BY

Dr.Raied Alattar

Is defined as,

―The Study of

composition

and

properties

of dental materials

and the

manner in which they

interact with the environment

in

which they are placed‖.

2

Science Of Dental

Materials

Very demanding.

There can be

1.

Temperature variations.

2.

pH Variations.

3.

Variations in Masticatory forces.

3

Oral Environment

Normal temperature of oral cavity (32℃ to

37℃).

On intake of a cold/hot food or drink

temperature range increases (0℃ to 70℃).

4

Temperature Variations

pH of saliva is neutral (7.0)

On intake of acidic fruit juices

or alkaline medicaments, pH

may vary from 2.0 to 11.0 .

5

pH Variations

1.

Analysis of the problem.

2.

Consideration of the

requirements.

3.

Consideration of the available

materials and their properties.

4.

Choice of a suitable material.

6

SELECTION OF DENTAL

MATERIALS

Basic and very important step.

Incorrect analysis may lead to

wrong treatment plan.

Poor prognosis and failure of

treatment.

e.g. Selection of a filling material.

7

1. Analysis of the

problem

Enlist the requirements that a

material must meet.

Requirements of a material are

dependent upon the situation.

8

2. Consideration of the

requirements

Clear concept about the properties.

In case of immediate problem,

Must choose from the materials in hand.

Dentist must be up to date with the

advancements.

Thorough comparison of Properties of the

available materials with requirements.

9

3. Consideration of the available

materials and their properties

Final step.

Narrowing the range of choice.

Factors:

1.

Availability.

2.

Ease of handling.

3.

Cost effectiveness.

10

4. Choice of a suitable

material

Biocompatible –

Non-toxic, non-irritating, non-allergenic

Mechanically stable & durable –

Strong, resistant to fracture

Resistant to Corrosion –

Does not deteriorate over time

Dimensionally Stable –

Little change by temperature & solvents

Characteristics of Ideal

Materials:

Minimal conduction –

Insulates against thermal/electrical change

Esthetic –

Looks like oral tissue

Easy to manipulate –

Minimal/reasonable effort & time needed

Adheres to tissues –

Retains onto, and seals, tooth structure

Characteristics of Ideal

Materials:

Tasteless and Odorless –

Not unpleasant to patient

Cleanable/Repairable –

Easily maintained or fixed

Cost-effective –

Affordability vs. benefits/disadvantages

Characteristics of Ideal

Materials:

Four Classes of Materials

Structure of Materials

Physical Characteristics

Mechanical Characteristics

Biologic Characteristics

Characteristics of

Materials:

METALS:

High thermal & electrical conductivity

High ductility

(bend without breakage)

High opacity

(do not transmit light)

High luster

(reflect light; appear shiny)

Crystalline arrangement of atoms

(solid)

Strong metallic bond

(high melting point - except

Mercury)

Classes of Materials:

METALS:

Strong, rigid, and stable materials

Can be ―cast‖ or formed into various shapes

Classes of Materials:

CERAMICS:

Compound of metal with non-metal

High melting points

Low thermal & electrical conductivity

Crystalline or Non-crystalline

Inert – biologically compatible

Used as fillers to reinforce composites

Esthetic - porcelains

Classes of Materials:

POLYMERS:

Man-made, long-chain, organic molecules

(carbon

atoms linked together)

Low thermal & electrical conductivity

Low strength and stability

Dental acrylics – dentures, sealants, temps

Impression materials

Adhesives – dental cements

Resin base for dental composites

Classes of Materials:

COMPOSITES:

Mixtures of two or more of the other classes (metals,

ceramics, polymers)

Example:

Dental Composite filling material

Resin matrix

(polymer)

+

glass filler

(ceramic)

Classes of Materials:

BONDS: forces holding atoms together

Primary Bonds – solids

Covalent: sharing electrons

Ionic: interaction of + and – charges

Metallic: share electrons of outer shell

Secondary Bonds – liquids

Less stable; weaker attractions

Bond liquid to liquid, or liquid to solid

Structure of Materials:

ATOMIC ARRANGEMENTS:

(when a material is

in a solid state)

Amorphous – irregular pattern of atoms;

―frozen liquids‖

i.e. glass, polymers

Crystalline – a regular pattern of columns

and rows, stacked upon each other; ―cubic‖

or other crystal patterns

i.e. metals

Structure of Materials:

THE END

The American National Standards Institute (ANSI), and

the American Dental Association (ADA), have

established more than 100 standard or specifications,

and helpful in the selection of materials for dental

practice

Thermal conductivity

Thermal conductivity: has been used as a

measure of the heat transferred and is

defined as a number of calories per second

flowing through an area of 1cm

2

In which the temperature drop along the length

of the specimen is 1

0

C/cm

Physical Characteristics:

Thermal Expansion

: temperature change causing a

material to expand or contract can create change in

dimension

Coefficient of Thermal Expansion:

the amount of dimensional change as a material

expands/contracts

Ideally, choose a restoration that expands &

contracts same as tooth.

Physical Characteristics:

Electrical & Thermal Conduction:

No need for materials to be conductive

Metals ARE good conductors

Galvanism

– a ―shock‖ created by 2 unlike metals in

contact + saliva so we need to Protect teeth from

stimulation; insulate!

Solubility and Sorption

The solubility of materials in the mouth and

sorption (adsorption plus absorption ) of oral fluids

by the material are important.) Least soluble =

porcelains & ceramics.)(Most soluble = polymers &

acrylics)

Solubility and Sorption are reported in two ways:

1.

In weight percent of soluble or sorption material.

2.

The weight of dissolved or sorption material per

unit of surface area (e.g. milligrams per square

centimetre)

Solubility and Sorption

Absorption : the uptake of liquid by the bulk solid.

E.g. the equilibrium absorption of water by acrylic

plastics is in the range of 2%.

Adsorption

:

concentration of molecules at the

surface of a solid or liquid, e.g. adsorption of

components of saliva at the surface of tooth

structure.

Physical Characteristics:

ADHESION:The force of attraction between

molecules or atoms of two different surfaces brought

into contact.

COHESION:The force of attraction between

molecules or atoms within a material.

Adhesive:

that which is being attached (“glue”)

Adherend:

the surface to which it will be attached

Surface tension

: a property of liquids in

which the exposed surface tends to contract

to the smallest possible area, as in the

spherical formation of drops; this is a

phenomenon attributed to the attractive

forces, or cohesion, between the molecules

of the liquid

Physical Characteristics:

Factors influencing ADHESION, (

adhesion):

Wettability

– the ability of the surface to become wet;

(

wettability

)

Surface Energy

– the available energy at the surface;

(

surface energy)

Surface Tension

– amount of attraction the molecules

have for one another;

(

surface tension)

Viscosity

– resistance to flow;

(

viscosity)

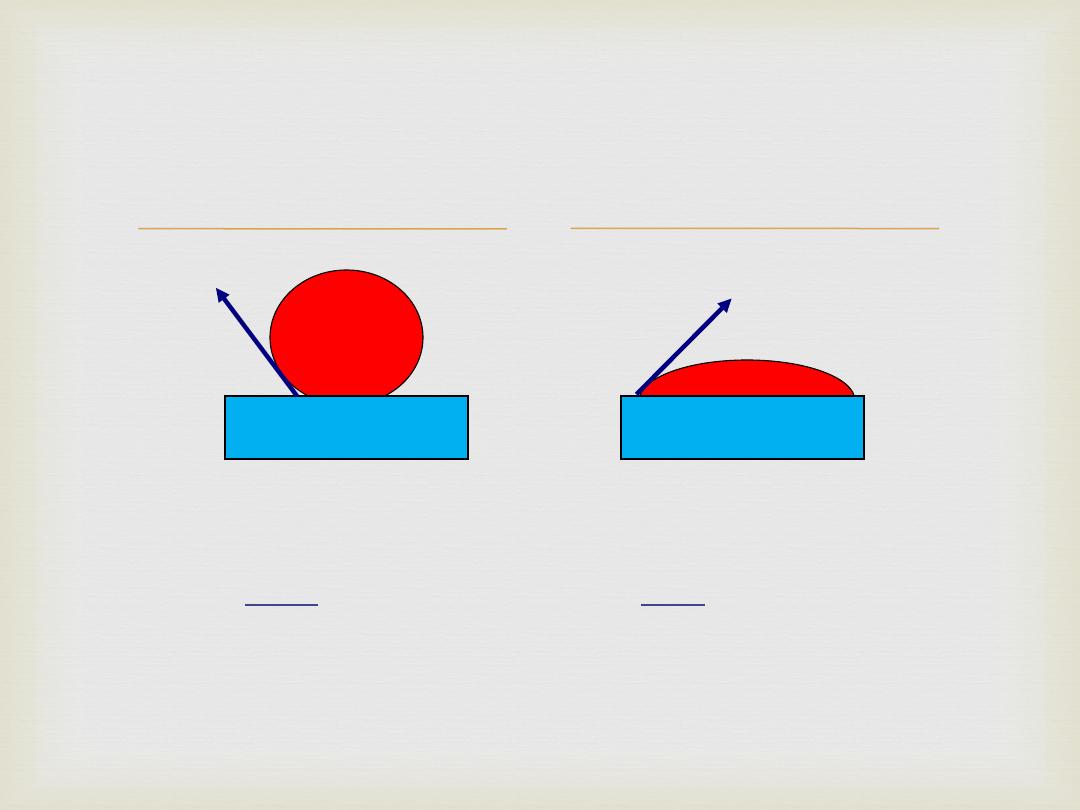

Wettability: Contact

Angle

adherend

adherend

Good Wetting:

Low contact angle;

Less than 90°

Poor Wetting:

High contact angle;

Over 90°

Rheological properties

Rheological properties: is the study of the

flow or deformation of materials (solid and

liquid).

Rheological properties of liquids and pastes

normally involve the measurement of

viscosity.

viscosity= Shear stress/shear rate.

Material of low viscosity requires only a low

pressure to produce a high flow rate

Physical Characteristics:

COLOR & ESTHETICS:

Created by light’s interaction with material

Hue

– dominant color

Value

– lightness of a color

Chroma

– intensity of a color

Translucency - teeth permit light to transmit

through them

High demand today for materials to match

natural tooth

Physical Characteristics:

CORROSION:

The deterioration of a metal by a chemical or

electrochemical reaction; irreversible

Tarnish: surface deterioration; discoloration

Methods of Corrosion:

―Battery‖ created: 2 metals + saliva =

release of metallic ions & destruction of metal

STRESS

STRESS

is the force with which a structure resists an external

load placed on it. It is the internal reaction to an

externally applied load and is equal in magnitude

but opposite in direction to the external load;

although technically the internal force, this is

difficult to measure and so the accepted way of

measuring stress is to measure the external load

applied to the cross sectional area; measured in

force per area units such as kg/cm2, MPa

(MN/m2),

Stress

= Force/Area

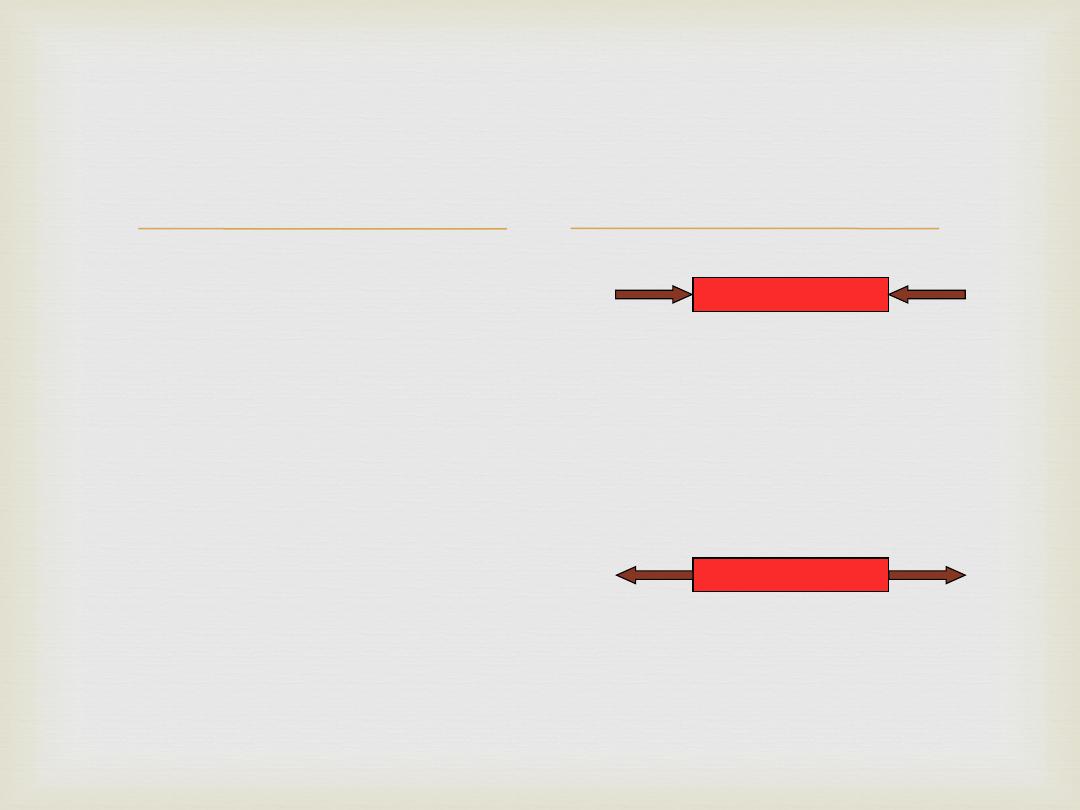

STRESS

Stress may be tensile sT,

compressive sC,

or shearing st,

depending on the sense of the strain produced.

Types of stresses

Axial

Compressive

Tensile

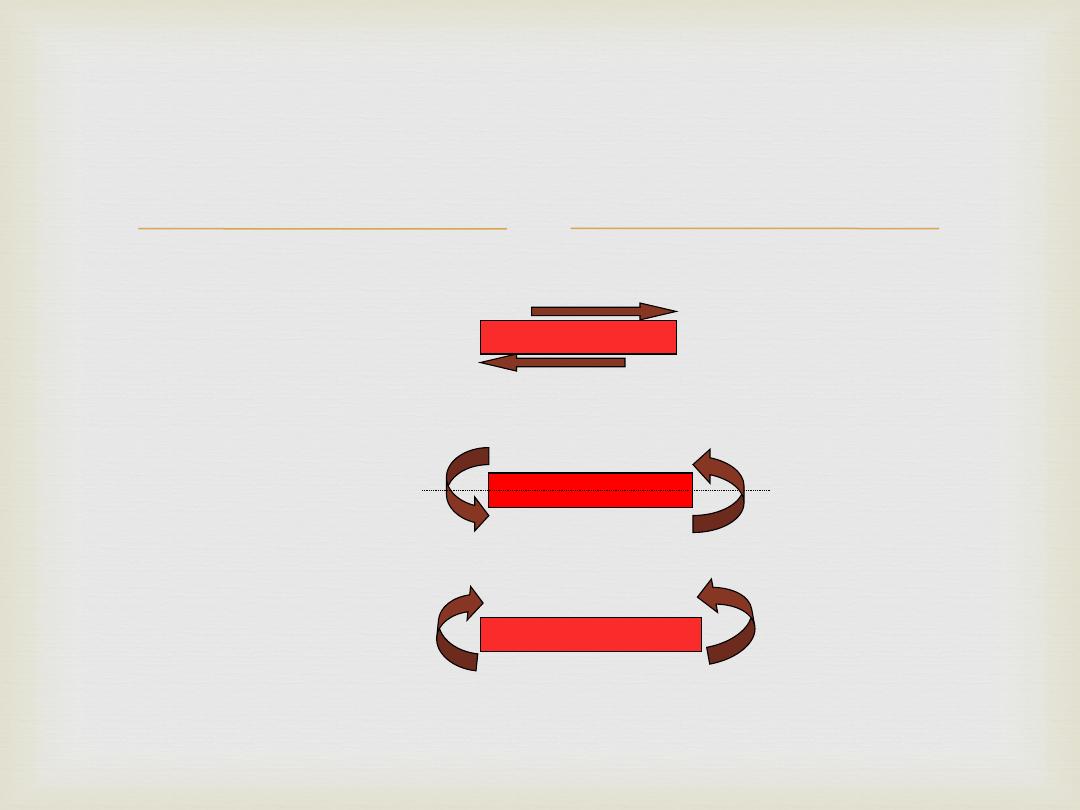

Types of stresses

Non Axial

Shear

Torsion

Bending

STRAIN

is the change in length per unit length that a material

undergoes when a force is applied to it; it is dimensionless because

it has length per length units of measurement; is often expressed as

a percentage.

Strain = Change in Length/Original Length

Strain can either be

elastic or plastic.

Elastic strain

is strain that totally disappears

once the external load that caused it is

removed. Elastic strain is based upon the

fact that a net force of zero exists between

two atoms when they are at equilibrium. If a

compressive or tensile force is exerted on

the atoms, an opposite force will attempt to

move them back to their equilibrium

position. When the applied force is released,

the atoms return to their original position;

therefore, the material is not permanently

deformed.

Strain

Plastic strain:

is strain that permanently remains once

the external load that caused it is removed. It occurs

when the force applied to the atoms moves

them so far from their equilibrium position that they do

not

return to it once the force is removed.

Change in length

Strain =

Original length

Compression

Strain may be recoverable or the material may

remain deformed (non-recoverable), or partially

recoverable. The extent to which the strain is

recovered is a function of the elastic properties of

materials.

Elastic Limit

– maximum stress level

tolerated by a material without

deformation

(a material will be deformed if any

more stress is put upon it)

Ultimate Strength

– the highest stress

tolerated before failure

(any more stress will

result in breakage of the material)

Yield strength :

the strength at which a small

amount of permanent (plastic) strain occurs,

usually 0.1% or 0.2%, and most frequently

measured in Mpa

Modulus of elasticity

: in metallurgy,

the coefficient found by dividing the unit stress, at

any point up to the proportional limit, by its

corresponding unit of elongation

(tension) or strain. A ratio of stress to strain. As the

modulus of elasticity rises, the material becomes

more rigid

Proportional Limit

- The point at which the

most metallic materials the elastic limit and

proportional limit are essentially the same.

Toughness

is the resistance to

. It is defined as the amount of

that a

material can absorb before

, and can be

found by finding the area

Toughness is measured in units of

per

3

)

Residual stress

are stresses that remain after

the original cause of the stresses has been

removed. Residual stresses occur for a

variety of reasons, including inelastic

deformations and heat treatment. Heat from

welding may cause localized expansion.

When the finished weldment cools, some

areas cool and contract more than others,

leaving residual stresses. Castings may also

have large residual stresses due to uneven

cooling.

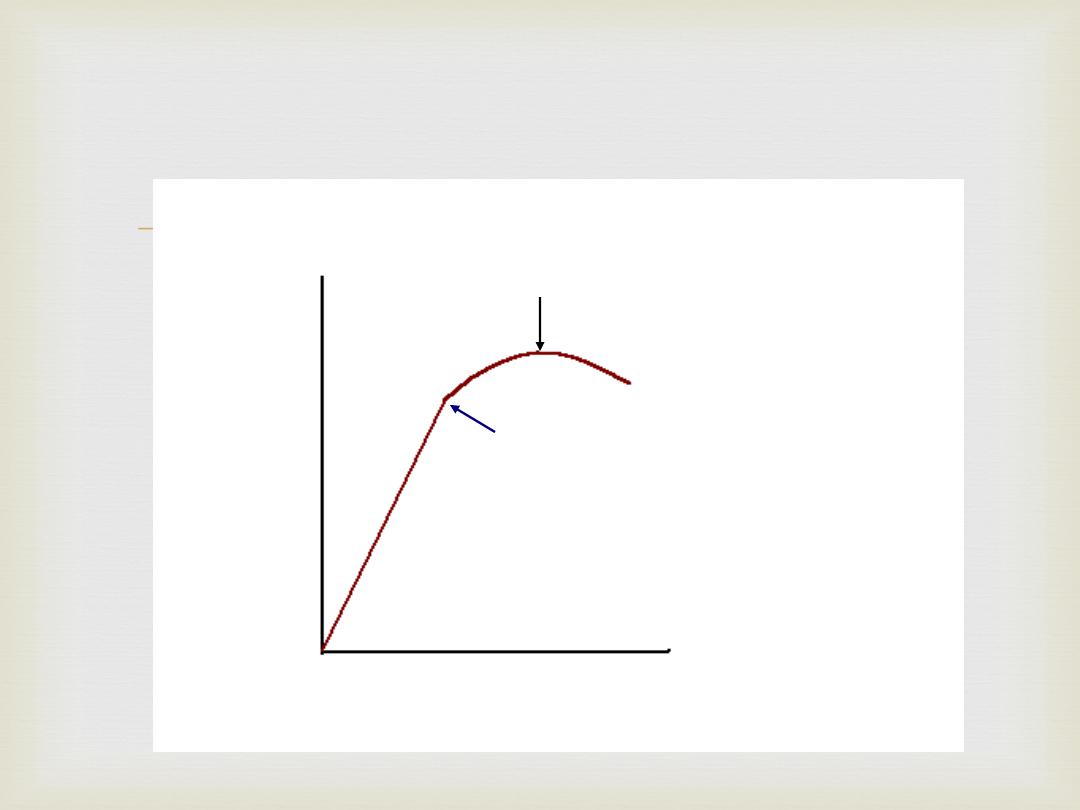

Stress-Strain Curve:

Strain

Stress

Elastic Limit

Proportional Limit

Modulus of

Elasticity

Ultimate Strength

Failure

Hardness:

an indication of the resistance to

penetration when indented by a hard

asperity. Low values of hardness number

indicate a soft material.

Common methods used for hardness test

include Vickers, Knoop, Brinell and Rockwell

Creep:

is simply defined as

1-

time-dependent plastic strain. The term

creep is usually applied to metals at

elevated temperatures, and is the low or

deformation of the material under a yield

strength.

2-

Creep: the slow change in dimensions of

an object due to prolonged exposure to high

temperature or stress

Fracture

This type of deformation is also not

reversible. A break occurs after the material

has reached the end of the elastic, and then

plastic, deformation ranges. At this point

forces accumulate until they are sufficient to

cause a fracture. All materials will eventually

fracture, if sufficient forces are applied.

DUCTILE MATERIALS

In ductile materials, such as metals, failure is

accompanied by plastic (permanent)

deformation. This

plastic deformation involves considerable

spending of energy - thus, the analysis

relating to

energy/unit volume = 0.5sTSe (Jm-3)

where sTS is the tensile strength and e the

strain at failure.

Abrasion 1

:

the wearing away of a substance or

structure (such as the skin or the teeth) through

some unusual or abnormal mechanical process

2

:

an abnormal wearing away of the tooth

substance by causes other than mastication—

attrition,erosion

Abrasive

:

a substance used for

abrading, smoothing, or polishing

Abrasive

1: tending to abrade 2: causing irritation

Abrasively

:

the property of one material to wear

away another material by means of frictional

contact

Setting expansion

: the dimensional increase

that occurs concurrent with the hardening of

various materials,

such as plaster of Paris, dental stone, die stone,

and dental casting investment

Biologic Characteristics:

The most prevalent concern:

Sealing

the interface

between restoration

and tooth!

Prevent leakage of bacteria, saliva, by-products

Prevent seepage of fluids into & out of the tooth

Dentinal tubules carry fluids, sealed by enamel

Hydrodynamic Theory – tooth pain is a result of the

fluid flow around odontoblastic processes, stimulating

nerve fibers

Temperature change can expand/contract these fluids