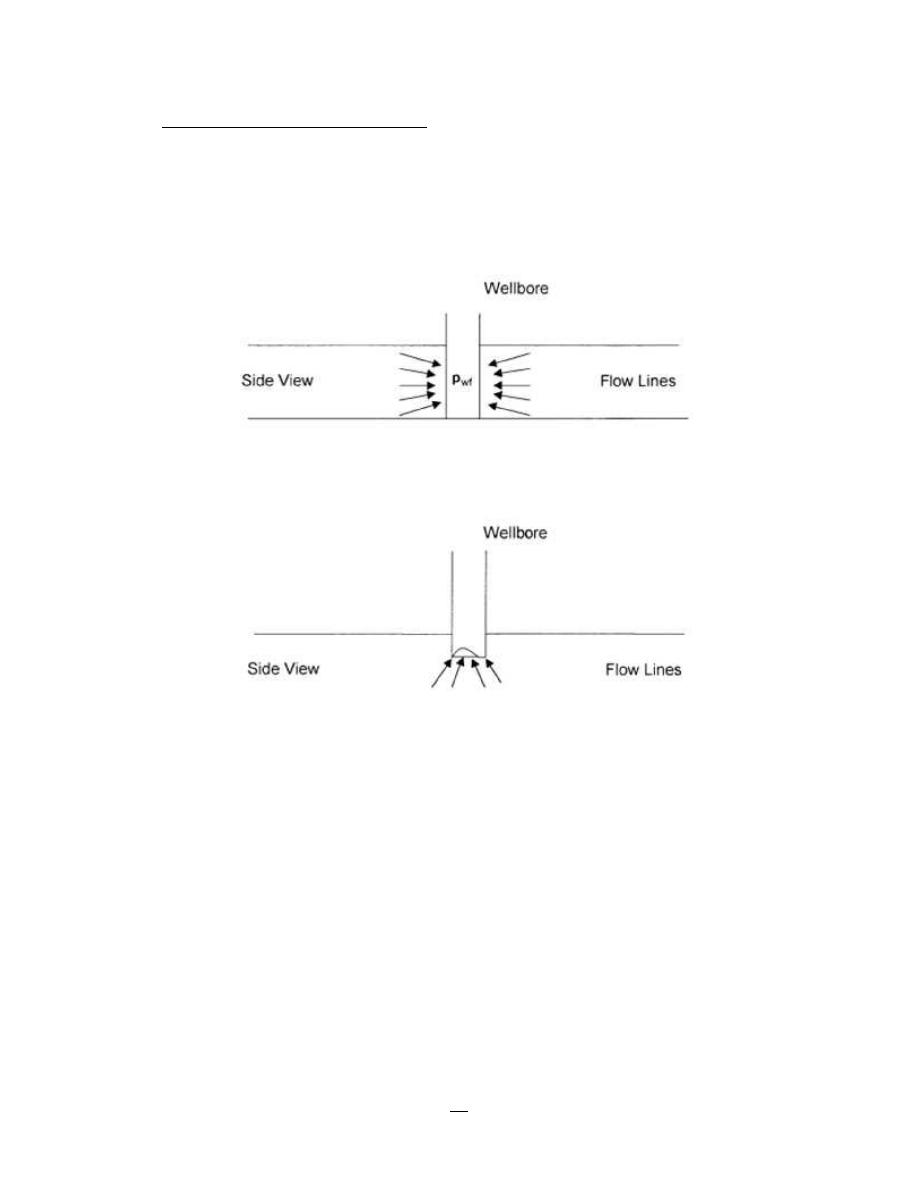

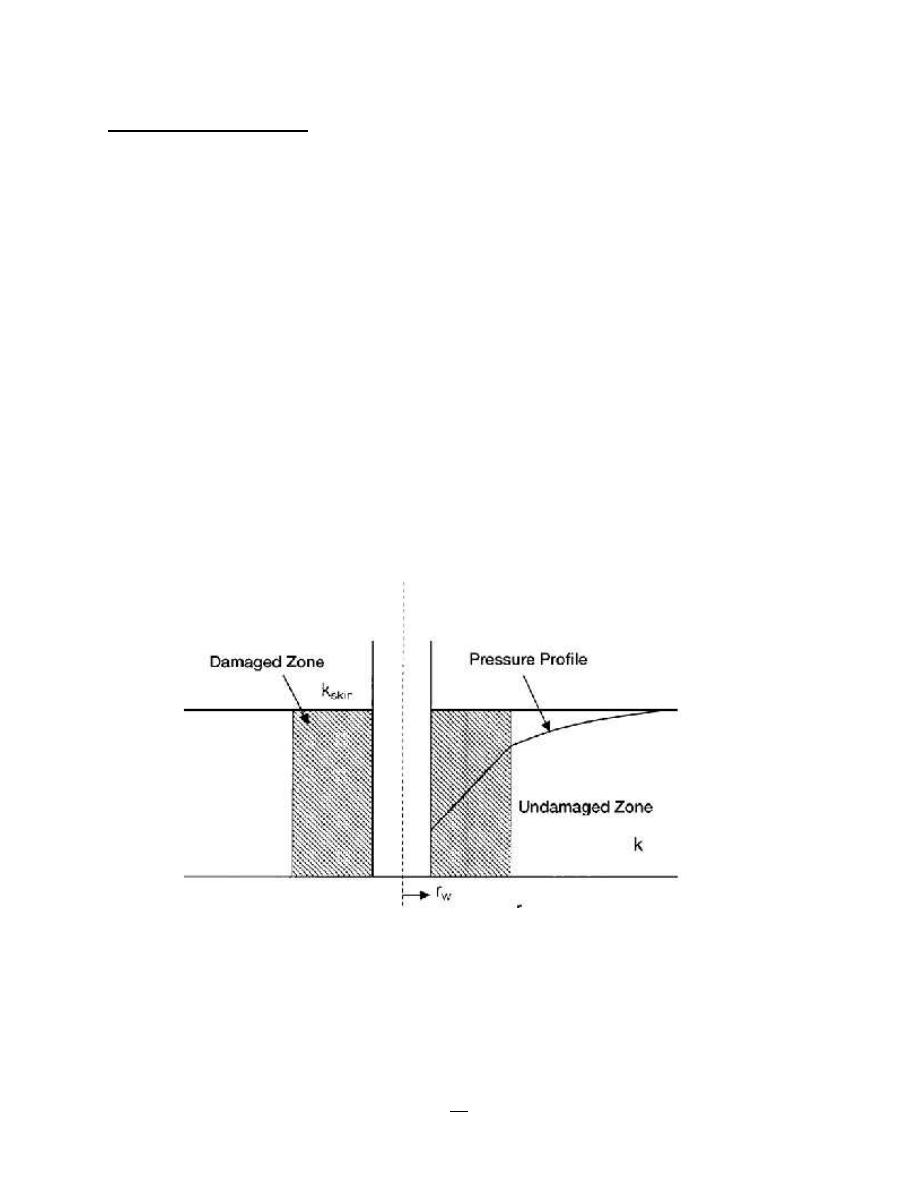

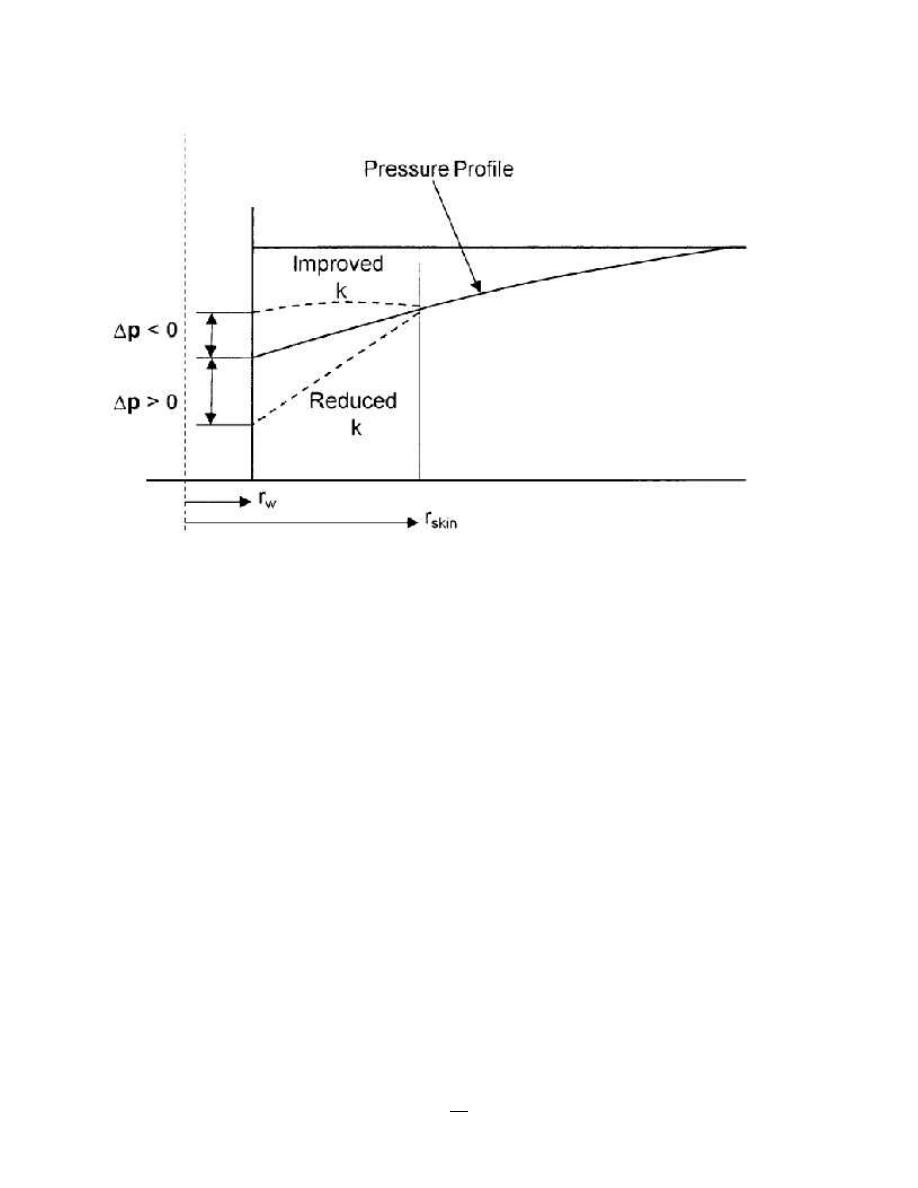

Radial Flow in the Reservoir:

Description of geometry is often possible only with the use of numerical simulators. For many

engineering purposes, however, the actual flow geometry may be represented by one of the

following flow geometries:

I.

Radial flow

II.

Linear flow

III.

Spherical and hemispherical flow

I.

Radial Flow:

In the absence of severe reservoir heterogeneities, flow into or away from a wellbore will follow

radial flow lines from a substantial distance from the wellbore. Because fluids move toward the

well from all directions and coverage at the wellbore, the term radial flow is given to

characterize the flow of fluid into the wellbore. Figure - 6 shows idealized flow lines and iso-

potential lines for a radial flow system.

Figure – 6: Ideal Radial Flow into the Reservoir

10

Production Engineering – I Herish N. Hamarash

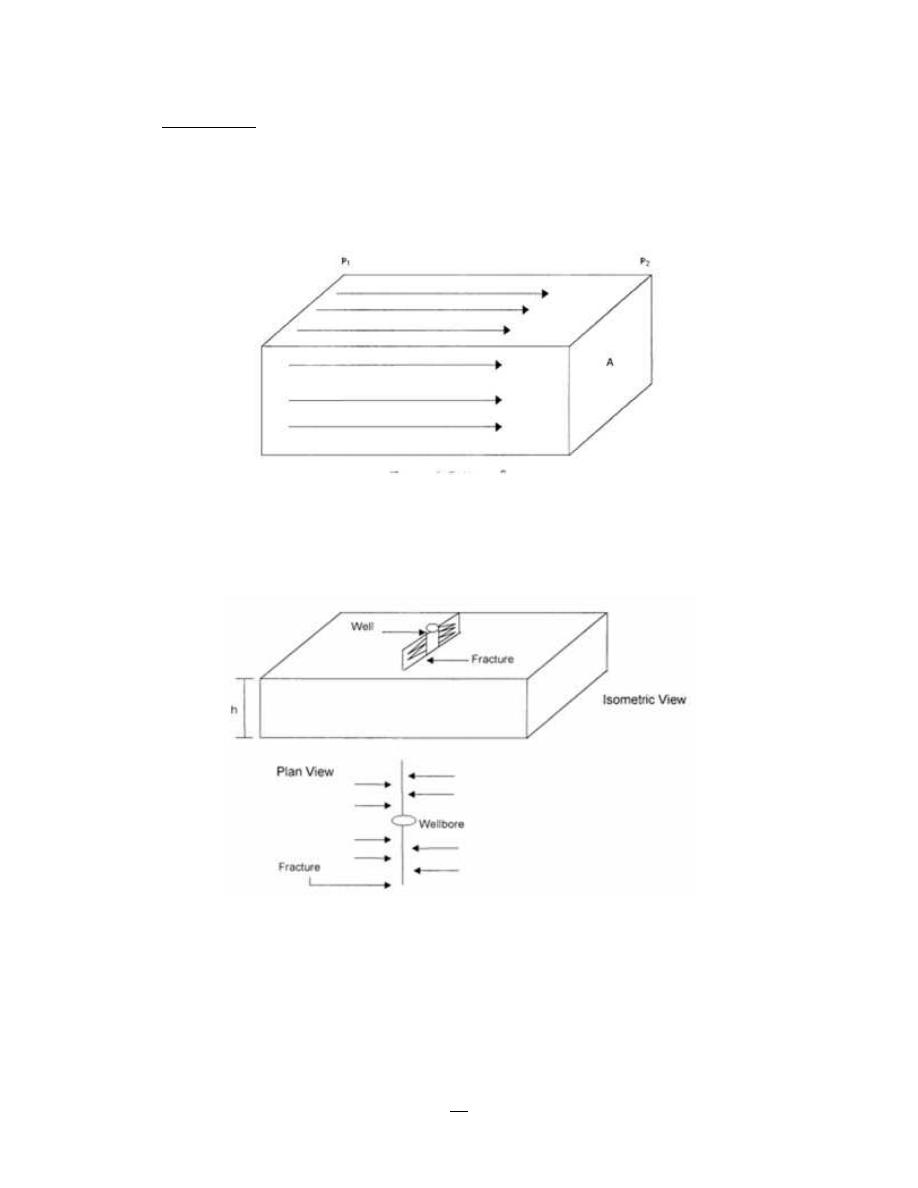

II.

Linear Flow

Linear flow occurs when flow paths are parallel and the fluid flows in a single direction. In

addition, the cross sectional area to flow must be constant. Figure - 7 shows an idealized linear

flow system. A common application of linear flow equations is the fluid flow into vertical

hydraulic fractures as illustrated in Figure - 8.

Figure - 7: Linear Flow

Figure - 8: Ideal Linear Flow into Vertical Fracture

11

Production Engineering – I Herish N. Hamarash

III.

Spherical and Hemispherical Flow

Depending upon the type of wellbore completion configuration, it is possible to have a spherical

or hemispherical flow near the wellbore. A well with a limited perforated interval could result in

spherical flow in the vicinity of the perforations as illustrated in Figure - 9. A well that only

partially penetrates the pay zone, as shown in Figure - 10, could result in hemispherical flow.

The condition could arise where coning of bottom water is important.

Figure - 9: Spherical Flow due to Limited Entry

Figure - 10: Hemispherical Flow

12

Production Engineering – I Herish N. Hamarash

FLUID FLOW EQUATIONS

Darcy’s Law

The fundamental law of fluid motion in porous media is Darcy’s Law. The mathematical

expression developed by Henry Darcy in 1856 states the velocity of a homogeneous fluid in a

porous medium is proportional to the pressure gradient and inversely proportional to the fluid

viscosity. For a horizontal linear system, this relationship is:

ν is the apparent velocity in centimeters per second and is equal to q/A, where q is the volumetric

flow rate in cubic centimeters per second and A is total cross-sectional area of the rock in square

centimeters. In other words, A includes the area of the rock material as well as the area of the pore

channels. The fluid viscosity, µ, is expressed in centipoise units, and the

Pressure gradient, dp/dx, is in atmospheres per centimeter, taken in the same direction as ν and q.

The proportionality constant, k, is the permeability of the rock expressed in Darcy units.

The negative sign in the equation is added because the pressure gradient is negative in the

direction of flow.

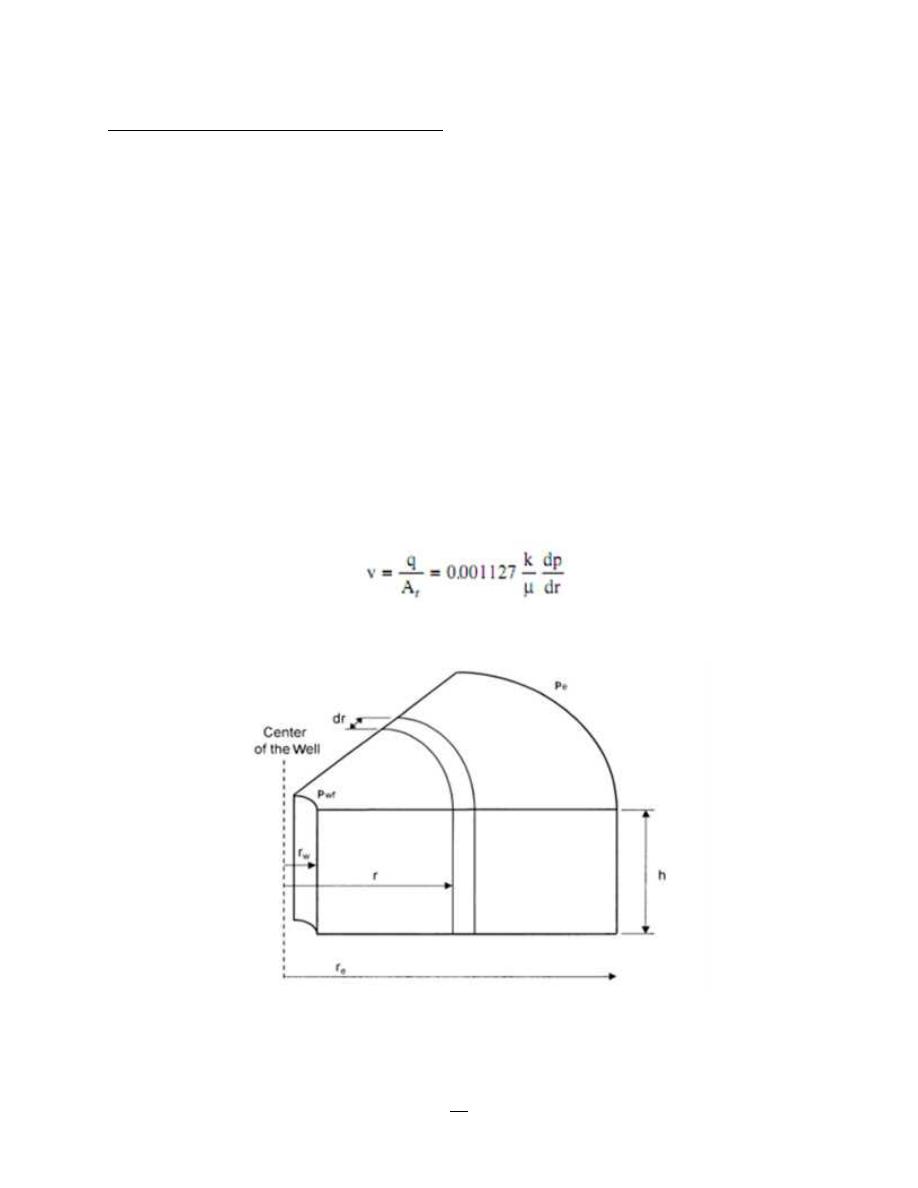

For a horizontal-radial system, the pressure gradient is positive and Darcy’s equation can be

expressed in the following generalized radial form:

Where

q= volumetric flow rate at radius r

A = cross-sectional area to flow at radius r

(∂p/∂r)= pressure gradient at radius r

ν=apparent velocity at radius r

The cross-sectional area at radius r is essentially the surface area of a cylinder. For a fully

penetrated well with a net thickness of h, the cross-sectional area A is given by:

13

Production Engineering – I Herish N. Hamarash

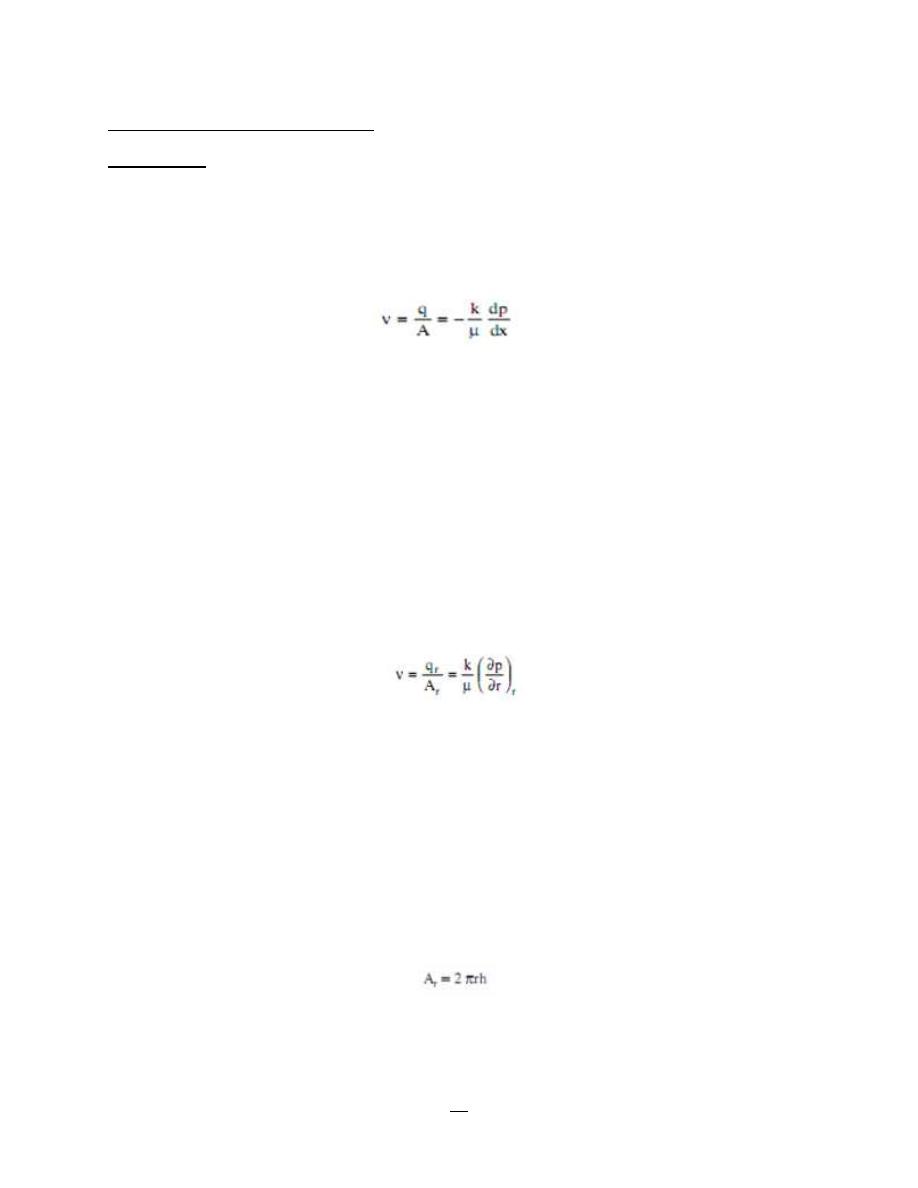

Linear Flow of Incompressible Fluids

In the linear system, it is assumed the flow occurs through a constant cross-sectional area A, where

both ends are entirely open to flow. It is also assumed that no flow crosses the sides, top, or bottom

as shown in Figure -11 below:\

Figure - 11: Linear Flow Model

If an incompressible fluid is flowing across the element dx, then the fluid velocity v and the flow

rate q are constants at all points. The flow behavior in this system can be expressed by the

differential form of Darcy’s equation and integrating over the length of the linear system gives

OR

It is desirable to express the above relationship in customary field units

Where:

q = flow rate, bbl/day

k = absolute permeability, md

p = pressure, psia

µ=viscosity, cp

L = distance, ft

A = cross-sectional area, ft2

14

Production Engineering – I Herish N. Hamarash

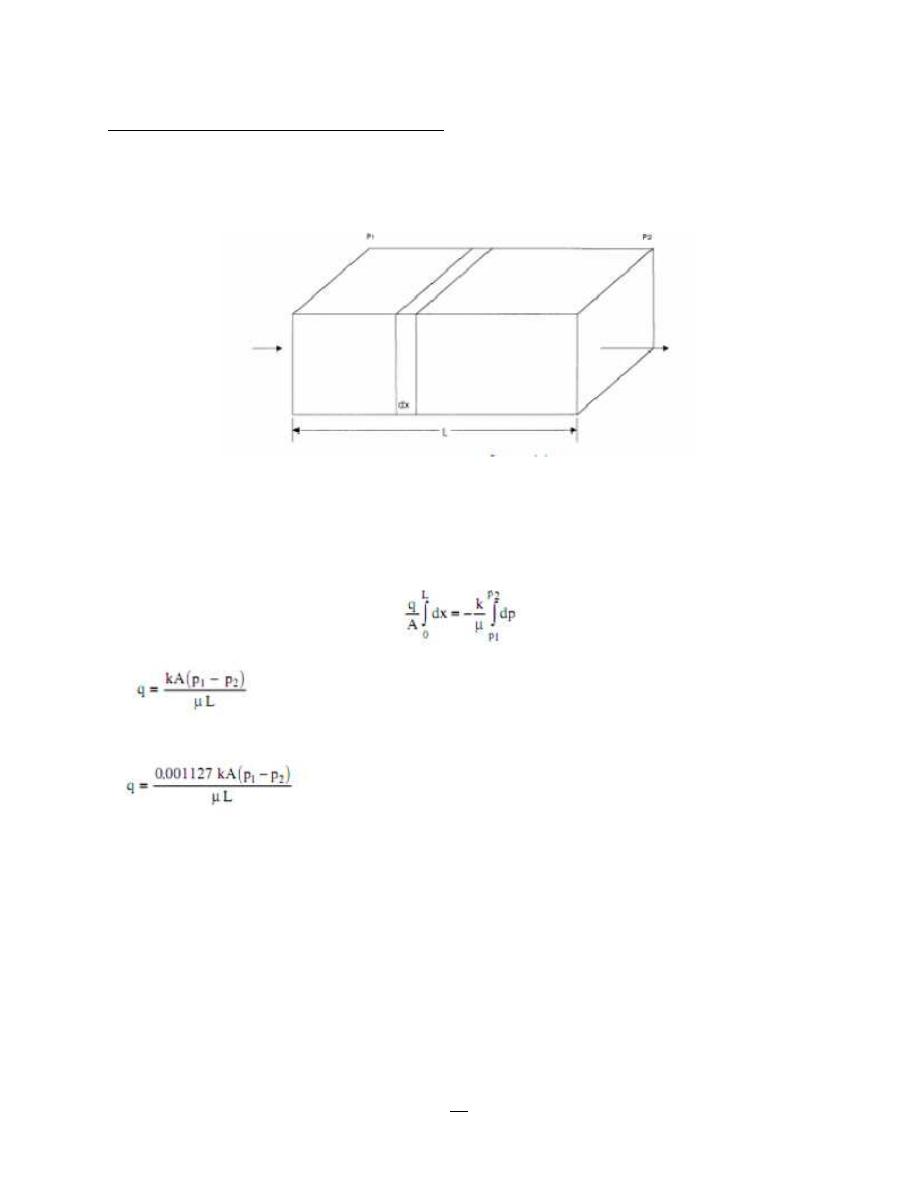

Example: An incompressible fluid flows in a linear porous media with the following properties:

Calculate:

a. Flow rate in bbl/day

b. Apparent fluid velocity in ft/day

c. Actual fluid velocity in ft/day

Solution:

15

Production Engineering – I Herish N. Hamarash

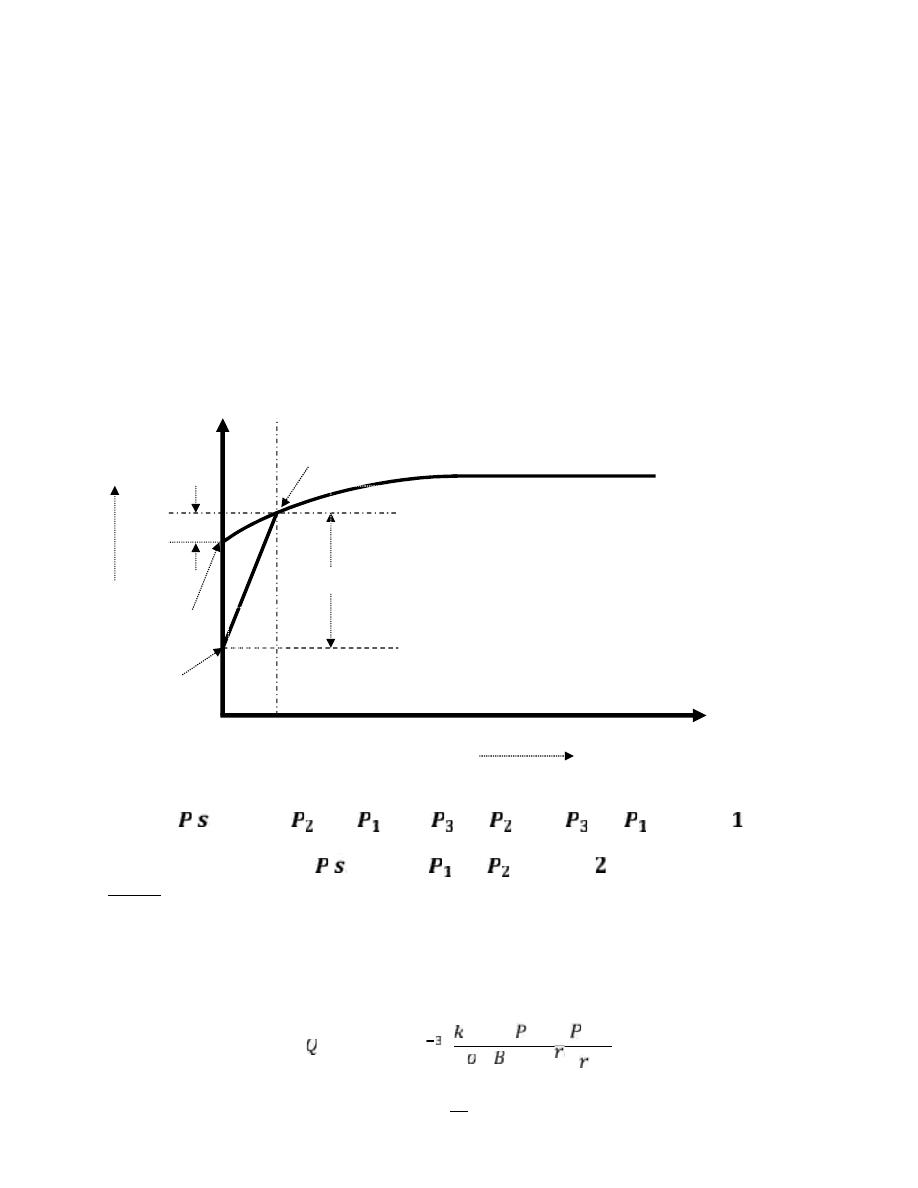

Radial Flow of Incompressible Fluids

In a radial flow system, all fluids move toward the producing well from all directions. Before

flow can take place, however, a pressure differential must exist. Thus, if a well is to produce oil,

which implies a flow of fluids through the formation to the wellbore, the pressure in the

formation at the wellbore must be less than the pressure in the formation at some distance from

the well.

The pressure in the formation at the wellbore of a producing well is know as the bottom-hole

flowing pressure (flowing BHP, Pwf). Consider Figure - 12 which schematically illustrates the

radial flow of

an incompressible fluid toward a vertical well. The formation is considered to a uniform

thickness h and a constant permeability k. Because the fluid is incompressible, the flow rate q

must be constant at all radii. Due to the steady-state flowing condition, the pressure profile

around the wellbore is maintained constant with time. Let Pwf represent the maintained bottom-

hole flowing pressure at the wellbore radius rw and pe denote the external pressure at the

external or drainage radius. Darcy’s equation as described earlier can be used to determine the

flow rate at any radius r:

Figure - 12: Radial Flow Model

16

Production Engineering – I Herish N. Hamarash

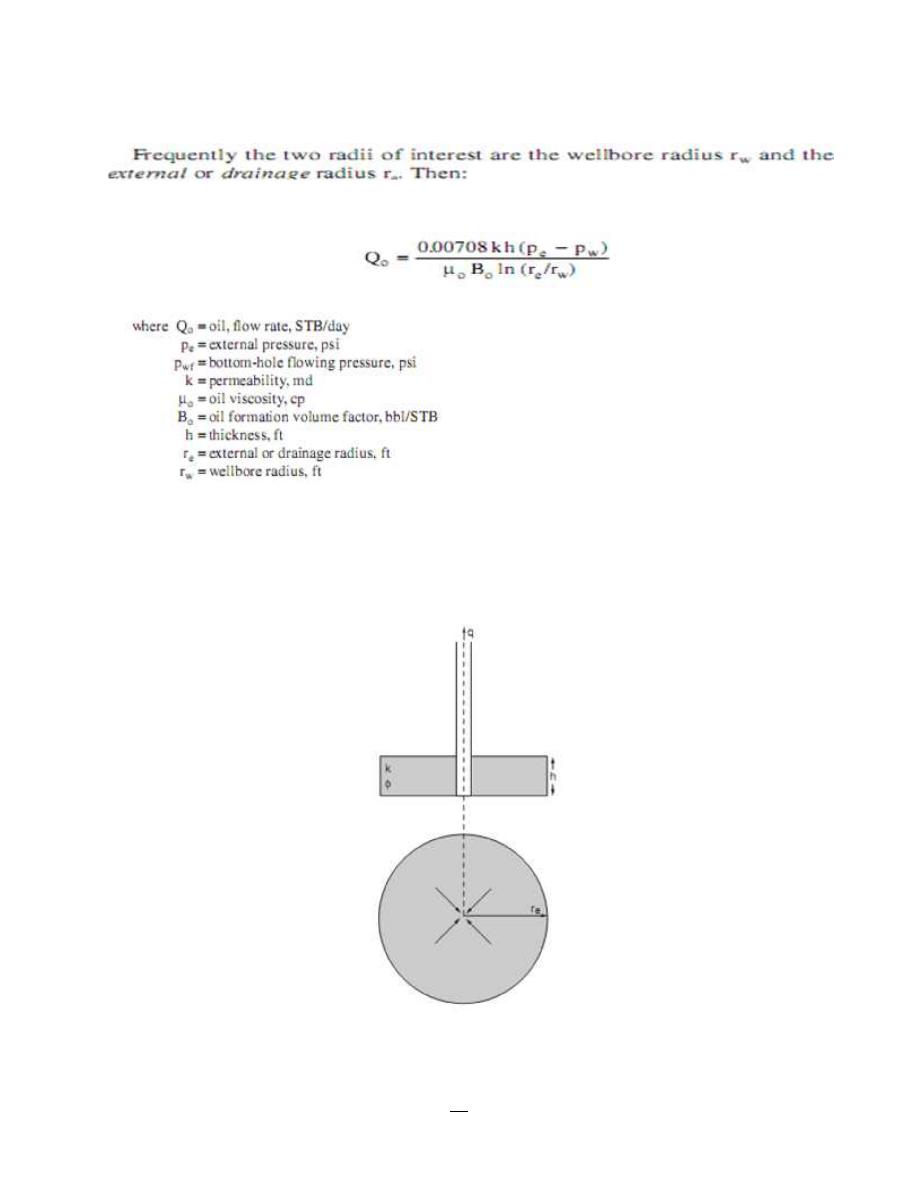

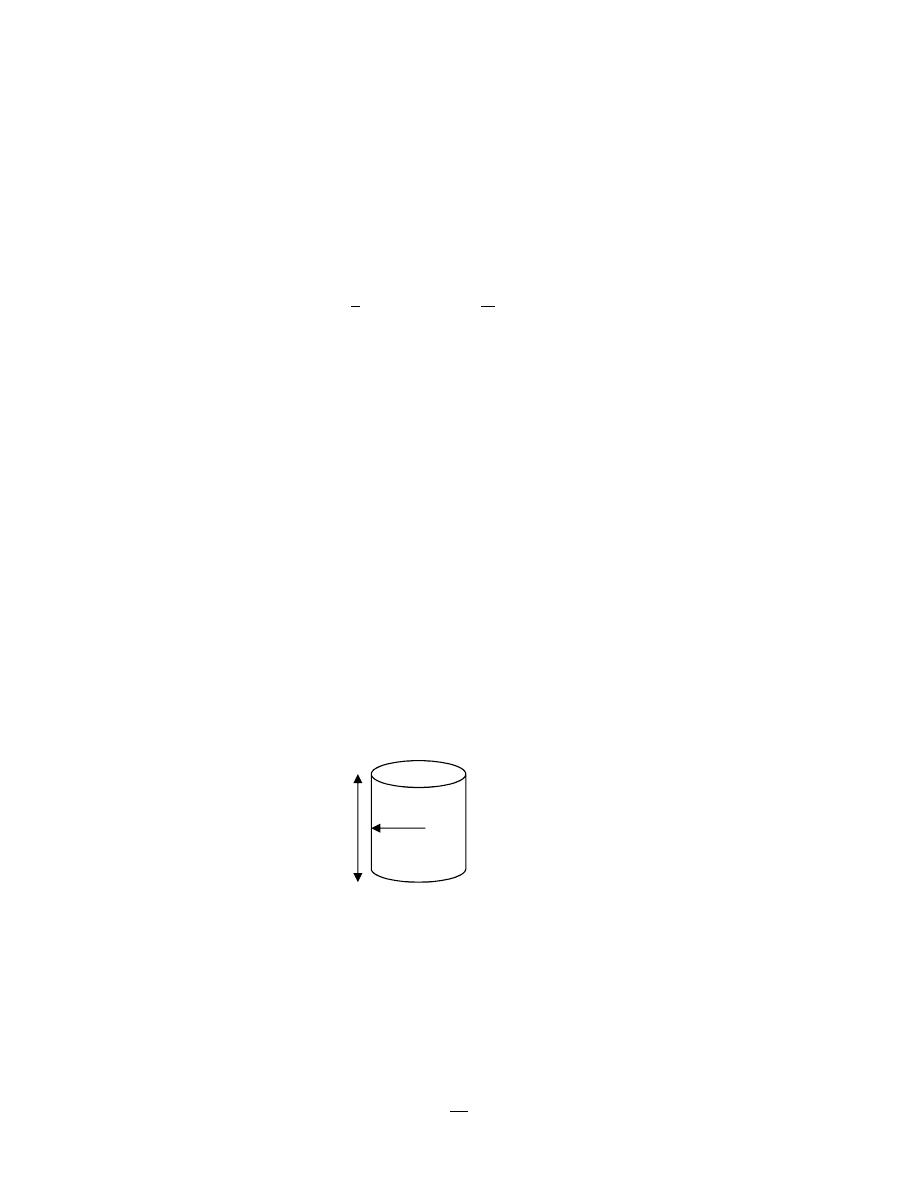

To account for the convergence effects of flow, a simplified model based upon the assumption of

radial flow to a central well located in the middle of a cylindrical reservoir unit is assumed as

shown in Figure - 13 below:

Figure 13: Radial Inflow Model

17

Production Engineering – I Herish N. Hamarash

The model assumes:

The reservoir is horizontal and of constant thickness h.

The reservoir has constant rock properties of φ and K.

Single phase flow occurs to the well bore.

The reservoir is circular of radius re.

The well is located at the center of the reservoir and is of radius r

w

.

The fluid is of constant viscosity µ.

The well is vertical and completed open hole, i.e. fluid enters the wellbore through the total

height h.

18

Production Engineering – I Herish N. Hamarash

Completion Design Consideration

Production technology contributes substantially as one of the major technical functions within an

operating company and in particular, to its economic performance and cashflow. As with any

commercial venture, the overall incentive will be to maximize profitability and it is in this

context that the operations for which the production technologist is responsible, are at the sharp

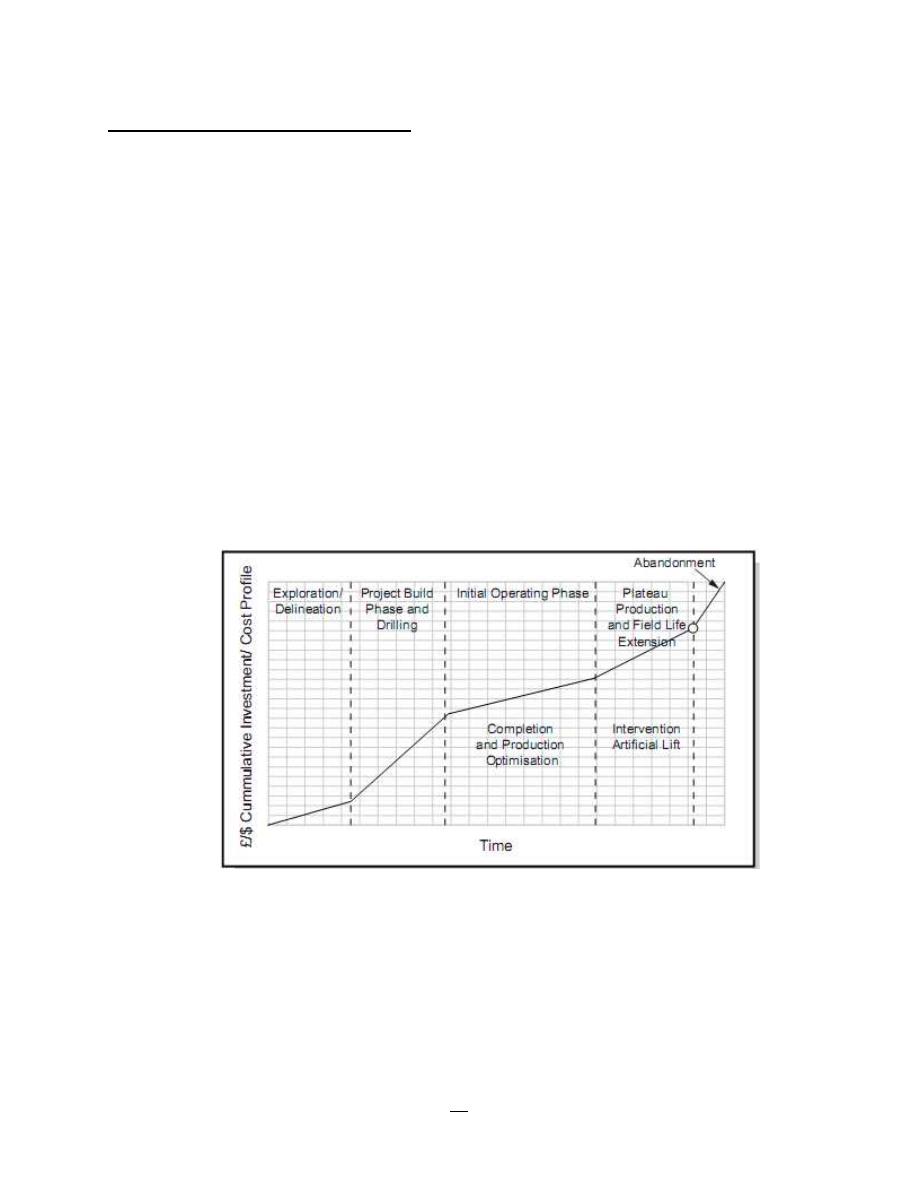

end of project economics. The objectives of an oil company operation could be broadly

classified, with respect to two complimentary business drivers, namely:

(a) Maximizing the magnitude of and accelerating cash flow

(b) Cost minimization in terms of cost/bbl.

Total cost minimization may not be recommended.

1-

Cashflow: The overall objectives would ideally be to maximize both cashflow and

recoverable reserves. This would normally require maintaining the well in an operational

state to achieve

o

maximum production rates

o

maximum economic longevity

o

minimum down time

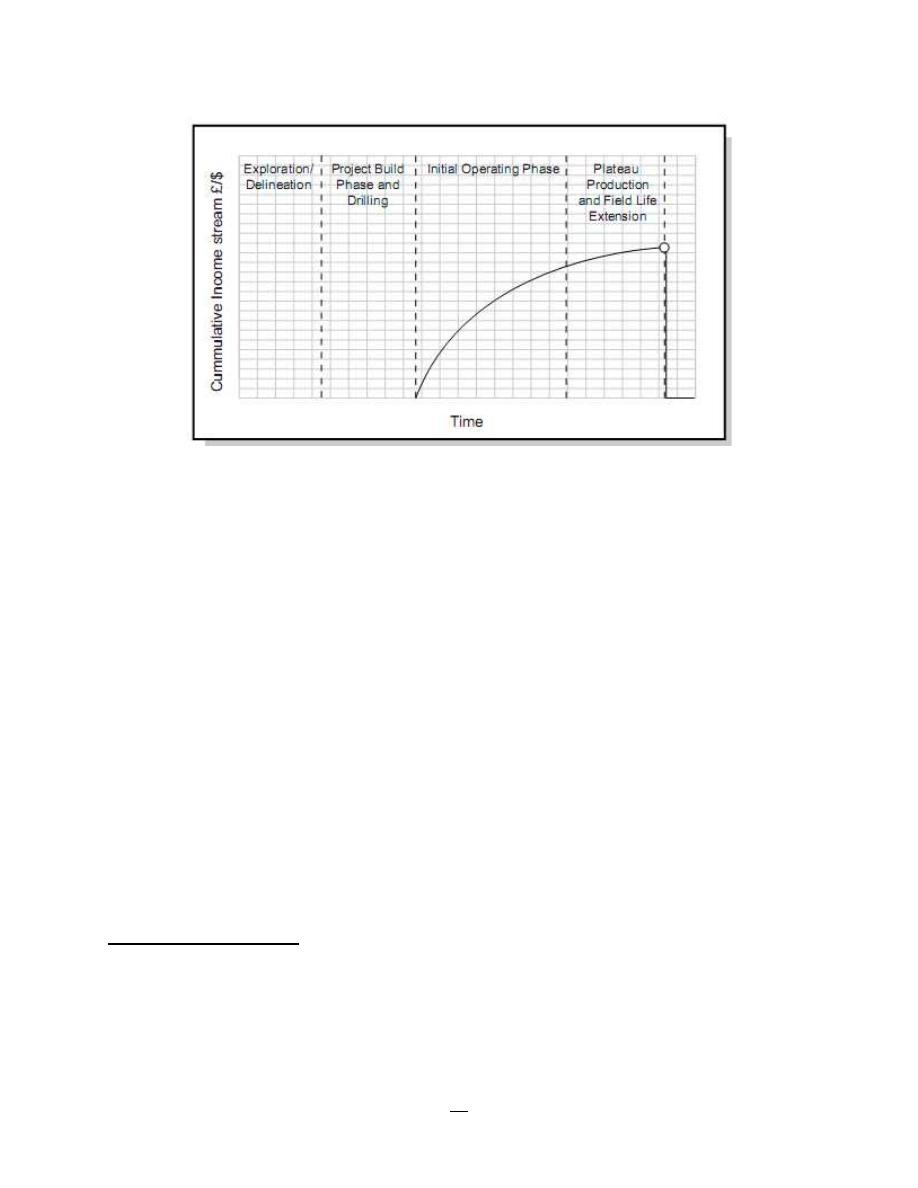

This is shown in Figures 14 & 15 bellow:

Figure - 14

19

Production Engineering – I Herish N. Hamarash

Figure - 15

Figures (14 & 15): Economic phase of field development and input from production

engineer

2-

Cost: In this category there would be both fixed and direct costs, the fixed costs being

those associated by conducting the operation and the direct or variable costs being

associated with the level of production and the nature of the operating problems. The

latter costs are therefore defined in terms of cost per barrel of oil produced. On this basis

the production technologist would seek to:

o

Minimize capital costs

o

Minimize production costs

o

Minimize treatment costs

o

Minimize workover costs

From the above, the bulk of the operations for which the production technologist is responsible

or has major inputs to, are at the sharp end of ensuring that the company’s operations are safe,

efficient and profitable. There for before a production well is drilled, a great deal of planning

must be undertaken to ensure that the design of the completion is the best possible. A number of

factors must be taken into account during this planning stage, which can broadly be split into the

objective of well drilling, reservoir considerations and mechanical considerations.

Objective of well drilling

The objective of well drilling is very important factor in well completion design, may be the

purpose from well drilling is clear from beginning or changed with time (a certain well completed

as producing well then after that convert to injection well or observation well depend on the

reservoir conditions).

20

Production Engineering – I Herish N. Hamarash

Reservoir considerations

Natural rock reservoir

The geological and experimental studies that conduct to delineate the nature of rock

reservoir (type of rock, including fault, reservoir permeability, etc…) is important to select

the adequate completion design.

Producing rate

To provide maximum economic recovery is often the starting point for well completion

design. Among other factors producing rate should determine the size of the producing

conduit.

Multiple reservoirs

Multiple reservoirs penetrated by a well pose the problem of multiple completions in one

drilled hole. Possibilities include multiple completions inside casing separated by packers,

or several strings of smaller casing cemented in one borehole to provide in effect separate

wells. Other possibilities include commingling of hydrocarbons from separate reservoir

downhole, or drilling several boreholes from one surface location.

Reservoir drive mechanism

Reservoir drive mechanism may determine whether or not the completion interval will

have to be adjusted as gas-oil or water-oil contacts move. A water drive situation may

indicate water production problems. Dissolved gas and gas drive reservoirs usually mean

declining productivity index and increasing gas-oil ratio.

Secondary recovery requirements

Secondary recovery needs may require a completion method conductive to selective

injection or production. Water flooding may increase volumes of fluid to be handled. High

temperature recovery processes may require special casing and casing cementing materials.

Stimulation

Stimulation may require special perforating patterns to permit zone isolation, perhaps

adaptability to high injection rates, and a well hookup such that after the treatment the zone

can be returned to production without contact with killing fluids.

Sand control

Sand control problems alone may dictate the type of completion method and maximum production

rates. On the other hand, reservoir fluid control problems may dictate that a less than desirable

type of sand control be used.

Artificial lift

21

Production Engineering – I Herish N. Hamarash

Artificial lift may mean single completions even where multiple zones exist.

Workover requirements

Workover frequencies, probably high where several reservoirs must be drained through

one wellbore, often dictate a completion conducive to wireline or through-tubing type

recompletion systems.

Mechanical considerations

The mechanical configuration or "well hookup" is often the key to being able to deplete the

reservoir effectively, monitor downhole performance, and modify the well situation when

necessary. The mechanical configuration of the well is the key to being able to do what ought to

be done in the well from the standpoint of controlling the flow of reservoir fluids, oil, gas, and

water.

Functional requirements

Operating conditions

Component design

Component reliability

Safety

KEY SUBJECT AREAS IN PRODUCTION ENGINEERING

Production technology is both a diverse and complex area. With the on-going development of the

Petroleum Industry the scope of the technological activities continues to expand and as always

increases in depth and complexity. It is however, possible to identify several key subject areas

within Production Technology namely:-

Well Productivity

Well Completion

Well Stimulation

Associated Production Problems

Remedial and Workover Techniques

Artificial Lift / Productivity Enhancement

Surface Processing

Methods of completion:

In the development of a hydrocarbon reservoir, a large number of wells are drilled and require to

be completed, to allow the structure to be depleted. However, the drilling and completion

operations are crucial to the long term viability of the wells in meeting the specified objectives.

The design and completion of both production and injection wells are required to satisfy a number

of objectives including:

Provision of optimum production/injection performance.

22

Production Engineering – I Herish N. Hamarash

Ensure safety.

Maximize the integrity and reliability of the completion over the envisaged life of the

completed well

Minimize the total costs per unit volume of fluid produced or injected, i.e. minimize the

costs of initial completion, maintaining production and remedial measures.

The fundamental design of a completion consists of four principal decision areas, namely:

1. Specification of the bottomhole completion technique.

2. Selection of the production conduit.

3. Assessment of completion string facilities.

4. Evaluation of well performance / productivity-injectivity

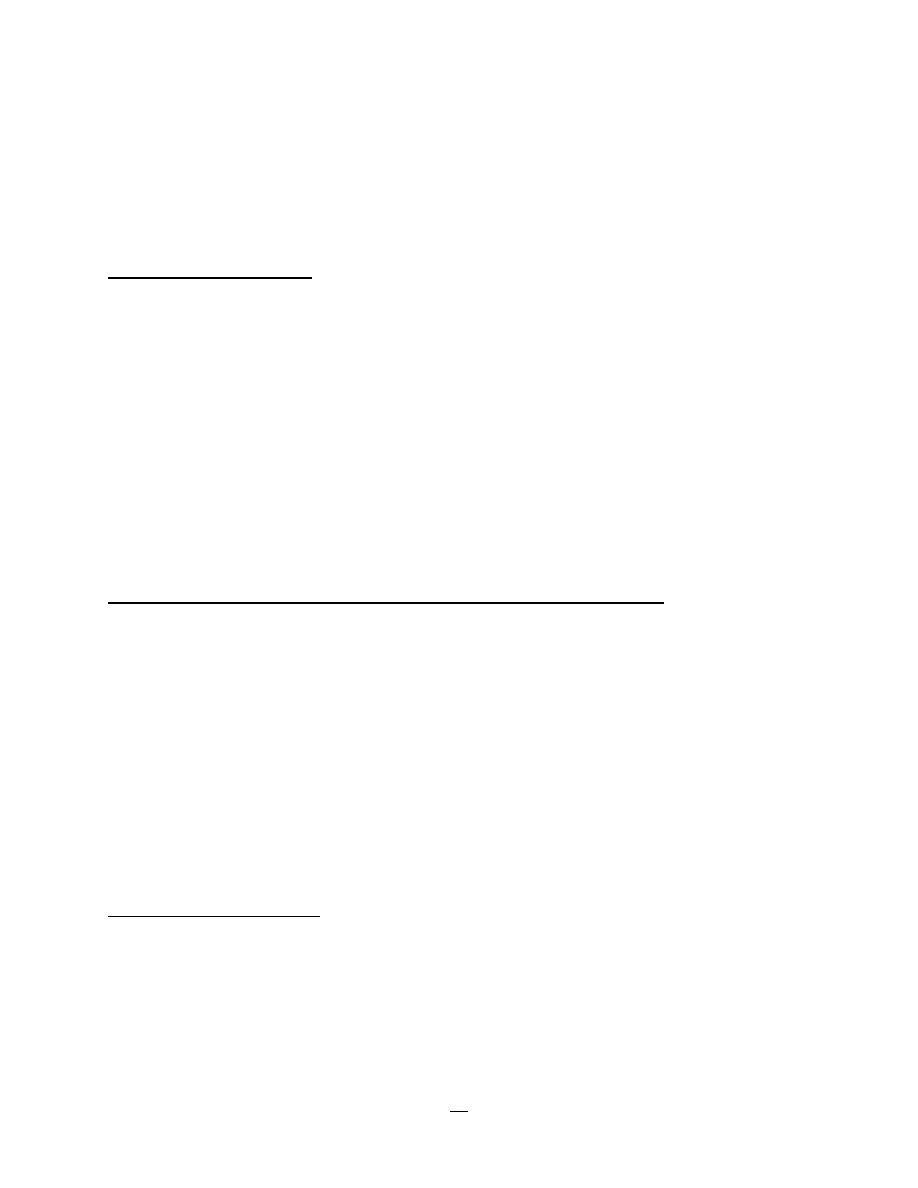

These four decision areas, as shown in Figure - 16, should provide a conceptual design for the

completion of the wells. However, this design process normally is initiated on the basis of data

from exploration wells and considerable uncertainty may exist as to the validity and accuracy of

that data. Thus a number of alternative designs for well completions will normally be selected

and retained as a contingency.

Figure - 16: Completion Design Strategy

Basically there are three main methods of completing a well which are:

1- Open-hole completion

2- Cased-hole completion

3- Liner completion; this completion can be include two types:

23

Production Engineering – I Herish N. Hamarash

a- Screen and liner completion.

b- Perforated liner completion.

1- Open-hole Completion:

The simplest approach to bottomhole completion would be to leave the entire drilled

reservoir section open after drilling, the production casing is set on top of producing zone

before drill the production formation that contain the hydrocarbon fluids, then after

casing was cemented, producing formation drilled, see figure - 17. Generally open-hole

has greater application in carbonate zones.

Figure - 17: Open-hole Completion

Advantages;

1- Adaptable to special drilling techniques to minimize formation damage or to prevent

lost circulation into the producing zone.

2- No perforating expense.

3- Log interpretation is not critical since entire interval is open

4- Full diameter opposite pay.

5- Can be easily deepened.

6- Easily converted to liner or perforated completion

24

Production Engineering – I Herish N. Hamarash

Limitation;

1- Excessive gas or water production difficult to control.

2- Selective critical section in production zone to fracturing or acidizing more difficult.

3- May require frequent well-bore cleanout.

4- Requires more rig time on completion

2- Cased-hole completion:

The production casing is cemented through producing zone and perforated, see figure - 18.

Figure - 18: Cased-hole Completion

Advantages;

1- Excessive gas or water production can be controlled more easily.

2- Can be selectively stimulated.

3- Log and formation samples available to assist in decision to set casing or abandon.

4- Full diameter opposite pay.

5- Can be easily deepened.

6- Will control most sand, and is adaptable to special sand control techniques.

7- Adaptable to multiple completion techniques.

8- Minimum rig time on completion.

Limitation;

1- Cost of casing cement and perforating for long zones may be significant.

2- No adaptable to special drilling techniques to minimize formation damage.

3- Log interpretation is critical for most of logs except production logging.

25

Production Engineering – I Herish N. Hamarash

Well productivity is less than productivity of open-hole well completion.

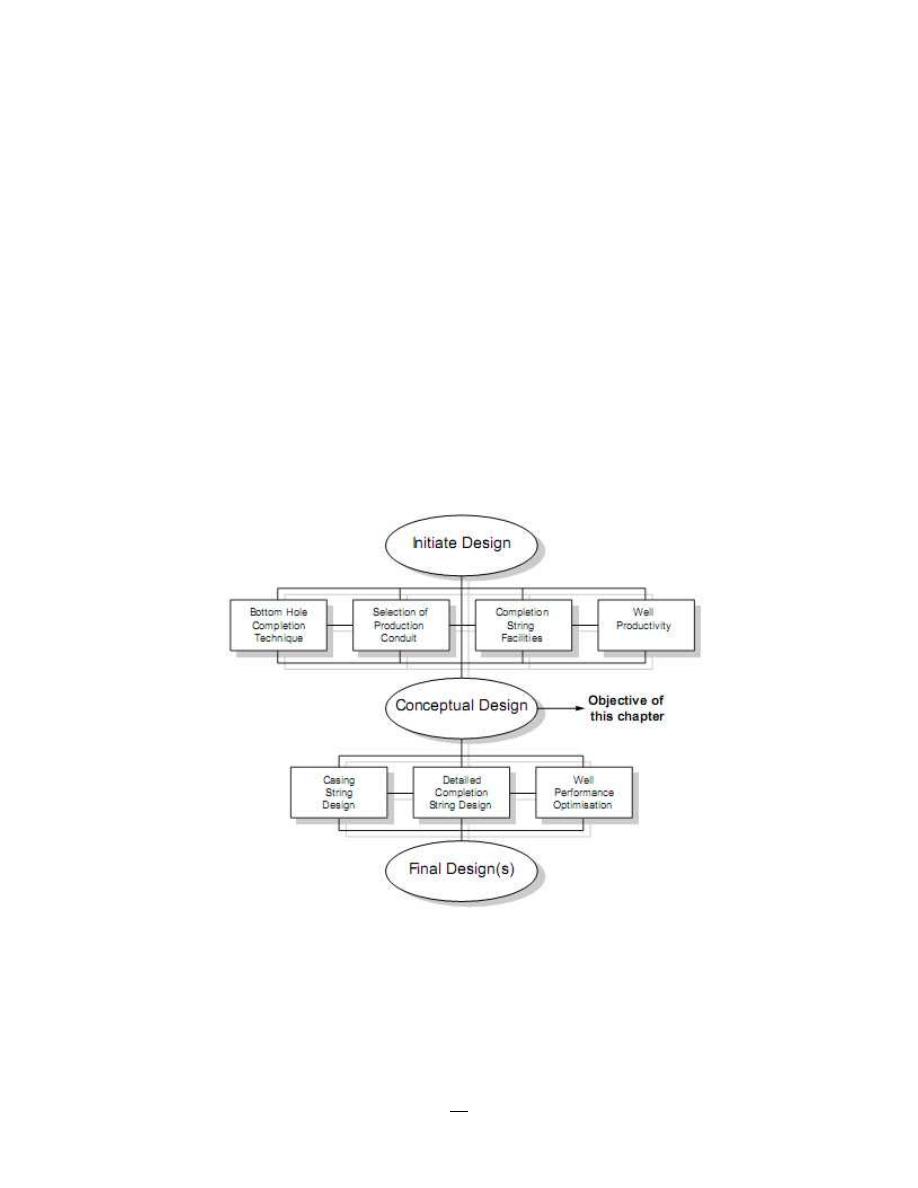

Liner completion:

I.

Screen and Liner completion.

The production casing is set on top of producing zone, than the screen and the liner is set through

producing zone, see figure - 19.

Advantages;

1- Adaptable to special drilling techniques to minimize formation damage or to prevent

lost circulation into the producing zone.

2- No perforating expense.

3- Log interpretation is not critical since entire interval is open

4- Do not require frequent well-bore cleanout.

5- Will control most sand, and is adaptable to special sand control techniques.

Limitation;

1- Excessive gas or water production difficult to control.

2- Selective critical section in production zone to fracturing or acidizing more difficult.

3- Wellbore deepened is not easy.

4- Requires more rig time on completion.

Figure - 19: Liner Completion

26

Production Engineering – I Herish N. Hamarash

II.

Perforated Liner completion

The production casing is set on top of producing zone, then the producing zone was drilled after

that the liner is set and cemented through producing, then perforated, see figure - 18.

Advantages;

1. Adaptable to special drilling techniques to minimize formation damage or to prevent

lost circulation into the producing zone.

2. Gas and water production easy to control.

3.

Selective critical section in production zone to fracturing or acidizing more easy.

4. Can be easily deepened.

5. Will control most sand because the liner obstructed sand movement, and is adaptable to

special sand control techniques.

Limitation;

1- Cost of casing cement and perforating for long zones may be significant.

2- Log interpretation is critical for most of logs.

3- Requires more rig time on completion.

4- Difficult conduct good cement operations for liner compare with the first stage of

casing cementing.

27

Production Engineering – I Herish N. Hamarash

SELECTION OF THE FLOW CONDUIT BETWEEN THE RESERVOIR

AND SURFACE

There are a number of optional methods by which fluid which enters the wellbore will be allowed

to flow to surface in a production well, or to the formation in an injection well. In the selection of

the method, a range of considerations may influence the choice including: cost, flow stability,

ability to control flow and ensure well safety or isolation; ensuring that the integrity of the well

will not be compromised by corrosion or erosion. In the case of multizone reservoir, the zonal

characteristics will determine to a large extent the flow system selected.

However, for a single zone completion, the following alternatives exist:

Tubingless casing flow.

Casing and tubing flow.

Tubing flow without annular isolation.

Tubing flow with annular isolation.

-

Tubingless Casing Flow: This type of completion use in wells produces with high

production rates and medium or low closed, flowing pressures. See figure - .20

Figure - 20: Tubingless Completion

-

Casing and Tubing Flow: In this type of completion the well produce through annulus

and tubing in same time, but the production rate in this type being less than in type of

producing through production casing. See figure - 21. Valid reasons for tubing may

include:

1- Better flow efficiency.

2- Permit circulation of kill fluids, corrosion inhibitors or paraffin solvents.

3- Provide multiple flow paths for artificial lift system.

4- Protect casing from corrosion, abrasion, or pressure.

28

Production Engineering – I Herish N. Hamarash

5- Provide indicate of monitoring bottom-hole flowing pressure.

Figure - 21: Casing and Tubing Flow

Tubing Flow without Annular Isolation: In situations where annular flow in a casing-string

completion would result in excessive phase slippage with consequent increased flowing pressure

loss and potential instability, the consideration could be given to merely closing the annulus at

surface and preventing flow. However, in reservoirs where the flowing bottomhole pressure is at

or below the bubble point, gas as it flows from the formation to the tubing tailpipe will migrate

upwards under buoyancy forces and some gas will accumulate in the annulus. This will result in

an increase in the casing head pressure at surface. In this type of completion the casing is

exposed continuously to produce fluid with the possibilities of erosion or corrosion. This,

coupled with the potential for annular heading, suggests that unless annular flow is required then

the annulus should not be left open to production, despite its simple design.

-

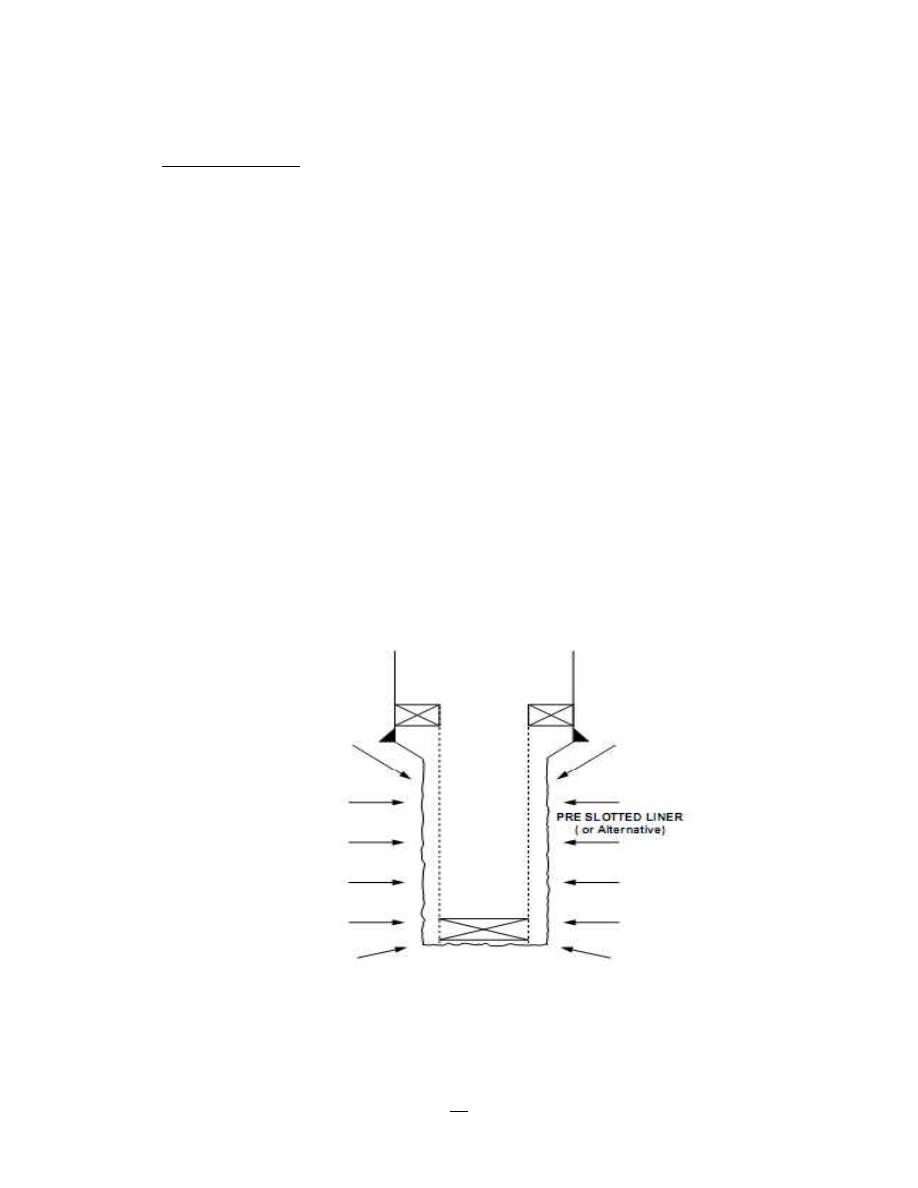

Tubing Flow with Annulus Isolation: For cases where a large cross sectional area for

flow is not necessary, then an open annulus can cause complications as discussed in 2.3

above. Therefore, in the majority of cases where tubing flow will take place, the annulus

is normally isolated by the installation of a packer. The packer has a rubber element which

when compressed or inflated will expand to fill the annulus between the tubing and the

casing. The packer is normally located as close to the top of the reservoir as possible to

minimize the trapped annular volume beneath the packer and hence the volume of gas

which could accumulate there. However, if the packer is installed, the ability to U-tube or

circulate fluid between the tubing and annulus is removed. If such a circulation capability

is required then it is necessary to install a tubing component which will allow annulus

communication or alternatively rely upon the ability to perforate the tubing which

consequently would necessitate tubing replacement prior to the recommencement of

29

Production Engineering – I Herish N. Hamarash

production. In both cases, the circulation point is normally as deep in the well as possible,

but above the packer. This completion system is by far the most widely used and offers

maximum well security and control. See Figure - 22 bellow:

Figure - 22: Tubing Flow with Annulus Isolation

Completion String

For any completion string we can define a range of operations or capabilities which may be

required. Some of the capabilities are considered to be essential, such as those providing

operational security or safety, whilst others can provide improved performance or flexibility.

However, as the degree of flexibility provided by the completion is increased, the more complex

is the design process and normally a sophisticated design will result which includes a large number

of string components.

Basic completion string functions and facilities

The basic facilities provided by a completion string must allow it to continue the production or

injection of fluids over as long a period as possible without major intervention to conduct well

repairs. Further, at all times, the design must ensure the safe operation of the well and reliably

allow for its shutdown in a variety of situations.

The completion string, production casing and wellhead must act as a composite pressure system

which prevents formation fluids and pressure escaping from the reservoir except via the production

tubing and the Xmas Tree into the surface processing facilities.

The following are considered to be the essential attributes for the majority of completion string

installations:

30

Production Engineering – I Herish N. Hamarash

A. The ability to contain anticipated flowing pressure and any hydraulic pressures

which may be employed in well operations and conduct fluid to surface

(production) or the reservoir (injection wells) with minimal flowing pressure loss

and optimal flow stability.

B. The ability to isolate the annulus between the casing and the production tubing if

flow instability is likely or it is desirable to minimize reservoir fluid contact with

the production casing.

C. The ability to affect downhole shut-in either by remote control or directly activated

by changing well flowing conditions, in the event that isolation at surface is not

possible.

D. A means to communicate or circulate (selectively when required) between the

annulus and the tubing.

E. A provision for physical isolation of the tubing by the installation of a plug to allow

routine isolation e.g. for pressure testing of the tubing.

Figure - 23 bellow is showing the general completion string components:

Figure - 23: General well completion string

31

Production Engineering – I Herish N. Hamarash

Conventional tubular configurations

:

The conventional completions methods consist of production casing have outside diameter

greater than 4 ½ inch, and include this is because that there are sizes production tubing vary to

reach 4 ½ inches;

Single-zone completion

Factors leading to selection of single-zone “conventional” completions:

1- High production rates.

2- Corrosive well fluids.

3- Operator tradition.

4- High pressures governmental policies.

Probability of well competition for single-zone depending on objectives from well drilling, and

that include:

Well produce through production casing

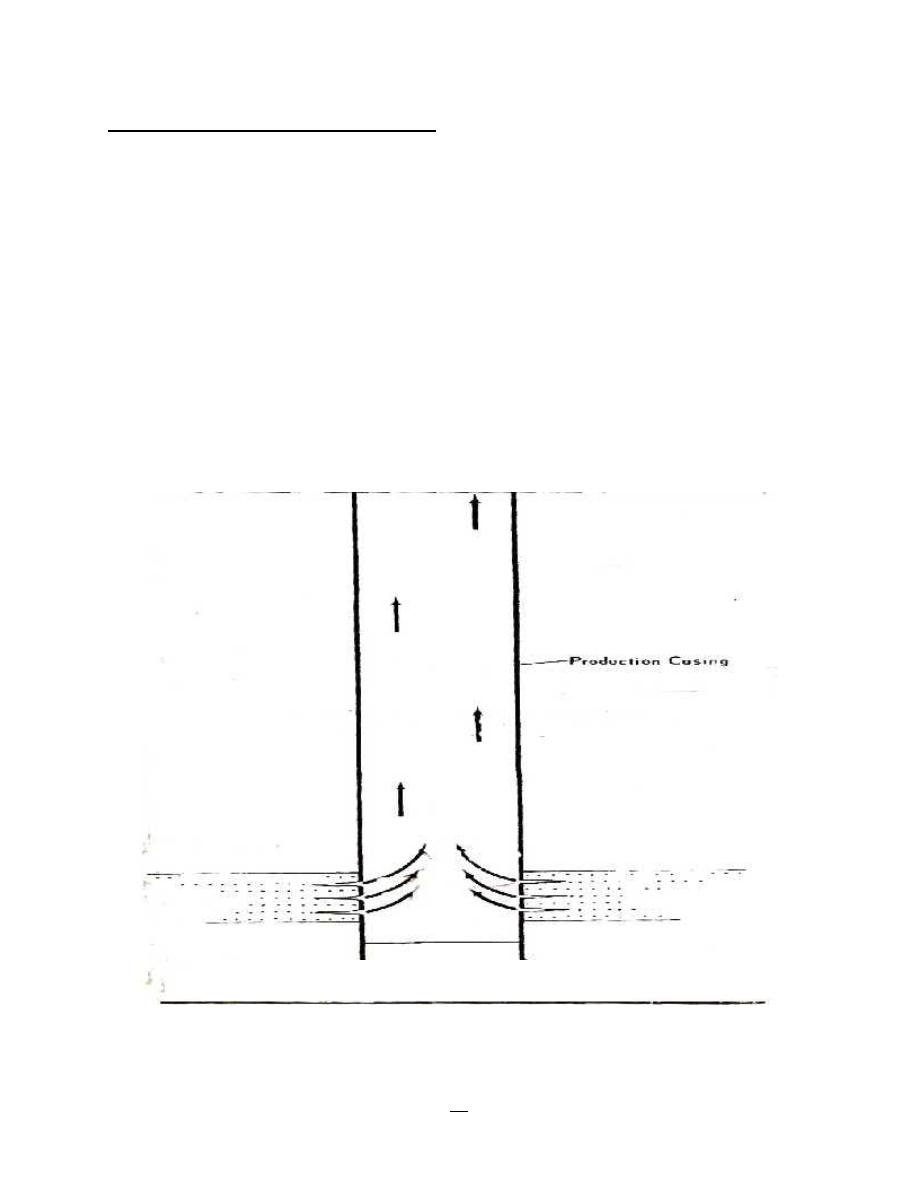

This type of completion use in wells produce with high production rates and medium or low closed,

flowing pressures. See figure - 24:

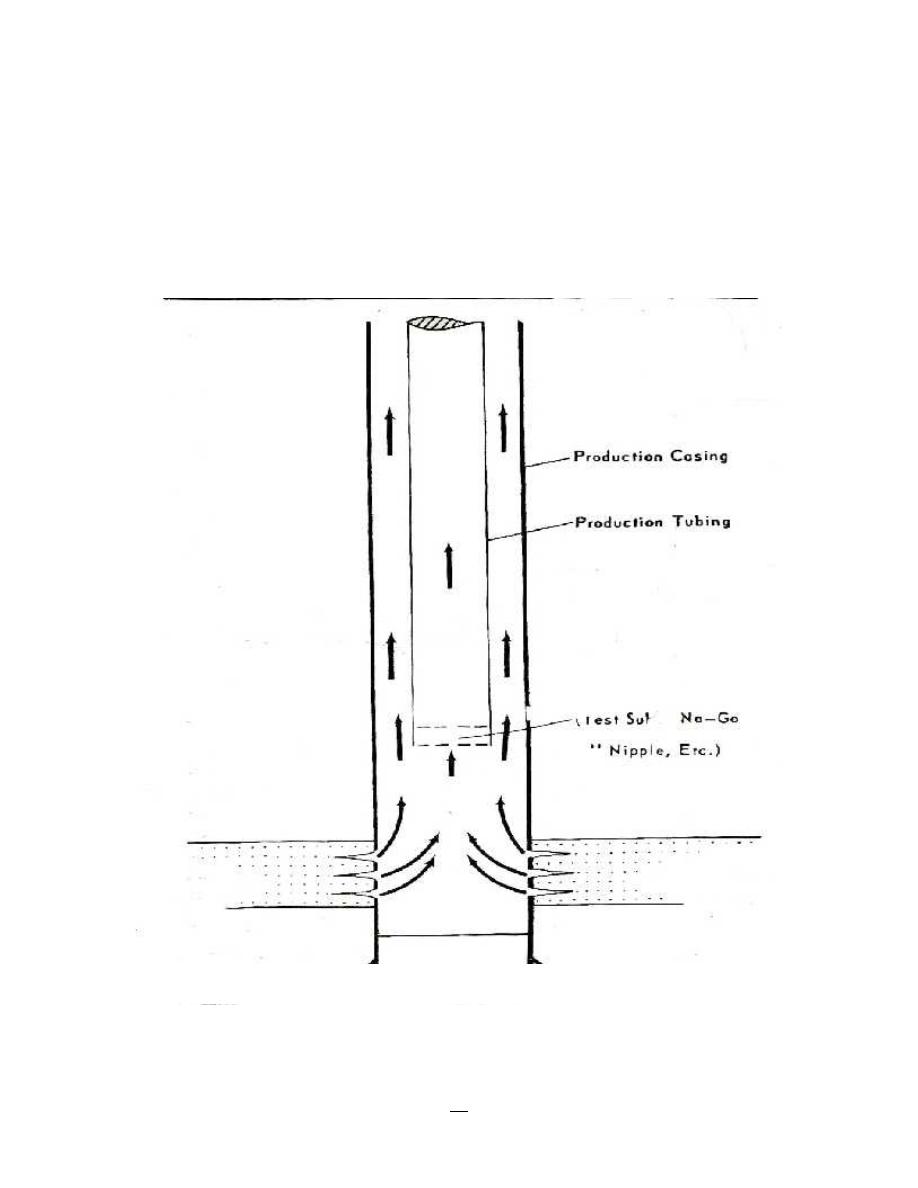

Well produce through production casing and production tubing

Figure - 24: Well produce through production casing

32

Production Engineering – I Herish N. Hamarash

In this type of completion the well produce through annulus and tubing in same time, but the

production rate in this type being less than in type of producing through production casing. See

figure - 25. Valid reasons for tubing may include:

6- Better flow efficiency.

7- Permit circulation of kill fluids, corrosion inhibitors or paraffin solvents.

8- Provide multiple flow paths for artificial lift system.

9- Protect casing from corrosion, abrasion, or pressure.

10- Provide indicate of monitoring bottom-hole flowing pressure.

Figure – 25: Well produce through production casing and production tubing

33

Production Engineering – I Herish N. Hamarash

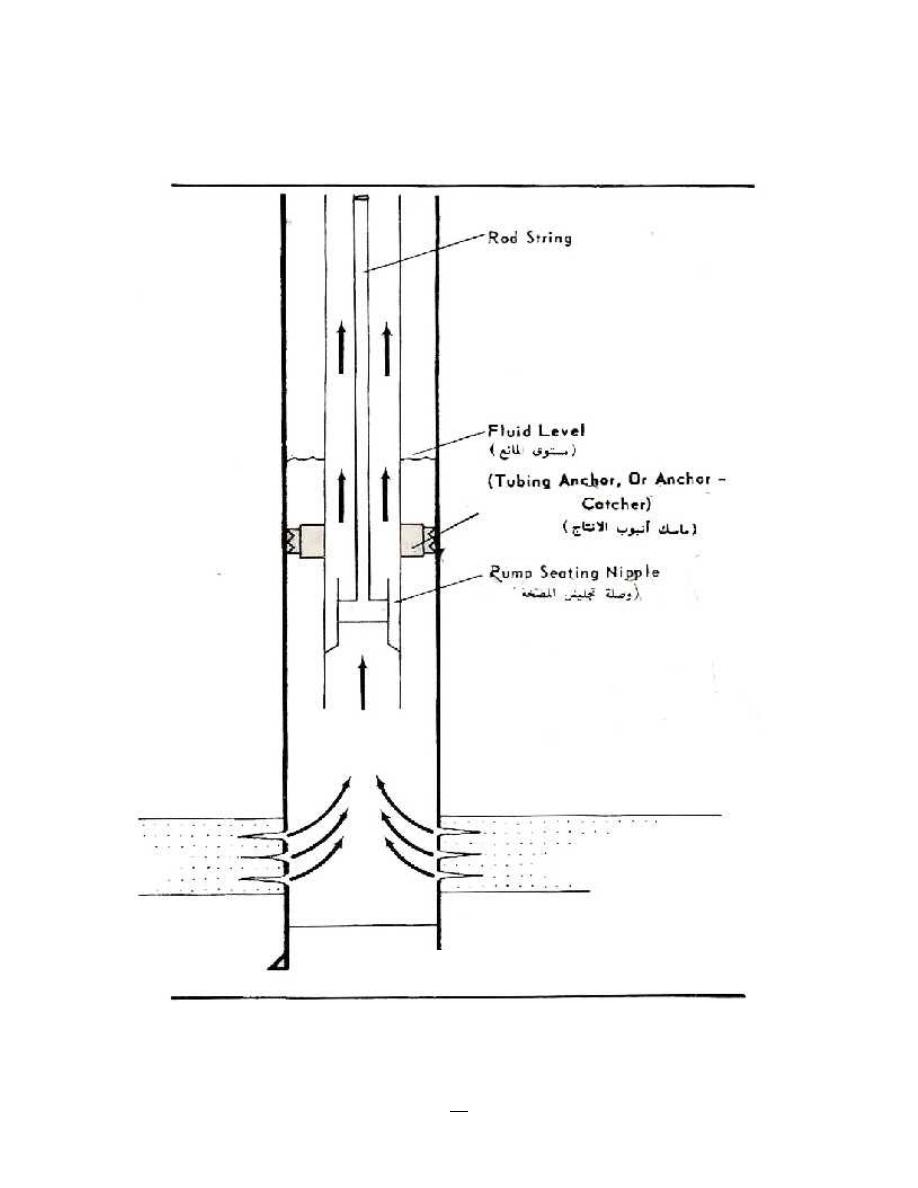

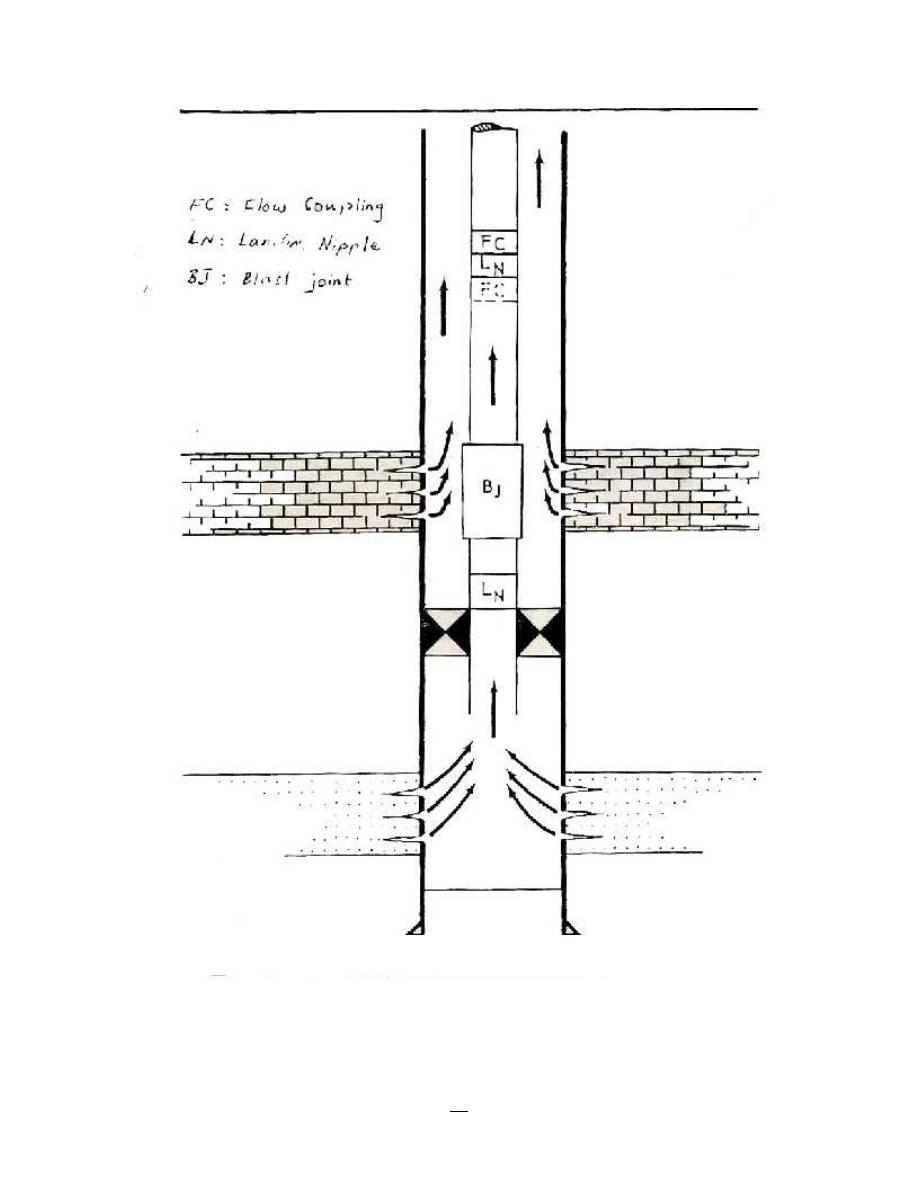

Well produce by artificial lift

In this type the well produce by pumping, where the tubing run in hole with pump seating nipple

to depth below working fluid level in well, see figure - 26.

Figure - 26: Well produce by pumping

34

Production Engineering – I Herish N. Hamarash

Well produce through production tubing

The well completed by using tubing and single production packer, in this completion the maximum

potential of well to produce by high flow rate impossible, compare with the well produce through

production casing and the well produce through production casing and production tubing, see

figure - 27. A packer should be run only where it accomplishes a valid objective such as:

1- Improve or stabilize flow.

2- Protect casing from well fluids or pressure however, it should be recognized that use of a

packer may increase pressure on casing in the event of a tubing leak.

3- Contain pressure in conjunction with an artificial lift system or safety shut-in system.

4- Hold on annular well-killing fluid.

Figure - 27: Well produce through production tubing

35

Production Engineering – I Herish N. Hamarash

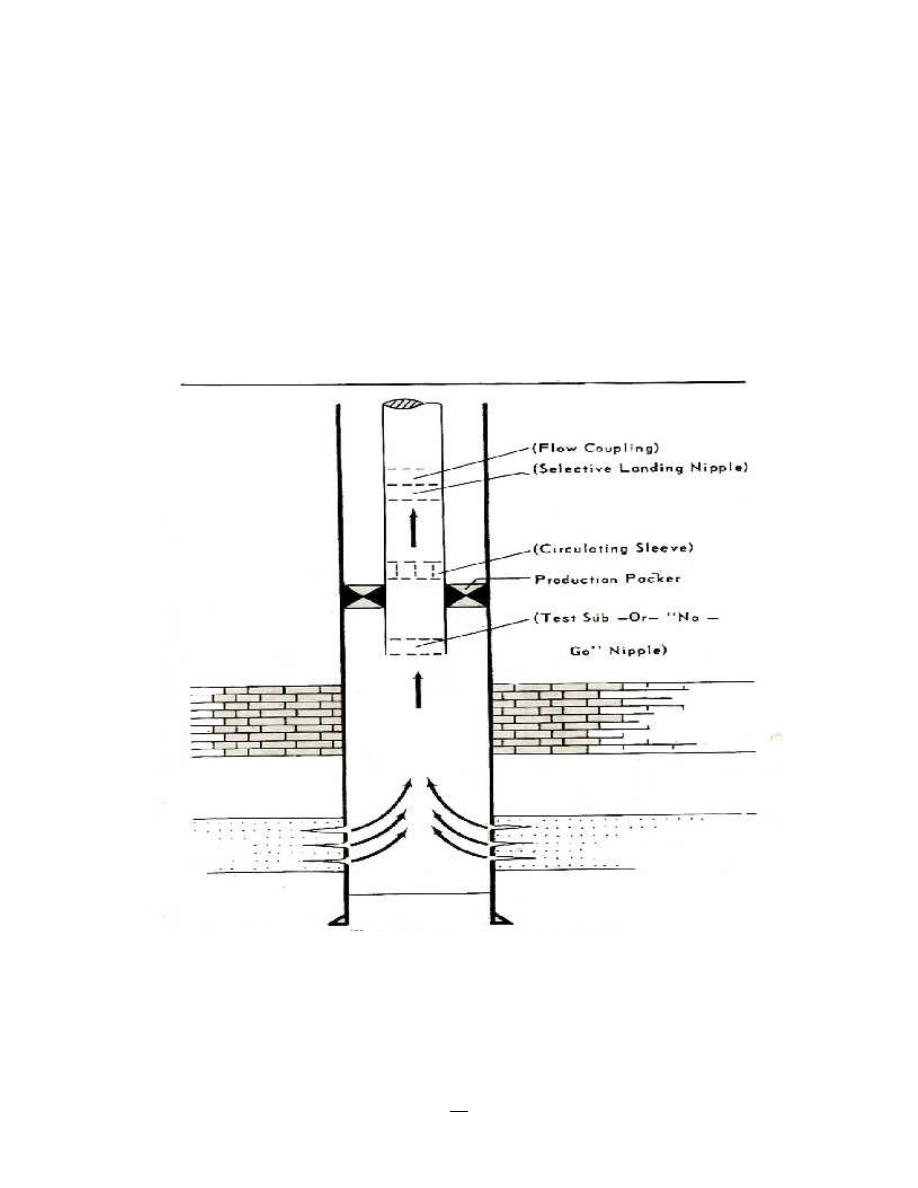

Single- well with alternate completion

This type is used, when the well penetrate two producing formations. The alternate produce

formation perforation at the primary well completion, then isolate by using dual production packer,

the alternate formation started to produce after the lower producing formation depleted by

perforating the part of tubing in front of alternate formation, see figure - 28. Blast joint used in

tubing part in front of alternate producing formation to resist the scratch that cause by produce

fluids, because the blast joint have thick wall.

Figure - 28: Single- well with alternate completion

36

Production Engineering – I Herish N. Hamarash

Multiple-zone completion

Factors leading to selection of multiple completions:

1- High producing rate

2- Faster payout

3- Multi-reservoir control equipments

Numerous configurations are possible utilized single or multiple strings of tubing;

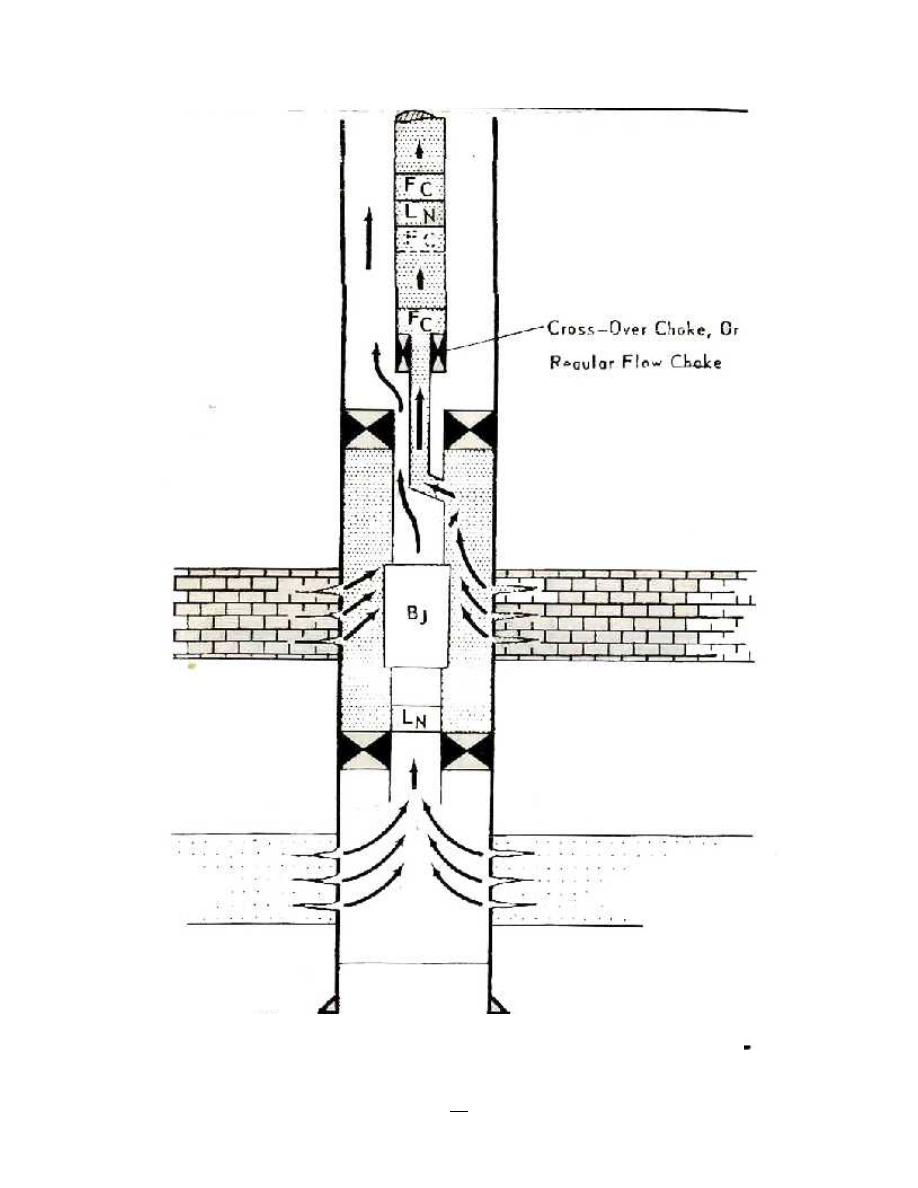

Dual completion-Single string-single packer

There is both tubing and annulus flow, see figure - 29. This is the lowest cost conventional dual.

Limitations

1- Upper zone cannot be produced through tubing, unless lower zone is blanked off.

2- Casing subject to pressure and corrosion.

3- Only lower zone can be artificially lifted.

4- Upper zone sand production may stick tubing.

5- Work-over of upper zone requires killing lower zone.

Cross-over dual completion-Single string-dual packer

Again, There is both tubing and annulus flow, see figure -30. Advantage is that cross-over choke

permits upper zone to be flowed through tubing.

Limitations

1- Casing subject to pressure and corrosion.

2- Must kill both zones for work-over of upper zone.

3- Any zones impossible can be artificially lifted.

37

Production Engineering – I Herish N. Hamarash

Figure - 29: Dual completion-Single string-single packer

38

Production Engineering – I Herish N. Hamarash

Figure – 30: Cross-over dual completion-Single string-dual packer

39

Production Engineering – I Herish N. Hamarash

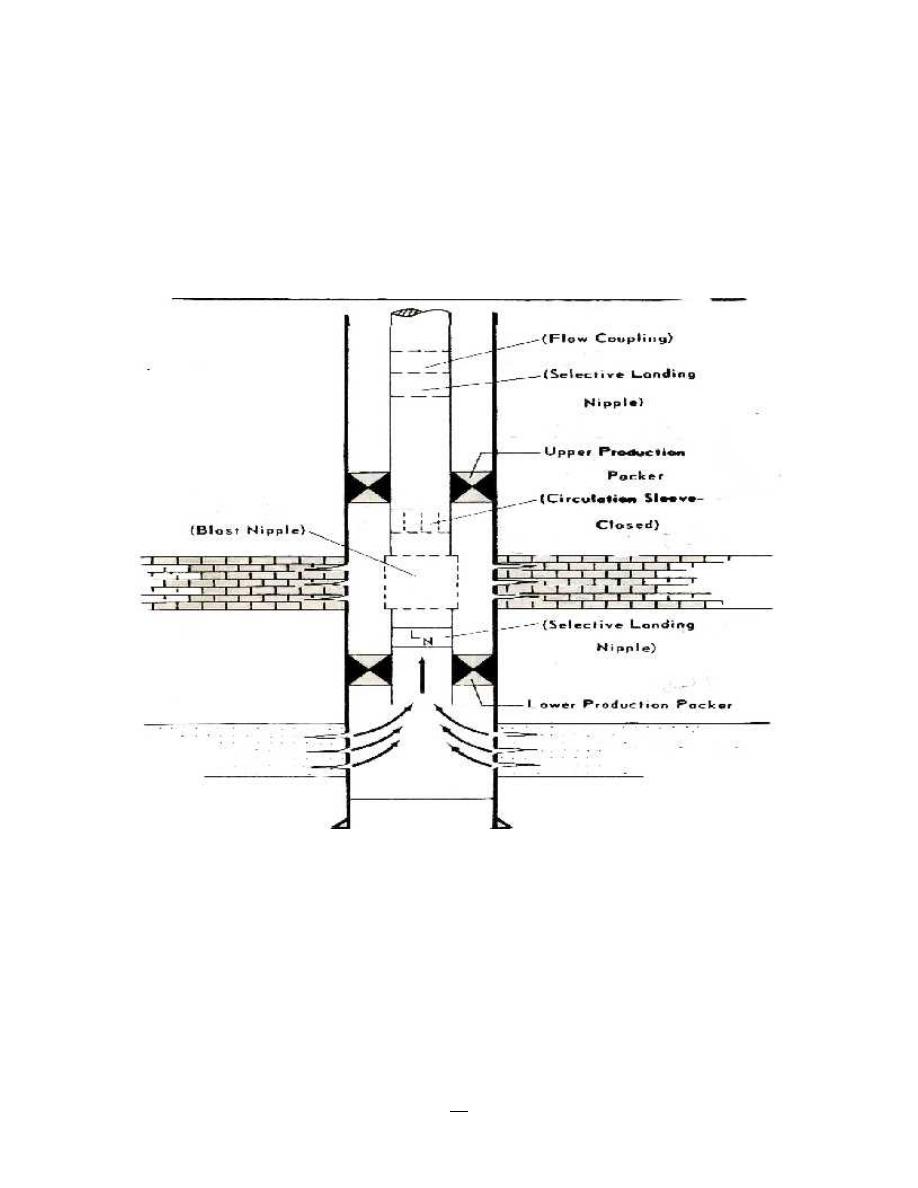

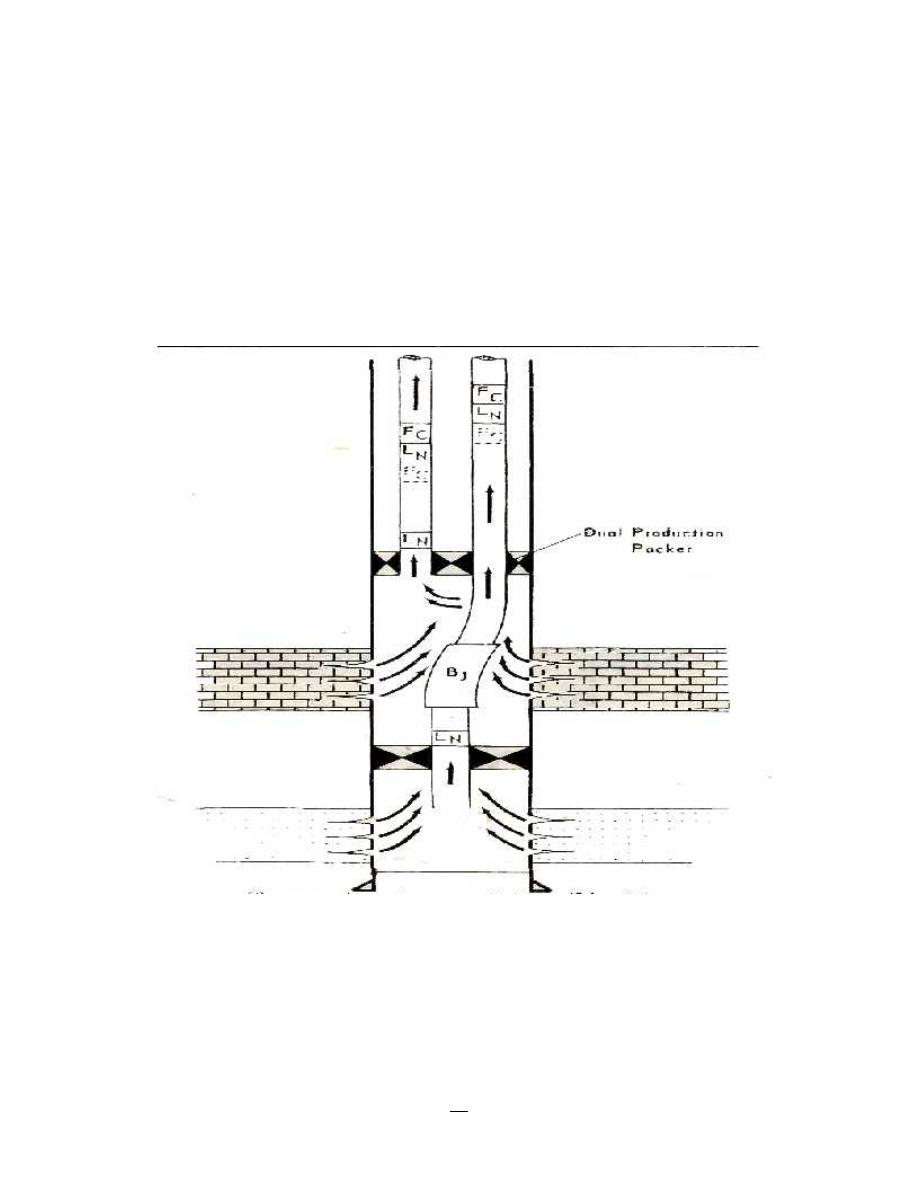

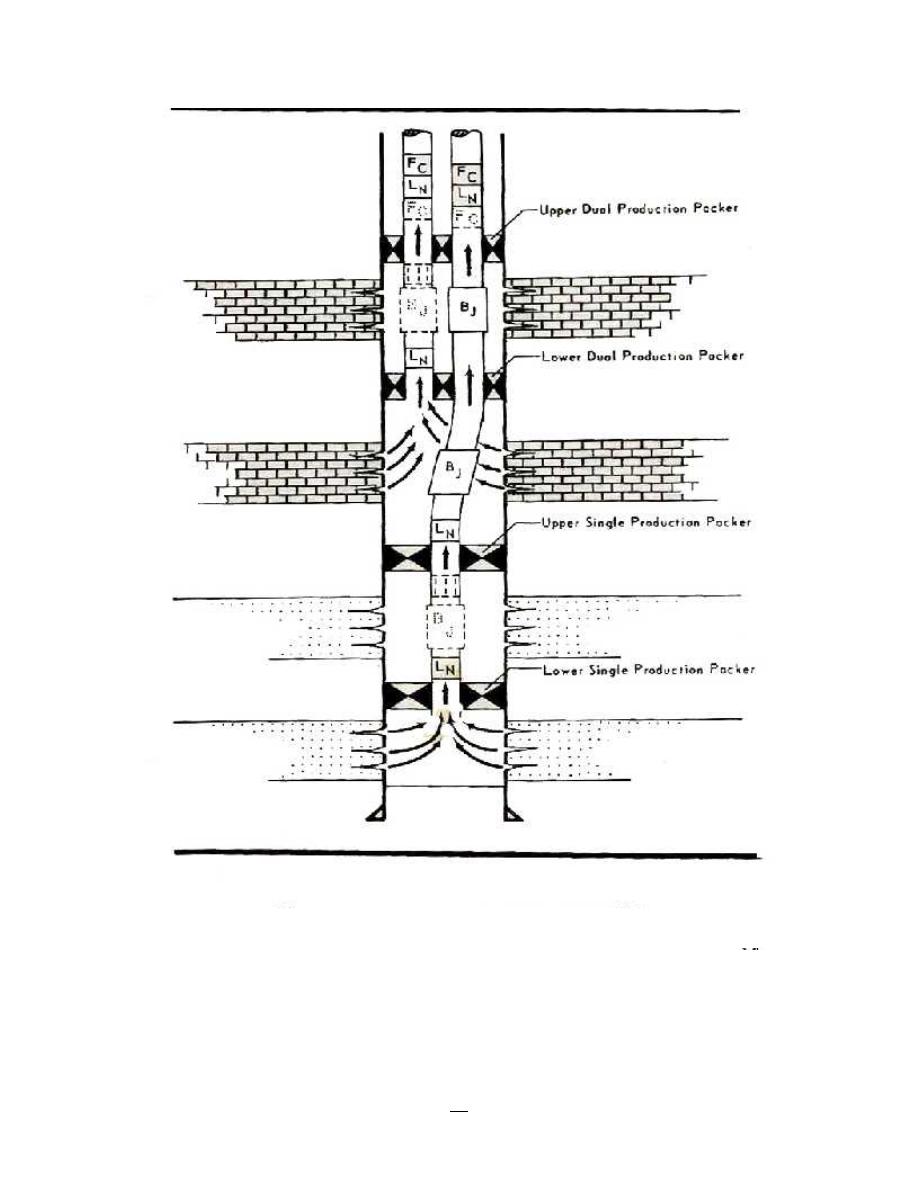

Dual completion-Parallel string-multiple packer

This is shown in figure - 31.

Advantages

1- Can lift several zones simultaneously.

2- Concentric tubing and wire line work-over practical in all zones.

Limitations

1- High cost.

2- Susceptibility to tubing and packer leaks.

3- Hesitation to perform stimulation treatments or work-over of individual zones.

Parallel dual completion with two alternate completions.

This is shown in figure - 32.

Limitations

Difficult of treating or even reperforating individual zones unless well is killed and tubing is pulled

Figure - 31: Dual completion-Parallel string-multiple packer

40

Production Engineering – I Herish N. Hamarash

Figure - 32: Parallel dual completion with two alternate completions

41

Production Engineering – I Herish N. Hamarash

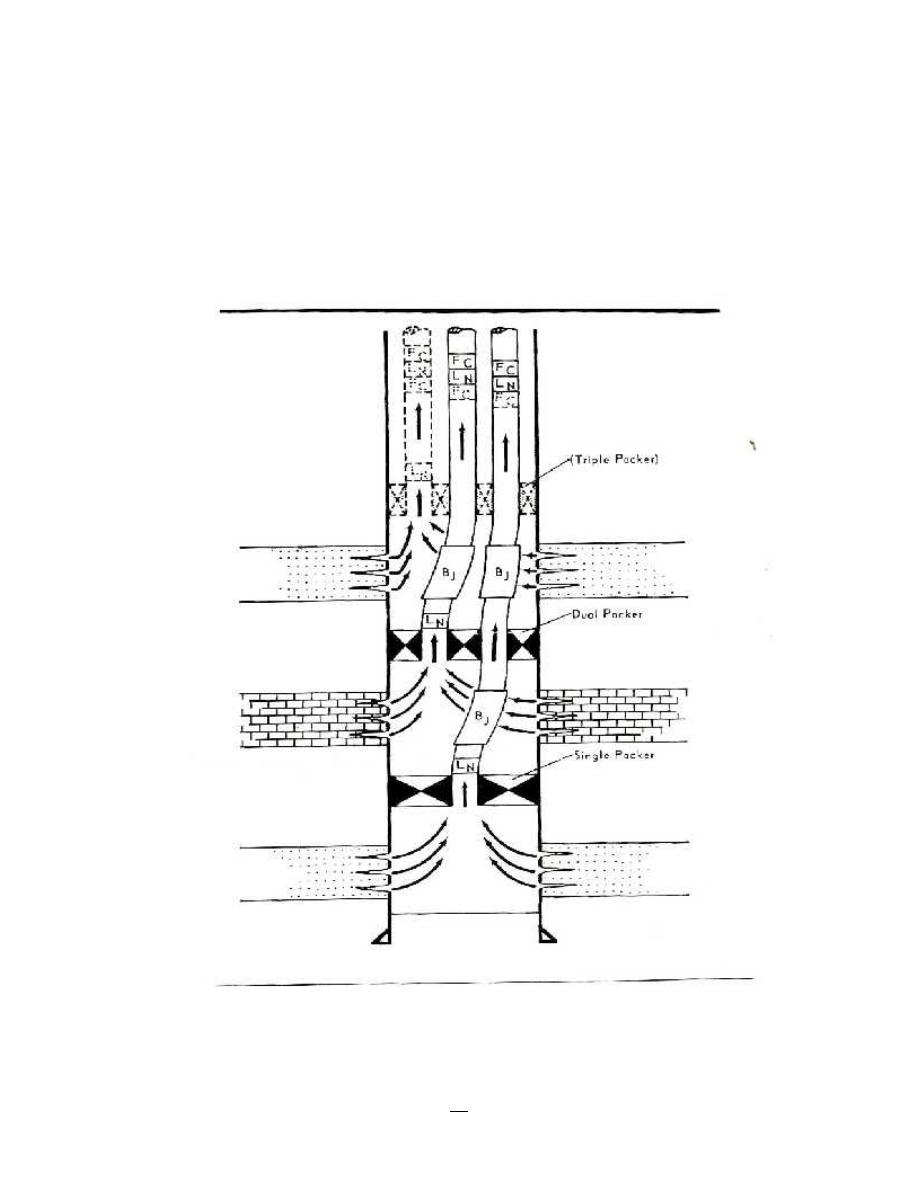

Triple completion

In this completion design, two or three production tubing used with production packers, see figure

- 33. In this type could produce with high production rates in one well, that make faster payout.

Limitations

1- Difficult made this completion.

May be communication occur between the fluids inside well, that produce from the three

formations

Figure – 33: Triple completion

42

Production Engineering – I Herish N. Hamarash

Completion Equipment

1- Production casing

Production casing is the last casing, which runs in hole then seated and cemented. In some

completions design the producing fluids produce through production casing, also run through it

production tubing and production packer. The different types of casing are classified according to

API standard classification. Selecting of casing type depending on completion programmer factors

and operating condition.

2- Production Tubing

The production tubing runs in hole for production and well control purpose, and to run in hole

measurement instrument through it. There are several types of tubing according to standard API.

3- Liner

Liner is part of casing which hanger in well, it doesn’t run from surface. Used to satisfy two

purposes:

1- Reduce the cost, which can be used as alternative to casing run from surface, when the

casing was damaged.

2- Used in sand control and gas coning.

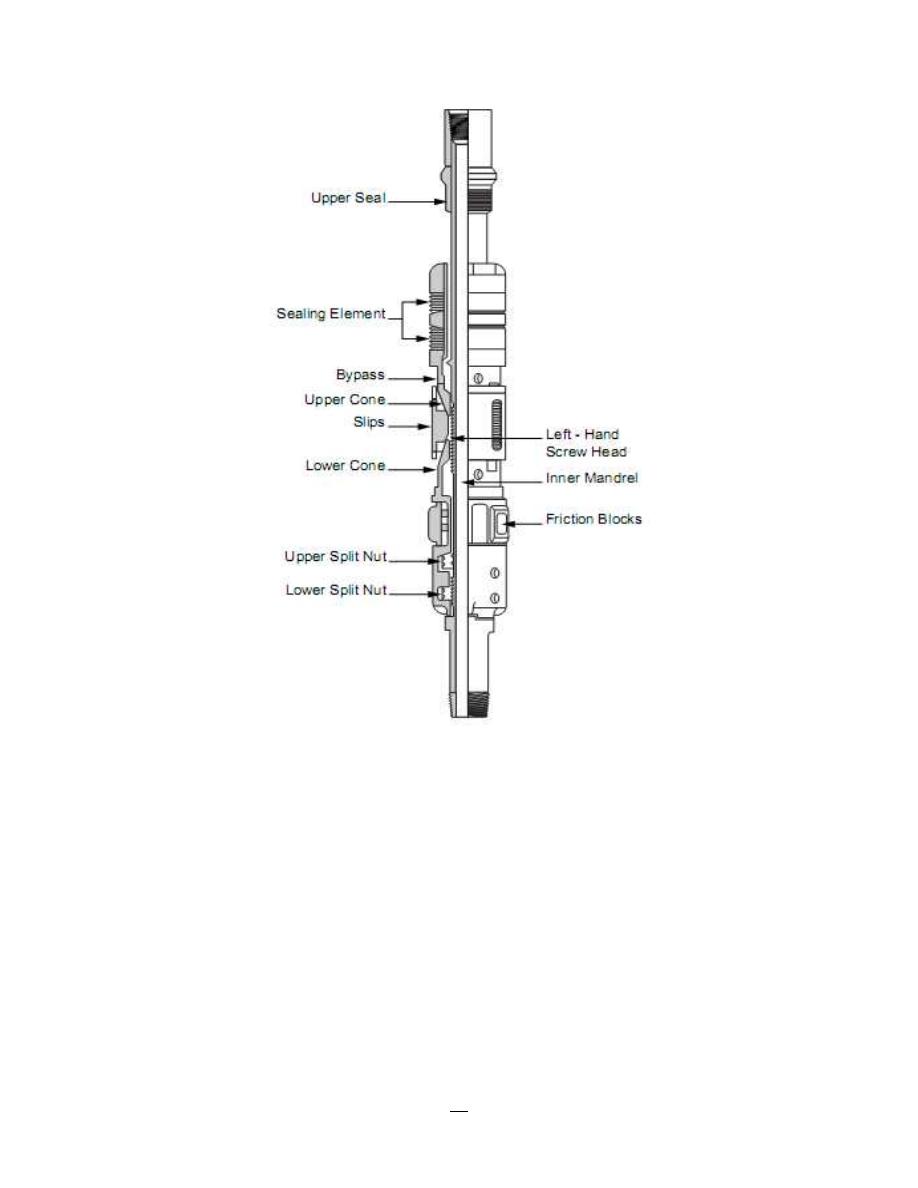

4- Production packer

Generally, production packers are classified into two types; permanent packer (this type could not

pull it out of hole, unless milling it then cleanout) and retrievable packer (this type could pull it

out of hole mechanically and can used it again). The main purpose from using packer is to isolate

the annulus from production zone (see figure –34 for the major components in production packer),

and it is useful to the following matters;

1- Protection the upper parts of casing from high pressure, and from any reaction with the

fluids that cause corrosion of casing in cases of production, injection and stimulation.

2- Protection the well form any leaks occur in casing.

3- Using in conjunction with subsurface safety valves (SSSV) to provide the safety.

4- To hold kill fluids or treating fluids in casing annulus.

43

Production Engineering – I Herish N. Hamarash

Figure - 34: Major Components of Production Packer

44

Production Engineering – I Herish N. Hamarash

5- Sliding Sleeve

Sliding sleeve is a nipple seat above production packer, used to open production tubing above

packer for fluids circulation operations and control on well in work-over operations. This nipple

opened and closed by special tools run in well by slick-line through tubing.

6- Subsurface Control Equipment

This equipment involves:

1- Subsurface safety valves (SSSV) used inside tubing which plug the tubing (close in the

well) at a certain depth in case the surface valves failed. Such as Ball valves and flapper

valves. These valves can control directly and indirectly.

2- Bottom hole-chokes and regulator used to reduce well head flowing pressure to prevent

hydrates (fluid freezing) in surface control equipment and surface flowing lines. This

equipment used in wells has high pressure, such as Ground Seat Bean and Positive Orifice

Bean.

3- Subsurface safety valves (chock valves) for injection wells, this valves used to prevent

reverse flow (back flow, control on flow direction), such as stem and seat valve and ball

valve.

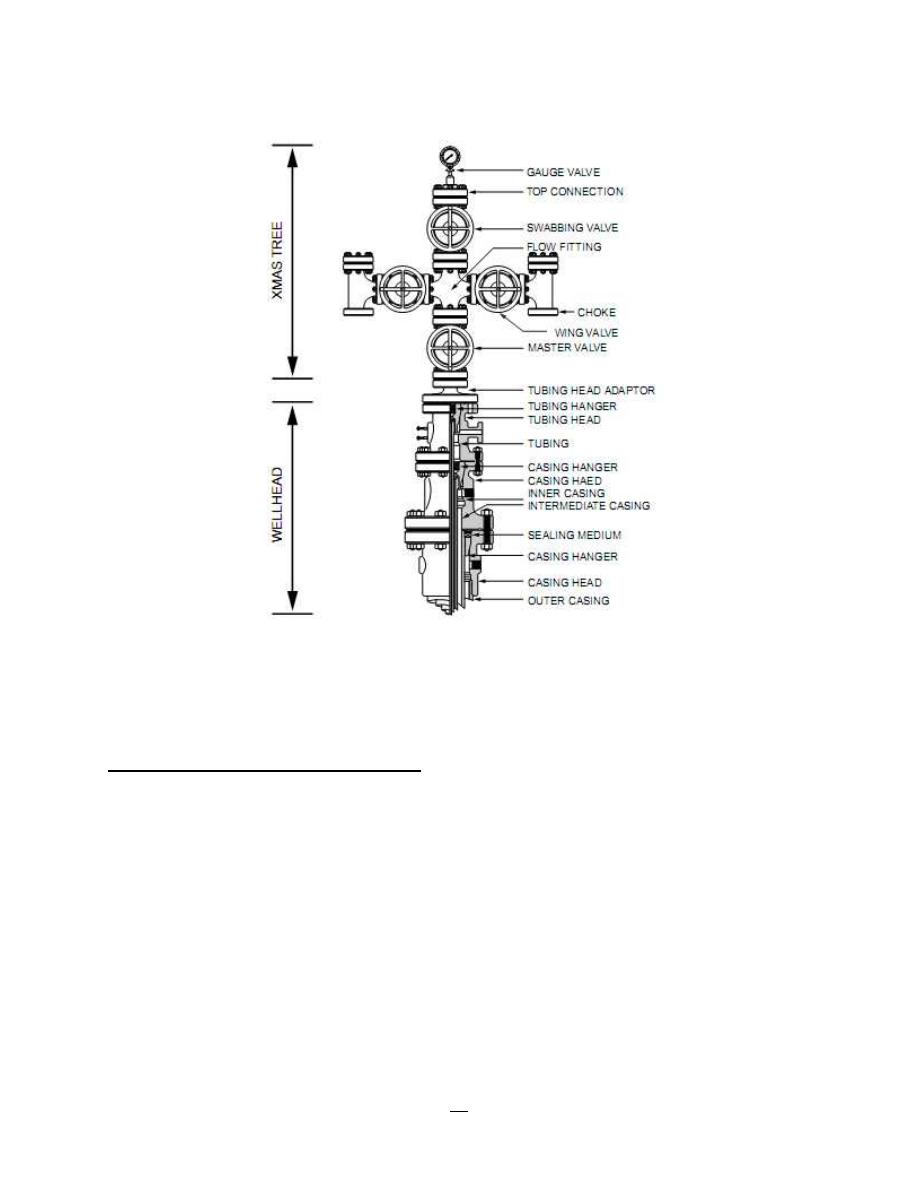

7- Wellhead/Xmas Tree

The wellhead provides the basis for the mechanical construction of the well at surface. It provides

for:

Suspension of all individual casings and tubulars, concentrically in the well.

Ability to install a surface closure/flow control device on top of the well namely:

-

Blow Out Preventer during drilling

-

X-mass tree for production and injection

Hydraulic access to the annuli between casing to allow cement placement and between

the production casing and tubing for well circulation.

The purpose of the Xmas tree is to provide valve control of the fluids produced from or injected

into the well. The Xmas tree is normally flanged up to the wellhead system after running the

production tubing. The wellhead provides the facility for suspending the casing strings and

production tubing in the well. There are a number of basic designs for Xmas trees, one of the

simplest is shown in Figure -35. Briefly, it can be seen that it comprises 2 wing valve outlets,

normally one for production and the other for injection, e.g. well killing. Additionally, the third

outlet provides vertical access into the tubing for wireline concentric conveyancing of wireline or

coiled tubing tools.

The lower valve is the master valve and it controls all hydraulic and mechanical access to the well.

In some cases, the importance of this valve to well safety is so great that it is duplicated. All outlets

have valves which in some cases are manually operated or in the case of sophisticated platform

systems and subsea wellsare remotely controlled hydraulic valves operated from a control room.

45

Production Engineering – I Herish N. Hamarash

Figure - 35: Simple Wellhead Assembly including Casing Spools and Xmas Tree

Production packer setting methods

1- Mechanical setting method

Production packer seated by moving production tubing in a certain direction, based on that there

are three types of packers:

A- Weight-Set Packer

The weight set packer is economical and ideally suited to low pressure situation, this packer

employ a slip and cone arrangement with the slips attached to a friction device such as drag springs

or drag blocks. The friction device engages the casing and holds the slips stationary with respect

to the remainder of the packer, see figure - 36.

The vertical movement of tubing causes the cone to move behind the slips and anchor the packer

in the casing. Tubing weight is then applied to expand the packing element (rubber element).

Release is affected by picking up tubing weight to pull the cone from behind the slips.

46

Production Engineering – I Herish N. Hamarash

Figure -36: Weight set packer

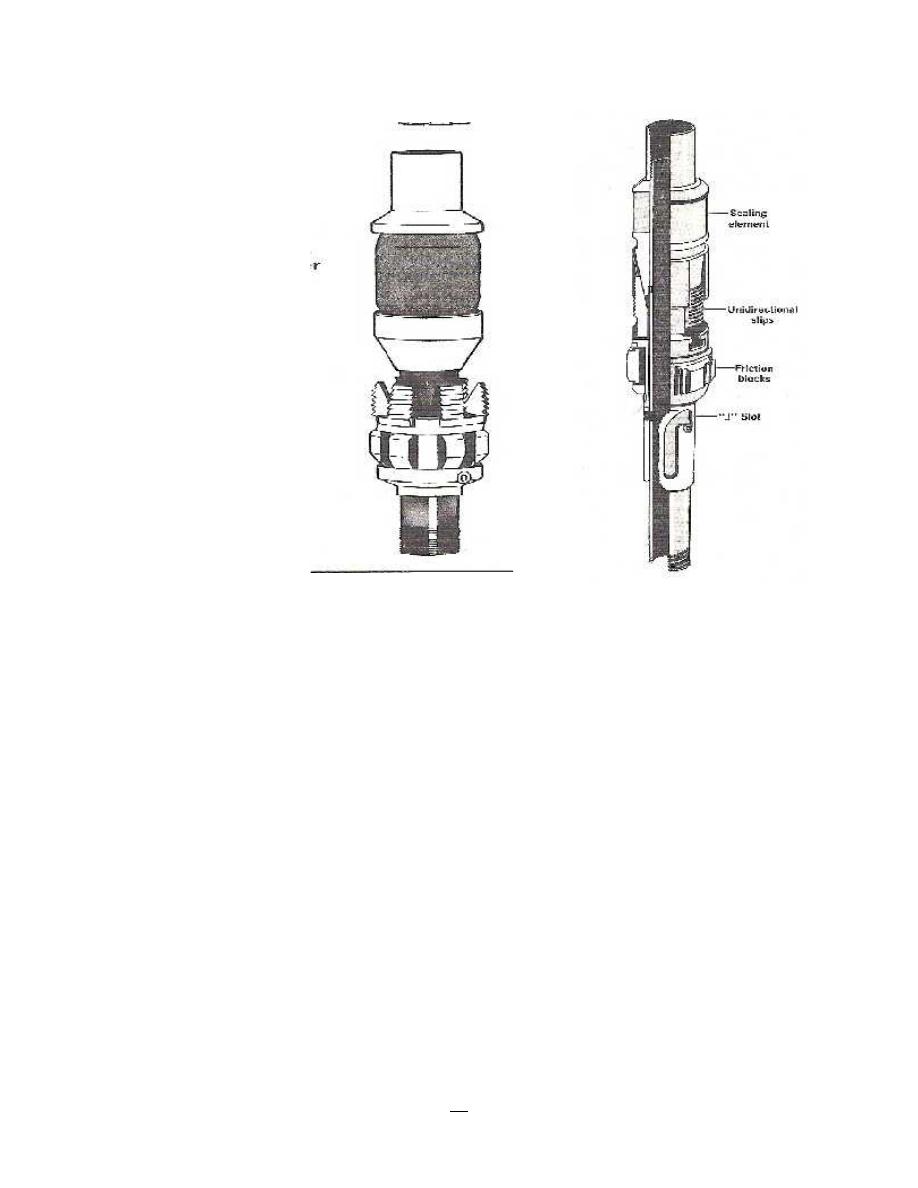

B- Tension-Set Packer

Tension packers are frequently used in shallow wells where insufficient tubing weight is available

to seal a weight-set packer. It are essentially set by pulling tension on the tubing by run the tubing

upside, release is effected by supply tension (run downside the tubing weight).

This features renders the tension packer particularly suitable for water injection wells or

stimulation work.

C- Rotational -Set Packer

These types of packers are set by rotate the production tubing and supply tubing weight in same

time or by rotate only, Release or back of the packer is effected by rotate the tubing to right

direction. It’s better to use this type in vertical shallow or medium wells.

2- Hydraulic Setting method

The packer with production tubing runs in hole through casing to a certain depth, after that the

packer set hydraulically by supply or increase the pressure gradually inside tubing. There is shear

plug below the packer, which cause pressure increased inside tubing (close tubing end) during

47

Production Engineering – I Herish N. Hamarash

packer setting operation, then it opened by drop steel segment or increased the pressure to critical

value. There is another type of packers, which the tubing closed below packer by steel ball or

equalizing check valve set in special nipple below packer. Principle advantage to use this type is:

the tubing can be landed, Christmas tree installed, and well circulated with a light fluid or gas

before setting the packer to initiate production without swabbing.

3- Electric setting method

By wire-line and electric cable the entire assembly packer is run in hole to the desired setting

depth. An electrically detonated powder charge was exploded inside packer that causes movement

of setting tools which set the packer, then the production tubing run in to engage with packer.

Well Completion Program

Well completion operations beginning after ending well drilling and cementing the production

casing. The well completion operations is very important therefore, it should be take in account all

risk and problems that predicted occurred on well in well completion program, and provide all

important required equipment and tools, these operations done by used drilling or work-over rig,

and sometimes need exist fire man in the location.

We will take simple well completion program for cased hole well to illustrate the operations steps;

1- Run in hole the last casing (production casing), land and cement it. At least wait for 72

hours to dry the cement. then install blow out preventers (BOP`s).

2- Run in hole adequate bit by drilling pipes to clean the well-bore from any residual cement,

also to check the bottom hole (total depth). Circulating the drill mud inside the well to sure

that well-bore be cleaning, then pull out of hole drilling pipes and bit.

3- Run in hole Cement Bond Log (CBL) to check the quality of cementing of production

casing.

4- Run in hole production tubing to bottom hole, then displace drill mud by completion fluid

through tubing until clean the well-bore from drill mud.

5- Observe the well behavior by notice any flow of completion fluid, that take indicate for

any leaks in production casing.

6-

In case of no leaks, and the well behavior is normal (static) after displace the mud, then

the tubing is rise and hang to depth above the highest perforated about 30 meters. After

that the well is observed to insure from the well and pressure stabilized.

7- Removed the BOP`s, and install the tubing head spool (donate).

8- Install X-mas tree and construct the valves, then test the X-mas and valve by work pressure

for time at least 15 minute per valve.

9- Install special perforating equipment on well head, which include pressure control

equipment and container that contain bullet and accessories.

10- Put the bullet gun in container, which the bullet is arranged according to perforating

configuration and with respect to depth of the perforated zone.

48

Production Engineering – I Herish N. Hamarash

11- After set the container on X-mas tree, the master valves is opened then the bullet gun run

in hole to depth of the zone that will be perforated. In perforated operations, the casing

joints are avoided to perforated which the casing joints locater are characterized by run in

hole Casing Collar Locater (CCL) log.

12- The zone will perforate by bomb the bullet from surface by special control station,

generally noticed increased the well head pressure after the perforated of the production

zone.

13- Pull out of hole the bullet gun and accessories to surface and closed the X-mas valves, the

well head pressure continued increased gradually.

14- The well head valves (tubing and annulus valves) linked to burn pipe to burn the fluid in

burn pit.

15- The well opened to flow by small choke size for cleanout purpose, the hydrocarbons fluid

was burned in burn pit that far about 300 meters from the well.

16- The burned of hydrocarbons was continued until the well cleaned from completion fluid or

water or residual drill mud, and the well reached stabilized condition. Then the well closed

and it will be ready to done evaluated tests.

49

Production Engineering – I Herish N. Hamarash

Perforation

Perforating of Oil and Gas Wells

In the majority of completions, once the reservoir has been drilled, production casing or a liner is

run into the well and cemented in place. To provide the communication path between the reservoir

and the wellbore, it will be necessary to produce holes through the wall of the casing, the cement

sheath and penetrate into the formation. This is accomplished by a technique called perforating.

The basic operation requires that a series of explosive charges are lowered into the well either on

an electric conductor (wireline cable), or on tubing or drillstring, and when the charges are located

at the required depth, they are detonated to produce a series of perforations through the wall of the

casing and the cement sheath.

Since the perforations will hopefully provide the only communication between reservoir and

wellbore, it is necessary to carefully design and execute the perforating operation, to provide the

required degree of reservoir depletion control and maximize well productivity/injectivity.

Although technology is available insure good perforating in most wells, unsatisfactory perforating

tends to be rule in many areas. The three most prevalent causes for poor perforating probably are:

1- A lack of understanding of the requirements for optimum perforating.

2- Inadequate control of gun clearance.

3-

The rather widespread practice of a warding perforating job on the basis of price, rather

than job quality.

Perforating Techniques

There are three main perforating methods of cased wells:

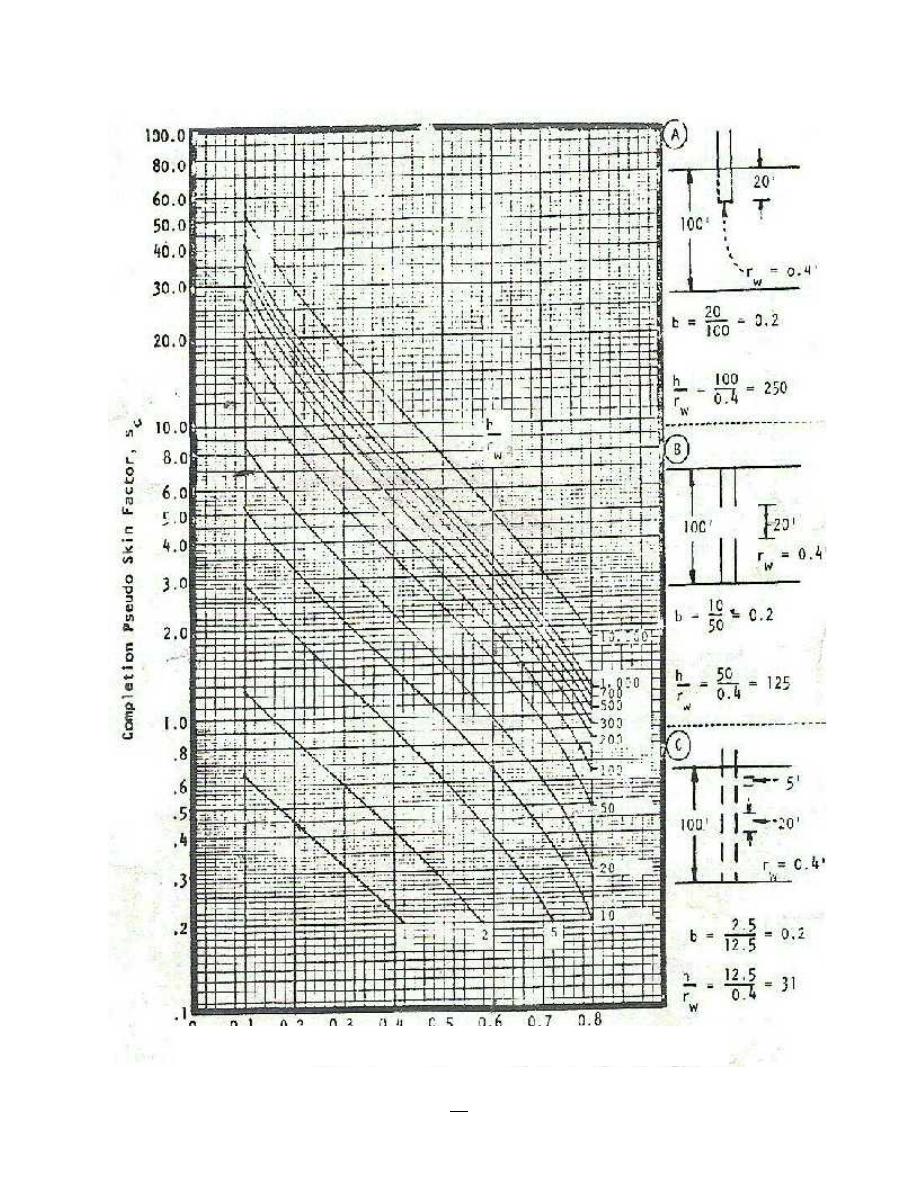

1- Bullet Perforators

Bullet guns have outside diameter 3 ¼ inch or larger, are applicable in the formation with

compressive strength less than about 6000 psi. Bullet perforators in the 3 ¼ inch or larger size

range, may provide deeper penetration that many jet guns in formations with less than about 2000

psi compressive strength.

This type could not used it through X-mas tree and tubing because the larger size of outsider

diameter of bullet guns, therefore, it used under drill mud control and install BOP`s on well head.

The Bullet guns run in hole by wire-line and connected with electric bomb instrument, when the

bullet is shoot, its velocity reached about 3300 ft/sec and it penetrate the casing and formation to

depth about 5 inch. The bullet loses velocity and energy when the gun clearance exceeds 0.5 inch.

50

Production Engineering – I Herish N. Hamarash

2- Jet perforators

This type characterized small size of Jet guns (2 1/8, 1 11/16 inch), so it could use through X-mas

and production tubing. Therefore, it is the better and more safety method used to perforate the

wells. The bullet consist from a solid metal body moved at a high speed about 20000 ft/sec, which

the solid material convert to liquid because the bomb wave high pressure, that make the bullet

penetrate the casing and formation to depth about 12 inch behind the casing. Bullet density equal

4 bullet/ft of perforated zone.

3- Hydraulic perforators

Used to make a fracture in production casing and the formation behind the casing. The fracture

create hydraulically by inject special liquid with high pressure and high inject velocity through

small choke size (1/4 inch). Sometimes add to inject liquid solid material (like sand) to assist in

penetration of casing and formation.

This method used to penetrate wells that drilled for water injection because this method creating

large perforate, which does not plug easily due to the suspension in the injected water.

See figure - 37 for perforating techniques:

51

Production Engineering – I Herish N. Hamarash

Figure - 37: Perforating Techniques

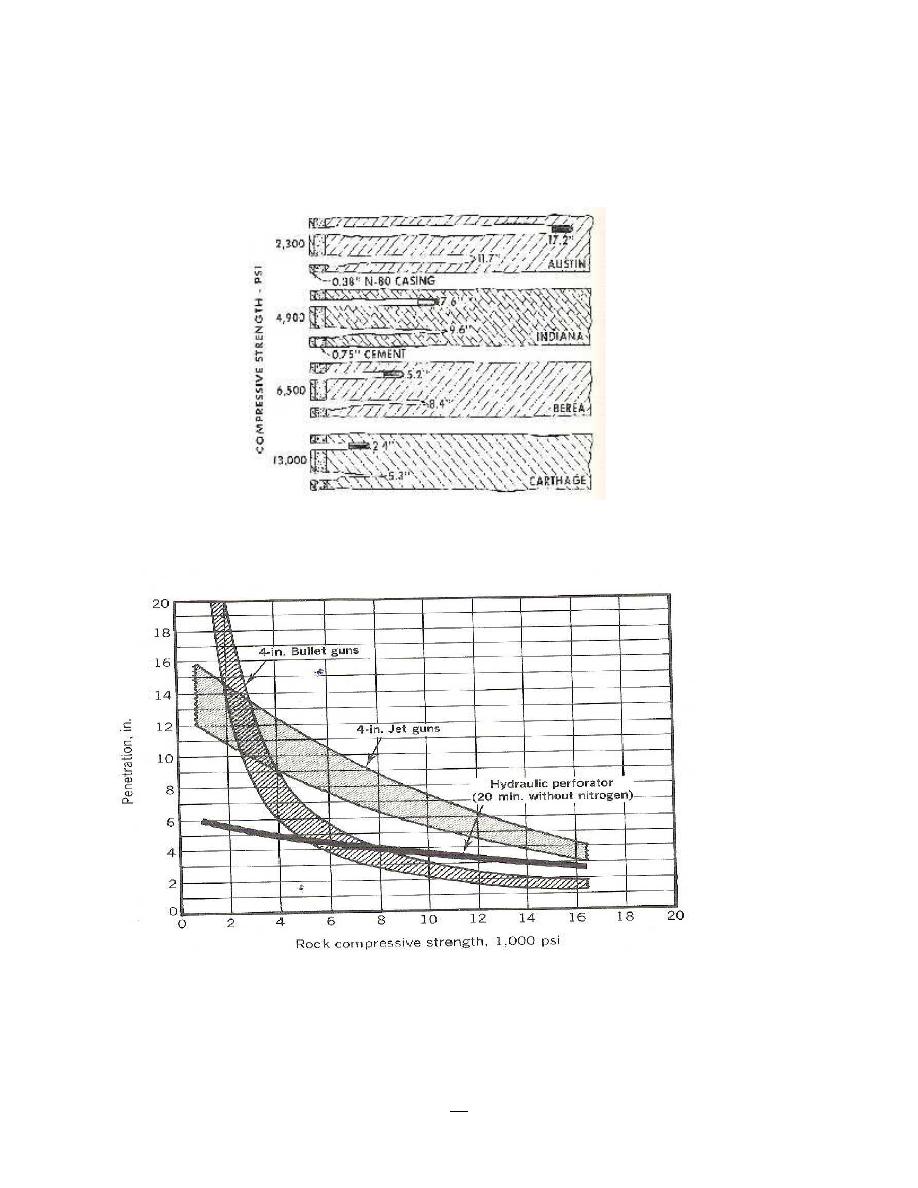

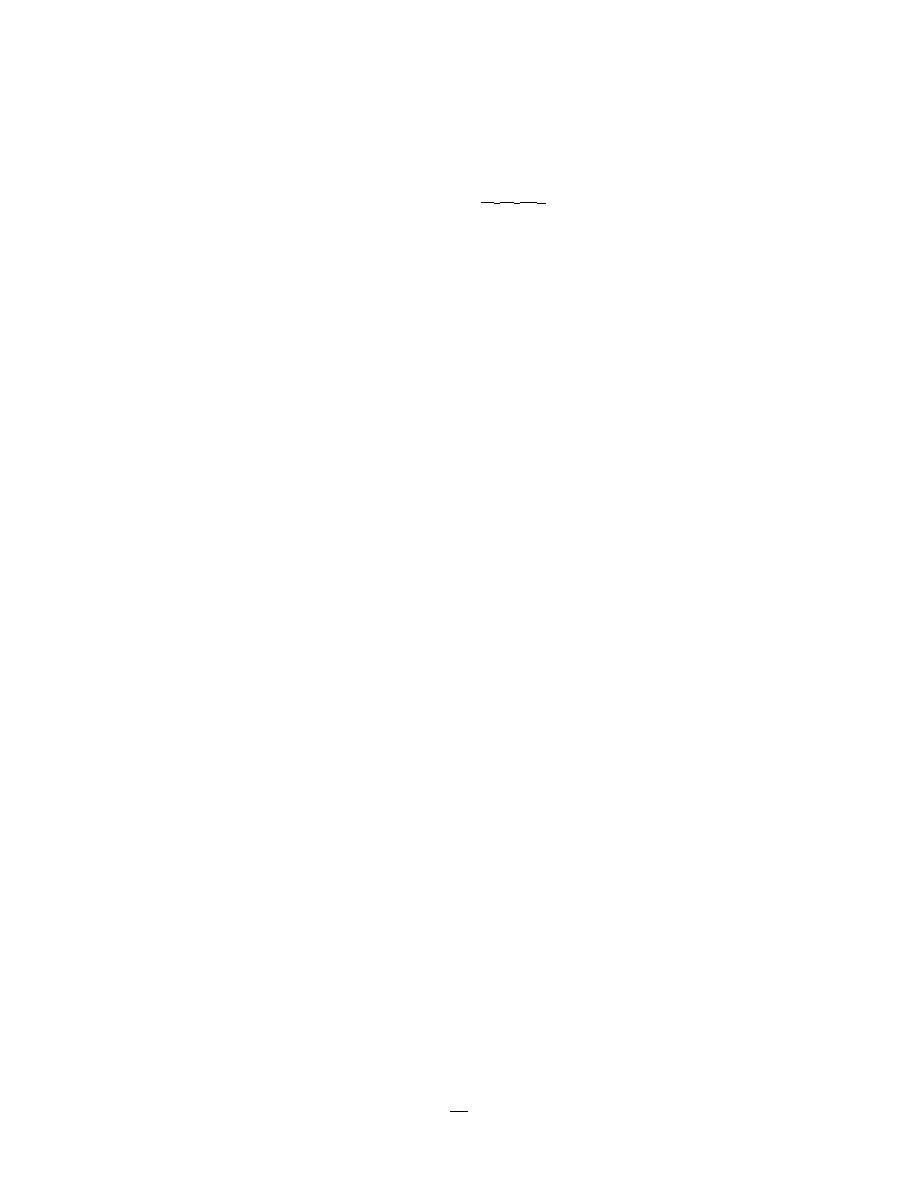

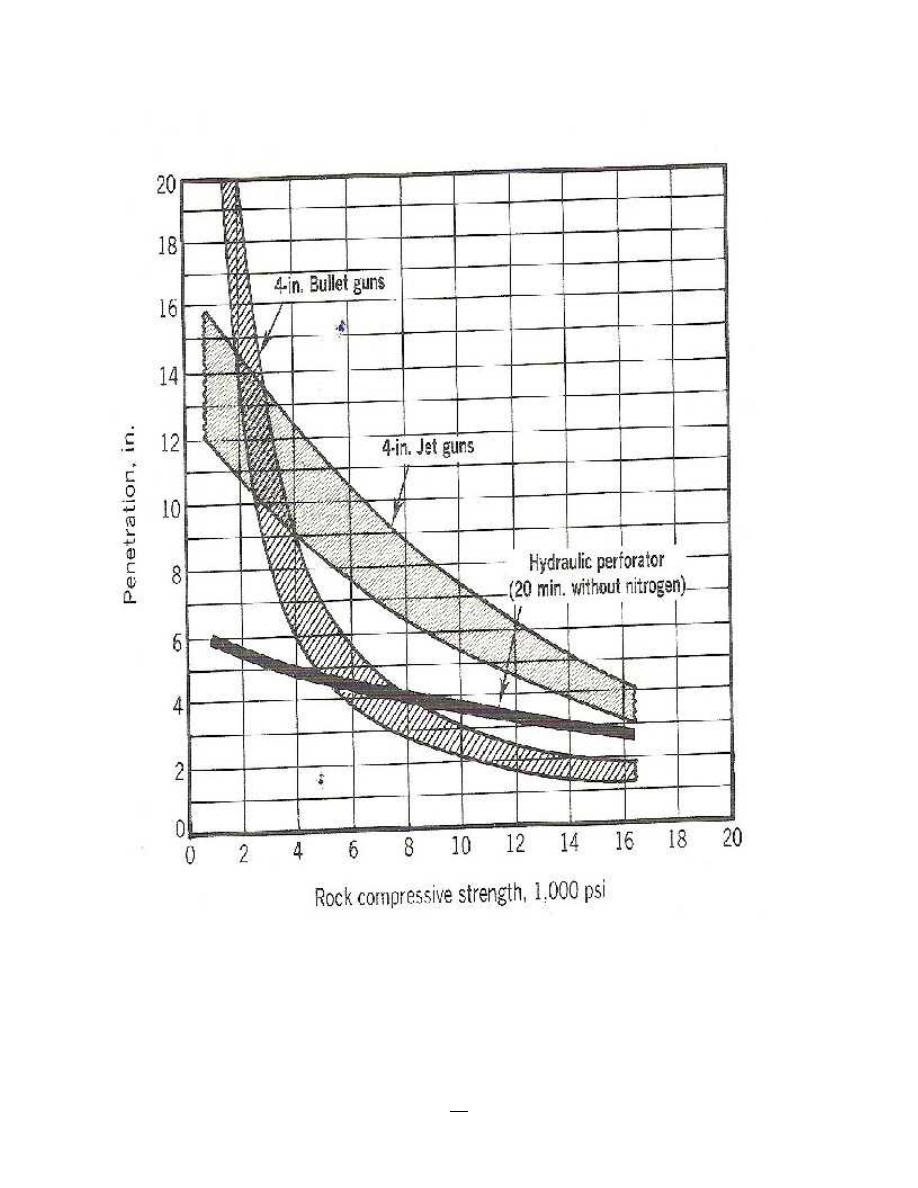

Effect of formation strength on perforator performance

As shown in figure - 38, jets penetrate deeper than bullets in hard formation. However, some best

bullet guns may penetrate deeper than some jets in low compressive strength formations,

particularly if guns are fired at zero clearance.

52

Production Engineering – I Herish N. Hamarash

Figure - 39 shows that penetration of jets, bullets, and hydraulic perforator was reduced with

increased compressive strength of formation penetrated. However, bullet penetration declined at a

more rapid rate as rock strength increased.

Figure - 38: Effect of formation compressive strength on penetration efficiency of bullet and jet

perforators

Figure - 39: Bullet, Jet and Hydraulic perforator performance in formations of various

compressive strength

53

Production Engineering – I Herish N. Hamarash

Perforation Charge Arrangement

In the preparation of a perforation gun, a number of charges are assembled on a carrier such that

upon detonation they will yield a series of perforations into the formation. The arrangement

provides for variation in the number of shots to be fired per unit interval, i.e. the shot density and

the direction in which all, or individual, charges will be shot, i.e. the shot phasing.

The number of shots installed in a perforating gun varies from low shot density, e.g. less than 1

shot/ft, to higher shot densities of up to 16 shots/ft. The lower shot densities are normally adequate

for production in reservoirs of moderate to high productivity or are selected for specific injection

operations where flow control is required. The higher shot densities will provide improved inflow

performance in all reservoirs but may only be significantly beneficial in reservoirs with a low

vertical permeability or where severe local drawdown might give rise to formation sand collapse.

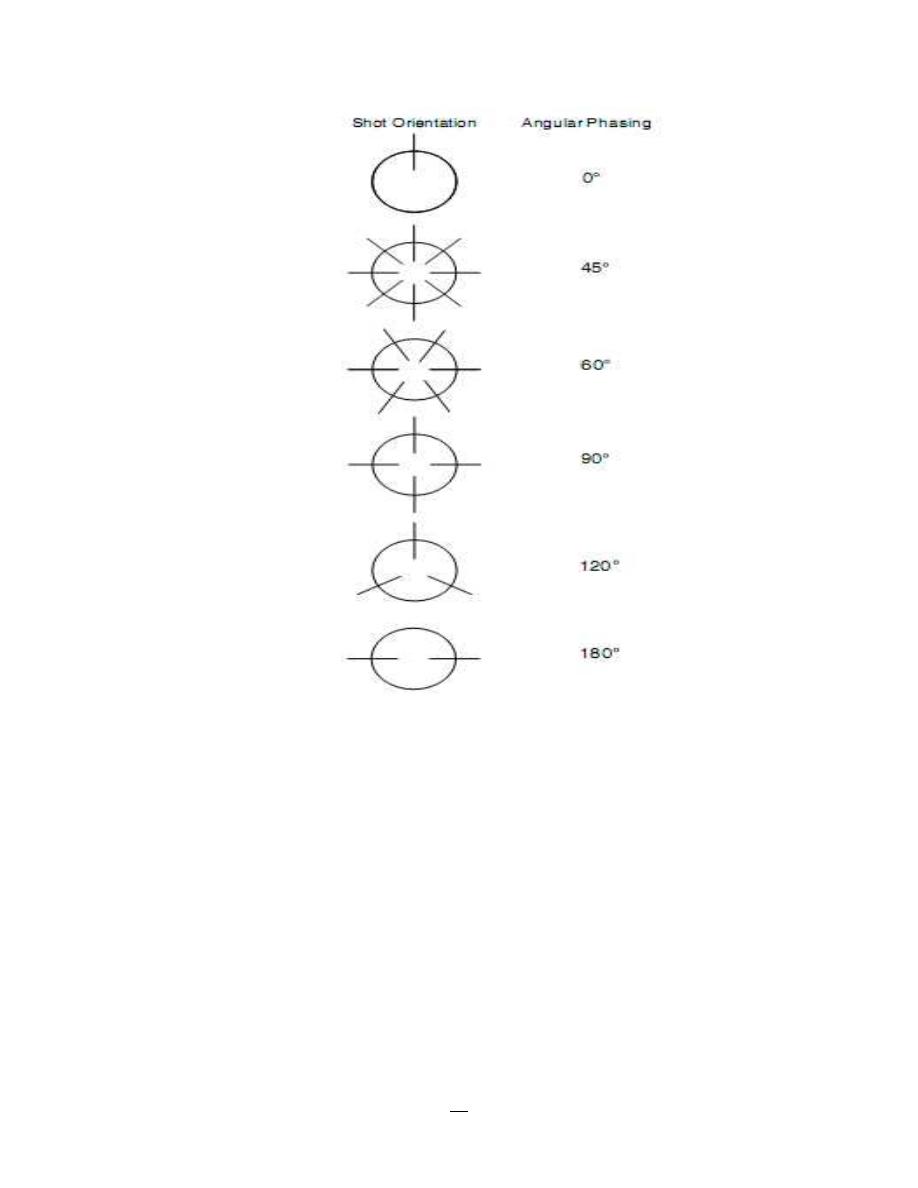

The orientation of perforations defined as the angular phasing can be:

1- 0° or in-line firing which can provide the minimum clearance for all perforation if the gun

is positioned to fire on the low side of the hole.

2- 45° to 90° phasing which provides the nearest approximation to radial flow.

3- 180° phasing in either of the two planar directions.

4- 120° phasing either with all 3 shots firing at 120° to each other or omitting 1 charge such

that the 2 shots fire at +60° and -60° angular phase.

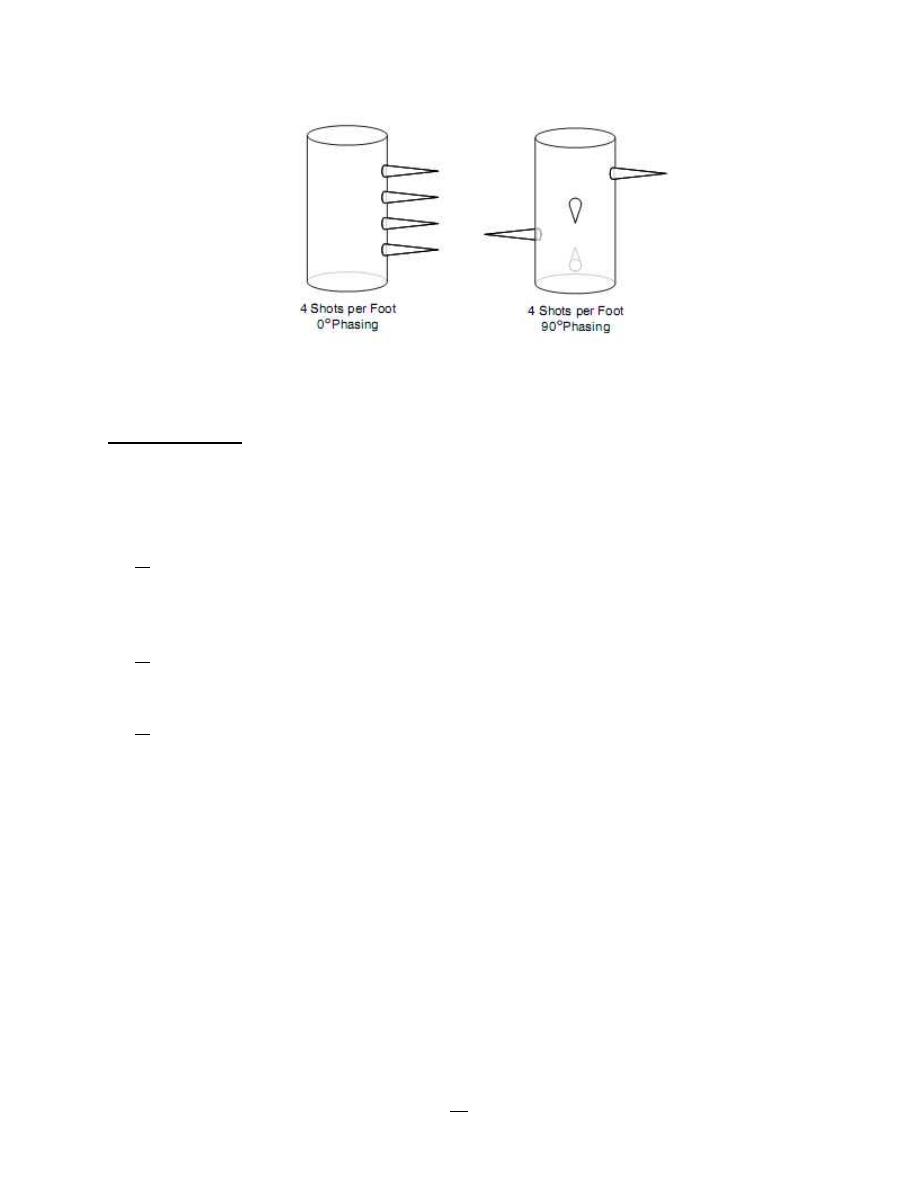

The phase orientations are depicted in (Figure - 40). All perforation flow patterns are utilised. 90°

phasing which provides the best radial depletion can be very effective when conducted with high

shot densities. However, the selection of phasing will depend not only on shot densities but gun

size, gun clearance, formation isotropy or anisotropy with respect to permeability. It is clear that

for each shot density a number of options regarding phasing can exist, for example, 4 shots/ft can

normally be fired at 0°, 90° or 180° phasing (Figure – 41).

54

Production Engineering – I Herish N. Hamarash

Figure - 41: Perforation Shot Phase Pattern

55

Production Engineering – I Herish N. Hamarash

Figure- 42: Perforation shot Density: Example of four shots/foot in line firing and 90º phasing

Perforating Fluid

Before perforation operators, the well should fill with a fluid does not cause any formation damage

when it connect with produce formation. The perforation should done at formation pressure lager

than hydrostatic pressure. There are different types of perforating fluid as following;

1- Salt water (Brine) or Oil; when used purity fluid, it will do not cause perforate plug. But

when the perforation operation done with difference pressure from well towards the

perforated formation, which cause moving suspension (fines of jets or bullets) into

perforators.

2- Acetic acid; this acid is the best perforating fluid under most conditions. Inhibitor corrosion

add to acetic acid to prevent corrosion of metal when connect with the acid for long period

and at high temperature, in case of absence of H2S gas.

3- Nitrogen gas; in case of perforation low pressure formation, or rig time and swabbing cost

is very expense, it better used Nitrogen gas in perforation operations.

56

Production Engineering – I Herish N. Hamarash

Selection of Perforated Intervals

The perforated interval in production zone selected based on result all or most the following

factors:

1- Electric, sonic, and radioactive logs show the border of oil and water formation.

2- Result of drill stem tests that conduct during well drilling.

3- Cores that extract from producing formation.

4- Geologic formations.

Take in account the following factors when select the perforating intervals;

1- The bottom perforated should far from Oil Water Contact (OWC) to avoid water coning.

2- The top perforated should far from Gas Oil Contact (GOC) to avoid gas coning.

3- Select zones with high porosity and permeability and avoid shale zones.

4- Select interval perforation that complete perforated with minimum numbers of guns run

(the gun length is 10 meters), to minimize the cost and provide the safety.

5- The well should fill with a fluid does not cause any formation damage.

57

Production Engineering – I Herish N. Hamarash

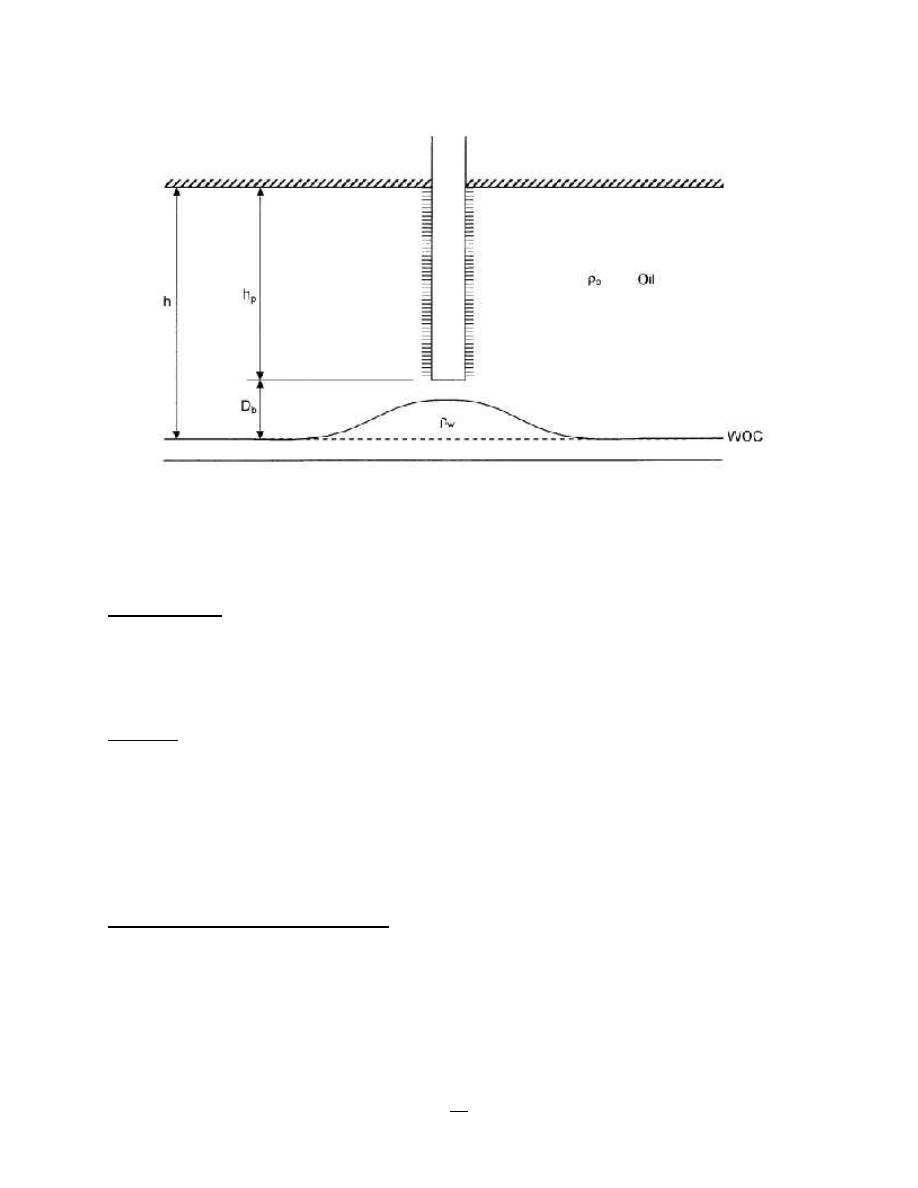

Water and Gas Coning

Coning is a term used to describe the mechanism underlying the upward movement of water and/or

the down movement of gas into the perforations of a producing well or the open hole interval.

Coning can seriously impact the well productivity and influence the degree of depletion and the

overall recovery efficiency of the oil reservoirs. The specific problems of water and gas coning are

listed below.

1- Costly added water and gas handling.

2- Reduced efficiency of the depletion mechanism.

3- The water is often corrosive and its disposal costly.

4- Loss of the total field overall recovery.

Delaying the encroachment and production of gas and water are essentially the controlling factors

in maximizing the field’s ultimate oil recovery.

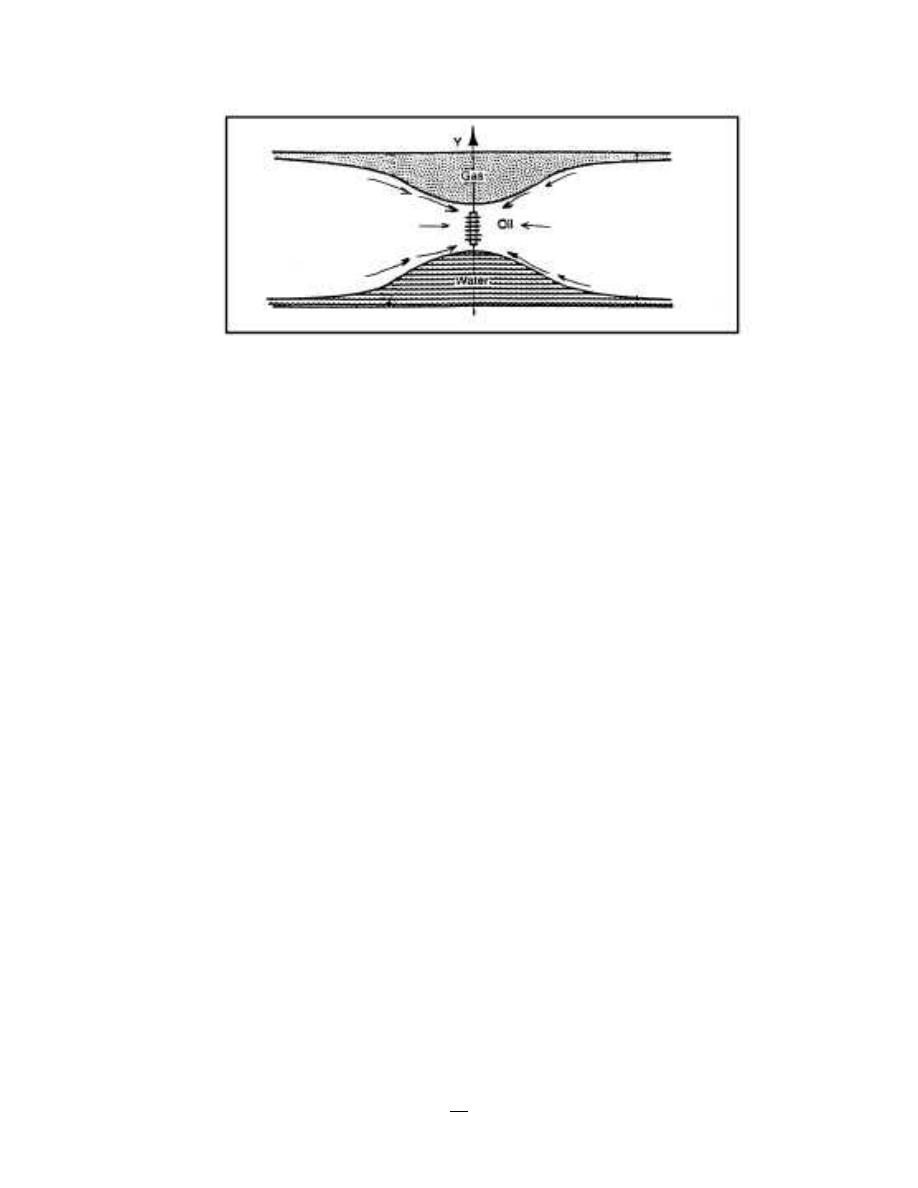

The coning is primarily the result of movement of reservoir fluids in the direction of least

resistance, balanced by a tendency of the fluids to maintain gravity equilibrium. The analysis may

be made with respect to either gas or water. Let the original condition of reservoir fluids exist as

shown schematically in figure - 43, water underlying oil and gas overlying oil.

Figure - 43: Original reservoir static condition

Production from the well would create pressure gradients that tend to lower the gas-oil contact and

elevate the water-oil contact in the immediate vicinity of the well. Counterbalancing these flow

gradients is the tendency of the gas to remain above the oil zone because of its lower density and

of the water to remain below the oil zone because of its higher density. These counterbalancing

forces tend to deform the gas-oil and water-oil contacts into a bell or cone shape as shown

schematically in figure - 44.

58

Production Engineering – I Herish N. Hamarash

Figure - 44: Gas and Water coning

There are essentially three forces that may affect fluid flow distributions a round the well-bores.

These are:

1- Capillary forces.

2- Gravity forces.

3- Viscous forces.

Capillary forces usually have negligible effect on coning and will be neglected. Gravity forces are

directed in the vertical direction and arise from fluid density difference.

Viscous forces refer to the pressure gradients associated fluid flow through the reservoir as

described by Darcy’s law. Therefore, at any given time, there is a balance between gravitational

and viscous forces at points on and away from the well completion interval. When the dynamic

(viscous) forces at the well-bore exceed gravitational forces, a “cone” will ultimately break into

the well.

We can expand on the above basic visualization of coning by introducing the concept of:

-

Stable cone.

-

Unstable cone

-

Critical production rate.

If a well is produced at a constant rate and the pressure gradients in the drainage system have

become constant, a steady-state condition is reached. If at this condition the dynamic forces at the

well are less than the gravity forces, then the water or gas cone that has formed will not extend to

the well. Moreover, the cone will neither advance nor recede, thus establishing what is known as

a stable cone. Conversely, if the pressure in the system is an unsteady-state condition, then an

unstable cone will continue to advance until steady-state conditions prevail.

The critical production rate is the rate above which the flowing pressure gradient at the well causes

water (or gas) to cone into the well. It is, therefore, the maximum rate of oil production without

concurrent production of the displacing phase by coning. At the critical rate, the built-up cone is

stable but is at a position of incipient breakthrough.

59

Production Engineering – I Herish N. Hamarash

Defining the conditions for achieving the maximum water-free and/or gas-free oil production rate

is a difficult problem to solve. Engineers are frequently faced with the following specific problems:

1- Predicting the maximum flow rate that can be assigned to a completed well without the

simultaneous production of water and/or free-gas.

2- Defining the optimum length and position of the interval to be perforated in a well in order to

obtain the maximum water and gas-free production rate.

Critical rate Q

oc

is defined as the maximum allowable oil flow rate that can be imposed on the well

to avoid a cone breakthrough. The critical rate would correspond to the development of a stable

cone to an elevation just below the bottom of the perforated interval in an oil-water system or to

an elevation just above the top of the perforated interval in a gas-oil system.

There are several empirical correlations that are commonly used to predict the oil critical rate,

including the correlations of:

1- Meyer and Gardner and Pirson Methods.

2- Craft and Hawkins Method.

3- Chaney Et AL. Method

1- Meyer and Gardner and Pirson Methods

Meyer, Gardner, and Pirson suggest that coning development is a result of the radial flow of

the oil and associated pressure sink around the well-bore. In their derivations, Meyer, Gardner,

and Pirson assume a homogeneous system with a uniform permeability throughout the reservoir,

i.e., k

h

= k

v

. It should be pointed out that the ratio k

h

/k

v

is the most critical term in evaluating and

solving the coning problem. They developed three separate correlations for determining the critical

oil flow rate:

-

Gas coning

-

Water coning

-

Combined gas and water coning.

Gas coning

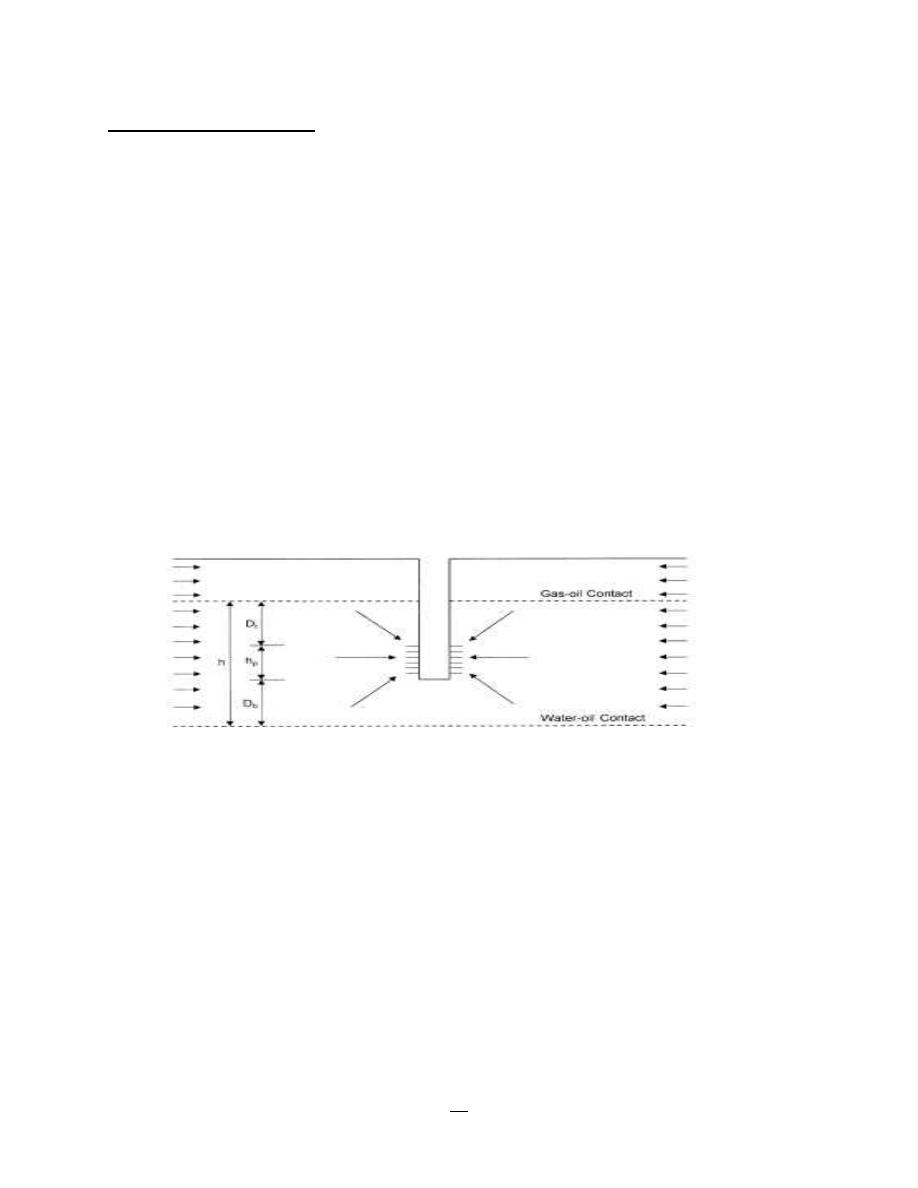

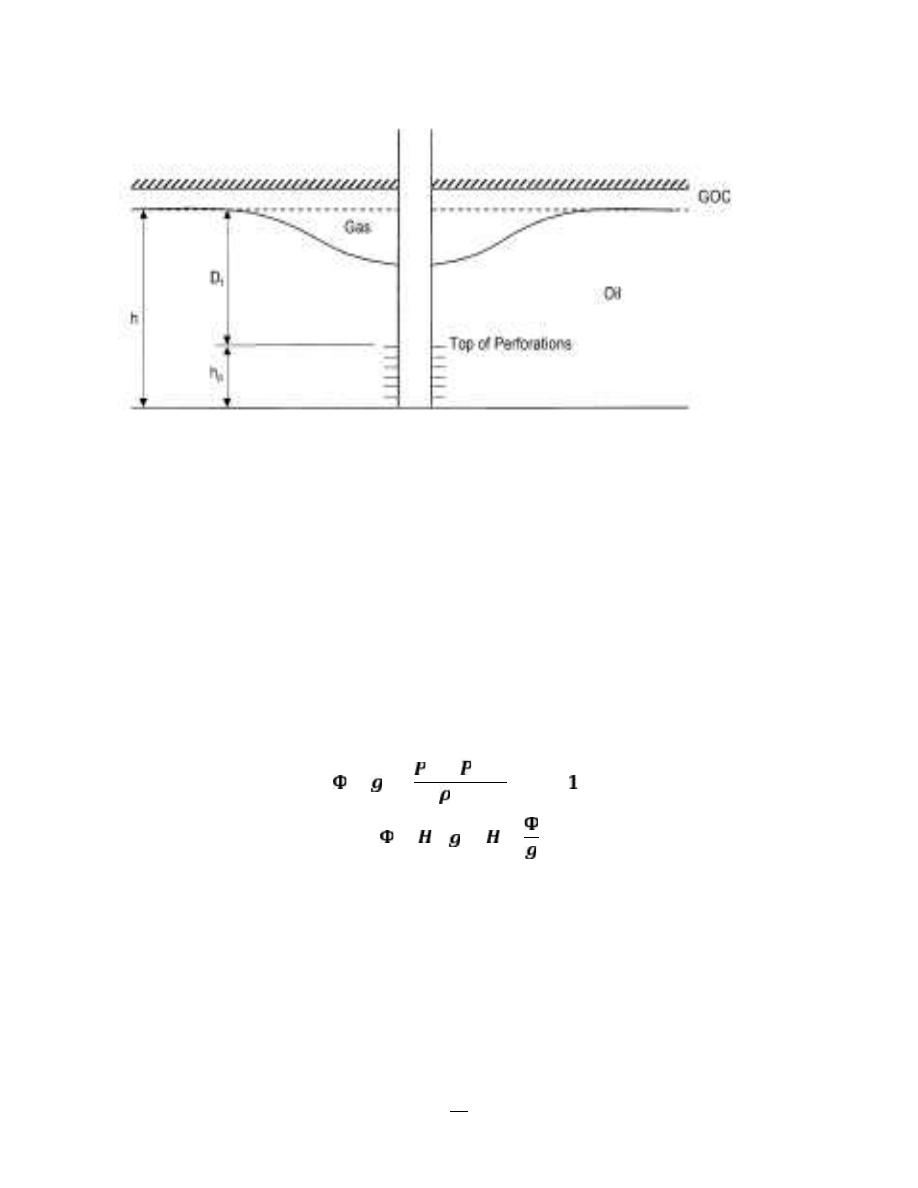

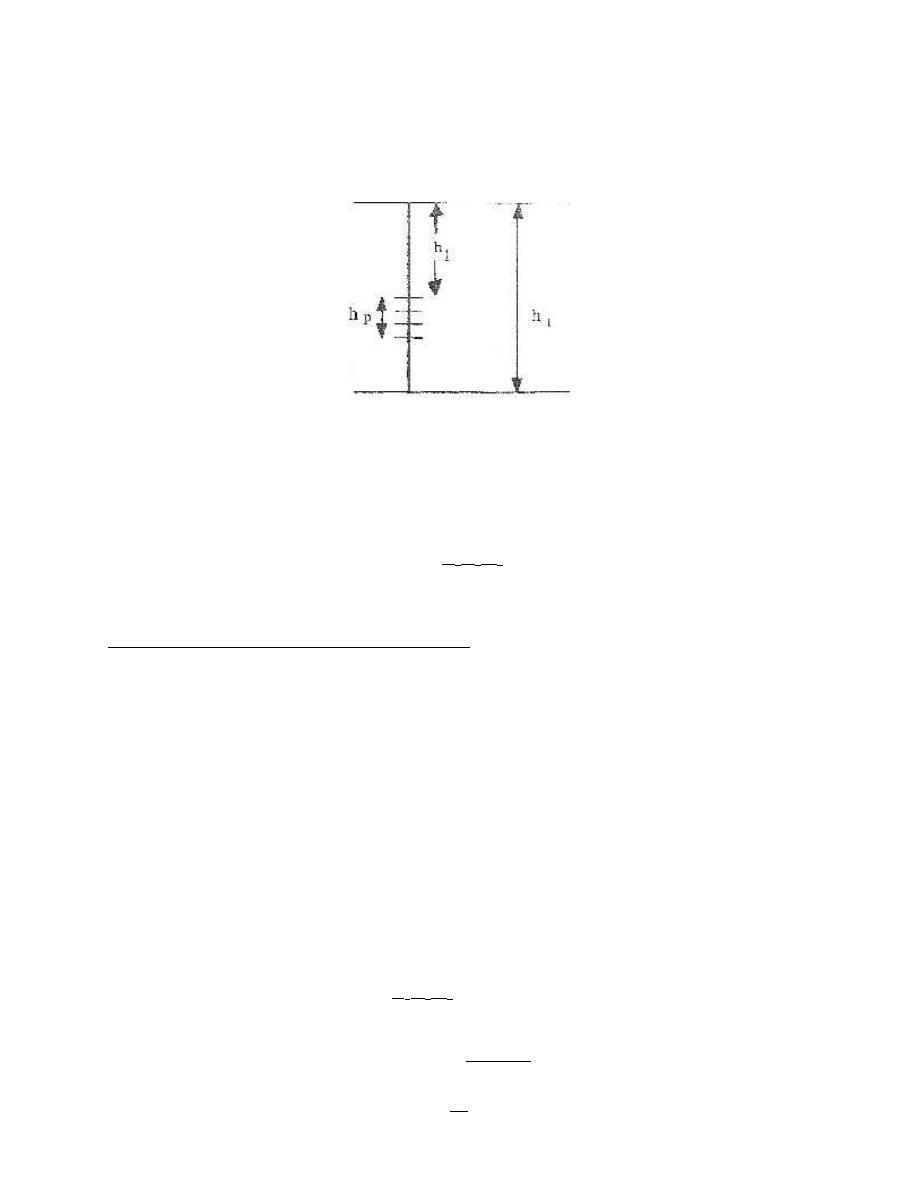

Consider the schematic illustration of the gas-coning problem shown in figure - 45. Meyer,

Gardner, and Pirson correlated the critical oil rate required to achieve a stable gas cone with the

following well penetration and fluid parameters:

-

Difference in the oil and gas density.

-

Depth D

f

from the original gas-oil contact to the top of the perforations.

-

The oil column thickness h.

The well perforated interval h, in a gas-oil system, is essentially defined as:

h =

h

p

– D

f

60

Production Engineering – I Herish N. Hamarash

Figure - 45: Gas coning

Meyer, Gardner, and Pirson propose the following expression for determining the oil critical flow

rate in a gas-oil system:

Summary of assumptions for gas-oil system:

1. Capillary forces usually have negligible effect on coning and will be neglected.

2. No gas drive, that means GOR remain constant

Ф = Potential = H

For any point, calculate H

=

+

−

… … … ( )

= ∗ → =

Hgas = z + Pg / (ρgas *g) ………. (2)

Hoil = z + Po / (ρoil *g) ………..(3)

Since Pc = zero i.e., Po = Pg (where Pc = Pg-Po = zero)

& Hg = constant (i.e., no gas drive).

For eg.(2) , solving for Pg →

(Hg – z) * ρg *g = Pg

..........(2-a)

61

Production Engineering – I Herish N. Hamarash

& also eq.(3) becomes:-

(Ho – z) * ρo * g = Po ………(3-a)

Since Pc = zero → Po = Pg

Then eq. (2-a) = eq. (3-a)

……….(4)

g

z) ρo *

–

= (Ho

g

z ) ρg *

–

(Hg

Solve eq. (4) for Ho

Ho = Hg * (ρg/ρo) + z [(ρo – ρg)/ρo] ……. (5)

Where Hg is constant

Derivative equation (5) respect to Ho

dHo = [(ρo-ρg)/ρo] dz …….(6)

'

Darcy`s law Q = k A ΔP / μ L (for linear flow)

Solving for oil flow:

Q → Qo

k → ko

L → dr

μ → μo

Radial area ↔ A = 2πrz

ΔP = ρo g dHo

Where P = ρ g H

Then Darcy's law →

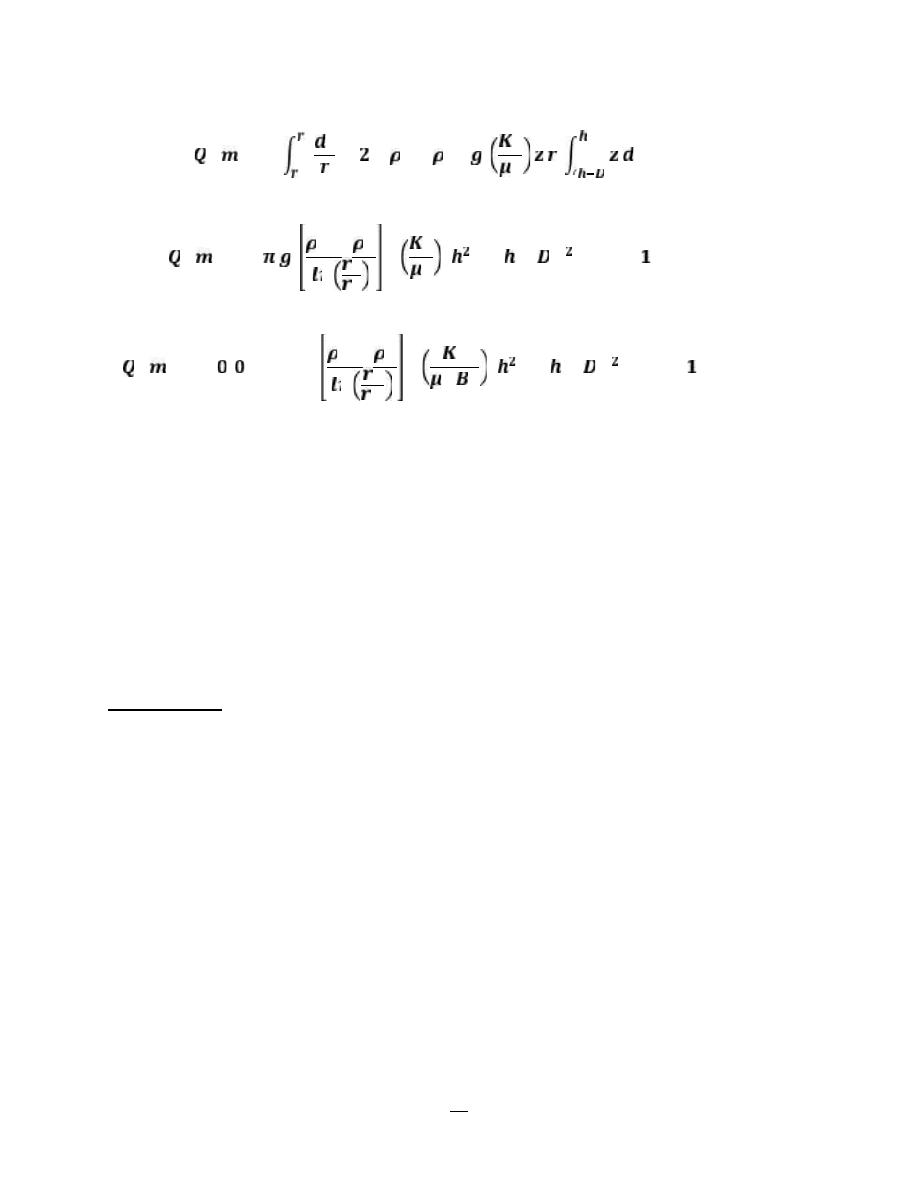

Qo = 2π ρo g (ko/μo) z r (dHo/dr) ……. (7)

Substitute the value of (dHo) [i.e. eg.(6) in eq.(7)]

For radial flow

Qo = 2π (ρo – ρg) g (ko/μo) z r (dz/dr) ………. (8)

z

r

62

Production Engineering – I Herish N. Hamarash

=

=

(

−

)

(

_

. =

−

∗

[ − ( −

) ] … … … ( )

Or in field units

. = .

∗

−

∗

[ − ( −

) ] … … … ( )

= maximum oil production rata without gas coning (critical rate), STB/day

max

o

Q

= oil density, gram/ cm³

o

ρ

= gas density, gram/ cm³

g

ρ

= drainage area radius, ft

e

r

bore radius, ft

-

= well

w

r

= oil permeability, md

o

k

o = oil viscosity, cp

μ

Bo = oil formation volume factor, bbl/STTB

h = thickness of oil zone (producing zone), ft

D

t

= Depth from the original gas-oil contact to the top of the perforations, ft

h

p

= Completion interval (Perforated interval), ft.

1):

-

Example (1

A vertical well is drilled in an oil reservoir overlaid by a gas cap. The related well and

reservoir data are given below:

= 110 md

v

= k

h

Horizontal and vertical permeability, i.e., k

= 0.85

ro

relative permeability, k

Oil

= 47.5 lb/ft³

o

Oil density, ρ

= 5.1 lb/ft³

g

Gas density, ρ

= 0.73 cp

o

Oil viscosity, µ

= 1.1 bbl/day

o

Oil formation volume factor, B

Oil column thickness, h = 40 ft

= 15 ft

p

Perforated interval, h

= 25 ft

t

of perforations, D

Depth from GOC to top

63

Production Engineering – I Herish N. Hamarash

0.5 ft

w =

r

bore radius,

-

Well

= 660 ft

e

Drainage radius, r

Using Meyer, Gardner, and Pirson relationships, calculate the critical oil flow rate.

Solution

The critical oil flow rate for this gas-coning problem can be determined by applying

equation (11). The following two steps summarize Meyer, Gardner, and Pirson

methodology.

o

Step 1. calculate effective oil permeability, k

k = 0.85 * 110 = 93.5 md

ro

= k

o

k

by applying equation (11)

oc

Step 2. solve for Q

-

(40

-

2

(5.1/62.4))/ln(660/0.25)](93.5/073*1.1) [40

-

(47.5/62.4)

=Qo max=0.001535[(

oc

Q

]

2

25)

=Qo max= 21.20 STB/day

oc

Q

Water Coning

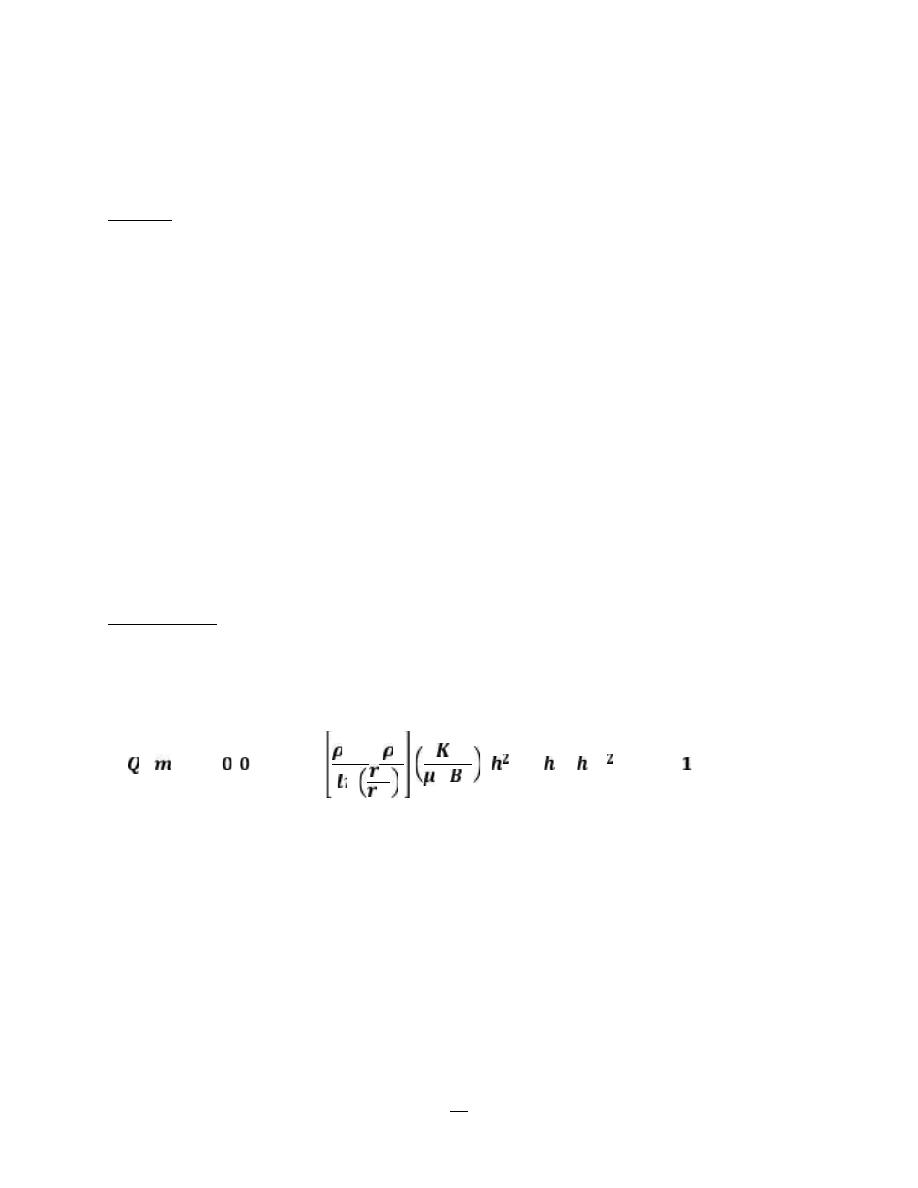

Meyer, Gardner, and Pirson proposed a similar expression for determining the critical oil rate in

the water coning system shown schematically in figure - 46.

The proposed relationship has the following form:

. = .

∗

−

[ − ( −

) ] … … … ( )

64

Production Engineering – I Herish N. Hamarash

Figure - 46: Water coning

Where:

ρw = water density, gram/ cm³

D

b

= Depth from the original water-oil contact to the bottom of the perforations, ft

2):

-

Example (1

Resolve example (1-1) assuming that the oil zone is underlaid by bottom water. The water

density is given as 63.76 lb/ft. the well completion interval is 15 ft as measured from the

top of the formation (no gas cap) to the bottom of the perforations.

Solution:

The critical oil flow rate for this water-coning problem can be estimated by applying

equation (12). The equation is designed to determine the critical rate at which the water

cone “touches” the bottom of the well to give.

Qo max = 0.001535 [((63.76/62.4)-(47.5/62.4))/ ln(660/0.25)] (93.5/0.73*1.1) [40

2

- -15

2

]

Qo max = 8.13 STB/day

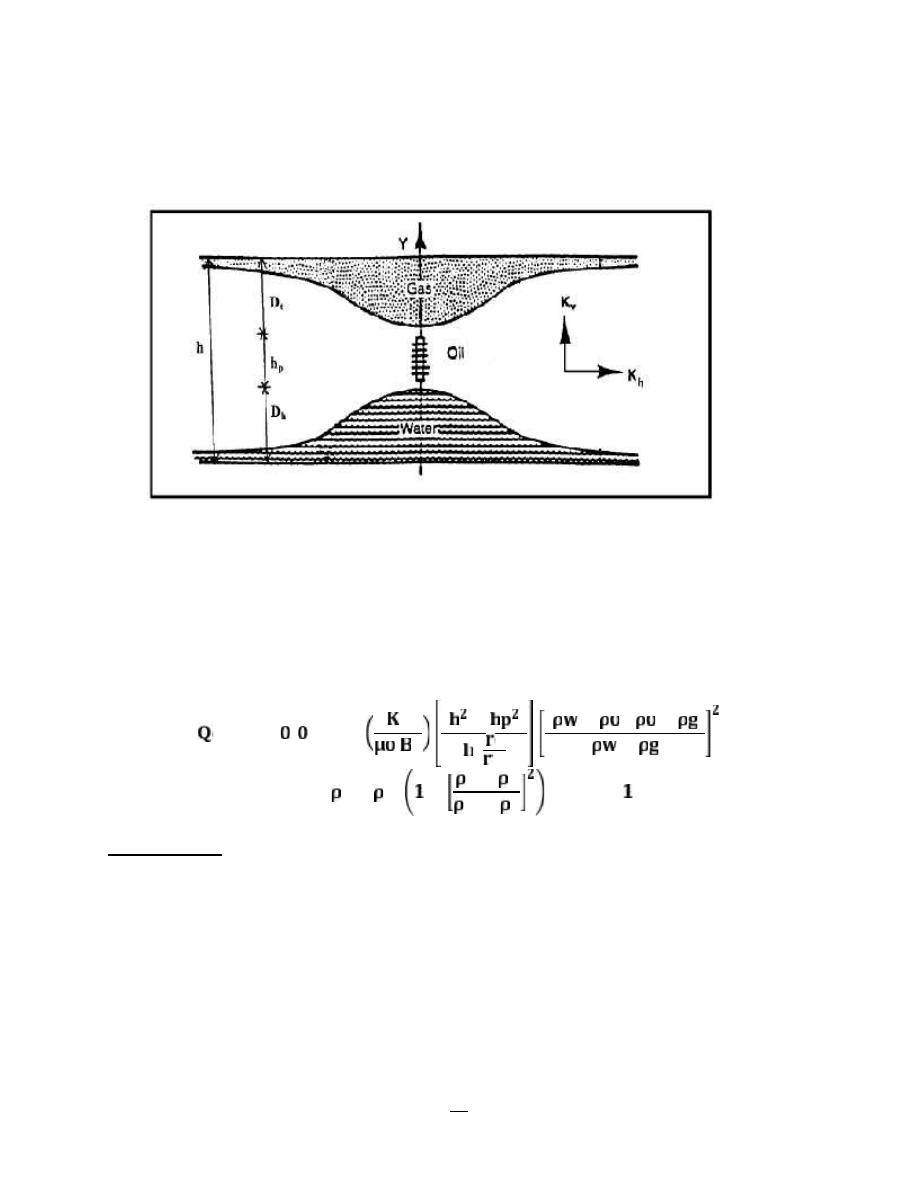

Simultaneous Gas and Water coning

If the effective oil-pay thickness h is comprised between a gas cap and a water zone figure - 47,

the completion interval h

p

must be such as to permit maximum oil-production rate without

having gas and water simultaneously produced by coning, gas breaking through at the top of the

interval and water at the bottom.

65

Production Engineering – I Herish N. Hamarash

This case is of particular interest in the production from a thin column underlaid by bottom water

and overlaid by gas.]

Figure - 47: The development of Gas and Water coning

For this combined gas and water coning, Pirson (1977) combined equation (11) and (12) to produce

the following simplified expression for determining the maximum oil-flow rate without gas and

water coning:

Qomax = Qow + Qog …. (13)

= .

( −

) (

−

)(

−

)

−

+ (

− )

−

−

−

… … … … ( )

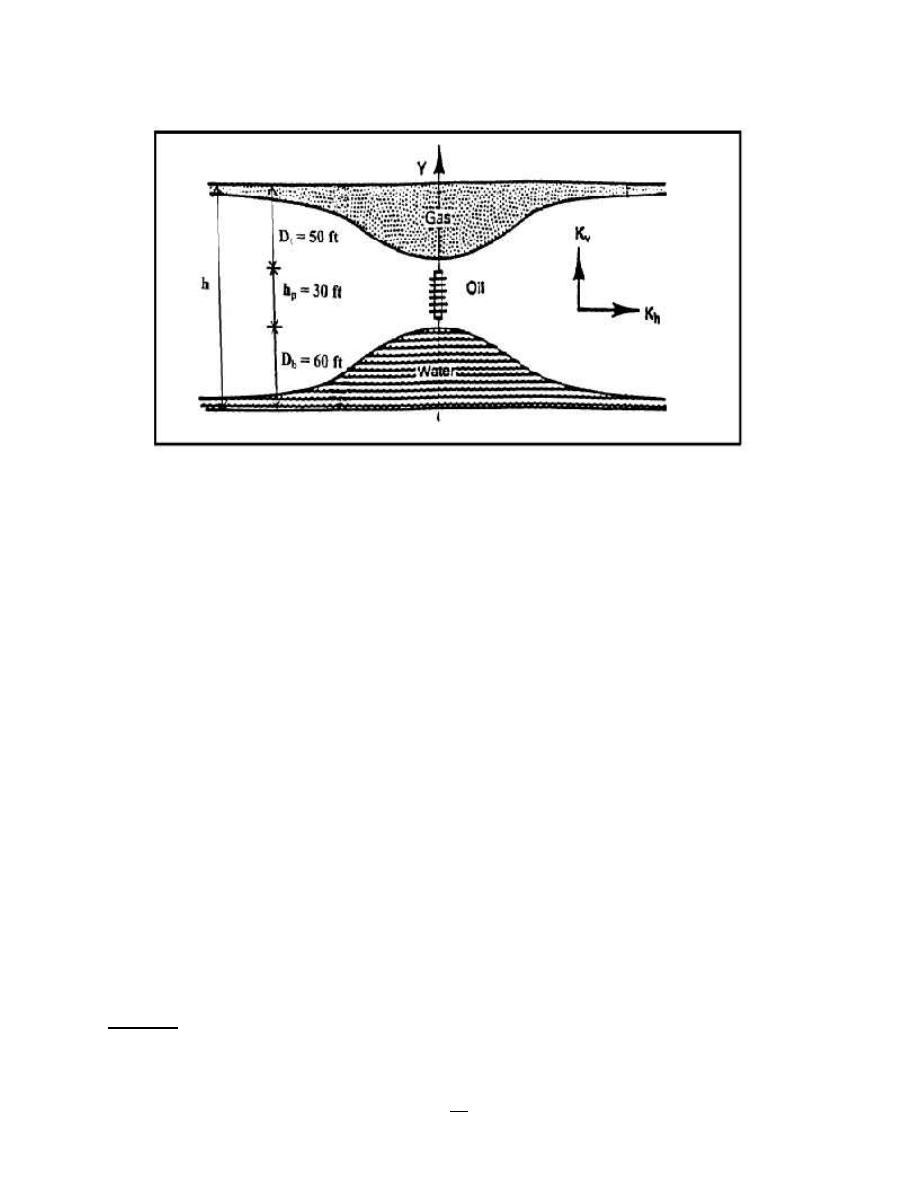

Example (1-3):

A vertical well is drilled in an oil reservoir that is overlaid by a gas cap and underlaid by bottom

water. Figure - 48 shows an illustration of the simultaneous gas and water coning.

66

Production Engineering – I Herish N. Hamarash

Figure – 48: Gas and Water coning problem (example, 1-3)

The following data are available:

= 110 md

v

= k

h

Horizontal and vertical permeability, i.e., k

= 0.85

ro

Oil relative permeability, k

= 93.5 md

o

Oil effective permeability, k

= 47.5 lb/ft³

o

Oil density, ρ

= 63.76 lb/ft³

w

Water density, ρ

b/ft³

= 5.1 l

g

Gas density, ρ

= 0.73 cp

o

Oil viscosity, µ

= 1.1 bbl/STB

o

Oil formation volume factor, FVF, B

Oil column thickness, h = 65 ft

= 15 ft

p

Perforated interval, h

= 25 ft

t

Depth from GOC to top of perforations, D

0.5 ft

w =

r

bore radius,

-

Well

Drainage radius, r

e

= 660 ft

Calculate the maximum permissible oil rate that can be imposed to avoid cones breakthrough,

i.e., water and gas coning.

Solution:

Apply equation (14) to solve for the simultaneous gas-and water coning problem, to give:

67

Production Engineering – I Herish N. Hamarash

Qomax =0.001535(93.5/0.73*1.1)[(65

2

-15

2

)/(ln(660/0.25)]

[((63.76/62.4)-(47.5/62.4))(((47.5/62.4)-(5.1/62.4))/((63.76/62.4)-(5.1/62.4)))

2

+((47.5/62.4)-

(5.1/62.4))(1-(((47.5/62.4)-(5.1/62.4))/((63.76/62.4)-(5.1/62.4))))

2

]

Qomax = 17.1 STB/day

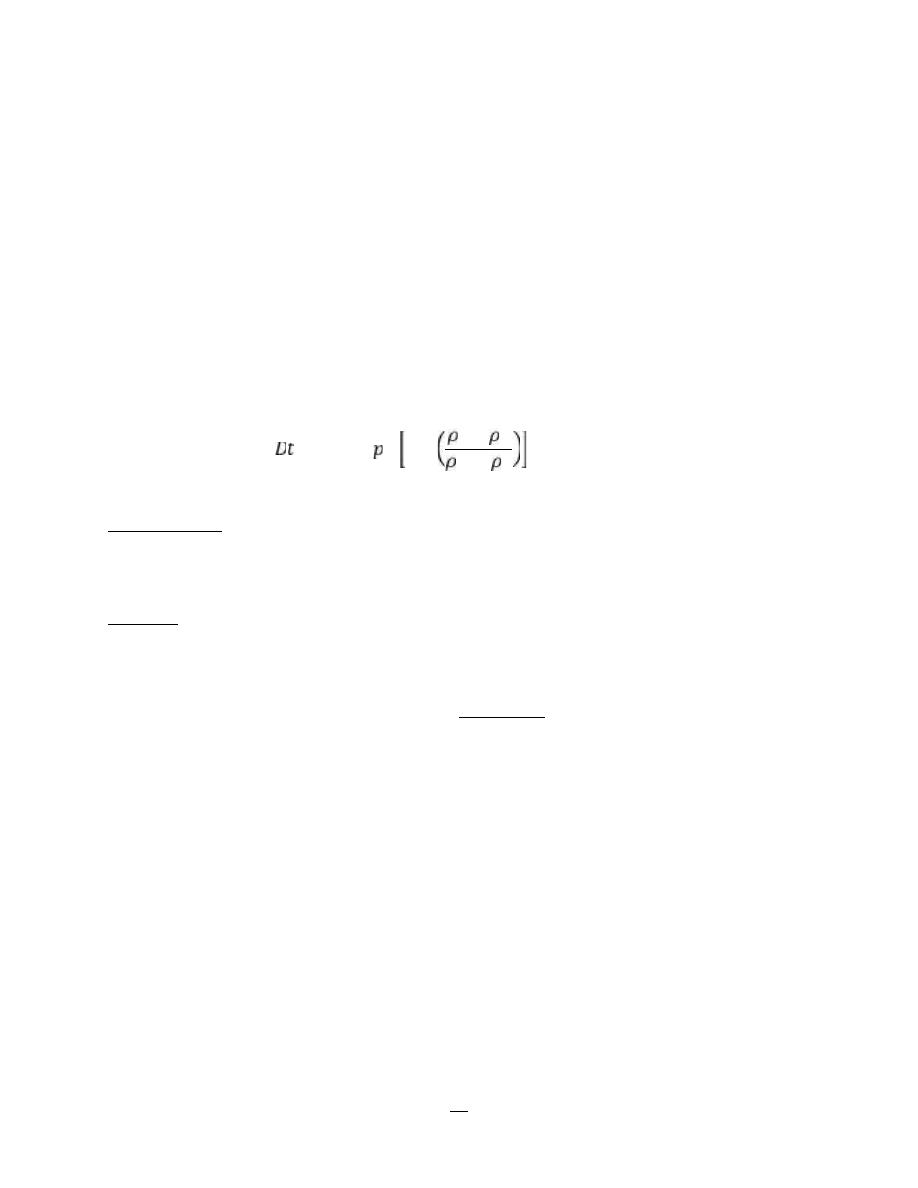

Pirson derives a relationship for determining the optimum placement of the desired h

p

feet of

perforation in an oil zone with a gas cap above and a water zone below. Pirson proposes that the

optimum distance D

t

from the GOC to the top of the perforations can determined from the

following expressed:

= (ℎ – ℎ ) 1 −

−

−

… . . (15)

Where the distance D

t

is expressed in feet.

Example (1-4):

Using the data given in example (1-3), calculate the optimum distance for the placement

of the 15 foot perforations.

Solution:

Applying equation (15) gives:

D

t

= (65 – 15 ) [ 1- 47.5 – 5.1 ] = 13.9 ft

63.76 – 5.1

There are other methods in water and gas coning calculation like:

-

Craft & Hawkins Method

-

Chaney Et AL. Method

68

Production Engineering – I Herish N. Hamarash

Completion Efficiency

Generally, there are difference types of well completions; the cased-hole completion has

advantage characterize the open-hole completion by:

1- Excessive gas or water production can be controlled more easily.

2- Can be selectively stimulated.

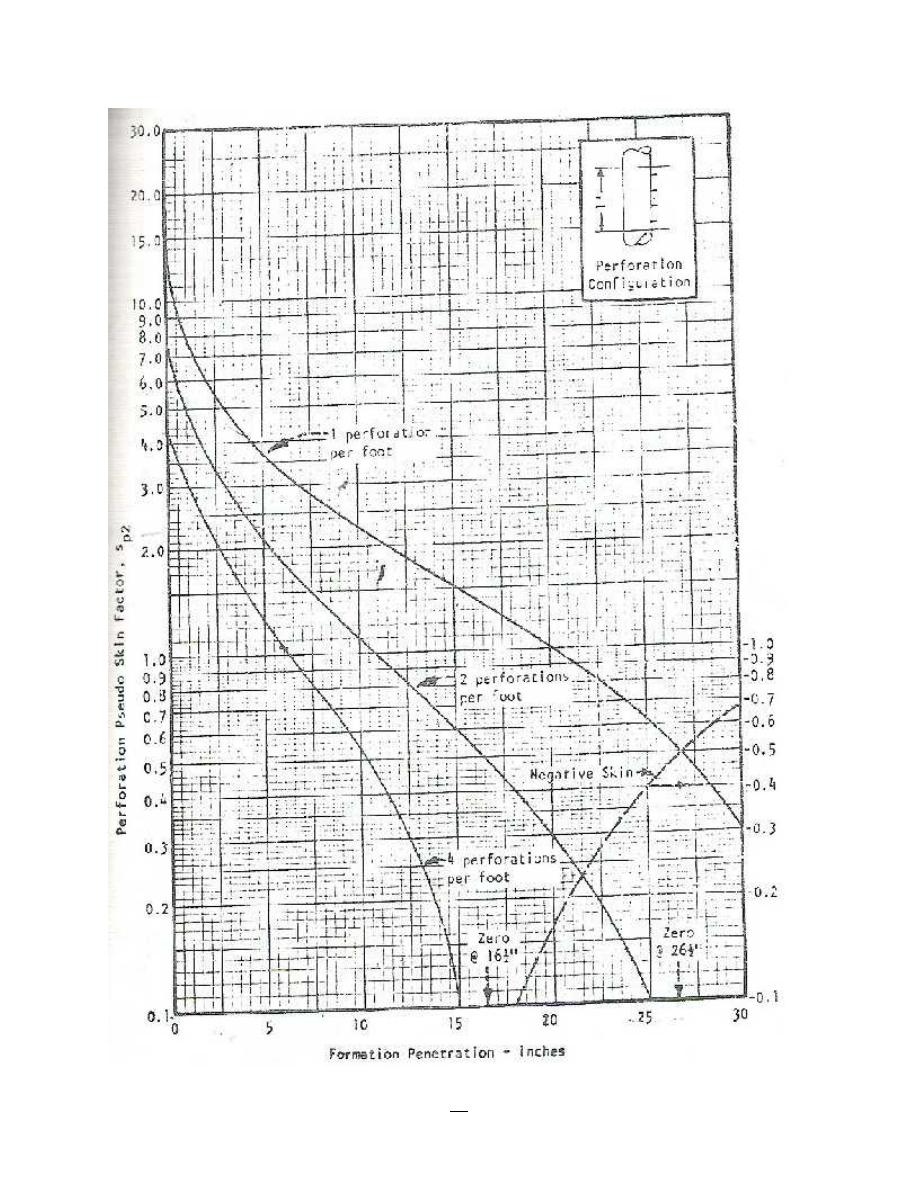

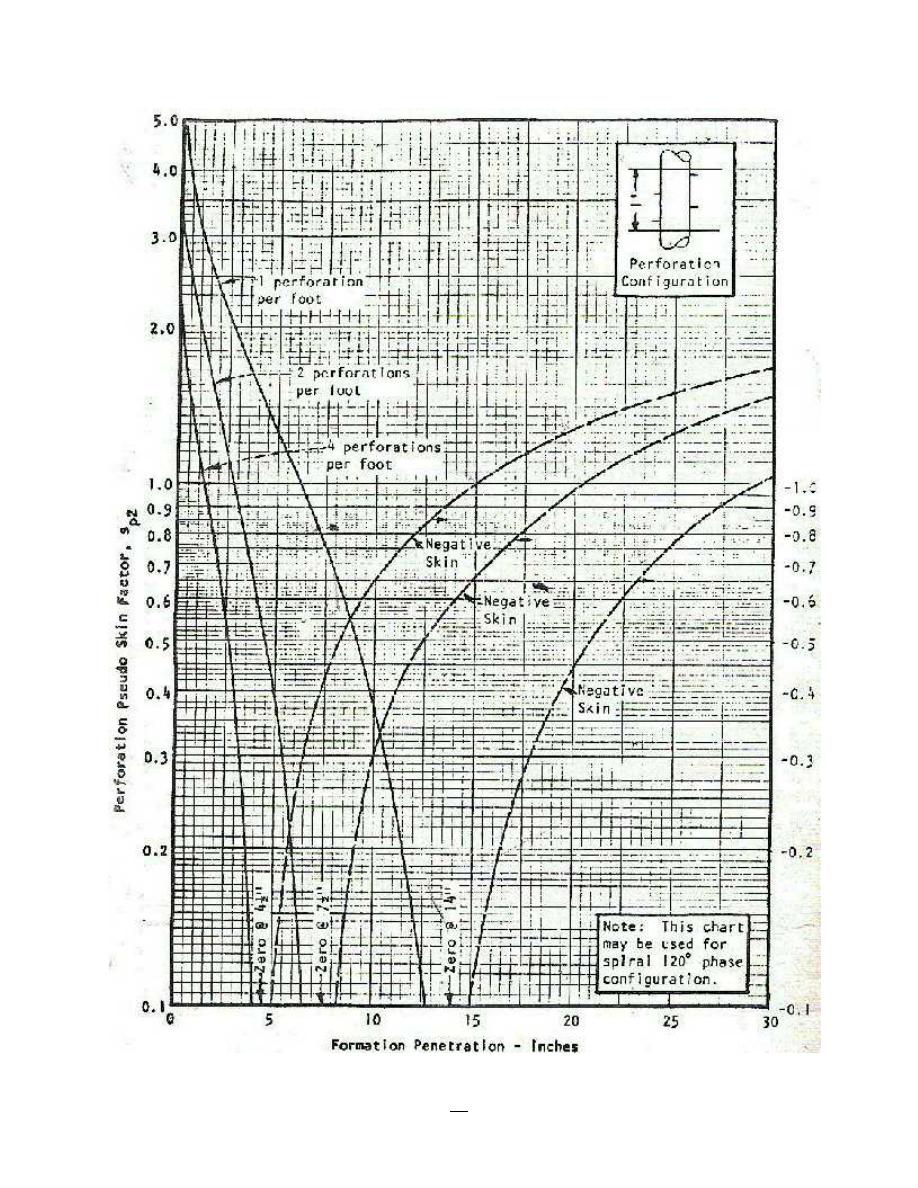

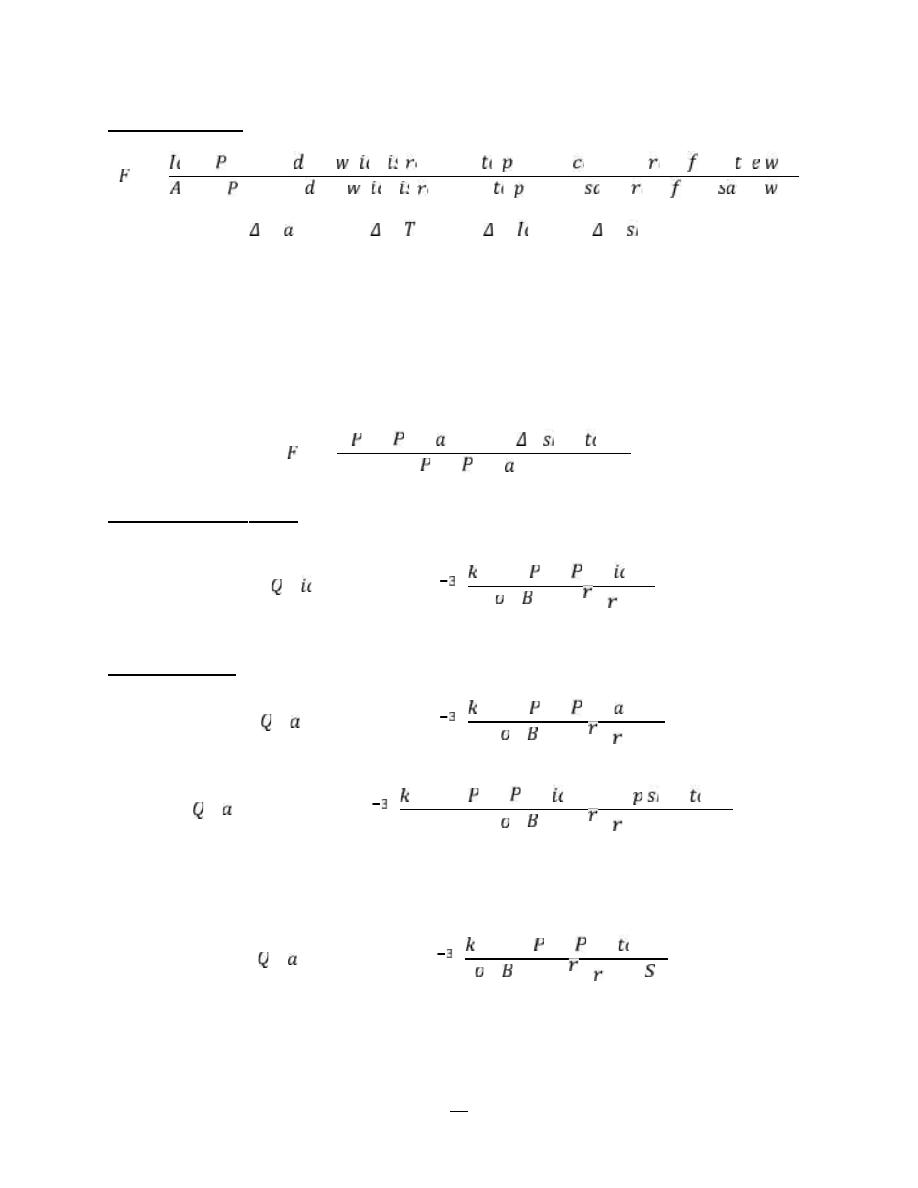

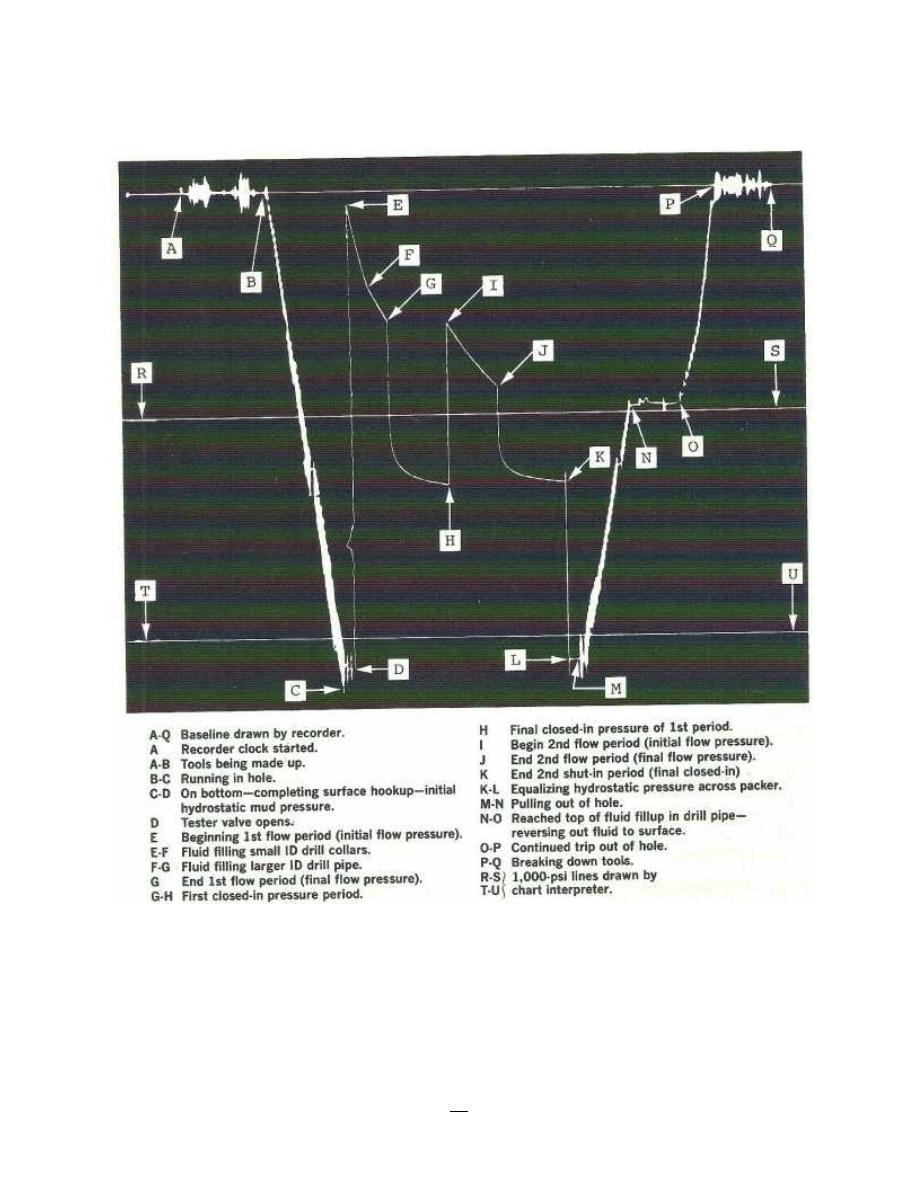

3- Adaptable to multiple completion techniques.