1

PROPERTIES AND STRENGTH OF MATERIALS

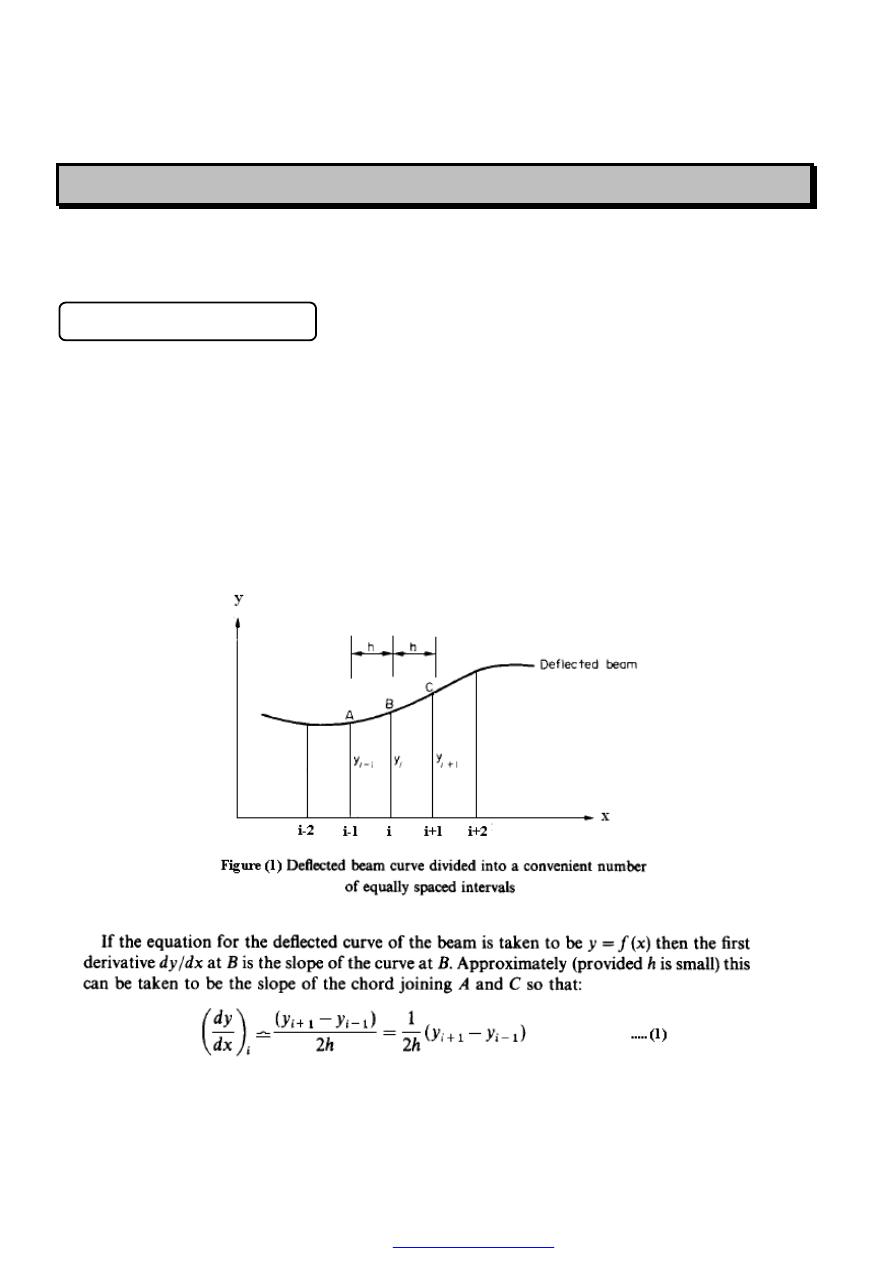

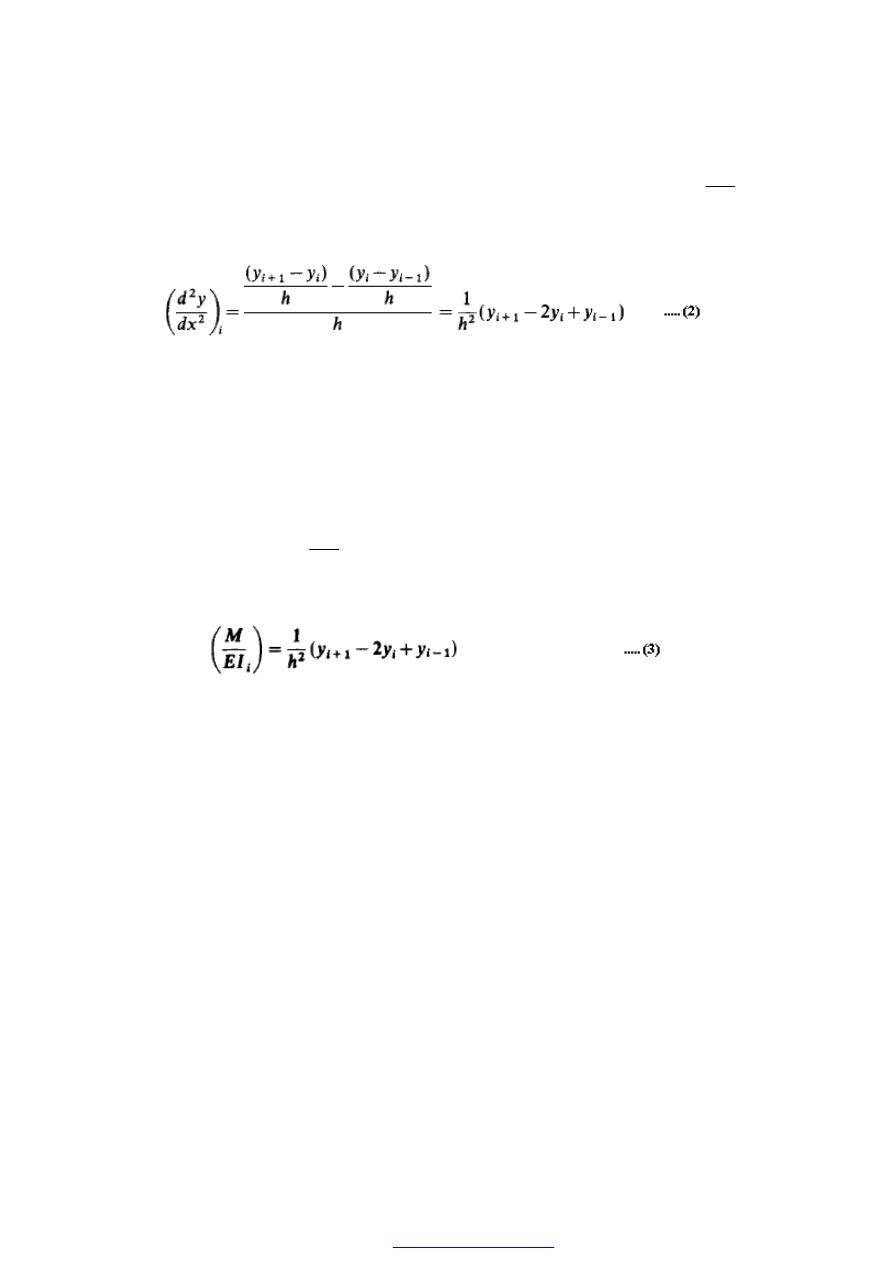

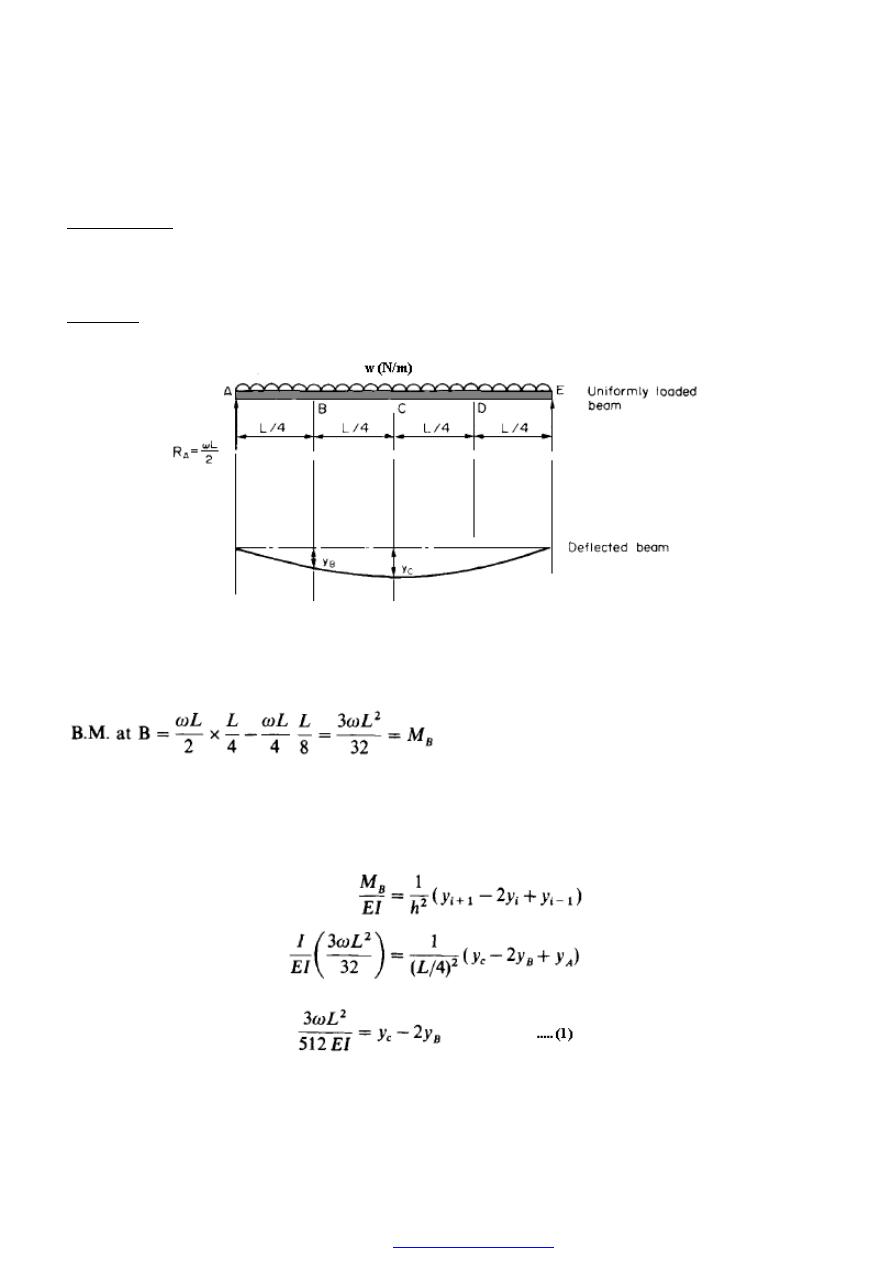

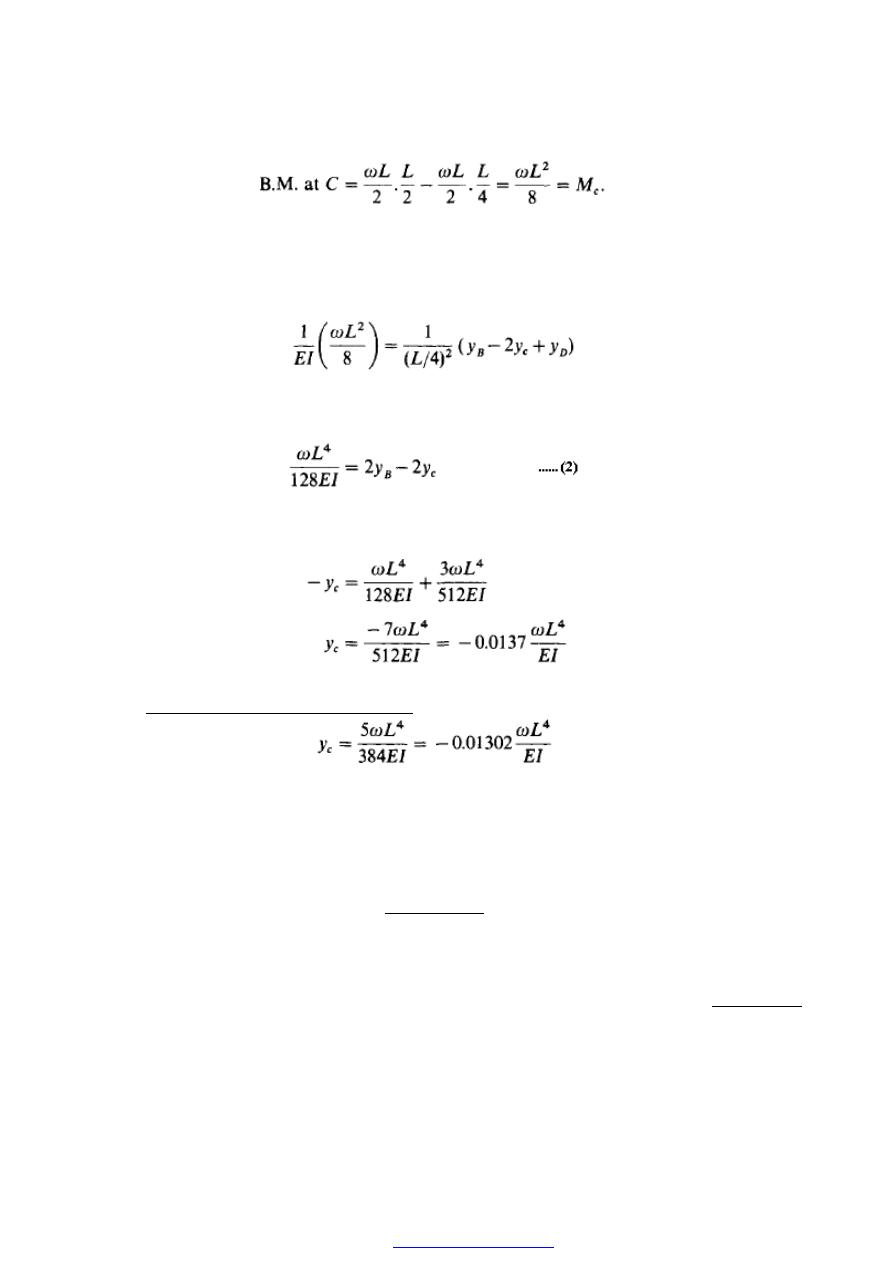

Dr. Muhannad Zedan

References

(1) Mechanics of Materials By: E. J. HEARN

(

2) Strength of Materials By: K. William

(3) Alloys: Preparation, Properties, Applications By: Fathi Habashi

(4) Materials for Engineers and Technicians By: Raymond A. Higgins

(5) Engineering Materials Science By: Milton Ohring

PDF created with pdfFactory Pro trial version

2

SIMPLE STRESS AND STRAIN

1. Load (P) (N)

In any engineering structure or mechanism the individual components will be

subjected to external forces arising from the service conditions or environment in which

the component works.

0

,

0

P

,

0

P

Y

X

=

Σ

=

Σ

=

Σ

o

M

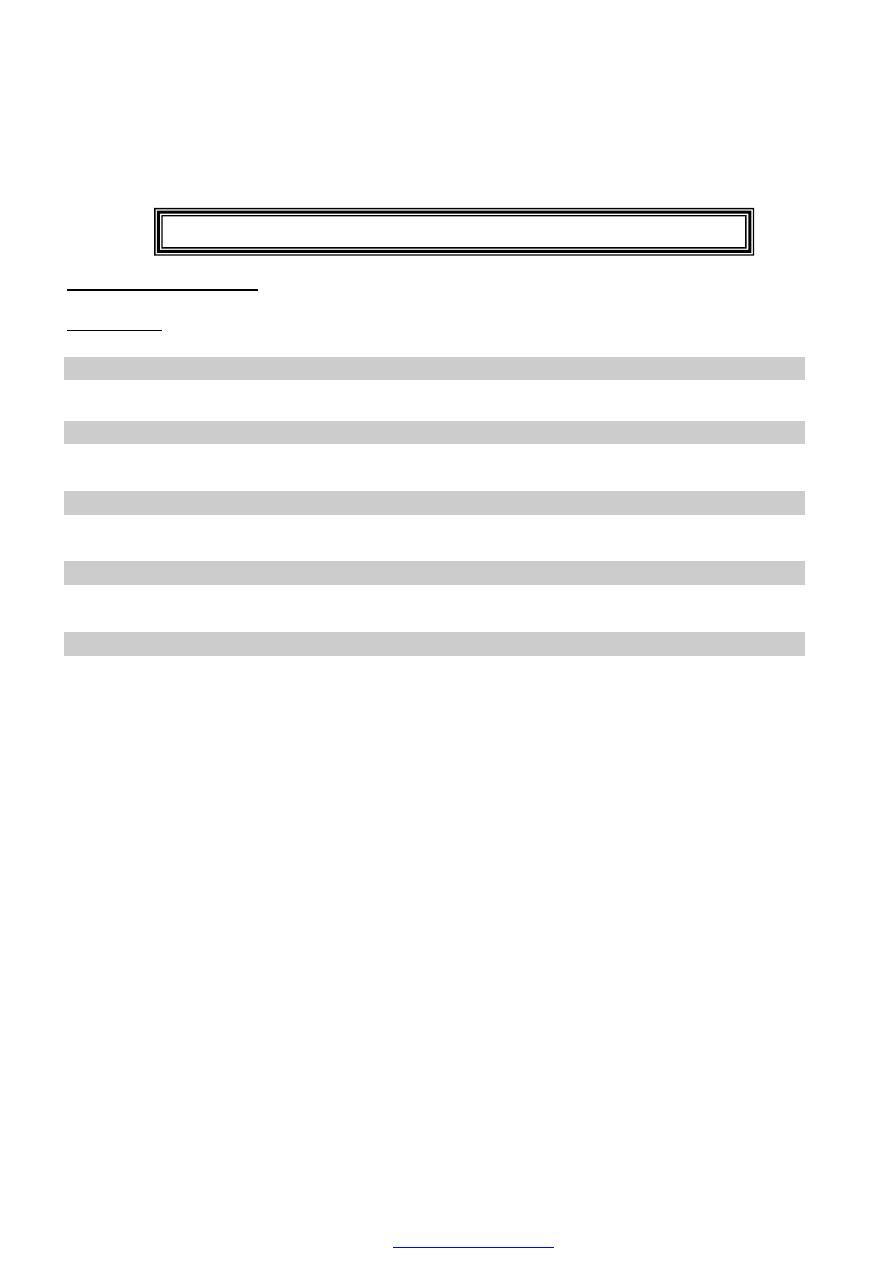

If a cylindrical bar is subjected to a direct pull or push along its axis as shown in

Figure (1), then it is said to be subjected to tension or compression.

Figure (1) Types of direct stress (Tension or Compression)

In the SI system of units load is measured in newtons, loads appear in SI multiples, i.e.

kilonewtons (kN) or meganewtons (MN). There are a number of different ways in which

load can be applied to a member. Typical loading types are:

(a) Static or dead loads, i.e. non-fluctuating loads, generally caused by gravity effects.

(b) Liue loads, as produced by, for example, lorries crossing a bridge.

(c) Impact or shock loads caused by sudden blows.

(d) Fatigue, fluctuating or alternating loads.

2. Direct or normal stress (

σ

),(N/m

2

)

A bar is subjected to a uniform tension or compression, i.e. a direct force, which is

uniformly or equally applied across the cross section, then the internal forces set up are

also distributed uniformly and the bar is said to be subjected to a uniform direct or

normal stress, the stress being defined as

A

P

area

Load

Stress

=

=

PDF created with pdfFactory Pro trial version

3

Stress

(σ)

may thus be (i) compressive stress or (ii) tensile stress depending on the

nature of the load and will be measured in units of (N/m

2

).

3. Direct strain (

ε

)

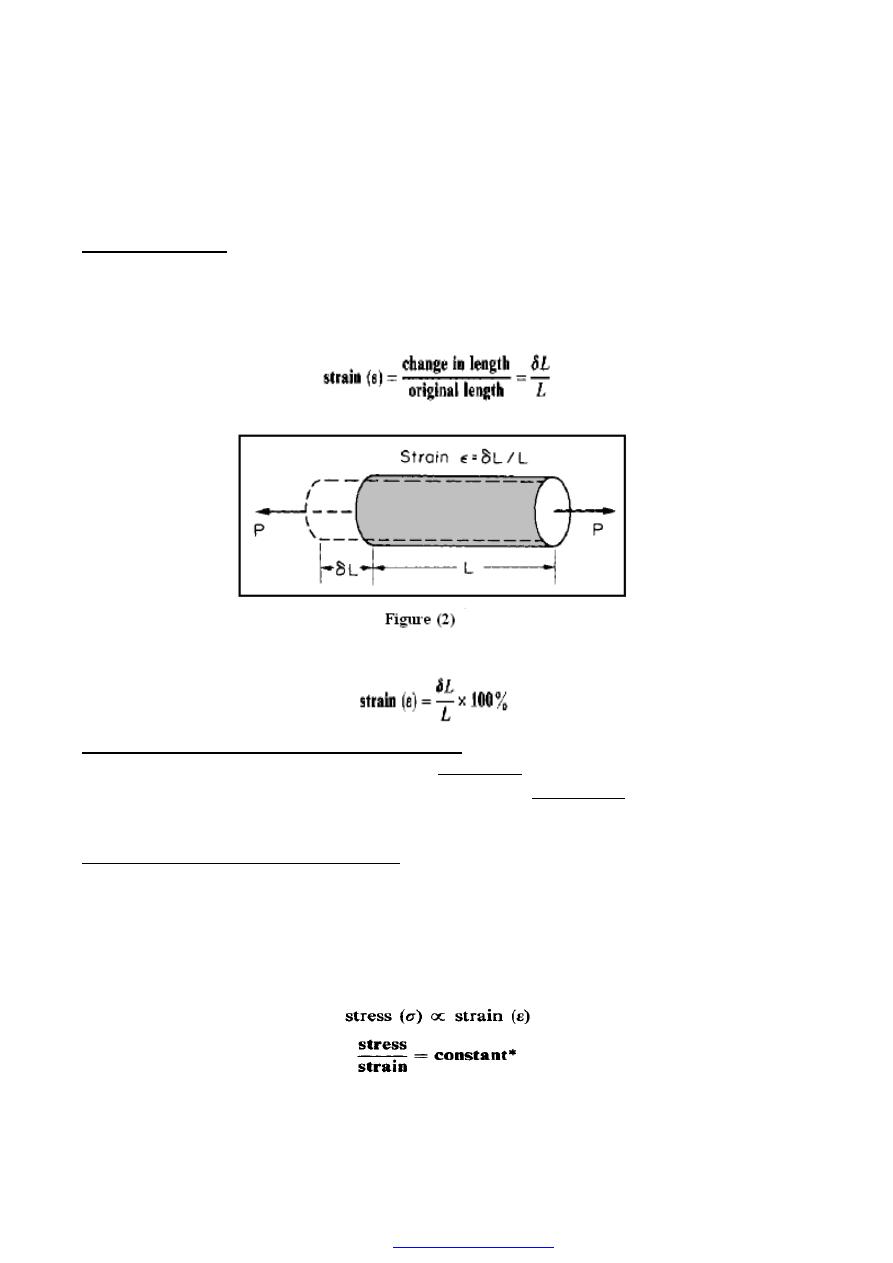

Figure (2) show a bar is subjected to a direct load, and hence a stress, the bar will change

in length. If the bar has an original length L and changes in length by an amount

δL, the

strain produced is defined as follows:

Strain is thus a measure of the deformation of the material and is non-dimensional,

Alternatively, strain can be expressed as a percentage strain

4. Sign convention for direct stress and strain

Tensile stresses and strains are considered

POSITIVE

in sense producing an increase in

length. Compressive stresses and strains are considered

NEGATIVE

in sense producing a

decrease in length.

5. Elastic materials - Hooke’s law (E), (N/m

2

)

A material is said to be elastic if it returns to its original, unloaded dimensions when

load is removed. A particular form of elasticity which applies to a large range of

engineering materials, at least over part of their load range, produces deformations which

are proportional to the loads producing them. stress is proportional to strain. Hooke

’s

law, in its simplest form*, therefore states that

PDF created with pdfFactory Pro trial version

4

Other classifications of materials with which the reader should be acquainted are as

follows:

A material which has a uniform structure throughout without any flaws or

discontinuities

is

termed

a

homogeneous

material.

Non-homogeneous

or

inhomogeneous materials such as concrete and poor-quality cast iron will thus have a

structure which varies from point to point depending on its constituents and the presence

of casting flaws or impurities.

If a material exhibits uniform properties throughout in all directions it is said to be

isotropic; conversely one which does not exhibit this uniform behaviour is said to be

nonisotropic or anisotropic.

An orthotropic material is one which has different properties in different planes. A

typical example of such a material is wood, although some composites which contain

systematically orientated “inhomogeneities” may also be considered to fall into this

category.

6. Modulus of elasticity - Young’s modulus (E), (N/m

2

)

Within the elastic limits of materials, i.e. within the limits in which Hooke’s law applies,

it has been shown that:

This constant is given the symbol E and termed the modulus of elasticity or Young

’s

modulus, Thus

ε

σ

=

=

Strain

Stress

E

…..(1)

L

A

L

P

E

δ

.

.

=

…..(2)

Young’s modulus E is generally assumed to be the same in tension or compression and

for most engineering materials has a high numerical value. Typically, E = 200 x l0

9

N/m

2

for steel.

E

σ

ε

=

……(3)

In most common engineering applications strains do not often exceed 0.003 or 0.3 % so

that the assumption used later in the text that deformations are small in relation to

original dimensions is generally well founded.

PDF created with pdfFactory Pro trial version

5

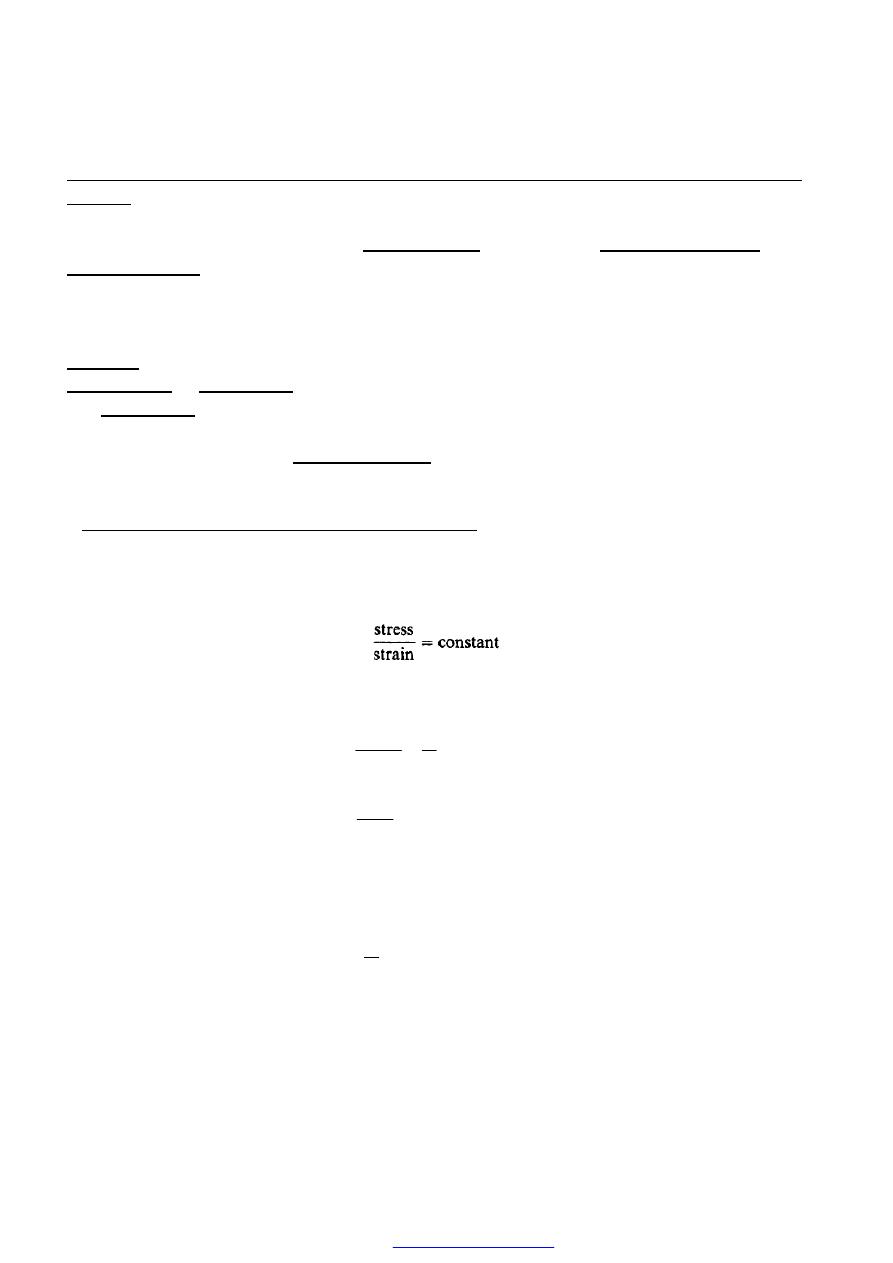

7. Tensile test

The standard tensile test in which a circular bar of uniform cross-section is subjected

to a gradually increasing tensile load until failure occurs. Measurements of the change in

length of a selected gauge length of the bar are recorded throughout the loading

operation by means of extensometers and a graph of load against extension or stress

against strain is produced as shown in Fig. (3); this shows a typical result for a test on a

mild (low carbon) steel bar; other materials will exhibit different graphs but of a similar

general form see Figures (5) to( 7).

Figure (3) Typical tensile test curve for mild steel.

For the first part of the test it will be observed that Hooke’s law is obeyed, the material

behaves elastically and stress is proportional to strain, giving the straight-line graph

indicated. Some point A is eventually reached, however, when the linear nature of the

graph ceases and this point is termed the limit of proportionality.

C, termed the upper yield point

D, the lower yield point

That stress which, when removed, produces a permanent strain or “set” of 0.1 % of the

original gauge length-see Fig. (4a).

Figure (4a) Determination of 0.1 % proof stress. Figure (4b) Permanent deformation or “set” after

straining beyond the yield point.

PDF created with pdfFactory Pro trial version

6

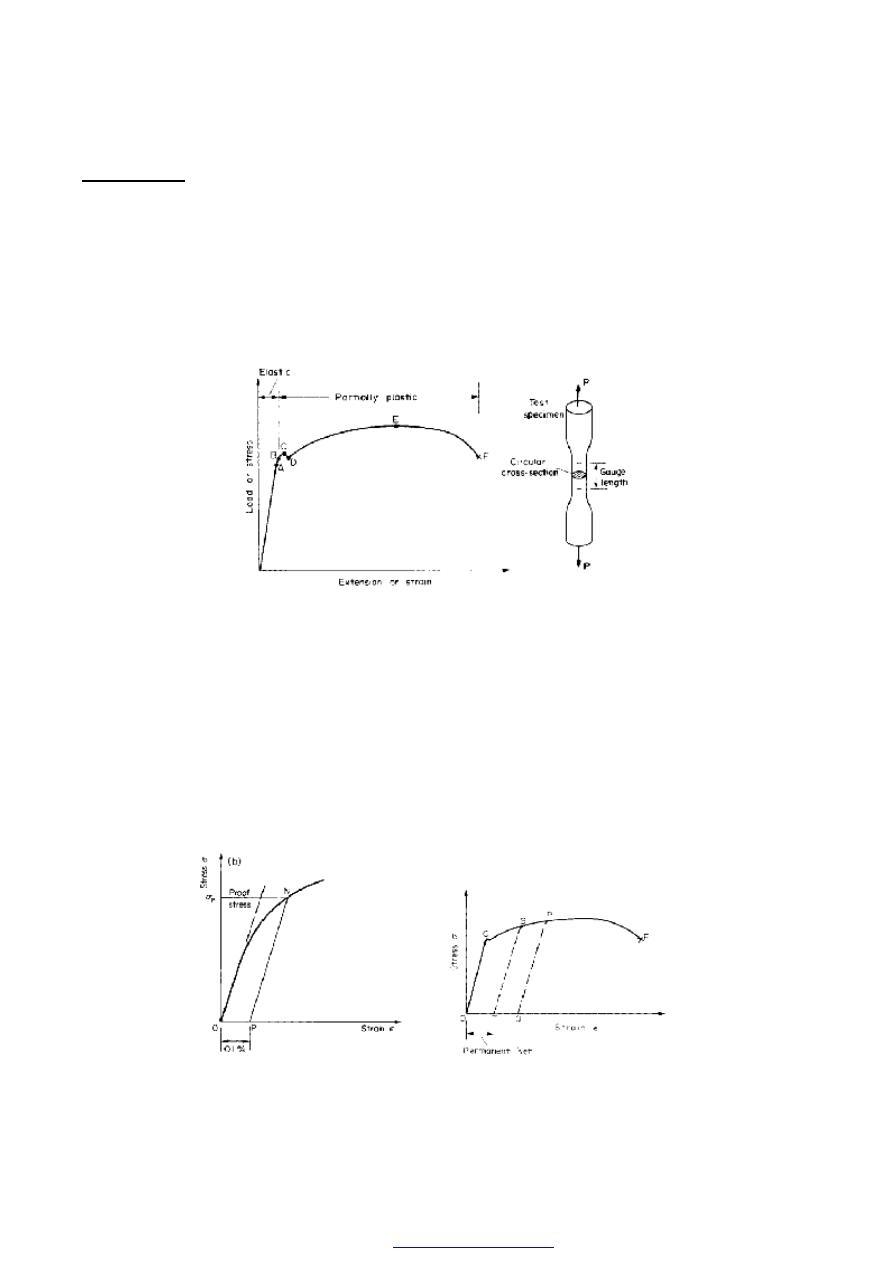

Typical stress-strain curves resulting from tensile tests on other engineering materials are

shown in Figs. (5) to (7).

Figure (5)Tensile test curves for various metals.

Figure (6) Typical stress - strain curves for hard drawn wire

material-note large reduction in strain values from those of Figure (5)

Figure(7) Typical tension test results for various types of

nylon and polycarbonate.

PDF created with pdfFactory Pro trial version

7

8. Ductile materials

It has been observed above that the partially plastic range of the graph of Figure (3)

covers a much wider part of the strain axis than does the elastic range. Thus the extension

of the material over this range is considerably in excess of that associated with elastic

loading. The capacity of a material to allow these large extensions, i.e. the ability to be

drawn out plastically, is termed its ductility. Materials with high ductility are termed

ductile materials, members with low ductility are termed brittle materials. A quantitative

value of the ductility is obtained by measurements of the percentage elongation or

percentage reduction in area, both

being defined below.

9. Brittle materials

A brittle material is one which exhibits relatively small extensions to fracture so that the

partially plastic region of the tensile test graph is much reduced (Fig. 8). Whilst Fig. (3)

referred to a low carbon steel, Fig. (8) could well refer to a much higher strength steel

with a higher carbon content. There is little or no necking at fracture for brittle materials.

Figure(8) Typical tensile test curve for a brittle material

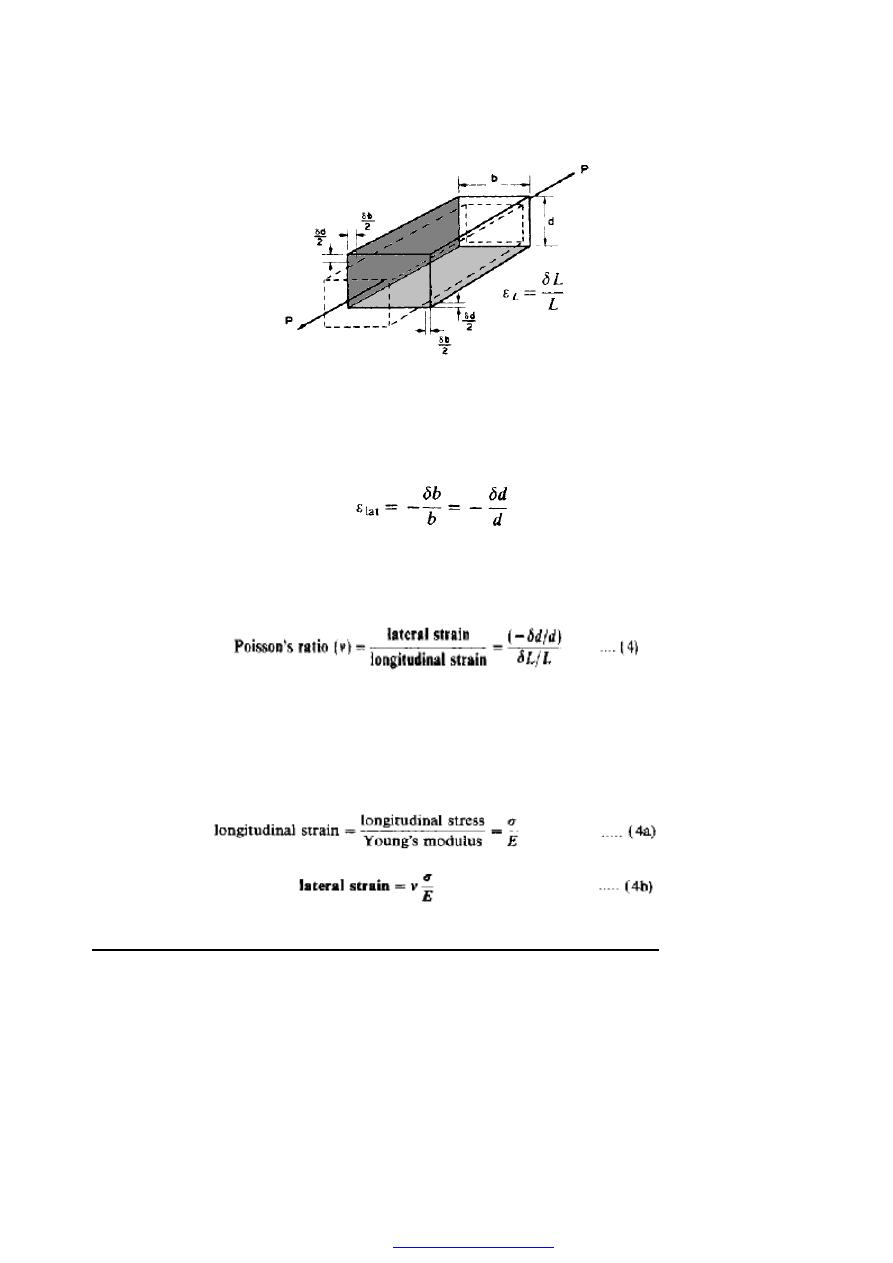

10. Poisson’s ratio (

ν)

Consider the rectangular bar of Figure (9) subjected to a tensile load. Under the action of

this load the bar will increase in length by an amount

δL giving a longitudinal strain in

the bar .

PDF created with pdfFactory Pro trial version

8

Figure (9)

The bar will also exhibit, however, a reduction in dimensions laterally, i.e. its breadth

and depth will both reduce. The associated lateral strains will both be equal, will be of

opposite sense to the longitudinal strain, and will be given by

Provided the load on the material is retained within the elastic range the ratio of the

lateral and longitudinal strains will always be constant. This ratio is termed Poisson

’s

ratio.

The negative sign of the lateral strain is normally ignored to leave Poisson’s ratio simply

as a ratio of strain magnitudes. It must be remembered, however, that the longitudinal

strain induces a lateral strain of opposite sign. For most engineering materials the value

of v lies between 0.25 and 0.33.

Since

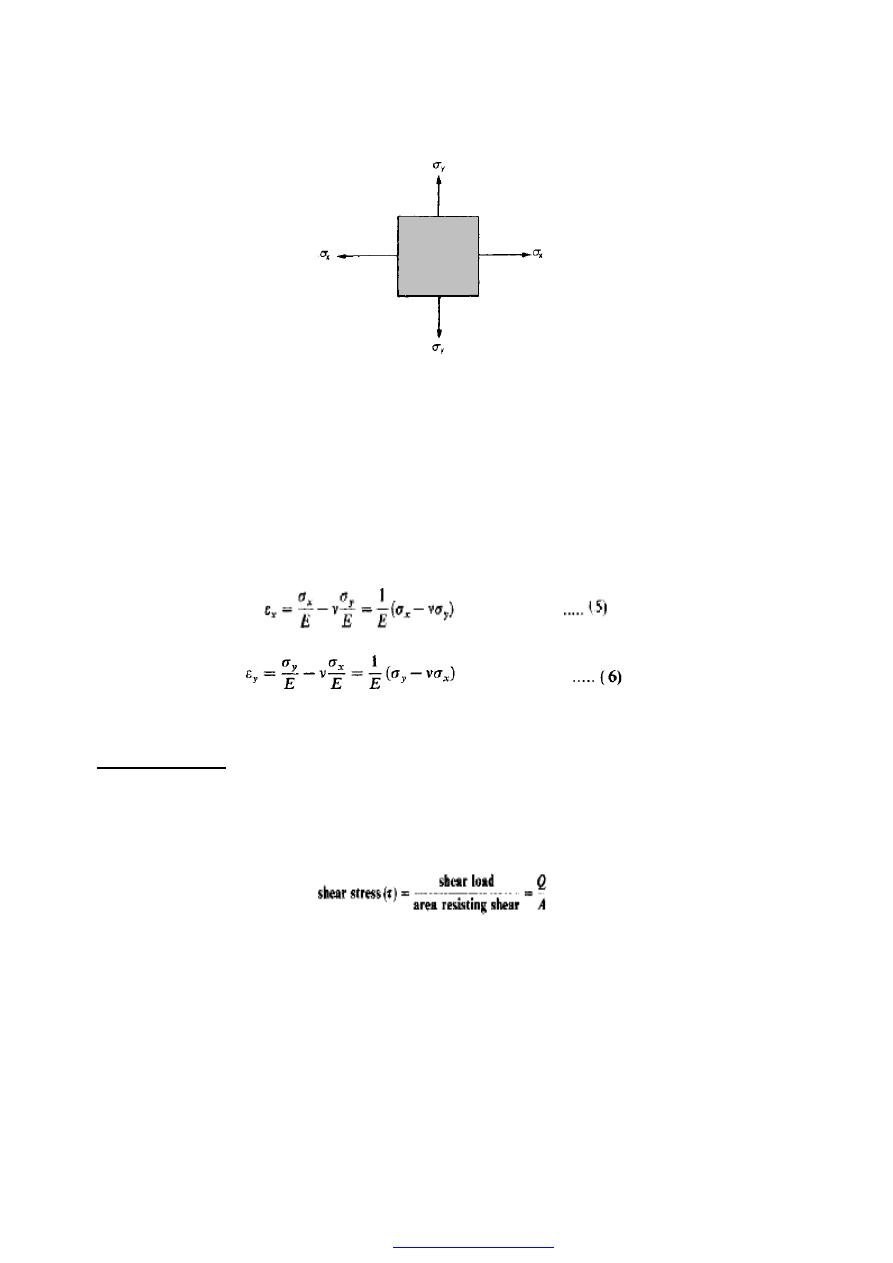

11. Application of Poisson’s ratio to a two-dimensional stress system

A two-dimensional stress system is one in which all the stresses lie within one plane such

as the X-Y plane as shown in figure (10).

PDF created with pdfFactory Pro trial version

9

Figure (10) Simple two-dimensional system of direct stresses.

The following strains will be produced

(a) in the X direction resulting from

ε

x

=

σ

x

/E

(b) in the Y direction resulting from

ε

y

=

σ

y

/E.

(c) in the X direction resulting from

ε

y

= - v(

σ

y

/E),

(d) in the Y direction resulting from

ε

x

= - v(

σ

x

/E).

strains (c) and (d) being the so-called Poisson

’s ratio strain, opposite in sign to the

applied strains, i.e. compressive.

The total strain in the X direction will therefore be given by

:

and the total strain in the Y direction will be:

If any stress is, in fact, compressive its value must be substituted in the above equations

together with a negative sign following the normal sign convention.

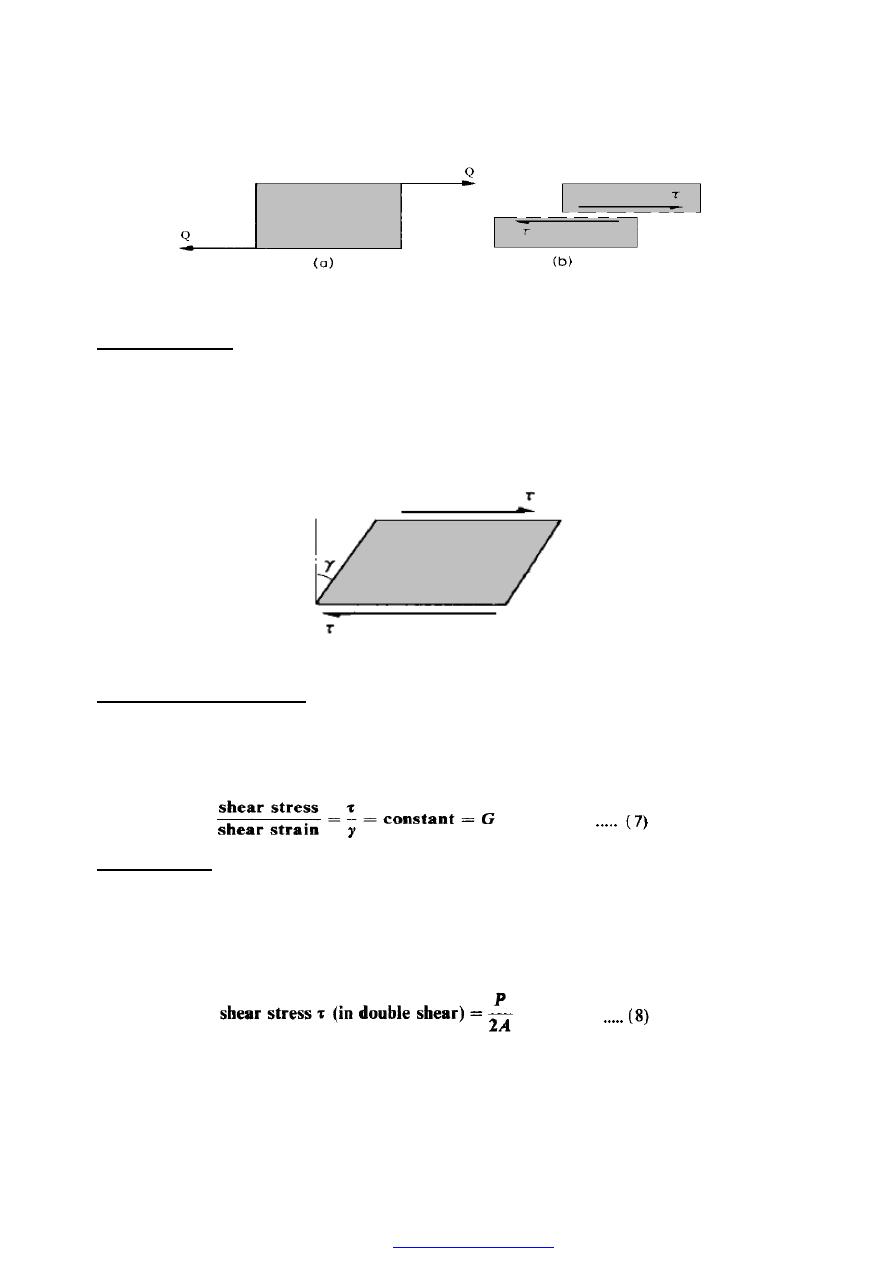

12. Shear stress(

τ

) , (N/m

2

)

Consider a block or portion of material as shown in Figure (11) subjected to a set of

equal and opposite forces Q. (Such a system could be realised in a bicycle brake block

when contacted with the wheel.) then a shear stress

τ is set up, defined as follows:

This shear stress will always be tangential to the area on which it acts; direct stresses,

however, are always normal to the area on which they act.

PDF created with pdfFactory Pro trial version

10

Figure(11) Shear force and resulting shear stress system showing typical form of failure by

relative sliding of planes.

13. Shear strain (

γ

)

If one again considers the block of Figure (11a)to be a bicycle brake block it is clear that

the rectangular shape of the block will not be retained as the brake is applied and the

shear forces introduced. The block will in fact change shape or “strain” into the form

shown in Figure (12) The angle of deformation y is then termed the shear strain.

Shear strain is measured in radians and hence is non-dimensional, i.e. it has no units

.

Figure (12) Deformation (shear strain) produced by shear stresses.

14. Modulus of rigidity (G), (N/m

2

)

For materials within the elastic range the shear strain is proportional to the shear

stress producing it, The constant G is termed the modulus of rigidity or shear modulus

and is directly comparable to the modulus of elasticity used in the direct stress

application.

15. Double shear

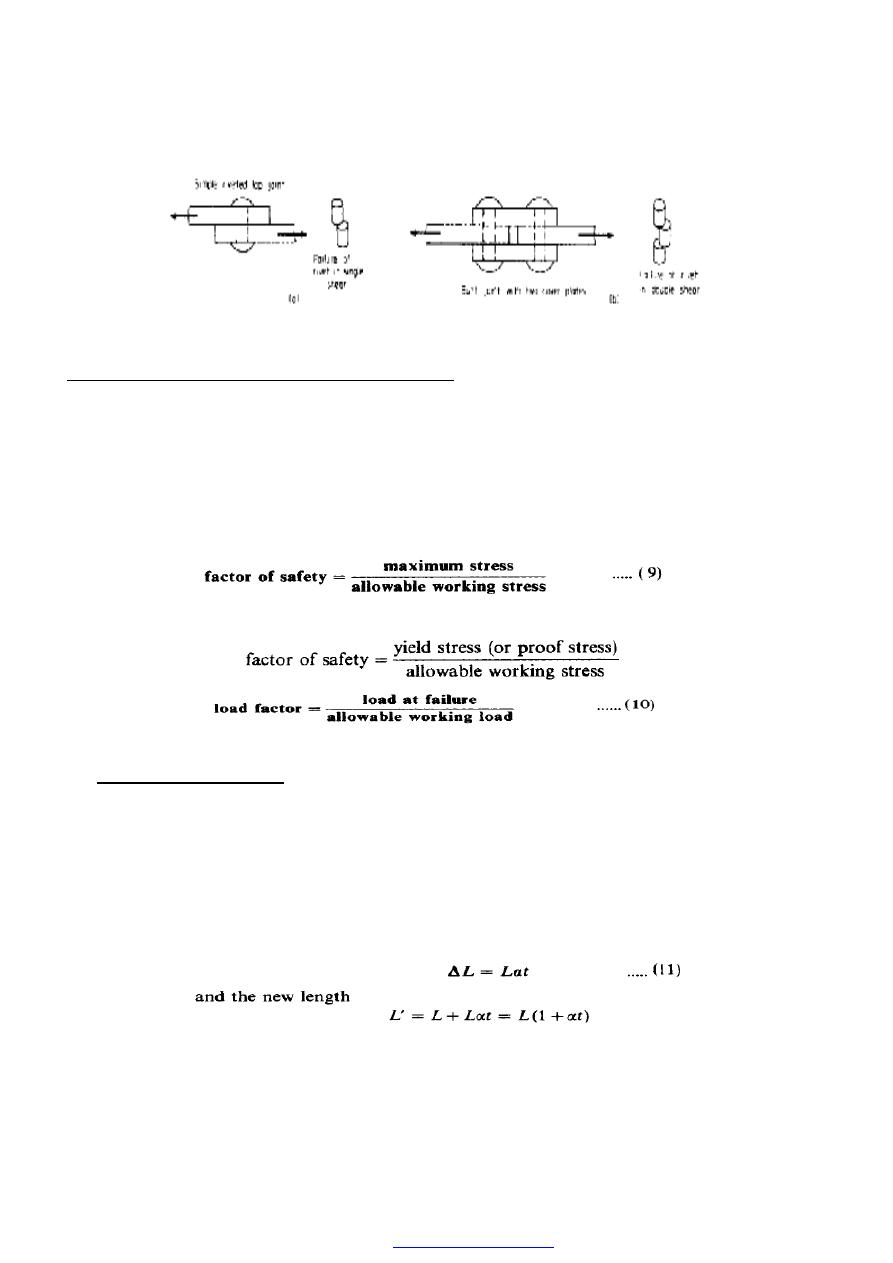

Consider the simple riveted lap joint shown in Figure (13a) When load is applied to

the plates the rivet is subjected to shear forces tending to shear it on one plane as

indicated. In the butt joint with two cover plates of Figure (13b), however, each rivet is

subjected to possible shearing on two faces, i.e. double shear. In such cases twice the

area

of metal is

resisting the applied forces so that the shear stress set up is given by

PDF created with pdfFactory Pro trial version

11

Figure (13) (a) Single shear. (b) Double shear.

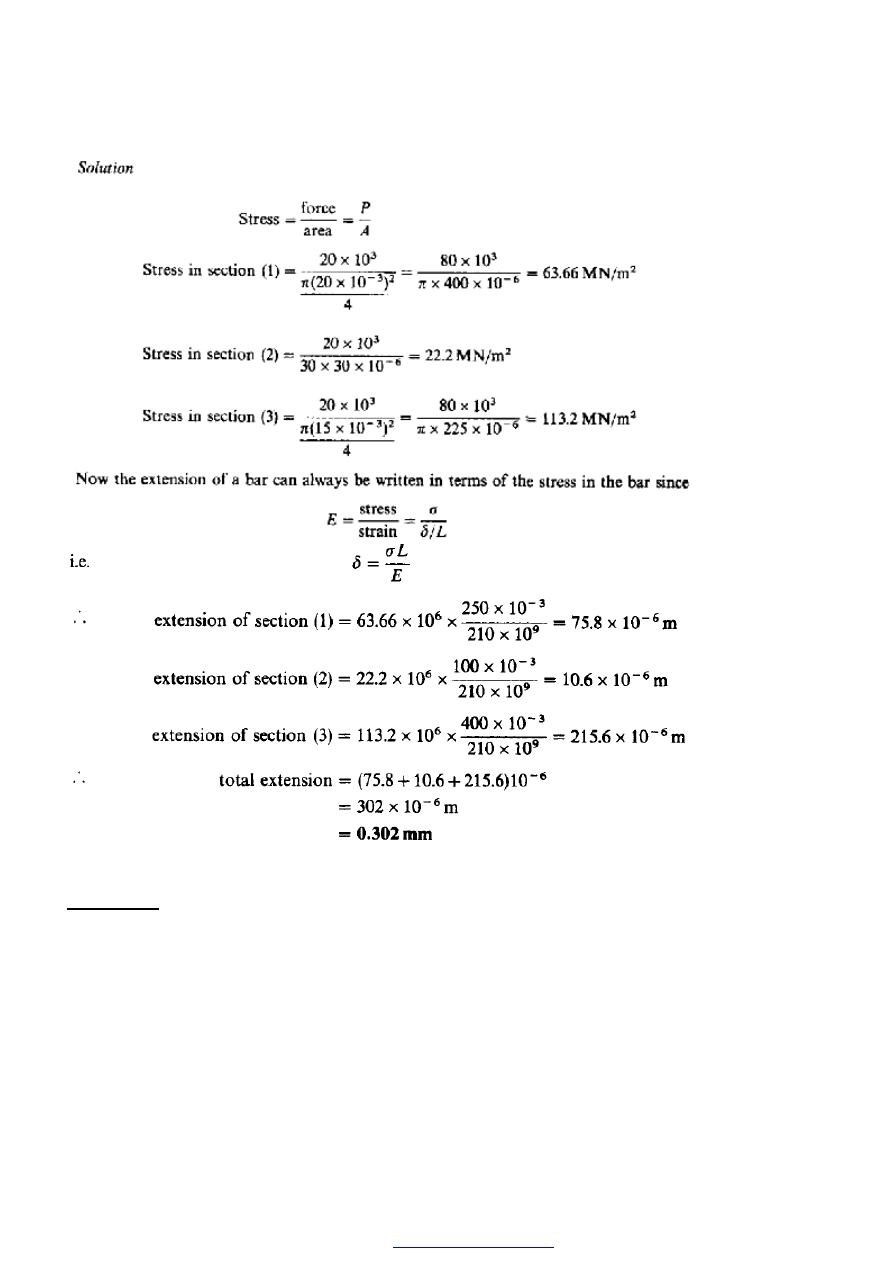

16. Allowable working stress-factor of safety

The most suitable strength or stiffness criterion for any structural element or component

is normally some maximum stress or deformation which must not be exceeded. In the

case of stresses the value is generally known as the maximum allowable working stress.

Because of uncertainties of loading conditions, design procedures, production methods,

etc., designers generally introduce a factor of safety into their designs, defined as follows

:

18. Temperature stresses

When the temperature of a component is increased or decreased the material

respectively expands or contracts. If this expansion or contraction is not resisted in any

way then the processes take place free of stress. If, however, the changes in dimensions

are restricted then stresses termed temperature stresses will be set up within the material.

Consider a bar of material with a linear coefficient of expansion

α

. Let the original length

of the bar be L and let the temperature increase be t. If the bar is free to expand the

change in length would be given by

PDF created with pdfFactory Pro trial version

12

Examples

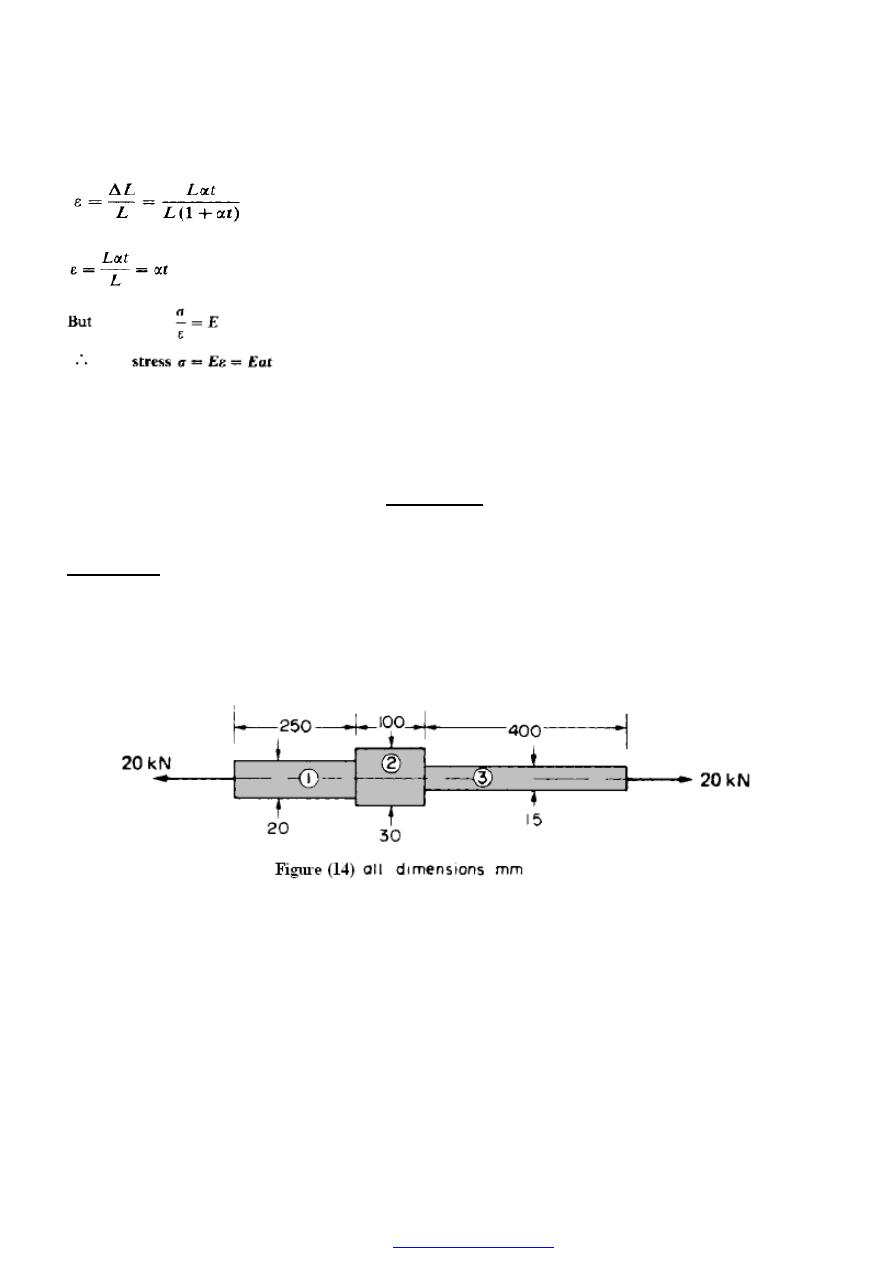

Example 1

Determine the stress in each section of the bar shown in Figure (14) when subjected to

an axial tensile load of 20 kN. The central section is 30 mm square cross-section; the

other portions are of circular section, their diameters being indicated. What will be the

total extension of the bar? For the bar material E = 210GN/m

2

.

PDF created with pdfFactory Pro trial version

13

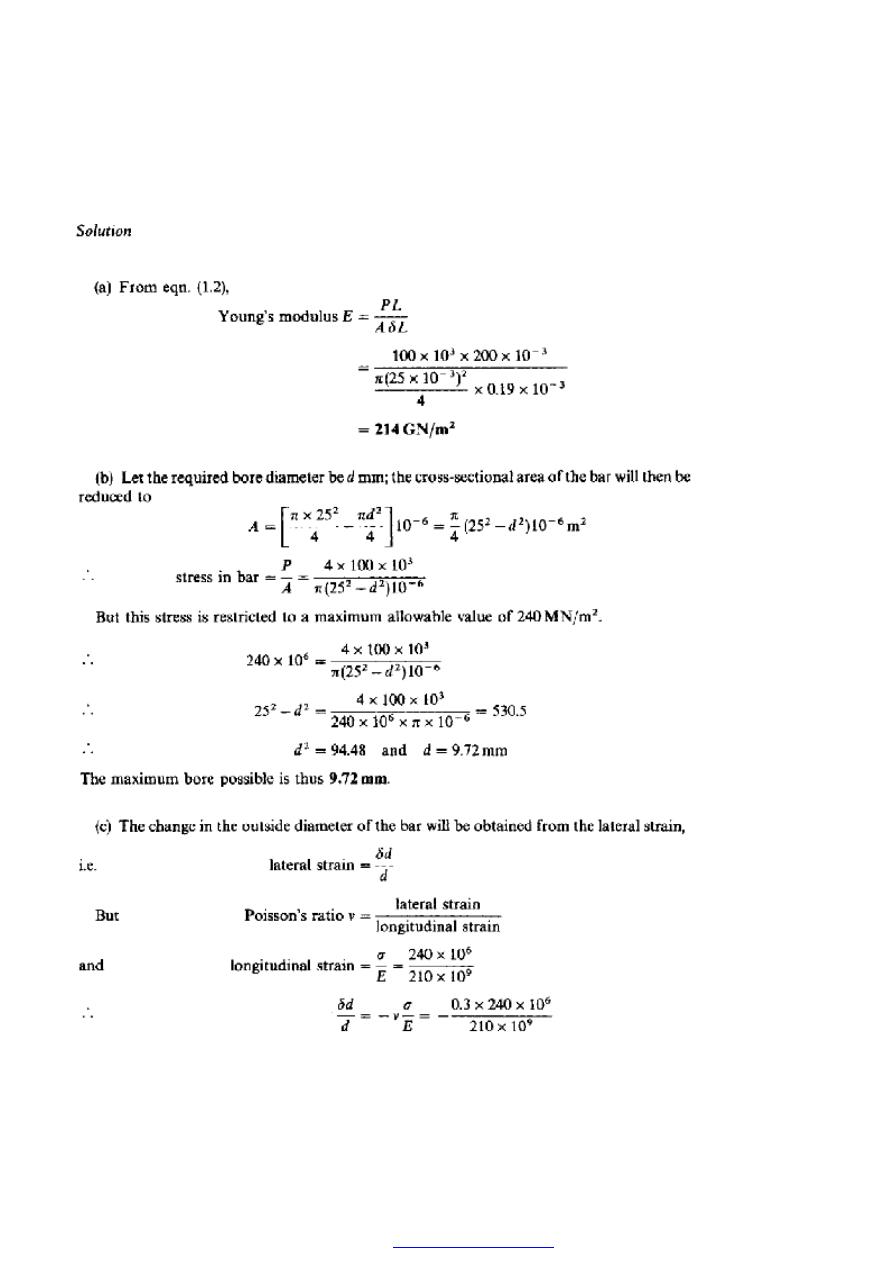

Example 2

(a) A 25 mm diameter bar is subjected to an axial tensile load of 100 kN. Under the

action of this load a 200mm gauge length is found to extend 0.19 x 10

-3

mm. Determine

the modulus of elasticity for the bar material.

(b) If, in order to reduce weight whilst keeping the external diameter constant, the bar is

bored axially to produce a cylinder of uniform thickness, what is the maximum diameter

of bore possible given that the maximum allowable stress is 240MN/m

2

? The load can be

assumed to remain constant at 100 kN.

PDF created with pdfFactory Pro trial version

14

(c) What will be the change in the outside diameter of the bar under the limiting stress

quoted in (b)? (E = 210GN/m2 and v = 0.3).

PDF created with pdfFactory Pro trial version

15

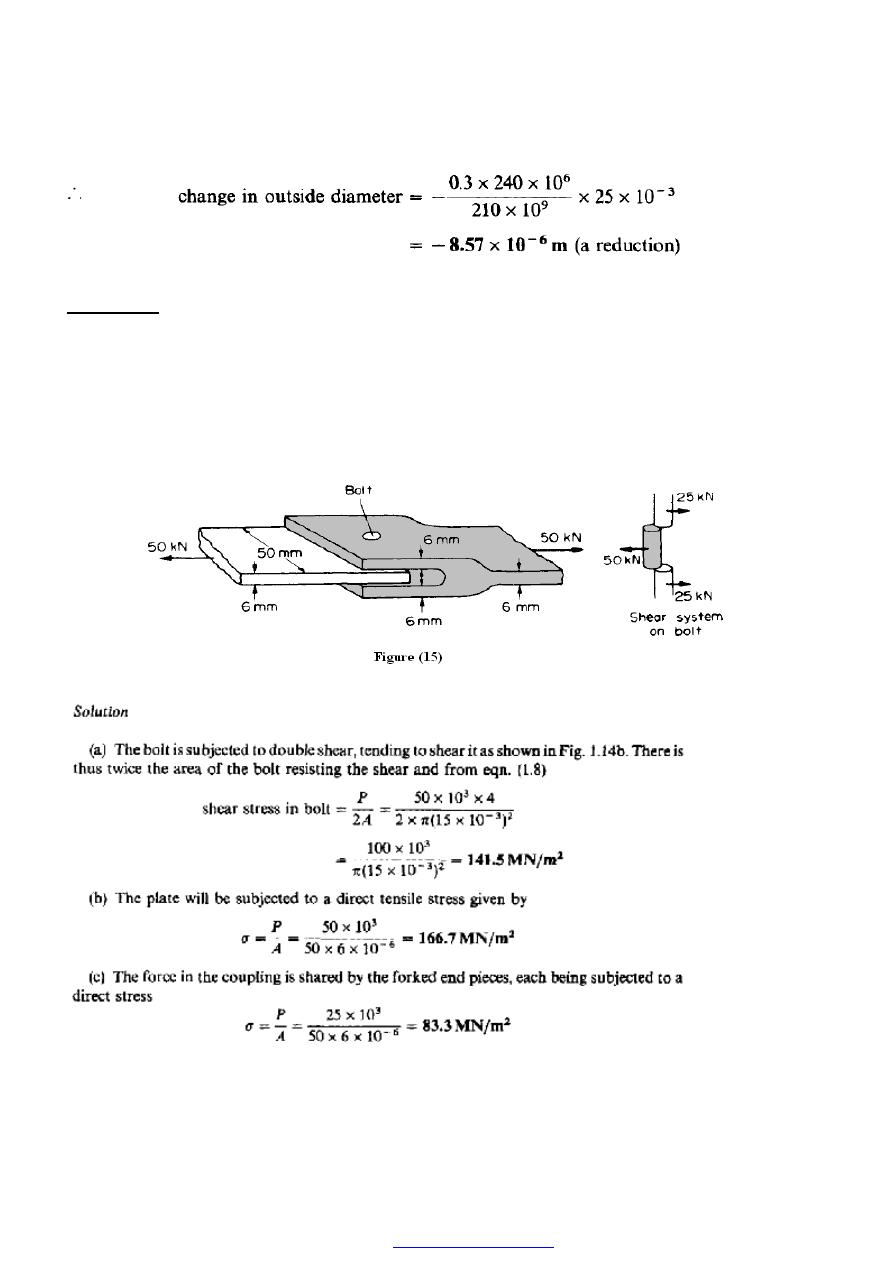

Example 3

The coupling shown in Figure (15) is constructed from steel of rectangular cross-section

and is designed to transmit a tensile force of 50 kN. If the bolt is of 15 mm diameter

calculate:

(a) the shear stress in the bolt;

(b) the direct stress in the plate;

(c) the direct stress in the forked end of the coupling

.

PDF created with pdfFactory Pro trial version

16

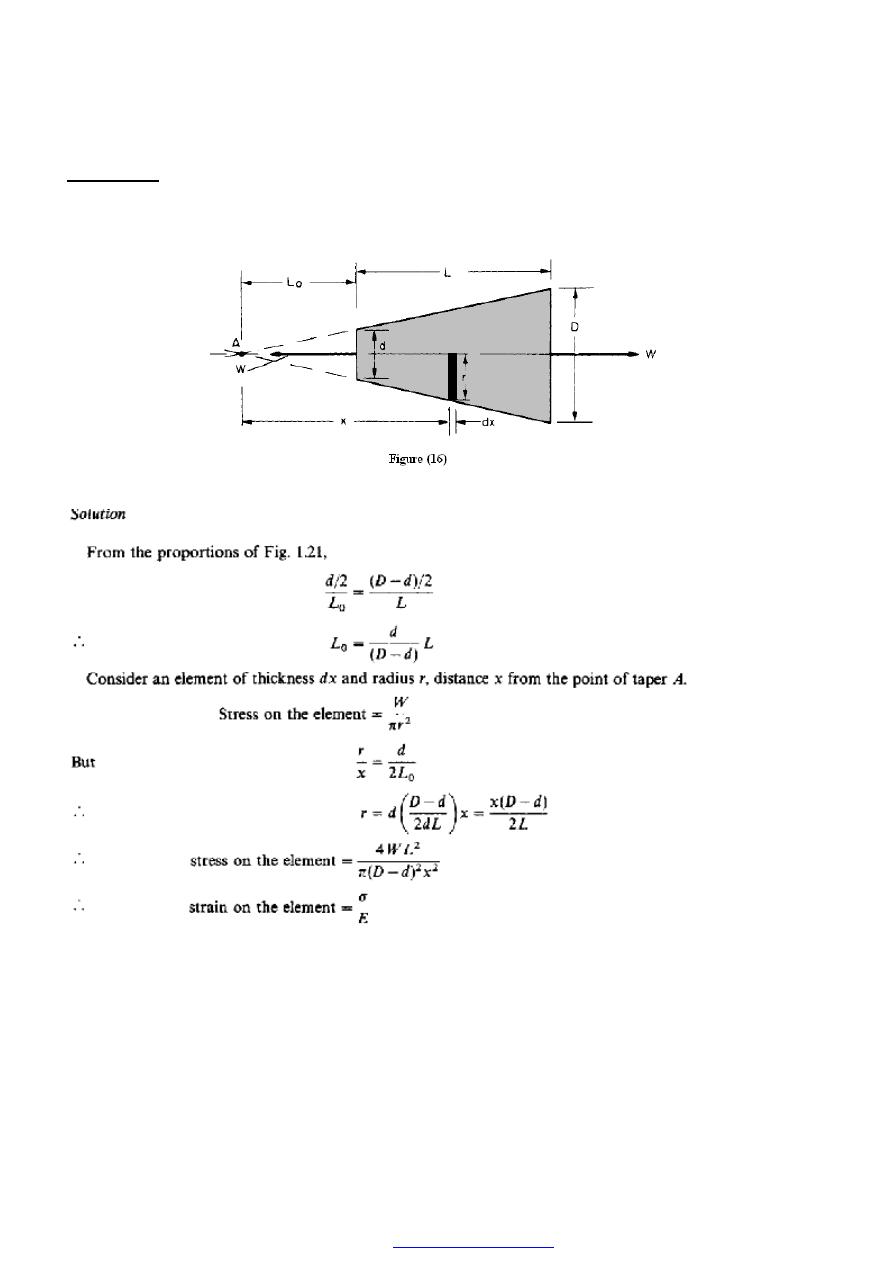

Example 4

Derive an expression for the total extension of the tapered bar of circular cross-section

shown in Figure (16) when it is subjected to an axial tensile load W.

PDF created with pdfFactory Pro trial version

17

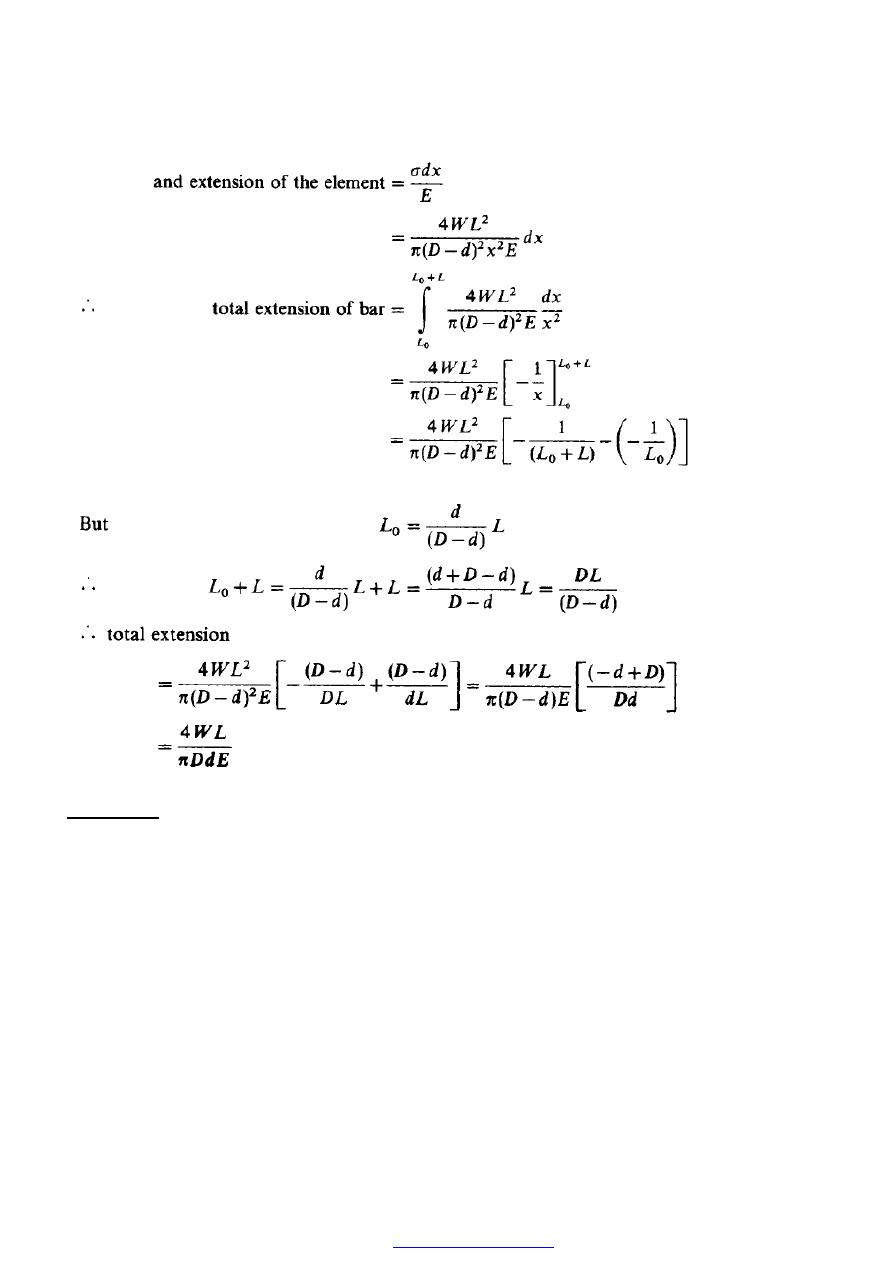

Example 5

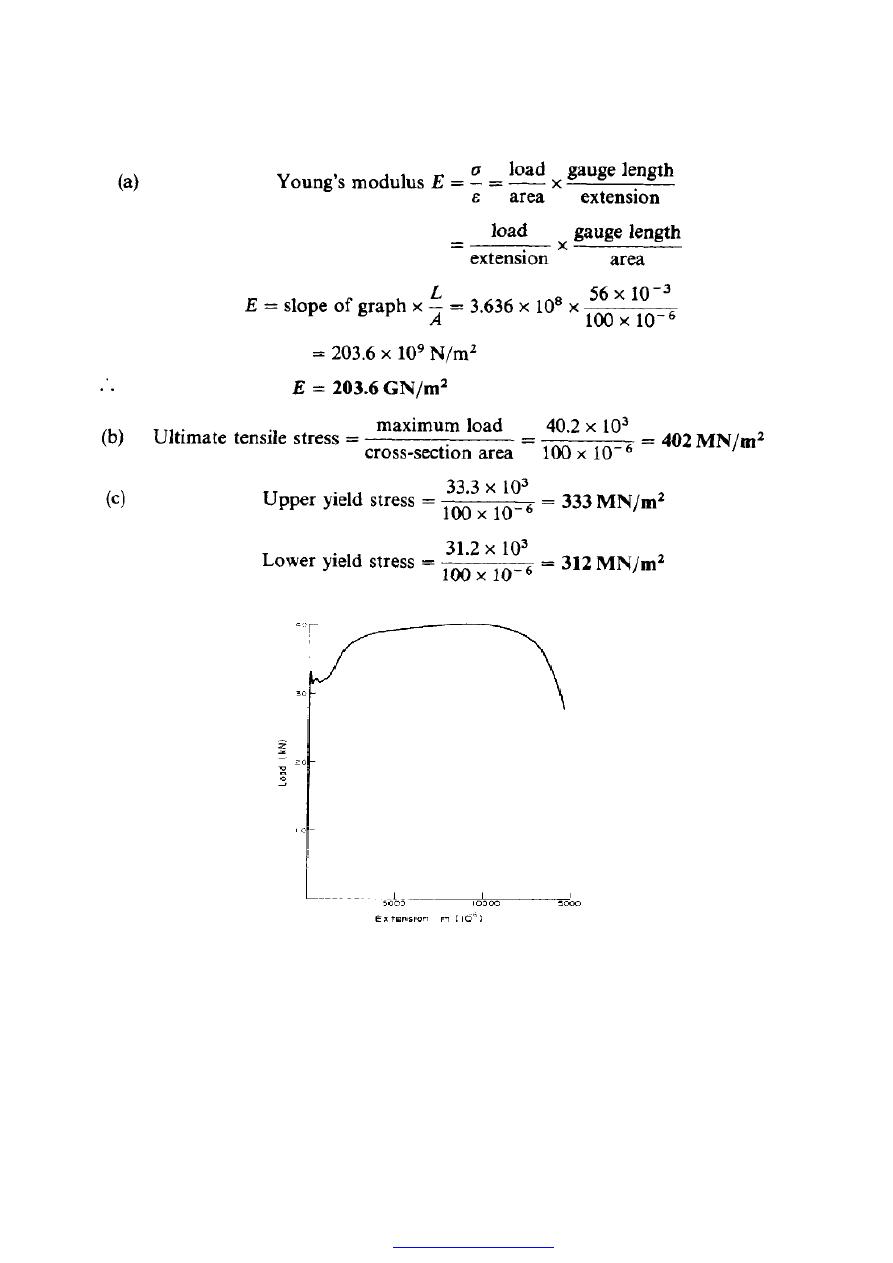

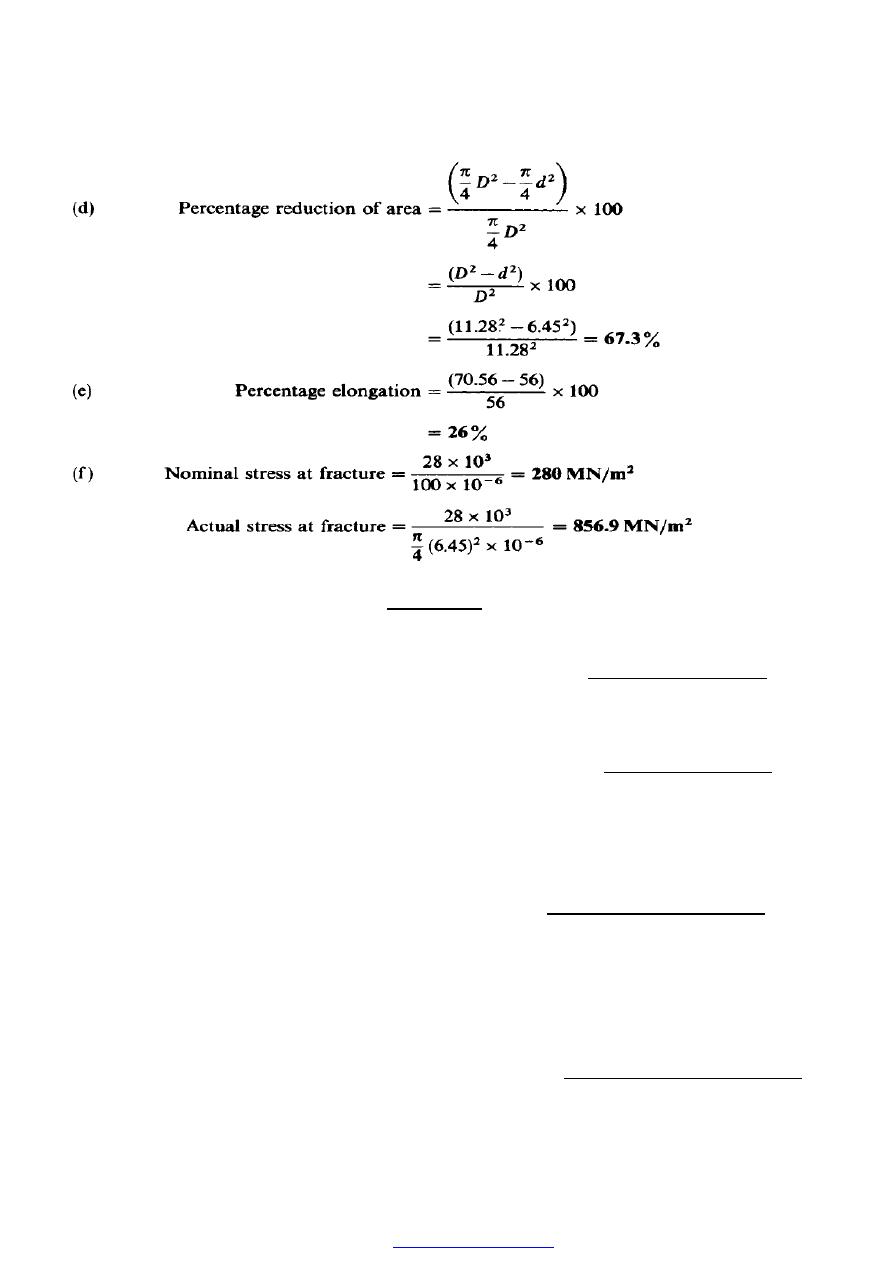

The following figures were obtained in a standard tensile test on a specimen of low

carbon steel:

diameter of specimen, 11.28 mm;

gauge length, 56mm;

minimum diameter after fracture, 6.45 mm.

Using the above information and the table of results below, produce:

(1) a load/extension graph over the complete test range;

(2) a load/extension graph to an enlarged scale over the elastic range of the specimen.

PDF created with pdfFactory Pro trial version

18

Using the two graphs and other information supplied, determine the values of

(a) Young's modulus of elasticity;

(b) the ultimate tensile stress;

(c) the stress at the upper and lower yield points;

(d) the percentage reduction of area;

(e) the percentage elongation;

(f) the nominal and actual stress at fracture.

Figure (17) Load-extension graph for elastic range.

PDF created with pdfFactory Pro trial version

20

Problems

1. (A). A 25mm square cross-section bar of length 300mm carries an axial compressive

load of 50kN. Determine the stress set up in the bar and its change of length when the

load is applied. For the bar material E = 200 GN/m

2

. [80 MN/m

2

; 0.12mm]

2. (A). A steel tube, 25 mm outside diameter and 12mm inside diameter, cames an axial

tensile load of 40 kN. What will be the stress in the bar? What further increase in load

is possible if the stress in the bar is limited to 225 MN/m

2

? [l06 MN/m

2

; 45 kN]

3. (A). Define the terms shear stress and shear strain, illustrating your answer by means

of a simple sketch. Two circular bars, one of brass and the other of steel, are to be

loaded by a shear load of 30 kN. Determine the necessary diameter of the bars (a) in

single shear, (b) in double shear, if the shear stress in the two materials must not

exceed 50 MN/m

2

and 100 MN/m

2

respectively. [27.6, 19.5, 19.5, 13.8mm]

4. (A). Two forkend pieces are to be joined together by a single steel pin of 25mm

diameter and they are required to transmit 50 kN. Determine the minimum cross-

sectional area of material required in one branch of either fork if the stress in the fork

material is not to exceed 180 MN/m

2

. What will be the maximum shear stress in the

pin?

[1.39 x 10

-4

m

2

; 50.9MN/m

2

.]

PDF created with pdfFactory Pro trial version

21

5. (A). A simple turnbuckle arrangement is constructed from a 40 mm outside diameter

tube threaded internally at each end to take two rods of 25 mm outside diameter with

threaded ends. What will be the nominal stresses set up in the tube and the rods,

ignoring thread depth, when the turnbuckle cames an axial load of 30 kN? Assuming

a sufficient strength of thread, what maximum load can be transmitted by the

turnbuckle if the maximum stress is limited to 180 MN/m

2

?

[39.2, 61.1 MN/m2, 88.4 kN]

6. (A). A bar ABCD consists of three sections: AB is 25 mm square and 50 mm long, BC

is of 20 mm diameter and40 mm long and CD is of 12 mm diameter and 50 mm long.

Determine the stress set up in each section of the bar when it is subjected to an axial

tensile load of 20 kN. What will be the total extension of the bar under this load? For

the bar material, E = 210GN/m

2

. [32,63.7, 176.8 MN/m

2

, 0.062mm]

7.(A). A steel bar ABCD consists of three sections: AB is of 20mm diameter and 200

mm long, BC is 25 mm square and 400 mm long, and CD is of 12 mm diameter and

200mm long. The bar is subjected to an axial compressive load which induces a stress

of 30 MN/m

2

on the largest cross-section. Determine the total decrease in the length of

the bar when the load is applied. For steel E = 210GN/m

2

.

[0.272 mm.]

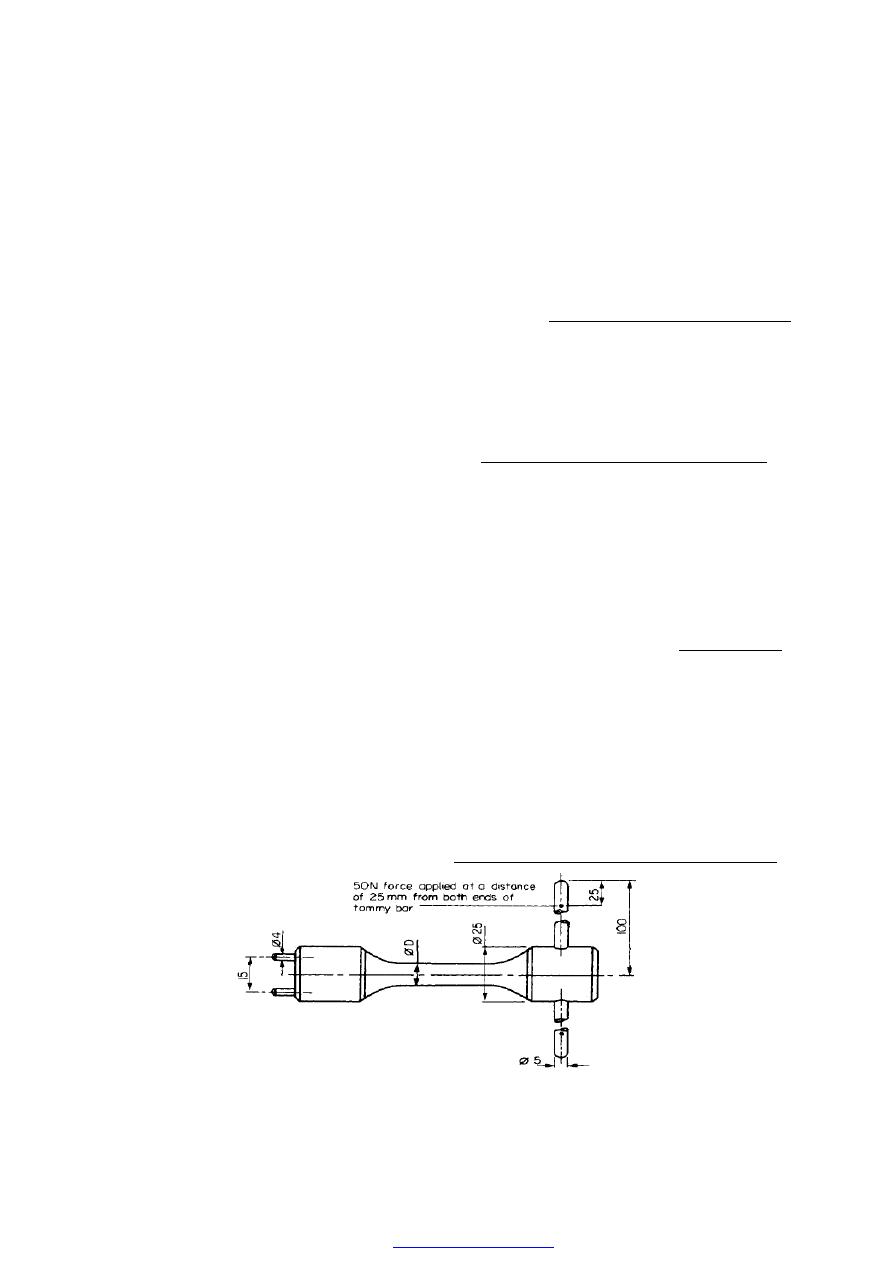

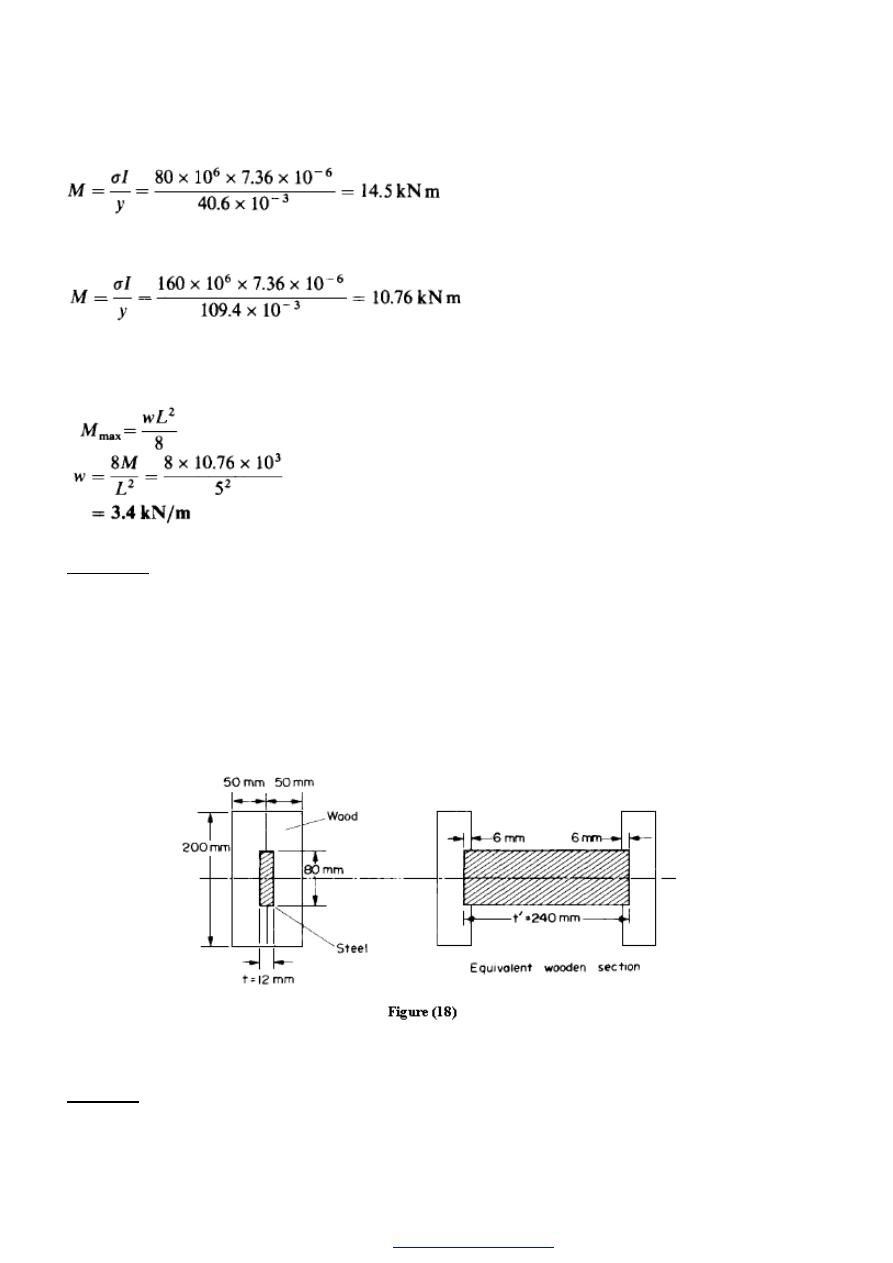

8. Figure (19) shows a special spanner used to tighten screwed components. A torque is

applied at the tommy -bar and is transmitted to the pins which engage into holes

located into the end of a screwed component.

(a) Using the data given in Figure (19) calculate:

(i) the diameter D of the shank if the shear stress is not to exceed 50N/mm

2

,

(ii) the stress due to bending in the tommy-bar,

(iii) the shear stress in the pins.

[9.14mm; 254.6 MN/m

2

; 39.8 MN/m

2

.]

Figure (19)

PDF created with pdfFactory Pro trial version

22

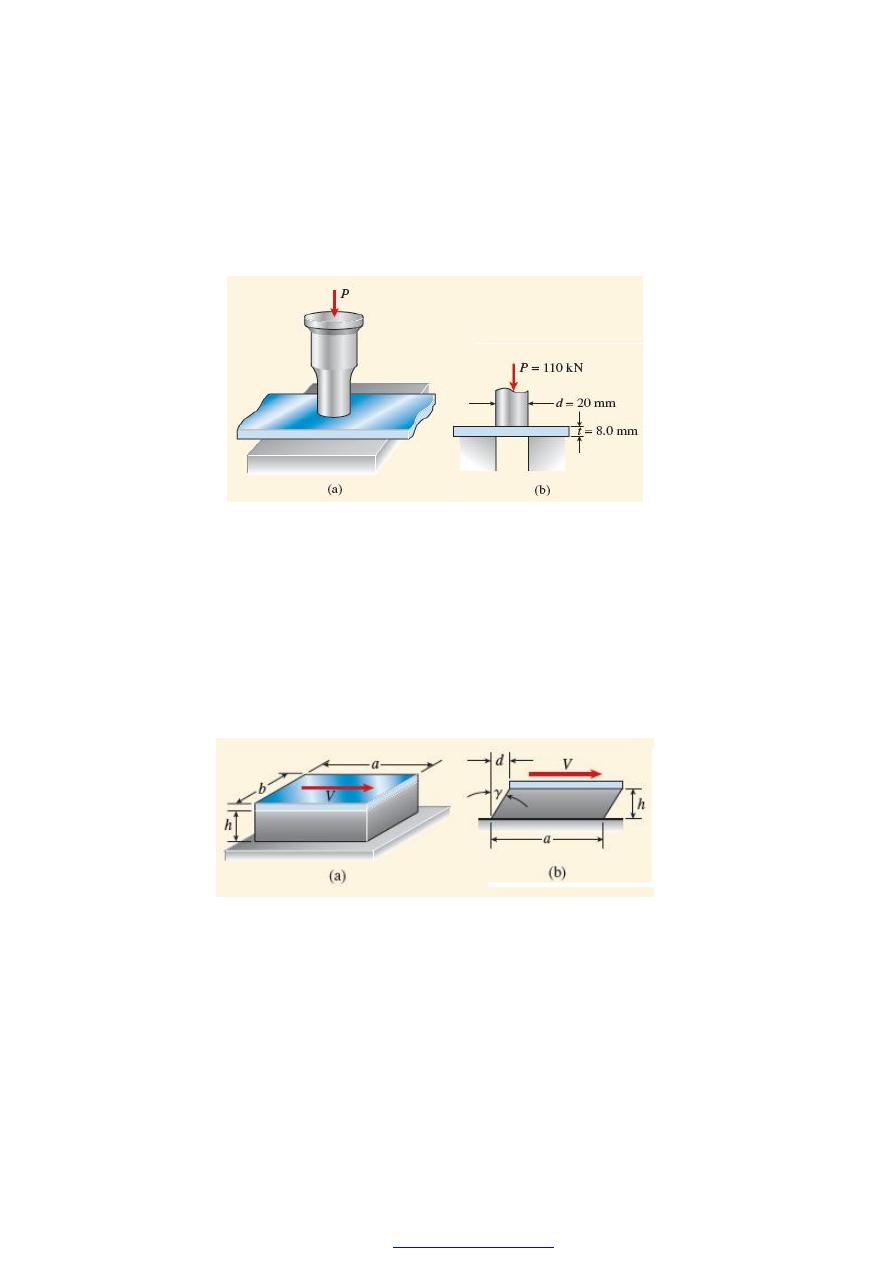

Q9-A punch for making holes in steel plates is shown in Figure (1a). Assume that a

punch having diameter d =20 mm is used to punch a hole in an 8-mm plate, as

shown in the cross-sectional view Figure (1b). If a force P= 110 kN is required to

create the hole, what is the average shear stress in the plate and the average

compressive stress in the punch?

Figure (1)

Q10-A bearing pad of the kind used to support machines and bridge girders consists of a

linearly elastic material (usually an elastomer, such as rubber) capped by a steel

plate Figure (2a). Assume that the thickness of the elastomer is h, the dimensions of

the plate are (a . b), and the pad is subjected to a horizontal shear force V. Obtain

formulas for the average shear stress (

τ

) in the elastomer and the horizontal

displacement d of the plate Figure (2b).

Figure (2)

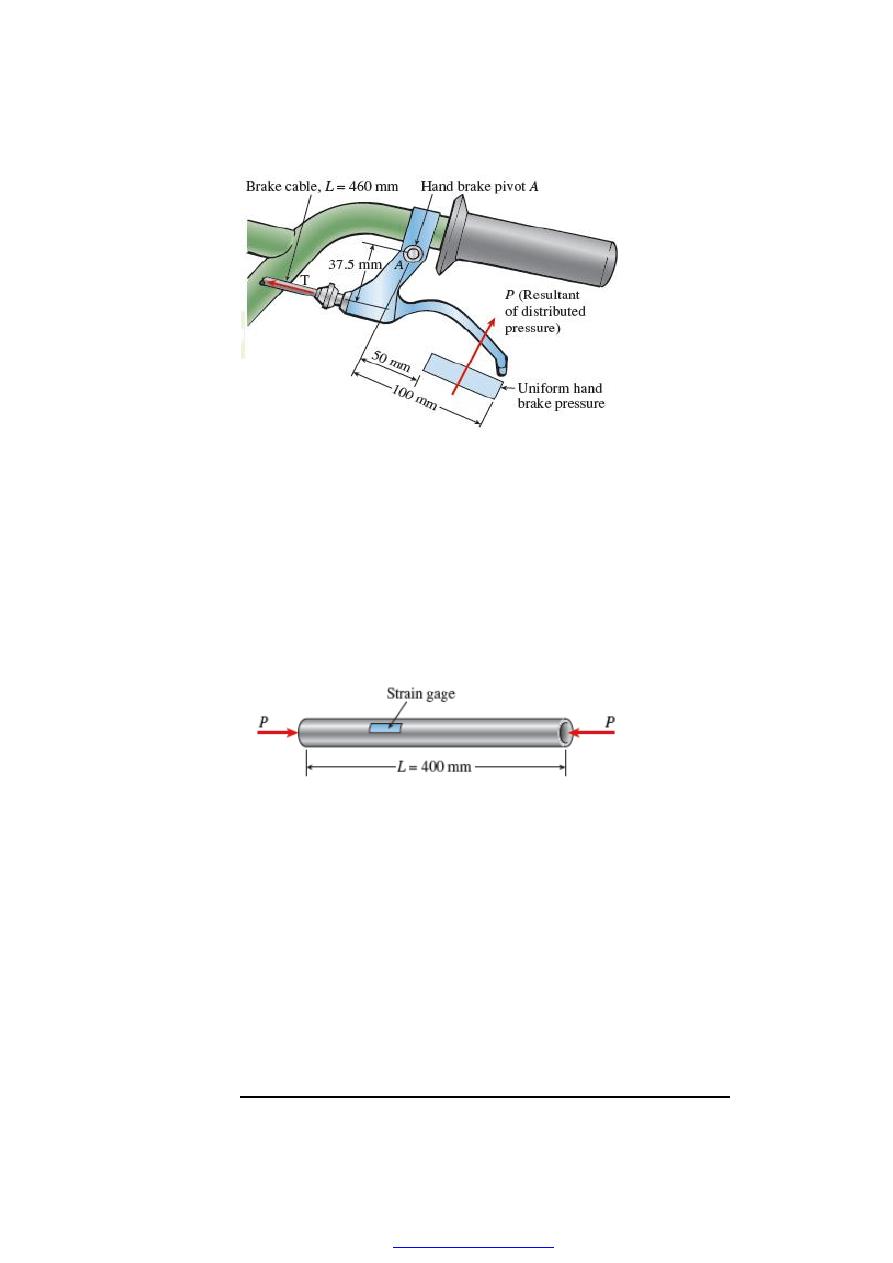

Q11-A force P of 70 N is applied by a rider to the front hand brake of a bicycle (P is the

resultant of an evenly distributed pressure). As the hand brake pivots at A, a tension T

develops in the 460-mm long brake cable (Ae =1.075 mm

2

) which elongates by

δ

= 0.214

mm. Find normal stress (

σ

) and strain (

ε

) in the brake cable.

PDF created with pdfFactory Pro trial version

23

Figure (3)

Q12-A circular aluminum tube of length L = 400 mm is loaded in compression by forces

P Figure (4). The outside and inside diameters are 60 mm and 50 mm, respectively. A

strain gage is placed on the outside of the bar to measure normal strains in the

longitudinal direction.

(a) If the measured strain is

ε

= 550 x 10

-6

, what is the shortening

δ

of the bar?

(b) If the compressive stress in the bar is intended to be 40 MPa, what should be the load

P?

Figure (4)

Q13-(a) A test piece is cut from a brass bar and subjected to a tensile test. With a load of

6.4 kN the test piece, of diameter 11.28 mm, extends by 0.04 mm over a gauge length of

50 mm. Determine:

(i) the stress, (ii) the strain, (iii) the modulus of elasticity.

(b) A spacer is turned from the same bar. The spacer has a diameter of 28 mm and a

length of 250mm. both measurements being made at 20°C. The temperature of the spacer

is then increased to 100°C, the natural expansion

being entirely prevented. Taking the coefficient of linear expansion to be18 x 10

-6

/

o

C

determine:

(i) the stress in the spacer, (ii) the compressive load on the spacer.

Ans. [64MN/m

2

, 0.0008, 80GN/m

2

, 115.2 MN/m

2

, 71 kN.]

PDF created with pdfFactory Pro trial version

24

COMPOUND BARS

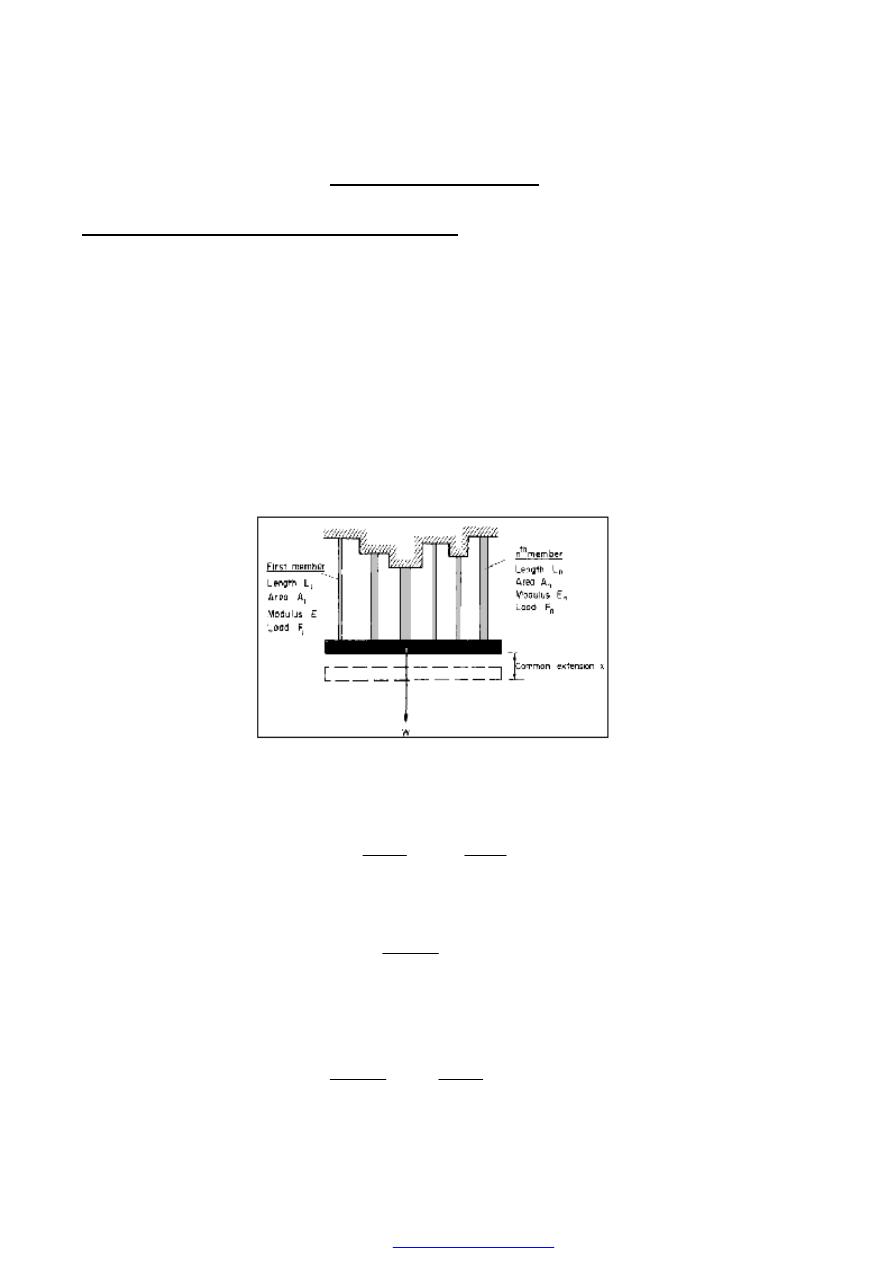

1. Compound bars subjected to external load

In certain applications it is necessary to use a combination of elements or bars made

from different materials. In overhead electric cables, for example, it is often convenient to

carry the current in a set of copper wires surrounding steel wires, the latter being

designed to support the weight of the cable over large spans. Such combinations of

materials are generally termed compound burs. This chapter is concerned with compound

bars which are symmetrically proportioned such that no bending results, when an external

load is applied to such a compound bar it is shared between the individual component

materials in proportions depending on their respective lengths, areas and Young’s

moduli. A compound bar consisting of n members, each having a different

length and cross-sectional area and each being of a different material as shown in figure

(1)

Figure (1) Compound bar formed of different materials

For the nth member,

n

n

n

n

n

x

A

L

F

E

strain

stress

.

.

=

=

n

n

n

n

L

x

A

E

F

.

.

=

....(1)

where F, is the force in the nth member ,A its cross-sectional area and

n

L

are its

length. The total load carried will be the sum of all such loads for all the members

∑

∑

=

=

n

n

n

n

n

n

L

A

E

x

L

x

A

E

W

.

.

.

.

...(2)

PDF created with pdfFactory Pro trial version

25

Now from equation (1) the force in member 1 is given by

1

1

1

1

.

.

L

x

A

E

F

=

But, from equation (2),

∑

=

n

n

n

L

A

E

W

x

.

W

L

A

E

L

A

E

F

∑

=

.

.

1

1

1

1

.....(3)

i

.e. each member carries a portion of the total load W proportional to its EAIL value. If

the wires are all of equal length the above equation reduces to

W

A

E

A

E

F

∑

=

.

.

1

1

1

....(4)

The stress in member 1 is then given by

1

1

1

A

F

=

σ

....(5)

2. Compound bars - “equivalent” or “combined” modulus

In order to determine the common extension of a compound bar it is convenient to

consider it as a single bar of an imaginary material with an equivalent or combined

modulus E,. Here it is necessary to assume that both the extension and the original

lengths of the individual members of the compound bar are the same; the strains in all

members will then be equal.

Now total load on compound bar = F

1

+ F

2

+ F

3

+ . . . + F, where F

1

, F

2

, etc., are the

loads in members 1, 2, etc.

But

force = stress x area

n

n

n

A

A

A

A

A

A

σ

σ

σ

σ

+

+

+

=

+

+

+

......

)

......

(

2

2

1

1

2

1

Where:

σ is the stress in the equivalent single bar. Dividing through by the common

strain

ε,

PDF created with pdfFactory Pro trial version

26

n

n

n

A

A

A

A

A

A

ε

σ

ε

σ

ε

σ

ε

σ

+

+

+

=

+

+

+

......

)

.......

(

2

2

1

1

2

1

n

n

n

c

A

E

A

E

A

E

A

A

A

E

+

+

+

=

+

+

+

.......

)

......

(

2

2

1

1

2

1

where

c

E

, is the equivalent or combined E of the single bar.

n

A

A

A

n

A

n

E

A

E

A

E

E

combined

+

+

+

+

+

+

=

...

2

1

.

....

2

.

2

1

.

1

∑

∑

=

A

A

E

E

c

.

....(6)

With an external load W applied,

∑

=

A

W

bar

equivalent

the

in

Stress

L

x

A

E

W

bar

equivalent

the

in

Strain

c

=

=

∑

.

∑

=

A

E

L

W

x

extension

common

c

.

.

....(7)

=extension of single bar

3. Compound bars subjected to temperature change

When a material is subjected to a change in temperature its length will change by an

amount

T

L

∆

.

.

α

where

α is the coefficient of linear expansion for the material, L is the original length and

T

∆

the temperature change. (An increase in temperature produces an increase in length

and a decrease in temperature a decrease in length except in very special cases of

materials with zero or negative coefficients of expansion which need not be considered

here.) If, however, the free expansion of the material is prevented by some external force,

then a stress is set up in the material. This stress is equal in magnitude to that which

would be produced in the bar by initially allowing the free change of length and then

applying sufficient force to return the bar to its original length.

Now:

PDF created with pdfFactory Pro trial version

27

T

L

Length

in

Change

∆

=

.

.

α

T

L

T

L

Strain

∆

=

∆

=

.

.

.

α

α

Therefore, the stress created in the material by the application of sufficient force to

remove this strain

T

E

E

x

strain

∆

=

=

.

.

α

Consider now a compound bar constructed from two different materials rigidly joined

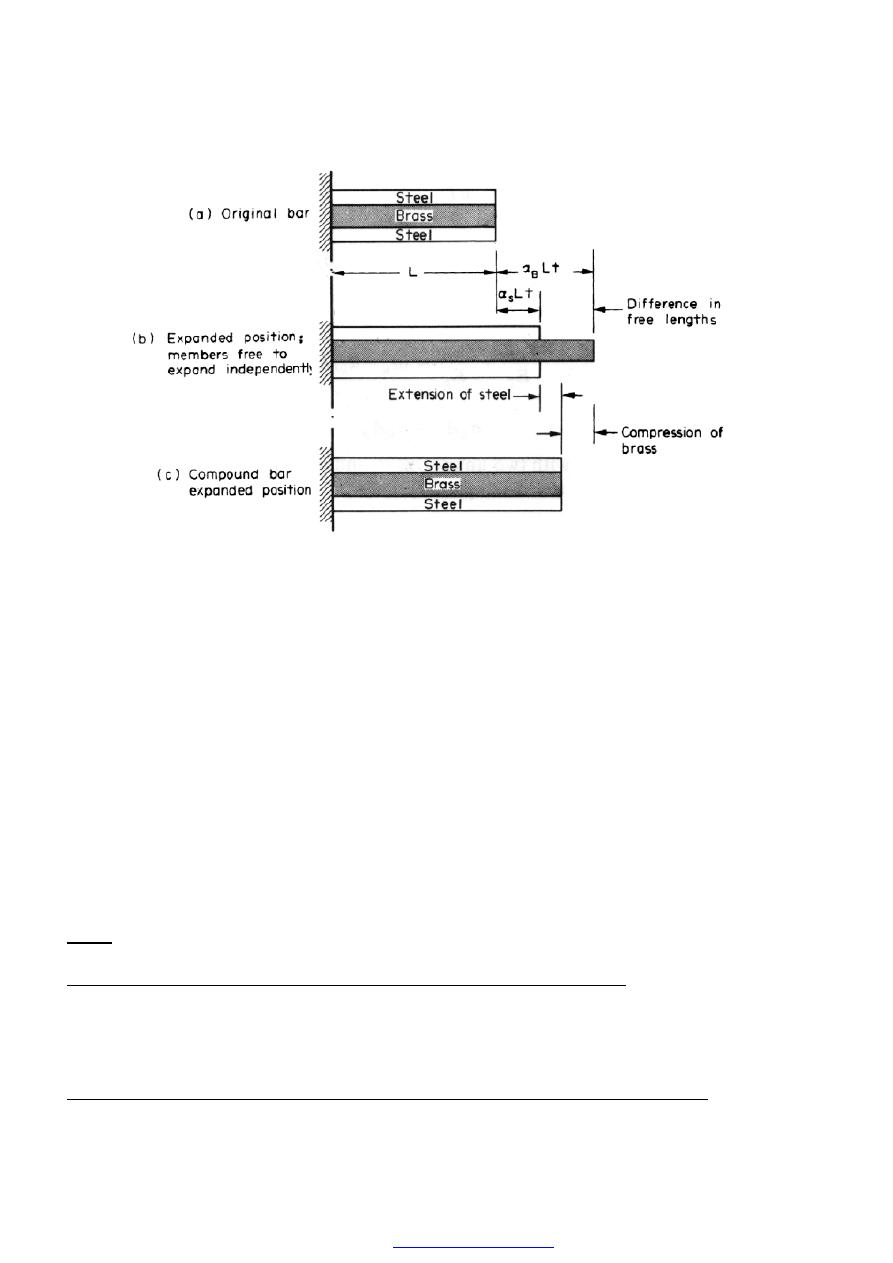

together as shown in Figure (2) and Figure (3a). For simplicity of description consider

that the materials in this case are steel and brass.

Figure (2)

In general, the coefficients of expansion of the two materials forming the compound bar

will be different so that as the temperature rises each material will attempt to expand by

different amounts. Figure (3b) shows the positions to which the individual materials will

extend if they are completely free to expand (i.e. not joined rigidly together as a

compound bar). The extension of any length L is given by

T

L

∆

.

.

α

PDF created with pdfFactory Pro trial version

28

Figure (3) Thermal expansion of compound bar.

Thus the difference of "free" expansion lengths or so-called free lengths

T

L

T

L

T

L

s

B

s

B

∆

−

=

∆

−

∆

=

.

).

(

.

.

.

.

α

α

α

α

since in this case the coefficient of expansion of the brass

(

B

α

) is greater than that for

the steel (

s

α

). The initial lengths L of the two materials are assumed equal. If the two

materials are now rigidly joined as a compound bar and subjected to the same

temperature rise, each material will attempt to expand to its free length position but each

will be affected by the movement of the other, The higher coefficient of expansion

material (brass) will therefore seek to pull the steel up to its free length position and

conversely the lower position. In practice a compromise is reached, the compound bar

extending to the position shown in Figure (3c), resulting in an effective compression of

the brass from its free length position and an effective extension of the steel from its free

length position. From the diagram it will be seen that the following rule holds.

Rule 1

(Extension of steel + compression of brass = difference in “free” lengths).

Referring to the bars in their free expanded positions the rule may be written as

(Extension of “short” member + compression of“1ong” member = difference in free

lengths).

Applying Newton’s law of equal action and reaction the following second rule also applies.

PDF created with pdfFactory Pro trial version

29

Rule 2

The tensile force applied to the short member by the long member is equal in magnitude

to the compressive force applied to the long member by the short member.

Thus, in this case,

tensile force in steel = compressive force in brass

Now, from the definition of Young’s modulus

L

L

strain

stress

E

/

∆

=

=

σ

where

∆L is the change in length

.

E

L

L

.

σ

=

∆

Also,

force = stress x area =

σ.A

where: A is the cross-sectional area, Therefore Rule 1 becomes

T

L

E

L

E

L

s

B

B

B

s

s

∆

−

=

+

.

).

(

.

.

α

α

σ

σ

....(8)

and Rule 2 becomes

B

B

s

s

A

A

.

.

σ

σ

=

....(9)

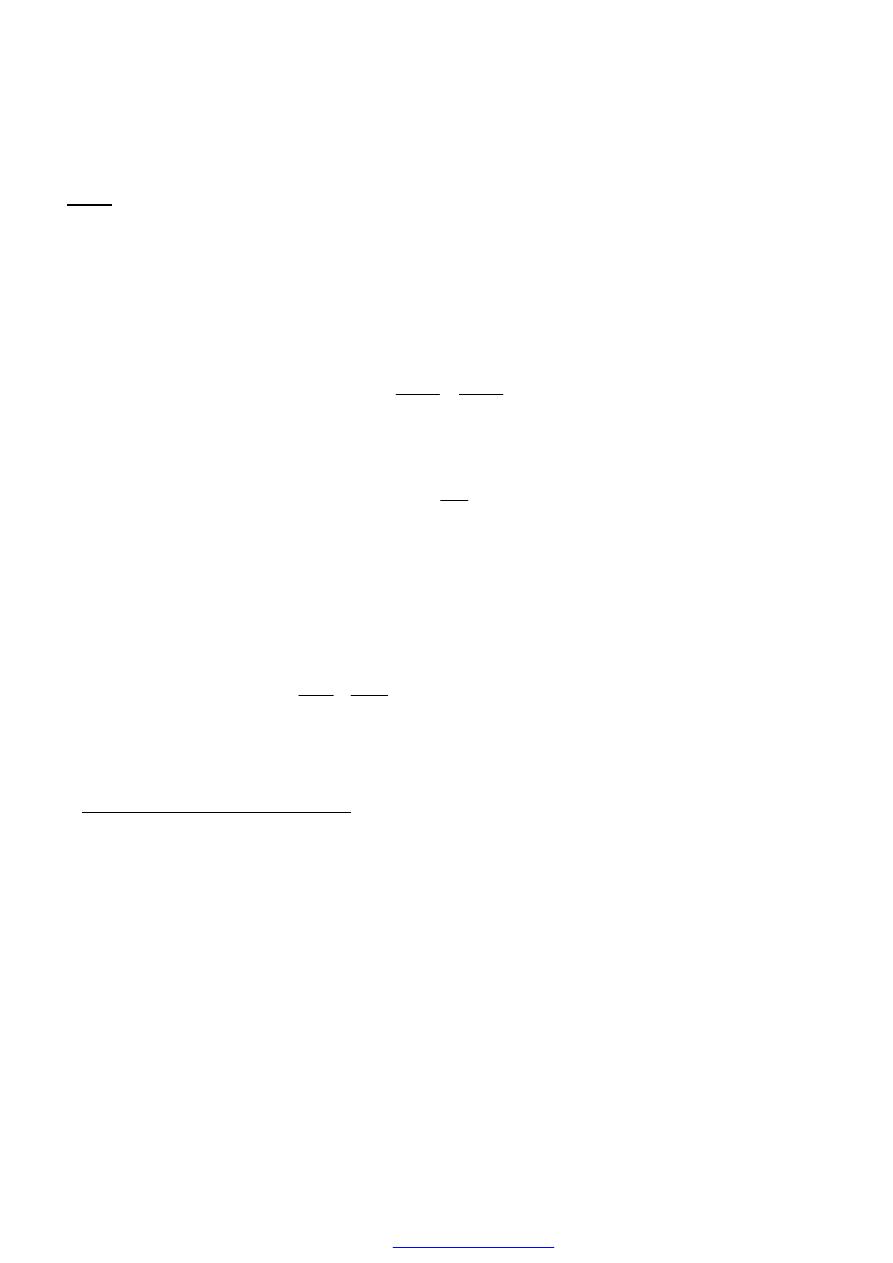

4. Compound bar (tube and rod)

Consider now the case of a hollow tube with washers or endplates at each end and a

central threaded rod as shown in Figure (4) At first sight there would seem to be no

connection with the work of the previous section, yet, in fact, the method of solution to

determine the stresses set up in the tube and rod when one nut is tightened.

The compound bar which is formed after assembly of the tube and rod, i.e. with the nuts

tightened, is shown in Figure (4c), the rod being in a state of tension and the tube in

compression. Once again Rule 2 applies, i.e.

compressive force in tube = tensile force in rod

PDF created with pdfFactory Pro trial version

30

Figure (4)

Figure (4a) and b show, diagrammatically, the effective positions of the tube and rod

before the nut is tightened and the two components are combined. As the nut is turned

there is a simultaneous compression of the tube and tension of the rod leading to the final

state shown in Figure ( 4c) . As before, however, the diagram shows that Rule 1 applies:

compression of tube +extension of rod = difference in free lengths

= axial advance of nut

i.e. the axial movement of the nut ( = number of turns n x threads per metre) is taken up

by combined compression of the tube and extension of the rod.

Thus, with suffix (t) for tube and (R) for rod,

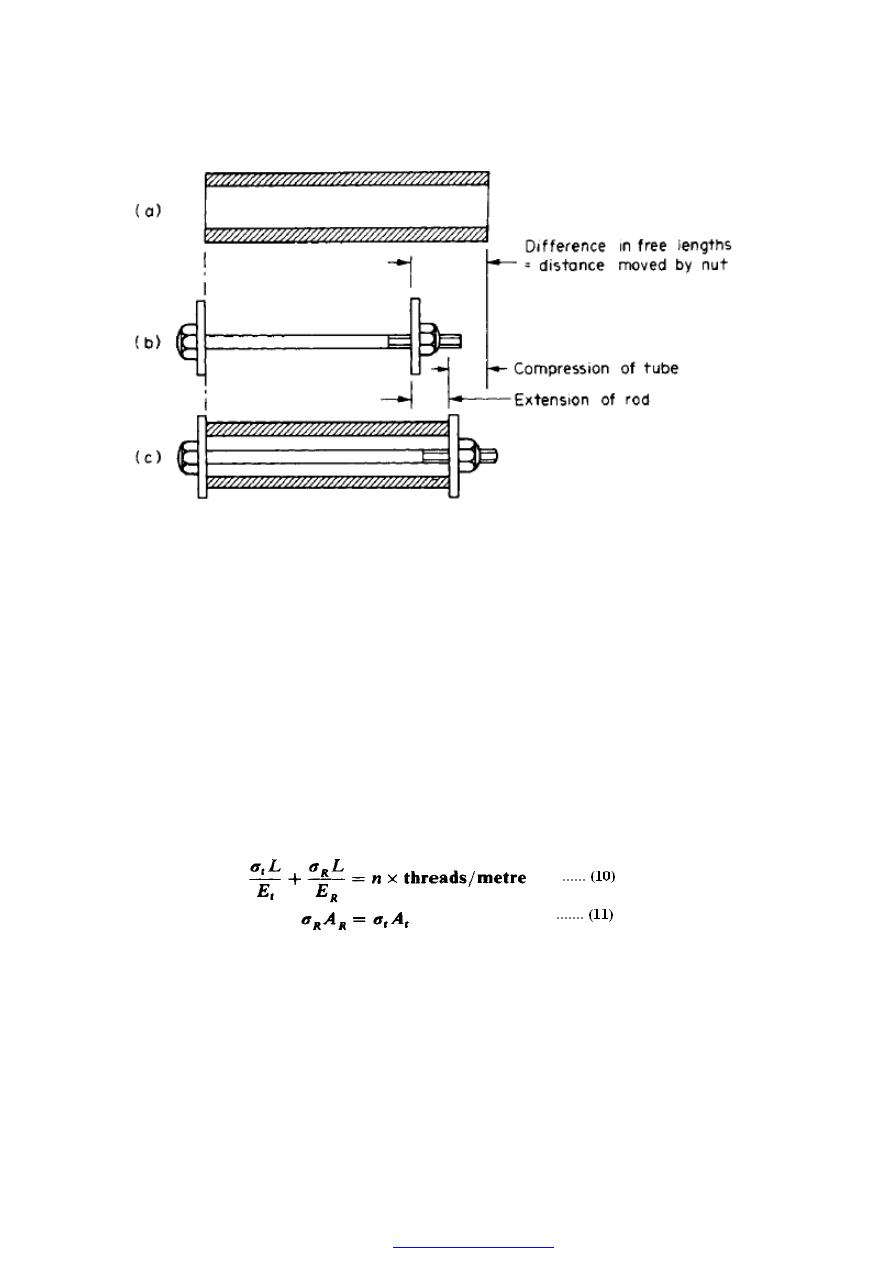

If the tube and rod are now subjected to a change of temperature they may be treated as a

normal compound bar and Rules 1 and 2 again apply

Figure (5),

PDF created with pdfFactory Pro trial version

31

Figure (5)

Where

(

/

R

σ )

;

and

(

/

R

σ

) ; are the stresses in the tube and rod due to temperature

change only and

(

t

α )

, is assumed greater than

(

R

α )

.

If the latter is not the case the two

terms inside the final bracket should be interchanged.

Also

Examples

Example 1

(a) A compound bar consists of four brass wires of 2.5 mm diameter and one steel wire of

1.5 mm diameter. Determine the stresses in each of the wires when the bar supports a

load of 500 N. Assume all of the wires are of equal lengths.

(b) Calculate the “equivalent” or “combined modulus for the compound bar and

determine its total extension if it is initially 0.75 m long. Hence check the values of the

stresses obtained in part (a).

For brass E = 100 GN/m

2

and for steel E = 200 GN/m

2

.

PDF created with pdfFactory Pro trial version

33

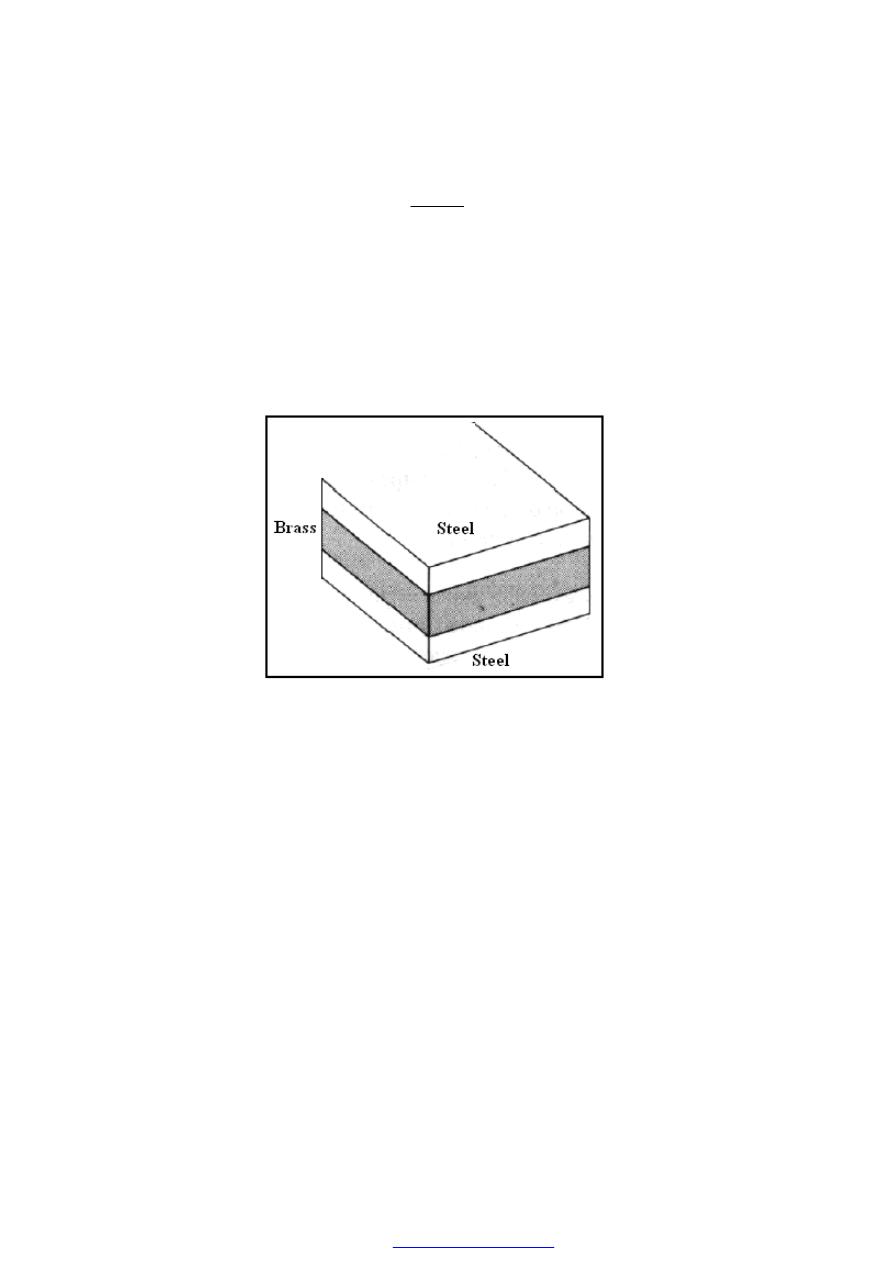

Example 2

(a) A compound bar is constructed from three bars 50 mm wide by 12 mm thick

fastened together to form a bar 50 mm wide by 36 mm thick. The middle bar is of

aluminium alloy for which E = 70 GN/m

2

and the outside bars are of brass with E =

100 GN/m

2

. If the bars are initially fastened at 18°C and the temperature of the whole

assembly is then raised to 50

o

C, determine the stresses set up in the brass and the

aluminium.

B

α

= 18 x per

o

C and

A

α

= 22 x per

o

C

(b) What will be the changes in these stresses if an external compressive load of 15 kN is

applied to the compound bar at the higher temperature?

Solution

With any problem of this type it is convenient to let the stress in one of the component

members or materials, e.g. the brass, be x.

Then, since

PDF created with pdfFactory Pro trial version

34

These stresses represent the changes in the stresses owing to the applied load. The total or

resultant stresses owing to combined applied loading plus temperature effects are,

therefore,

PDF created with pdfFactory Pro trial version

35

Example 3

A 25 mm diameter steel rod passes concentrically through a bronze tube 400 mm long, 50

mm external diameter and 40 mm internal diameter. The ends of the steel rod are

threaded and provided with nuts and washers which are adjusted initially so that there is

no end play at 20°C.

(a) Assuming that there is no change in the thickness of the washers, find the stress

produced in the steel and bronze when one of the nuts is tightened by giving it one tenth

of a turn, the pitch of the thread being 2.5 mm.

(b) If the temperature of the steel and bronze is then raised to 50°C find the changes that

will occur in the stresses in both materials.

The coefficient of linear expansion per

o

C is 11 x 10

-6

for steel and for bronze and 18 x10

-

6

. E for steel = 200 GN/m

2

. E for bronze = 100 GN/m

2

.

Solution

(a) Let x be the stress in the tube resulting from the tightening of the nut and

R

σ

the

stress in the rod

PDF created with pdfFactory Pro trial version

37

SHEARING FORCE AND BENDING MOMENT

DIAGRAMS

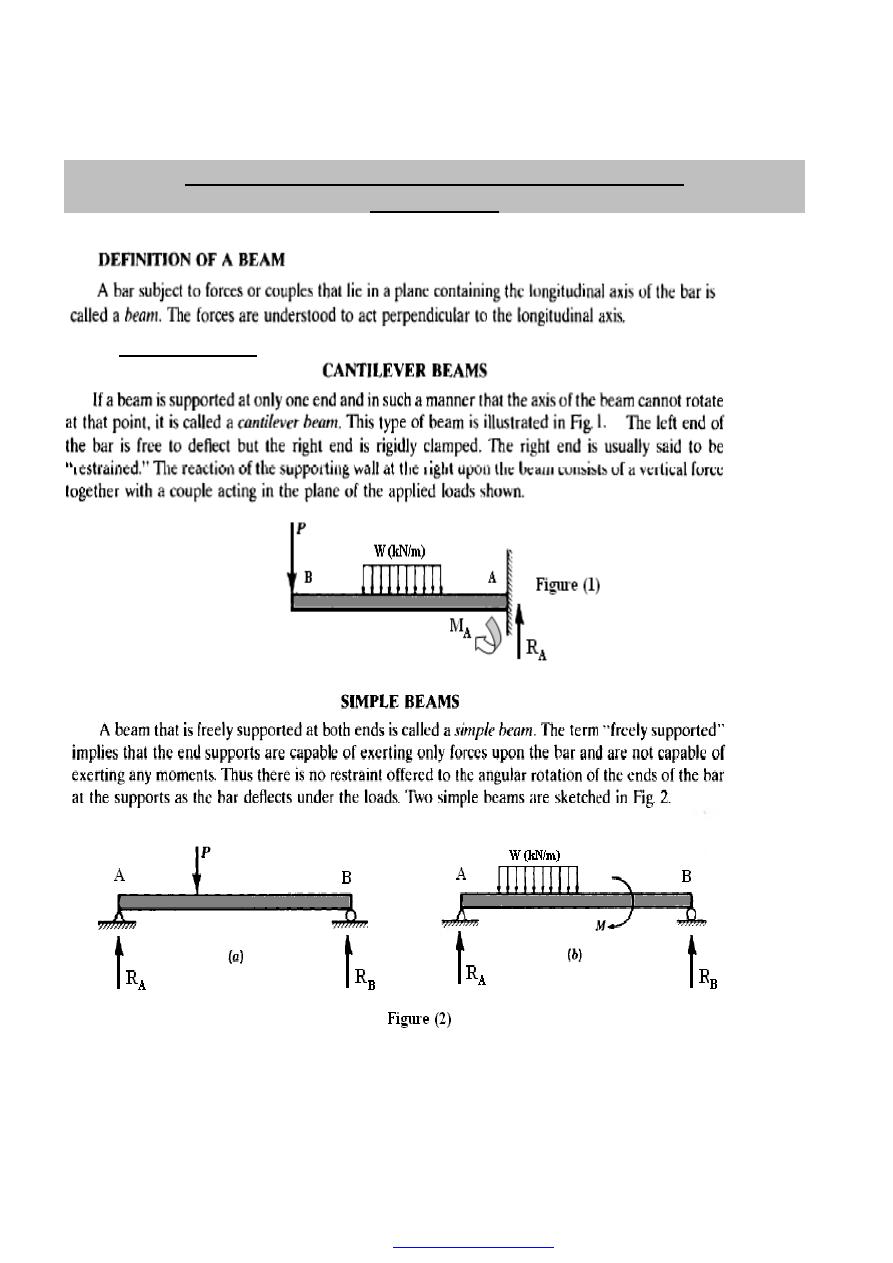

1. Types of Beams

PDF created with pdfFactory Pro trial version

38

2. Shearing force and bending moment

At every section in a beam carrying transverse loads there will be resultant forces on

either side of the section which, for equilibrium, must be equal and opposite, and whose

combined action tends to shear the section in one of the two ways shown in Figure (4 a

and b). The shearing force (S.F.) at the section is defined therefore as the algebraic sum

of the forces taken on one side of the section.

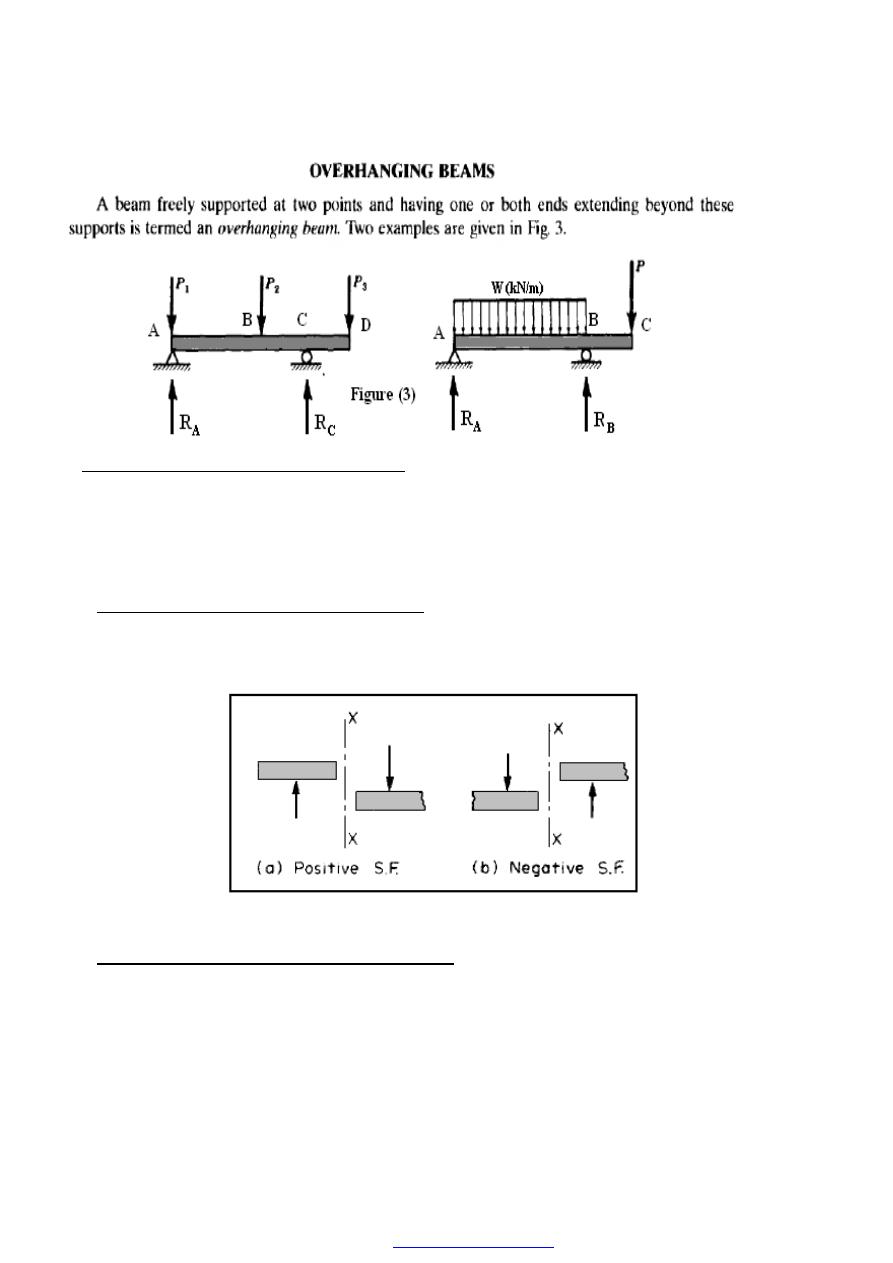

2.1. Shearing force (S.F.) sign convention

Forces upwards to the left of a section or downwards to the right of the section are

positive. Thus Figure (4a) shows a positive S.F. system at X-X and Figure (4b) shows a

negative S.F. system.

Figure (4) S.F. sign convention

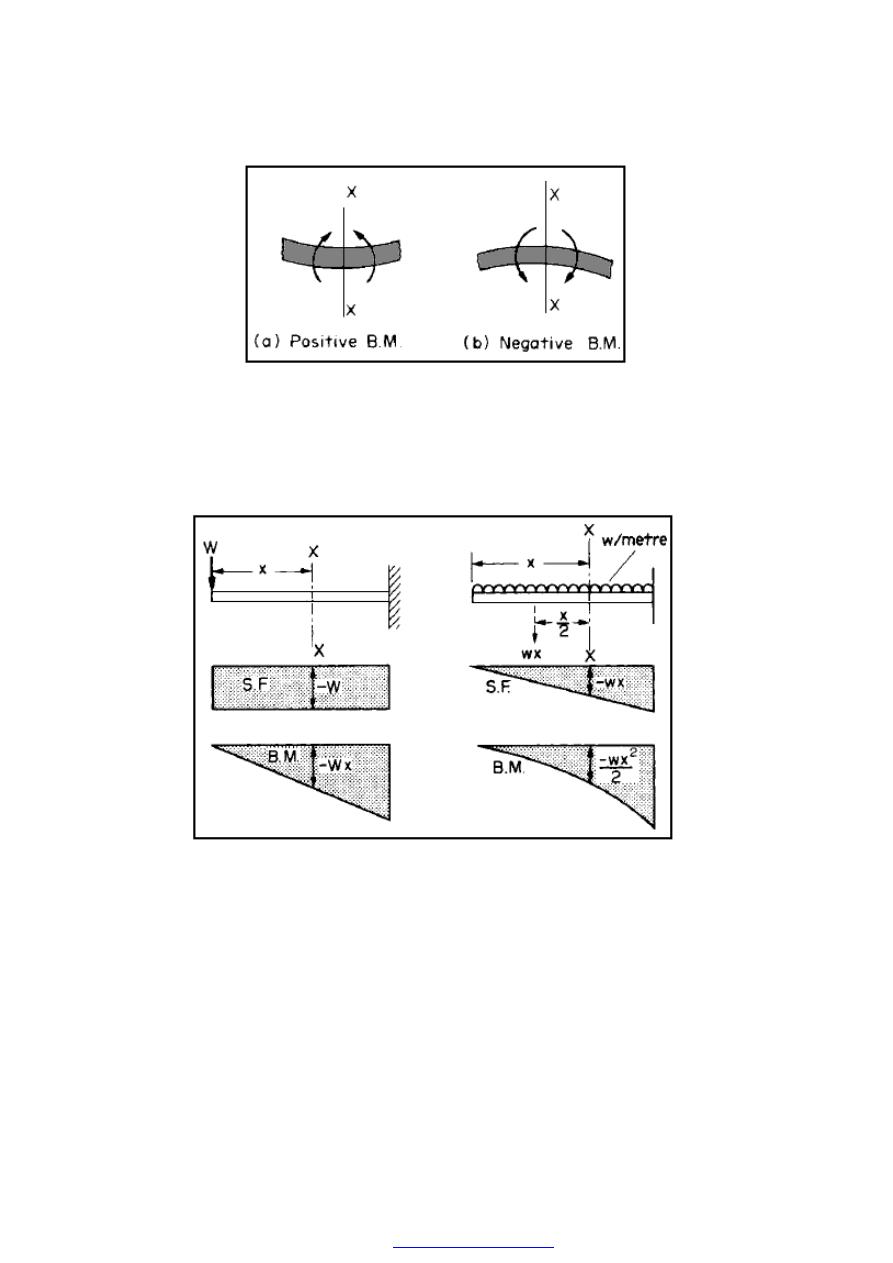

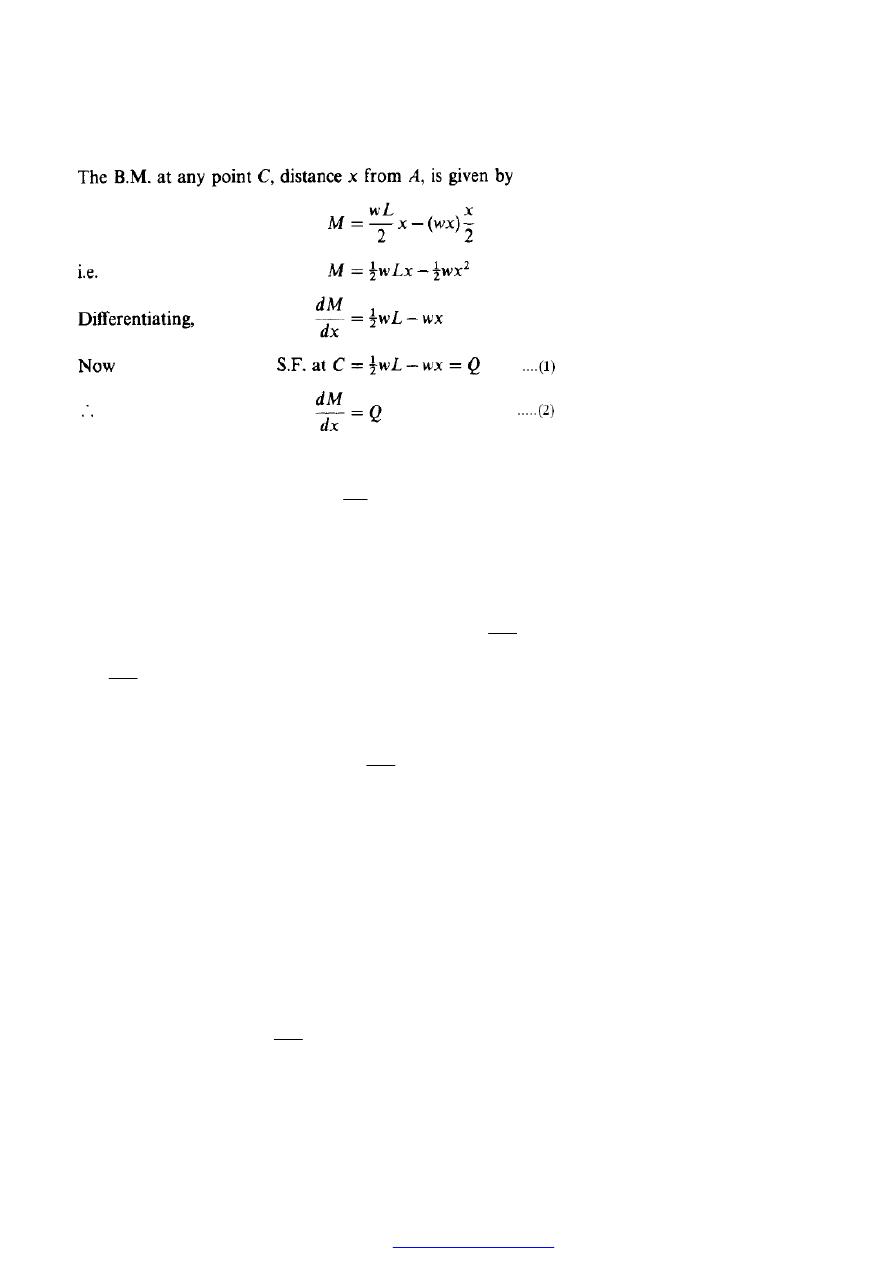

2.2. Bending moment (B.M.) sign convention

Clockwise moments to the left and counterclockwise to the right are positive. Thus

Figure (5a) shows a positive bending moment system resulting in sagging of the beam at

X-X and Figure (5b) illustrates a negative B.M. system with its associated hogging beam.

PDF created with pdfFactory Pro trial version

39

Figure (5) B.M. sign convention.

It should be noted that whilst the above sign conventions for S.F. and B.M. are somewhat

arbitrary and could be completely reversed, the systems chosen here are the only ones

which yield the mathematically correct signs for slopes and deflections of beams in

subsequent work and therefore are highly recommended.

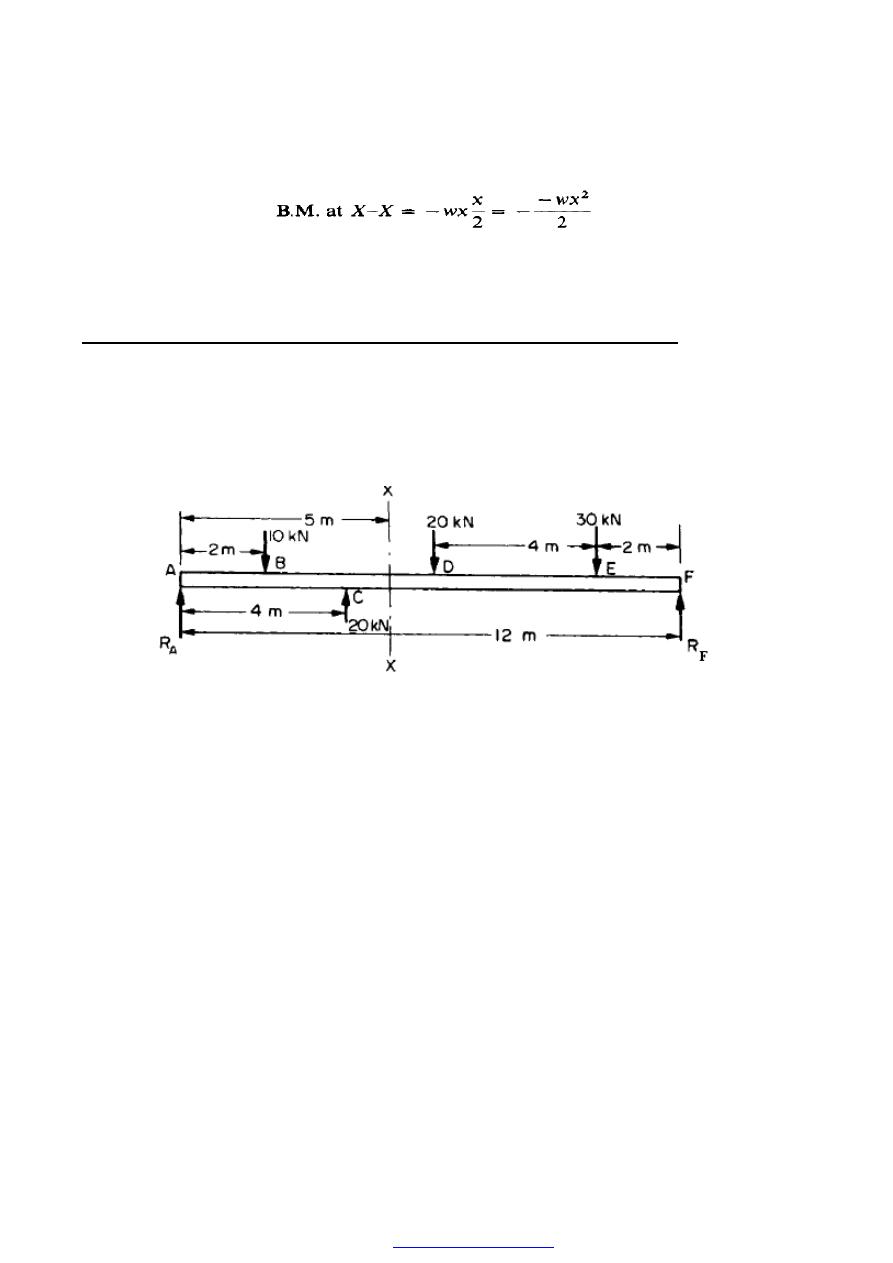

Figure (6) S.F.-B.M. diagrams for standard cases.

Thus in the case of a cantilever carrying a concentrated load (W) at the end Figure (6),

the S.F. at any section X-X, distance x from the free end, is S.F. = - W. This will

be true whatever the value of x, and so the S.F. diagram becomes a rectangle. The B.M.

at the same section X-X is- W.x and this will increase linearly with x. The B.M. diagram

is therefore a triangle. If the cantilever now carries a uniformly distributed load, the S.F.

at X-X is the net load to one side of X-X, i.e. -wx. In this case, therefore, the S.F.

diagram becomes triangular, increasing to a maximum value of - WL at the support. The

B.M. at X-X is obtained by treating the load to the left of X-X as a concentrated load of

the same value acting at the centre of gravity,

PDF created with pdfFactory Pro trial version

40

Plotted against x this produces the parabolic B.M. diagram shown.

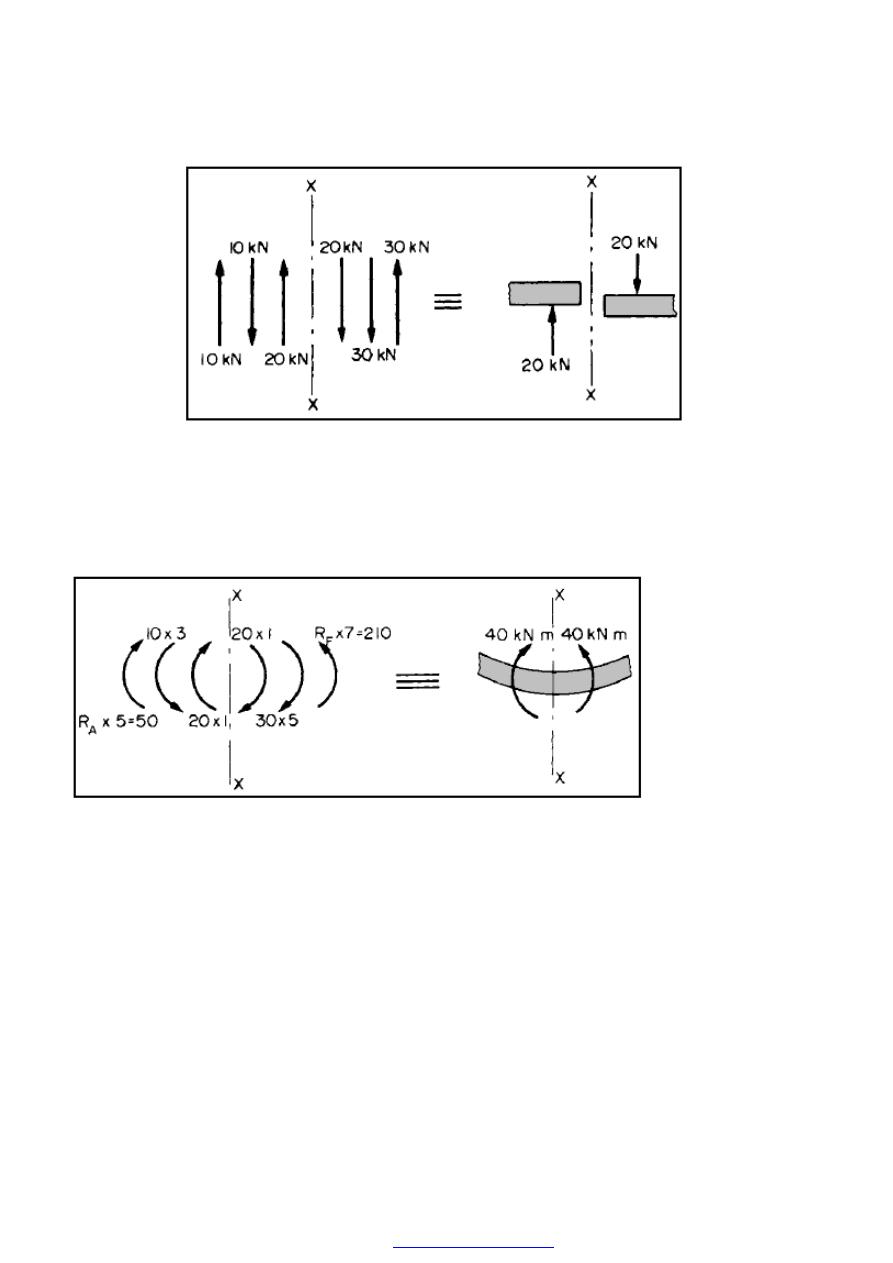

3. S.F. and B.M. diagrams for beams carrying concentrated loads only

In order to illustrate the procedure to be adopted for the determination of S.F. and B.M.

values for more complicated load conditions, consider the simply supported beam shown

in

Figure (4) carrying concentrated loads only. (The term simply supported means that the

beam can be assumed to rest on knife-edges or roller supports and is free to bend at the

supports without any restraint.)

Figure (7)

The values of the reactions at the ends of the beam may be calculated by applying normal

equilibrium conditions, i.e. by taking moments about F.

Thus

R

A

x 12 = (10 x 10) + (20 x 6) + (30 x 2) - (20 x 8) = 120

R

A

= 10 kN

For vertical equilibrium

total force up = total load down

R

A

+R

F

= 10+20+30-20 = 40

R

F

= 30 kN

At this stage it is advisable to check the value of RF by taking moments about A.

Summing up the forces on either side of X-X we have the result shown in Figure (8)

Using the sign convention listed above, the shear force at X-X is therefore +20kN,i.e the

resultant force at X-X tending to shear the beam is 20 kN.

PDF created with pdfFactory Pro trial version

41

Figure (8) Total S.F. at X-X.

Similarly, Figure (9) shows the summation of the moments of the forces at X-X, the

resultant B.M. being 40 kNm.

Figure (9)

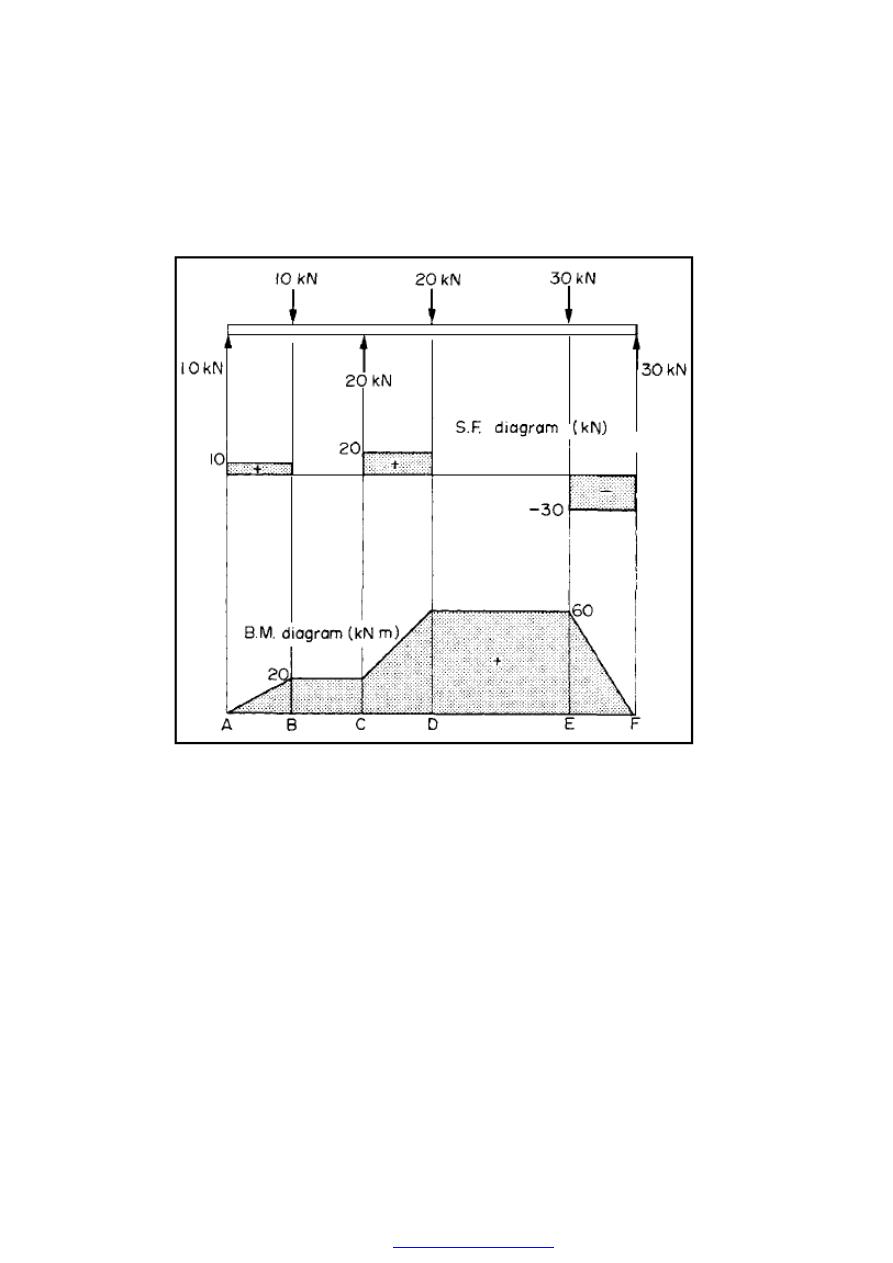

In practice only one side of the section is normally considered and the summations

involved can often be completed by mental arithmetic. The complete S.F. and B.M.

diagrams for the beam are shown in Figure (9).

B.M. at A = o

B.M. at B = + (10 x 2) = +20 kN.m

B.M. at C= +(l0 x 4)-(10 x 2) = +20kN.m

B.M. at D = +(l0 x 6)+ (20 x 2)- (10 x 4) = +60 kN.m

B.M. at E = + (30 x 2) = +60 kN.m

B.M. at F = 0

PDF created with pdfFactory Pro trial version

42

All the above values have been calculated from the moments of the forces to the left of

each section considered except for E where forces to the right of the section are taken

.

Figure (10)

It may be observed at this stage that the S.F. diagram can be obtained very quickly when

working from the left-hand side, since after plotting the S.F. value at the support all

subsequent steps are in the direction of and equal in magnitude to the applied loads, e.g.

10 kN up at A, down 10 kN at B, up 20 kN at C, etc., with horizontal lines

joining the steps to show that the S.F. remains constant between points of application of

concentrated loads.

The S.F. and B.M. values at the left-hand support are determined by considering a

section an infinitely small distance to the right of the support. The only load to the left

(and hence the S.F.) is then the reaction of 10 kN upwards, Le. positive, and the bending

moment

= reaction x zero distance = zero.

PDF created with pdfFactory Pro trial version

43

The following characteristics of the two diagrams are now evident and will be

explained

later in this chapter:

(a) between B and C the S.F. is zero and the B.M. remains constant;

(b) between A and B the S.F. is positive and the slope of the B.M. diagram is positive;

vice

(c) the difference in B.M. between A and B = 20 kN m = area of S.F. diagram between A

and B.

4. S.F. and B.M. diagrams for uniformly distributed loads

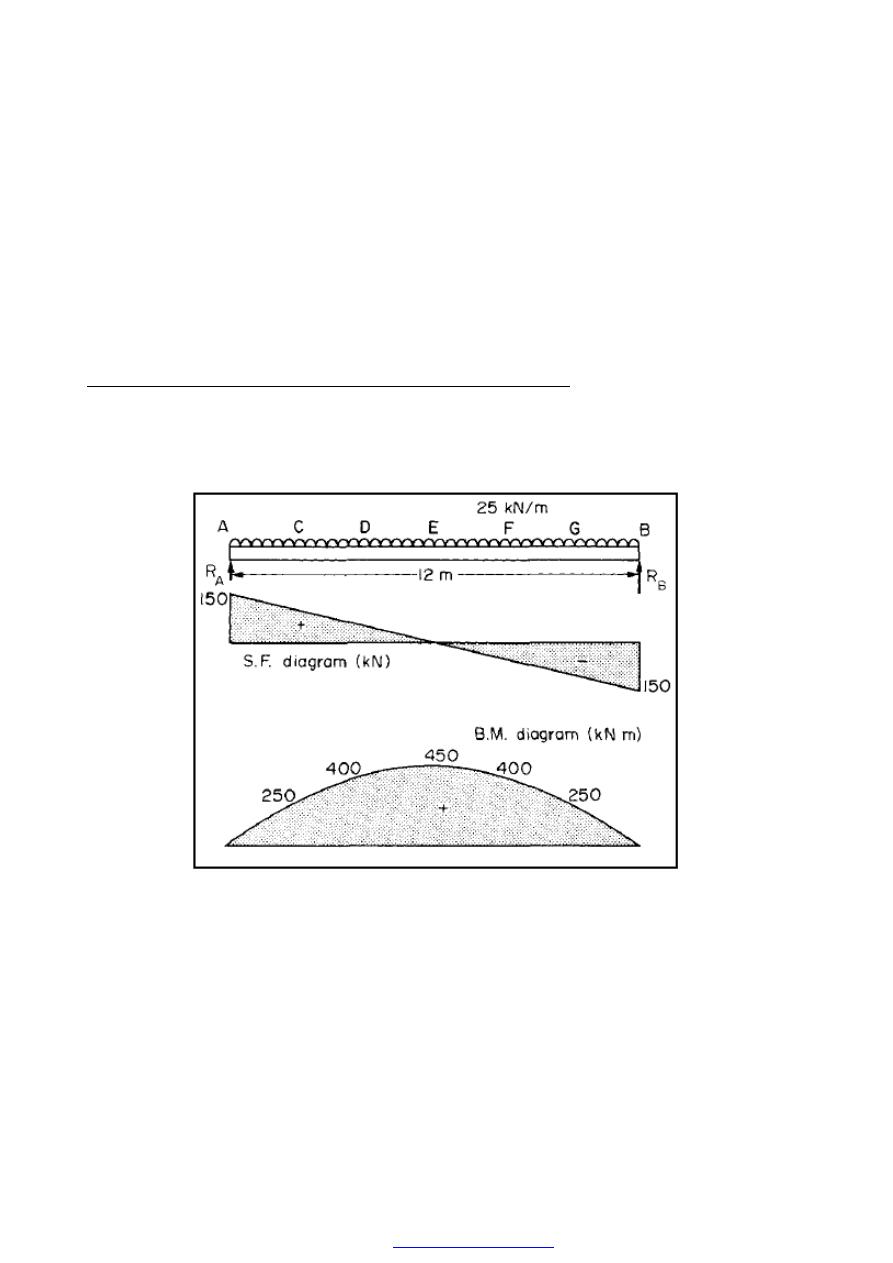

Consider now the simply supported beam shown in Figure (11) carrying a u.d.1. w = 25

kN/m across the complete span.

Figure (11)

Here again it is necessary to evaluate the reactions, but in this case the problem is

simplified by the symmetry of the beam. Each reaction will therefore take half the

applied load,

i.e.

PDF created with pdfFactory Pro trial version

44

The S.F. at A, using the usual sign convention, is therefore + 150kN.

is, therefore, Consider now the beam divided into six equal parts 2 m long. The S.F. at

any other point C

150 - load downwards between A and C

= 150 - (25 x 2) = + 100 kN

The whole diagram may be constructed in this way, or much more quickly by noticing

that the S.F. at A is + 150 kN and that between A and B the S.F. decreases uniformly,

producing the required sloping straight line, shown in Fig. 3.7. Alternatively, the S.F. at

A is + 150 kN and between A and B this decreases gradually by the amount of the

applied load (By 25 x 12 = 300kN) to - 150kN at B. When evaluating B.M.’s it is

assumed that a u.d.1. can be replaced by a concentrated load of equal value acting at the

middle of its spread. When taking moments about C, therefore, the portion of the u.d.1.

between A and C has an effect equivalent to that of a concentrated load of

25 x 2 = 50 kN acting the centre of AC, i.e. 1 m from C.

Similarly, for moments at D the u.d.1. on AD can be replaced by a concentrated load of

The B.M. diagram will be symmetrical about the beam centre line; therefore the values of

B.M. at F and G will be the same as those at D and C respectively. The final diagram is

therefore as shown in Figure (11) and is parabolic.

Point (a) of the summary is clearly illustrated here, since the B.M. is a

maximum when the S.F. is zero. Again, the reason for this will be shown later.

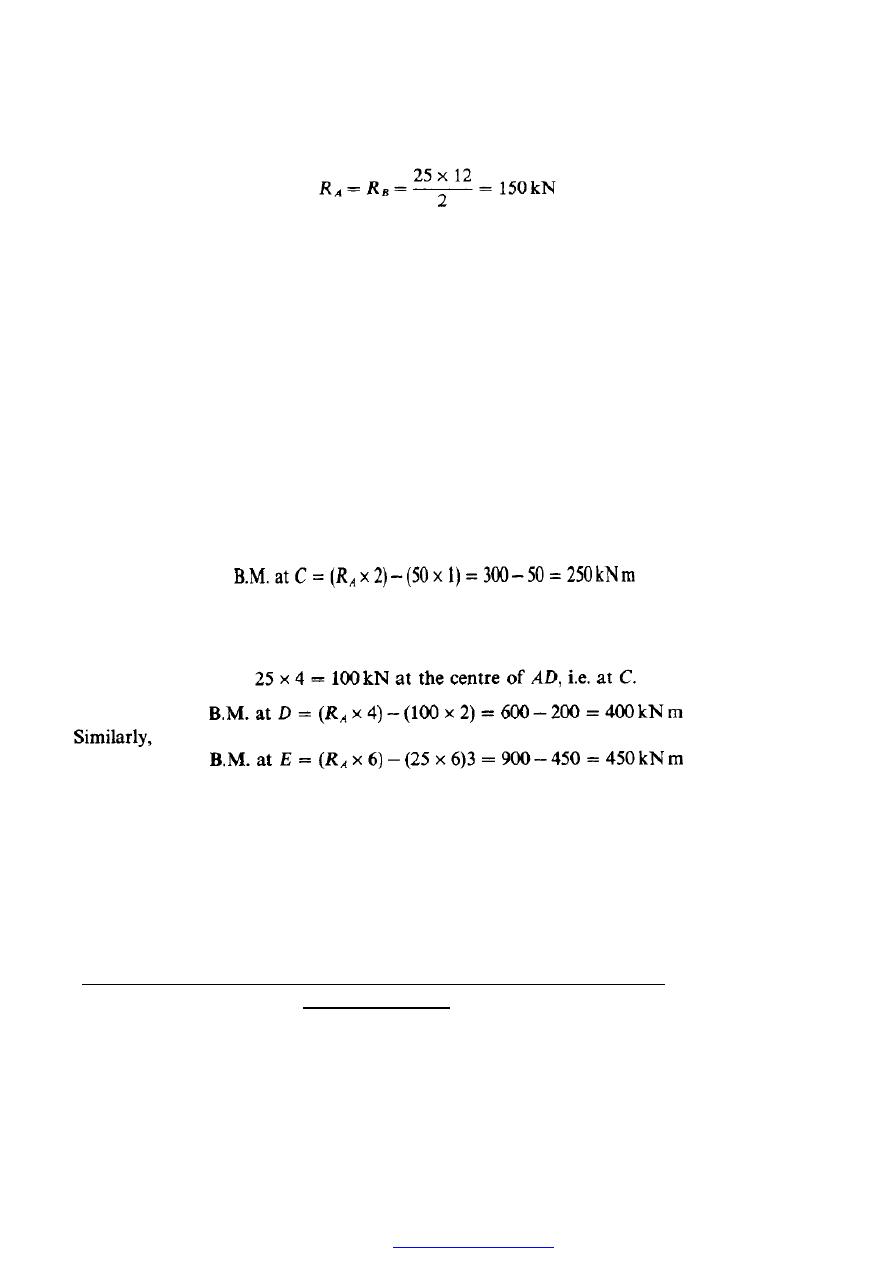

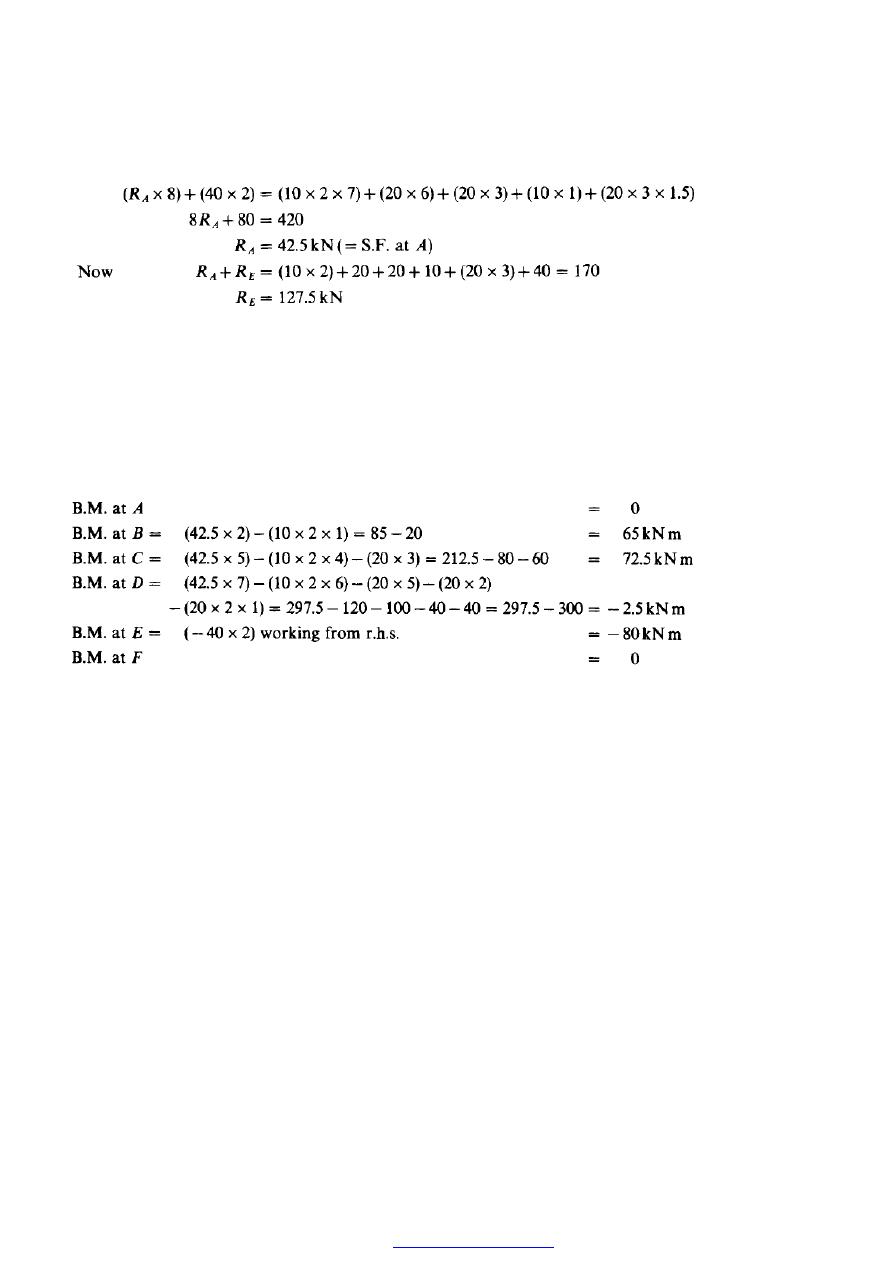

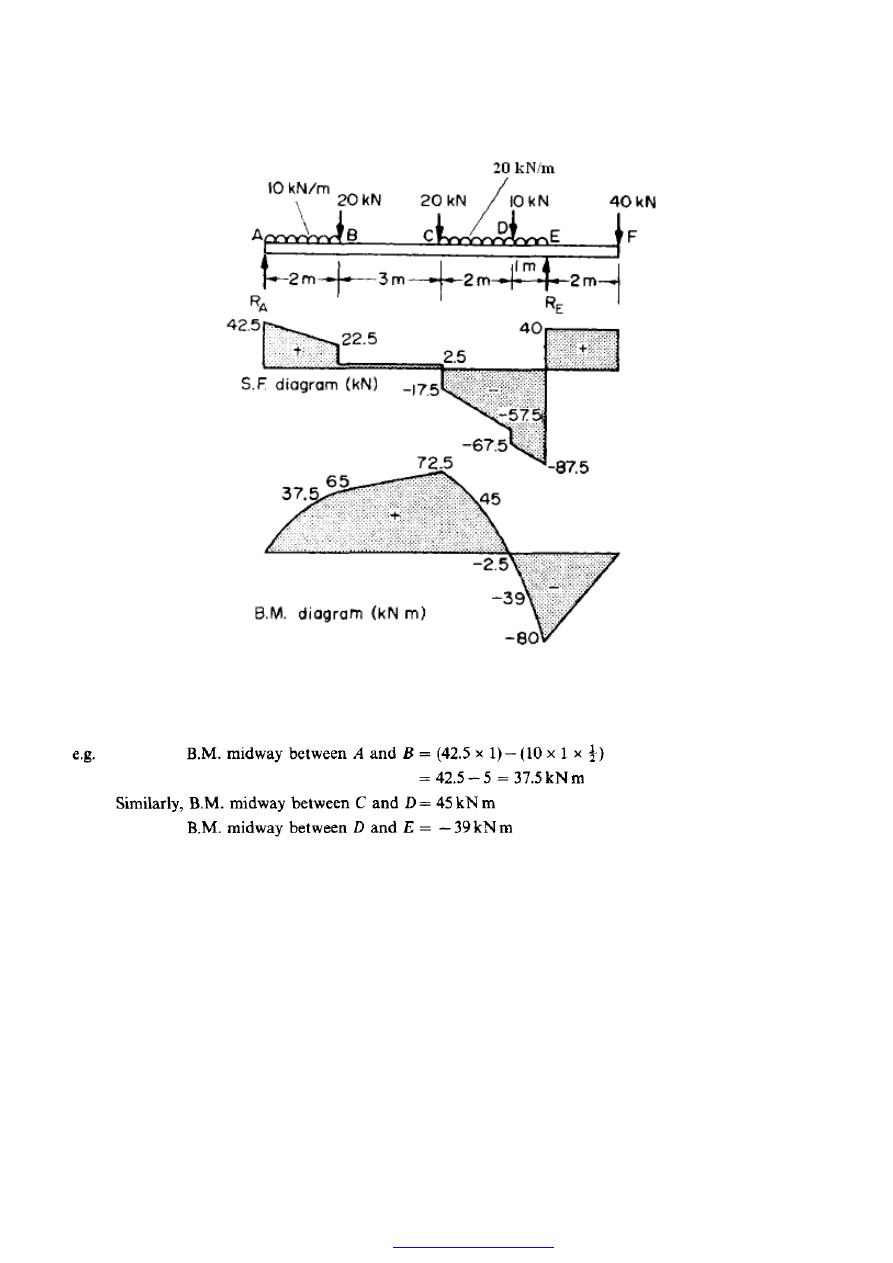

5. S.F. and B.M. diagrams for combined concentrated and uniformly

distributed loads

Consider the beam shown in Figure (12) loaded with a combination of concentrated loads

and u.d.1.s.

Taking moments about E

PDF created with pdfFactory Pro trial version

45

Working from the left-hand support it is now possible to construct the S.F. diagram, as

indicated previously, by following the direction arrows of the loads. In the case of the

u.d.l.’s the S.F. diagram will decrease gradually by the amount of the total load until the

end of the u.d.1. or the next concentrated load is reached. Where there is no u.d.1. the

S.F. diagram remains horizontal between load points. In order to plot the B.M. diagram

the following values must be determined:

PDF created with pdfFactory Pro trial version

46

Figure (12)

For complete accuracy one or two intermediate values should be obtained along each

u.d.l. portion of the beam,

The B.M. and S.F. diagrams are then as shown in Figure (12)

PDF created with pdfFactory Pro trial version

47

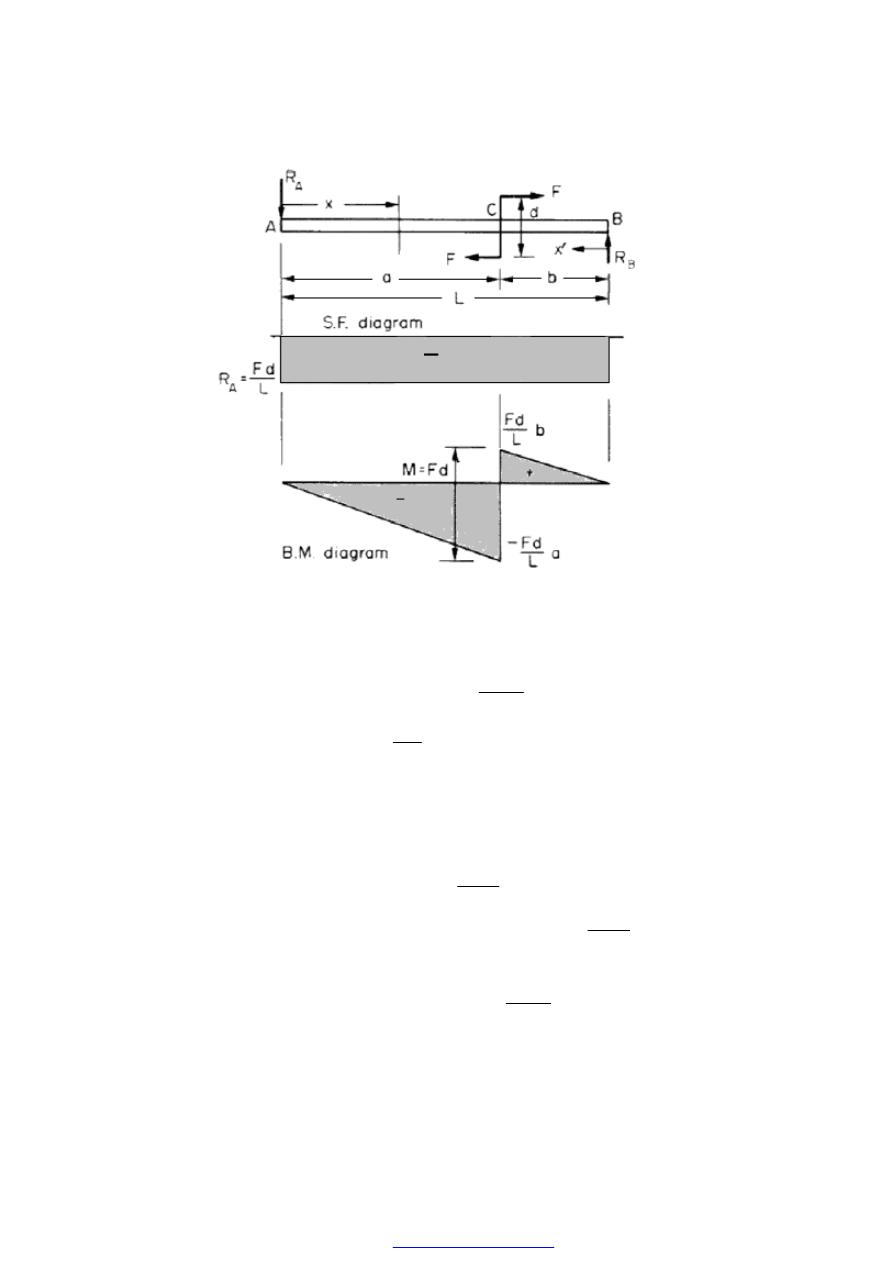

5. Points of contraflexure

A point of contraflexure is a point where the curvature of the beam changes sign. It is

sometimes referred to as a point of inflexion and will be shown later to occur at the point,

or points, on the beam where the B.M. is zero.

For the beam of Figure (9) therefore, it is evident from the B.M. diagram that this point

lies somewhere between C and D (B.M. at C is positive, B.M. at D is negative). If the

required point is a distance x from C then at that point

Since the last answer can be ignored (being outside the beam), the point of contraflexure

must be situated at 1.96 m to the right of C.

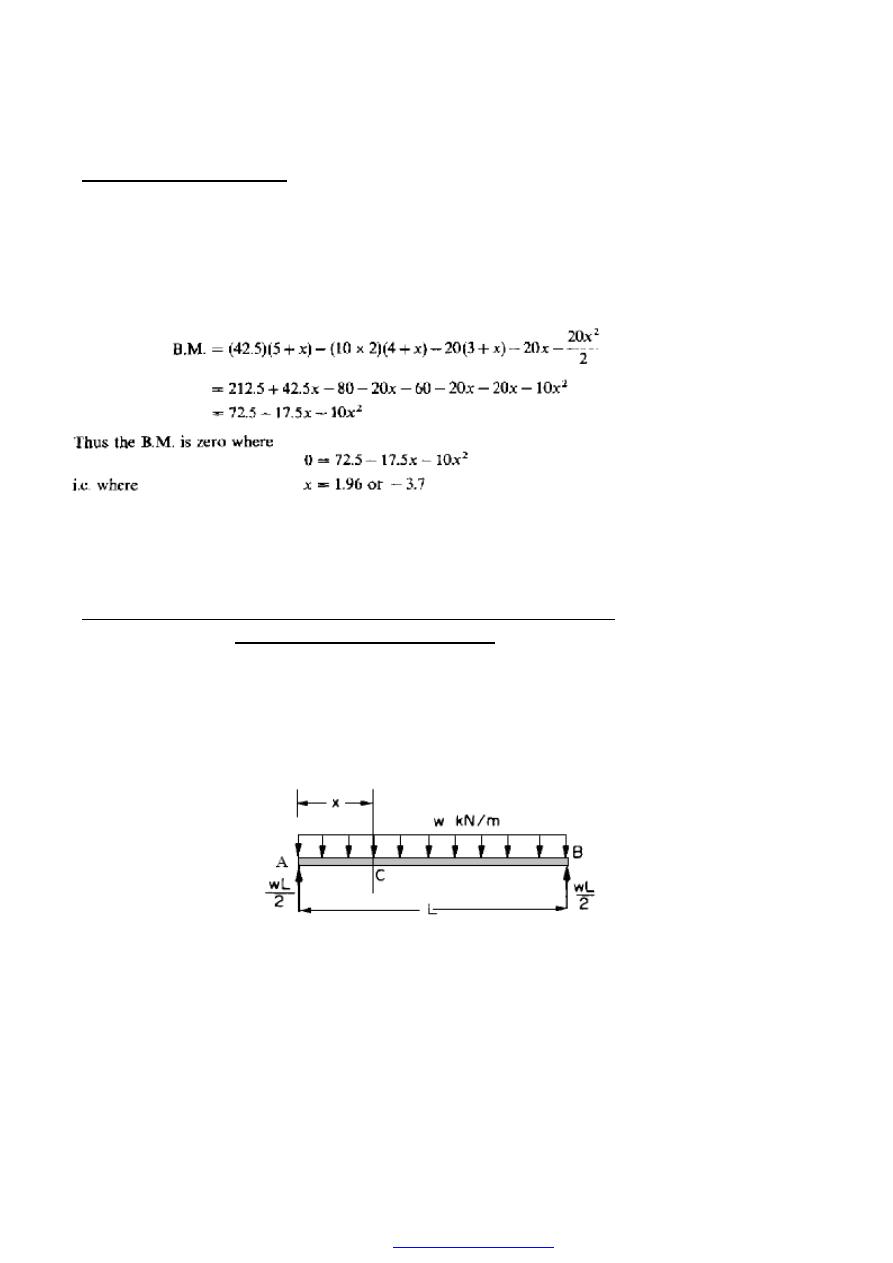

6. Relationship between shear force Q, bending moment M and

intensity of loading W (kN/m)

Consider the beam AB shown in Figure (10) carrying a uniform loading intensity

(uniformly distributed load) of W (kN/m). By symmetry, each reaction takes half the total

load, i.e., WL/2.

Figure (10)

PDF created with pdfFactory Pro trial version

48

Differentiating equation (1),

W

dx

dQ

−

=

.....(3)

These relationships are the basis of the rules stated in the summary, the proofs of which

are as follows:

(a) The maximum or minimum B.M. occurs where

0

=

dx

dM

But

Q

dx

dM

=

Thus where S.F. is zero B.M. is a maximum or minimum.

(b) The slope of the B.M. diagram =

Q

dx

dM

=

Thus where Q = 0 the slope of the B.M. diagram is zero, and the B.M. is therefore

constant.

(c) Also, since Q represents the slope of the B.M. diagram, it follows that where the S.F.

is positive the slope of the B.M. diagram is positive, and where the S.F. is negative the

slope of the B.M. diagram is also negative.

(d) The area of the S.F. diagram between any two points, from basic calculus, is

∫

dx

Q

But,

Q

dx

dM

=

or

∫

=

dx

Q

M

PDF created with pdfFactory Pro trial version

49

i.e. the B.M. change between any two points is the area of the S.F. diagram between these

points.

This often provides a very quick method of obtaining the B.M. diagram once the S.F.

diagram has been drawn.

(e) With the chosen sign convention, when the B.M. is positive the beam is sagging and

when it is negative the beam is hogging. Thus when the curvature of the beam changes

from sagging to hogging, as at x-x in Figure (11), or vice versa, the B.M.

changes sign, i.e. becomes instantaneously zero. This is termed a point of inflexion or

contra flexure. Thus a point of contra flexure occurs where the B.M. is zero.

Figure (11) Beam with point contraflexure at X-X

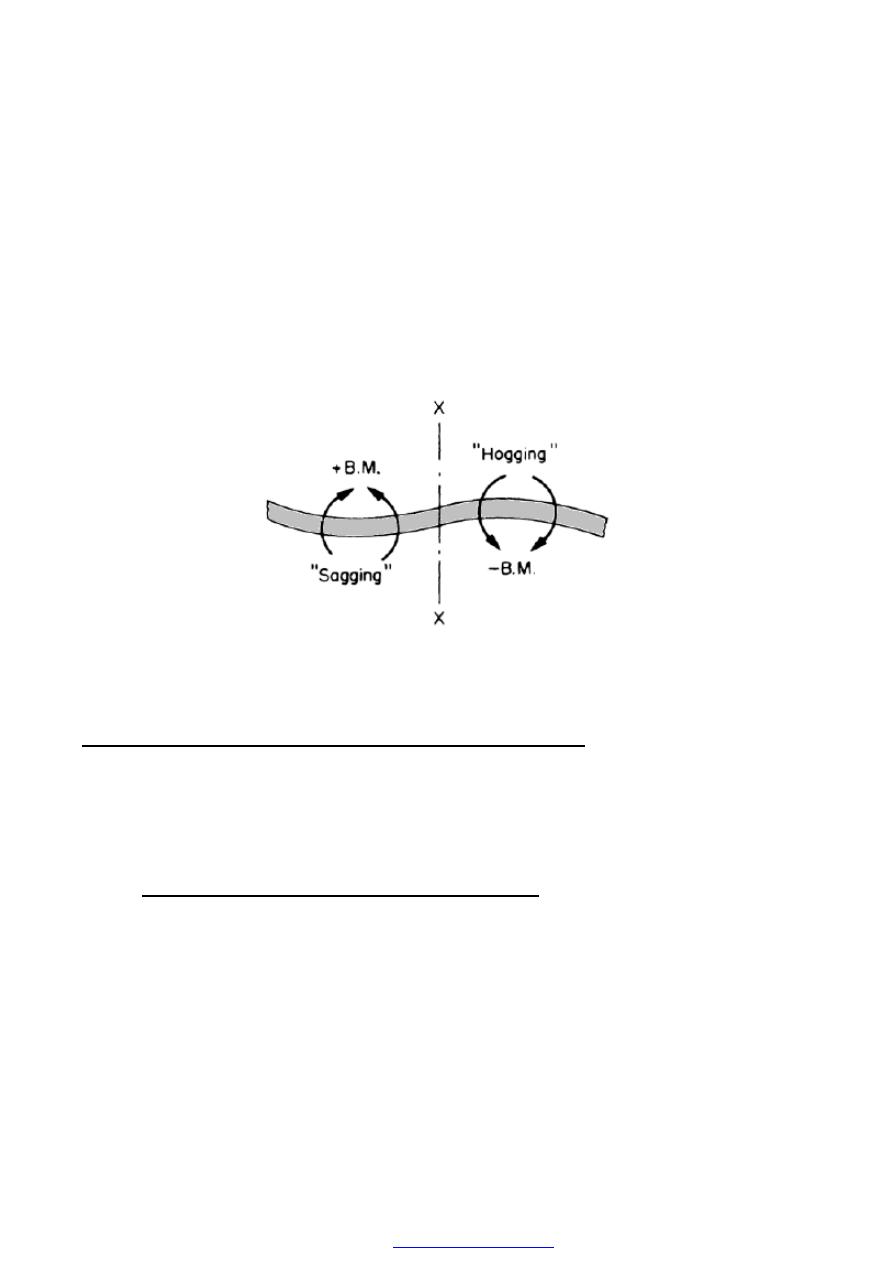

7. S.F. and B.M. diagrams for an applied couple or moment

In general there are two ways in which the couple or moment can be applied: (a) with

horizontal loads and (b) with vertical loads, and the method of solution is different for

each.

Type (a): couple or moment applied with horizontal loads

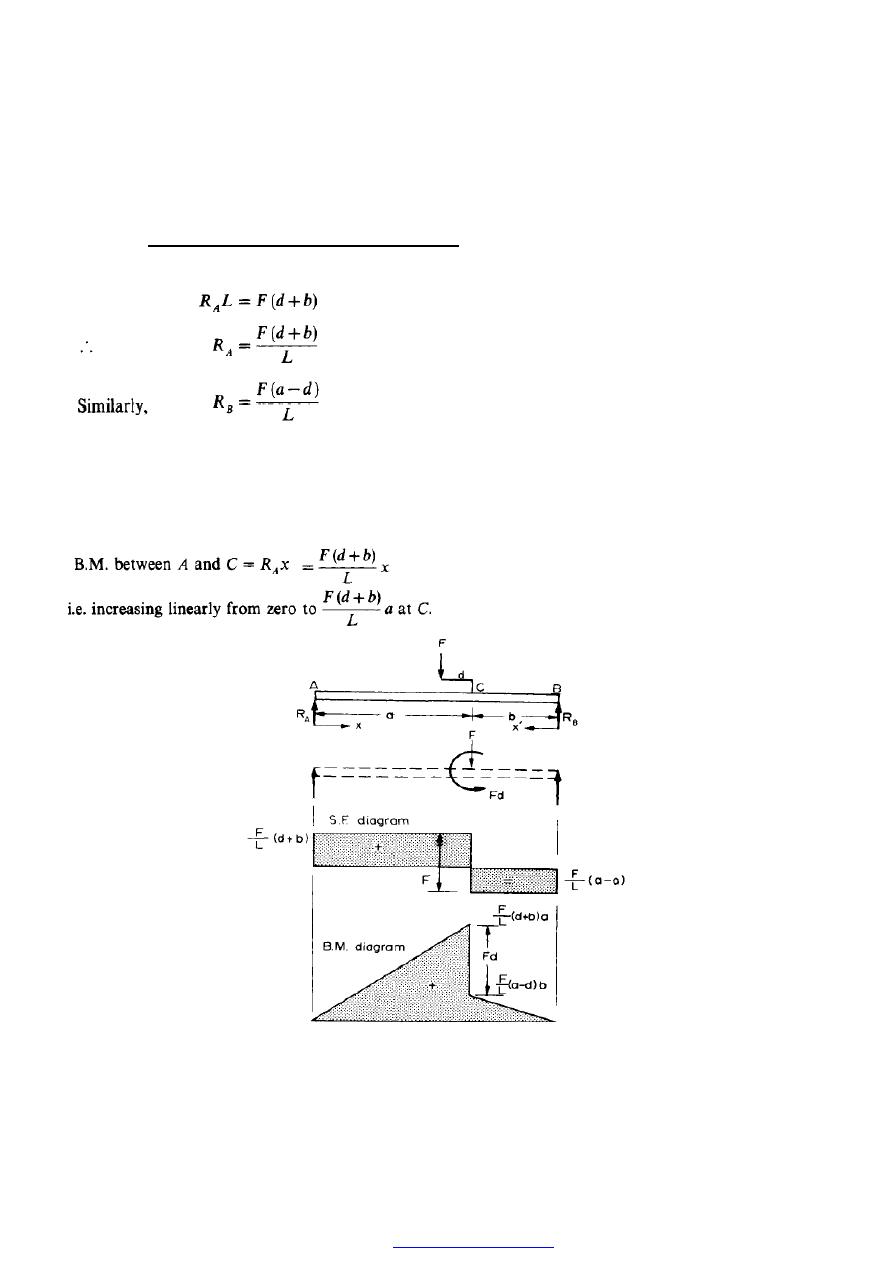

Consider the beam AB shown in Figure (12) to which a moment (F.d) is applied

by means of horizontal loads at a point C, distance a from A.

PDF created with pdfFactory Pro trial version

50

Figure (12)

Since this will tend to lift the beam at A, R

A

acts downwards.

Moments about B:

d

F

L

A

R

.

.

=

,

L

d

F

A

R

.

=

and for vertical equilibrium

L

d

F

A

R

B

R

.

=

=

The S.F. diagram can now

be drawn as the horizontal loads have no effect on the vertical

shear.

The B.M. at any section between A and C is

x

L

d

F

x

A

R

M

.

.

.

−

=

−

=

Thus the value of the B.M. increases linearly from zero at A to

a

L

d

F

.

.

−

at C

Similarly, the B.M. at any section between C and B is

x

L

d

F

x

B

R

d

F

x

A

R

M

.

.

.

.

.

−

=

=

+

−

=

PDF created with pdfFactory Pro trial version

51

i.e. the value of the B.M. again increases linearly from zero at B to - b at C. The B.M.

diagram is therefore as shown in Figure (12).

Type (b): moment applied with vertical loads

Consider the beam AB shown in Figure (13); taking moments about B:

The S.F. diagram can therefore be drawn as in Figure (13) and it will be observed that in

this case (F) does affect the diagram. For the B.M. diagram an equivalent system is used.

The offset load F is replaced by a

moment and a force acting at C, as shown in Figure

(13). Thus

Figure (13)

PDF created with pdfFactory Pro trial version

52

Examples

Example 1

Draw the S.F. and B.M. diagrams for the beam loaded as shown in Figure

(14), and determine(a) the position and magnitude of the maximum B.M., and (b) the

position of any point of contraflexure.

Figure (14)

PDF created with pdfFactory Pro trial version

53

The S.F. diagram may now be constructed as shown in Figure (14) .

Calculation of bending moments

The maximum B.M. will be given by the point (or points) at which dM/dx (Le. the shear

force) is zero. By inspection of the S.F. diagram this occurs midway between D and E,

i.e. at1.5 m from E.

The B.M. diagram is therefore as shown in Figure (14) Alternatively, the B.M. at any

point between D and E at a distance of x from A will be given by

(b) Since the B.M. diagram only crosses the zero axis once there is only one point of

contraflexure, i.e. between B and D. Then, B.M. at distance y from C will be given by

The point of contraflexure occurs where B.M. = 0, i.e. where M

yy

= 0,

i.e. point of contraflexure occurs 0.12 m to the left of B.

PDF created with pdfFactory Pro trial version

54

Example 2

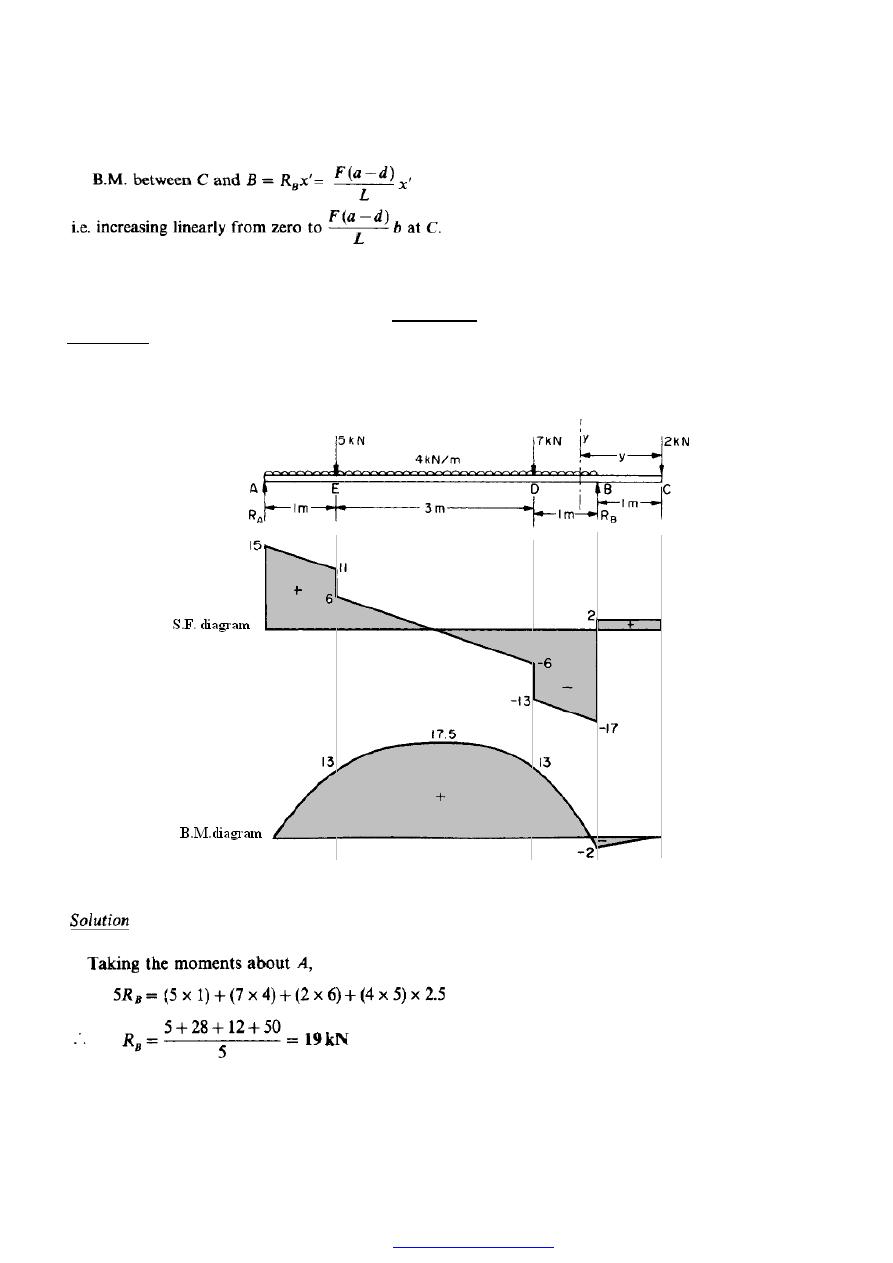

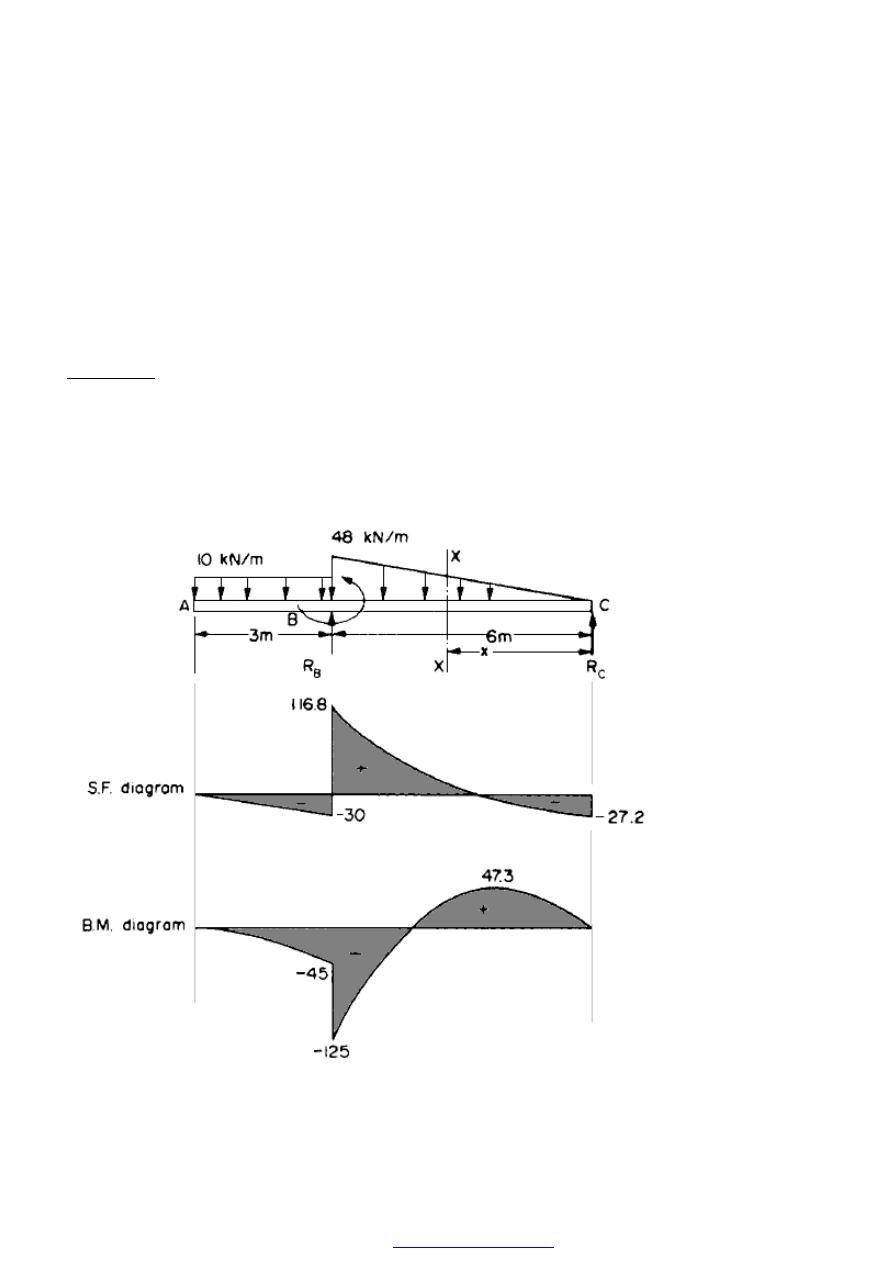

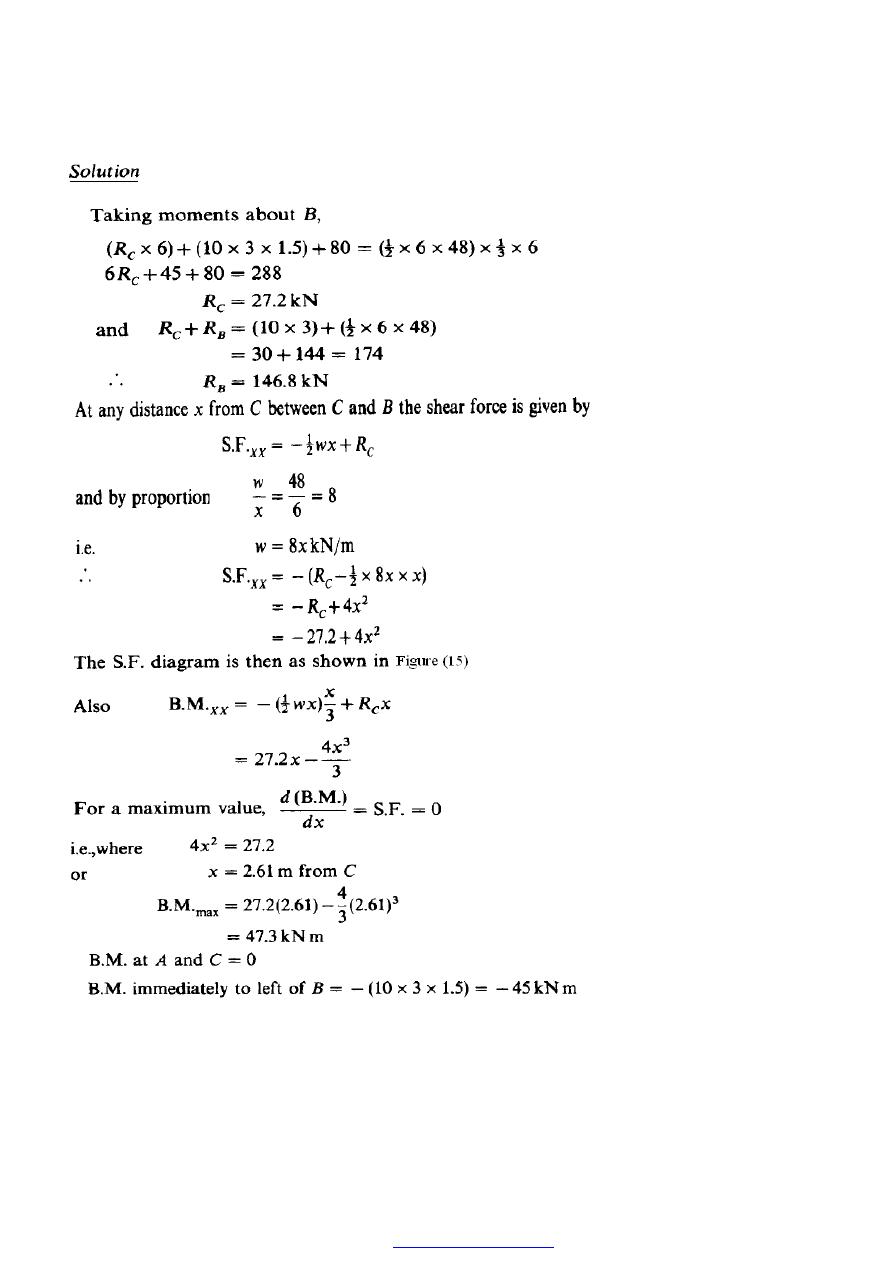

A beam ABC is 9 m long and supported at B and C, 6 m apart as shown in Figure (15).

The beam carries a triangular distribution of load over the portion BC together with an

applied counterclockwise couple of moment 80 kN m at B and a uniform distributed load

(u.d.1.) of 10 kN/m over AB, as shown. Draw the S.F. and B.M. diagrams for the beam.

Figure (15)

PDF created with pdfFactory Pro trial version

55

At the point of application of the applied moment there will be a sudden change in B.M. of 80 kN.

m. (There will be no such discontinuity in the S.F. diagram; the effect of the moment will merely

be reflected in the values calculated for the reactions.) The B.M. diagram is therefore as shown in

Figure (15).

PDF created with pdfFactory Pro trial version

56

Problems

1. A beam AB, 1.2 m long, is simply-supported at its ends A and B and carries two

concentrated loads, one of 10 kN at C, the other 15 kN at D. Point C is 0.4 m from A,

point D is 1 m from A. Draw the S.F. and B.M. diagrams for the beam inserting

principal values.

[9.17, - 0.83, -15.83 kN; 3.67, 3.17 kN.m]

2 . The beam of question (1) carries an additional load of 5 kN upwards at point E, 0.6 m

from A. Draw the S.F. and B.M. diagrams for the modified loading. What is the

maximum B.M.?

[6.67, -3.33, 1.67, -13.33 kN; 2.67, 2, 2.67 kN.m.]

3. A cantilever beam AB, 2.5 m long is rigidly built in at A and carries vertical

concentrated loads of 8 kN at B and 12 kN at C, 1 m from A. Draw S.F. and B.M.

diagrams for the beam inserting principal values.

[-8, -20 kN; -11.2, -31.2kN.m]

4. A beam AB, 5 m long, is simply-supported at the end B and at a point C, 1 m from A.

It carries vertical loads of 5 kN at A and 20kN at D, the centre of the span BC. Draw

S.F. and B.M. diagrams for the beam inserting principal values. [ - 5 , 11.25, -

8.75kN; - 5 , 17.5 kN.m]

5. A beam AB, 3 m long, is simply-supported at A and E. It carries a 16 kN concentrated

load at C, 1.2 m from A, and a u.d.1. of 5 kN/m over the remainder of the beam. Draw

the S.F. and B.M. diagrams and determine the value of the maximum B.M.

[12.3, -3.7, -12.7kN; 14.8 kN.m.]

6. A simply supported beam has a span of 4m and carries a uniformly distributed load of

60 kN/m together with a central concentrated load of 40 kN. Draw the S.F. and B.M.

diagrams for the beam and hence determine the maximum B.M. acting on the beam.

[S.F. 140, k20, -140 kN; B.M. 0, 160,0 kN.m]

7. A 2 m long cantilever is built-in at the right-hand end and carries a load of 40 kN at

the free end. In order to restrict the deflection of the cantilever within reasonable

limits an upward load of 10 kN is applied at mid-span. Construct the S.F. and B.M.

PDF created with pdfFactory Pro trial version

57

diagrams for the cantilever and hence determine the values of the reaction force and

moment at the support. [30 kN, 70 kN. m.]

8. A beam 4.2 m long overhangs each of two simple supports by 0.6 m. The beam carries

a uniformly distributed load of 30 kN/m between supports together with concentrated

loads of 20 kN and 30 kN at the two ends. Sketch the S.F. and B.M. diagrams for the

beam and hence determine the position of any points of contraflexure.

[S.F. -20, +43, -47, +30 kN; B.M. - 12, 18.75, - 18kN.m; 0.313 and 2.553 from

left hand support.]

9. A beam ABCDE, with A on the left, is 7 m long and is simply supported at Band E.

The lengths of the various portions are AB = 1.5 m, BC = 1.5 m, CD = 1

m and DE = 3 m. There is a uniformly distributed load of 15 kN/m between B and a

point 2 m to the right of B and concentrated loads of 20 kN act at A and D with one of

50 kN at C.

(a) Draw the S.F. diagrams and hence determine the position from A at which the S.F. is

zero.

(b) Determine the value of the B.M. at this point.

(c) Sketch the B.M. diagram approximately to scale, quoting the principal values.

[3.32 m; 69.8 kN,m; 0, -30, 69.1, 68.1, 0 kN.m]

10. A beam ABCDE is simply supported at A and D. It carries the following loading: a

distributed load of 30 kN/m between A and B a concentrated load of 20 kN at B; a

concentrated load of 20 kN at C; a concentrated load of 10 kN at E; a distributed

load of 60 kN/m between D and E. Span AB = 1.5 m, BC = CD = DE = 1 m.

Calculate the value of the reactions at A and D and hence draw the S.F. and B.M.

diagrams. What are the magnitude and position of the maximum B.M. on the beam?

[41.1, 113.9kN; 28.15kN.m; 1.37 m from A.]

PDF created with pdfFactory Pro trial version

58

T

T

O

O

R

R

S

S

I

I

O

O

N

N

Simple torsion theory

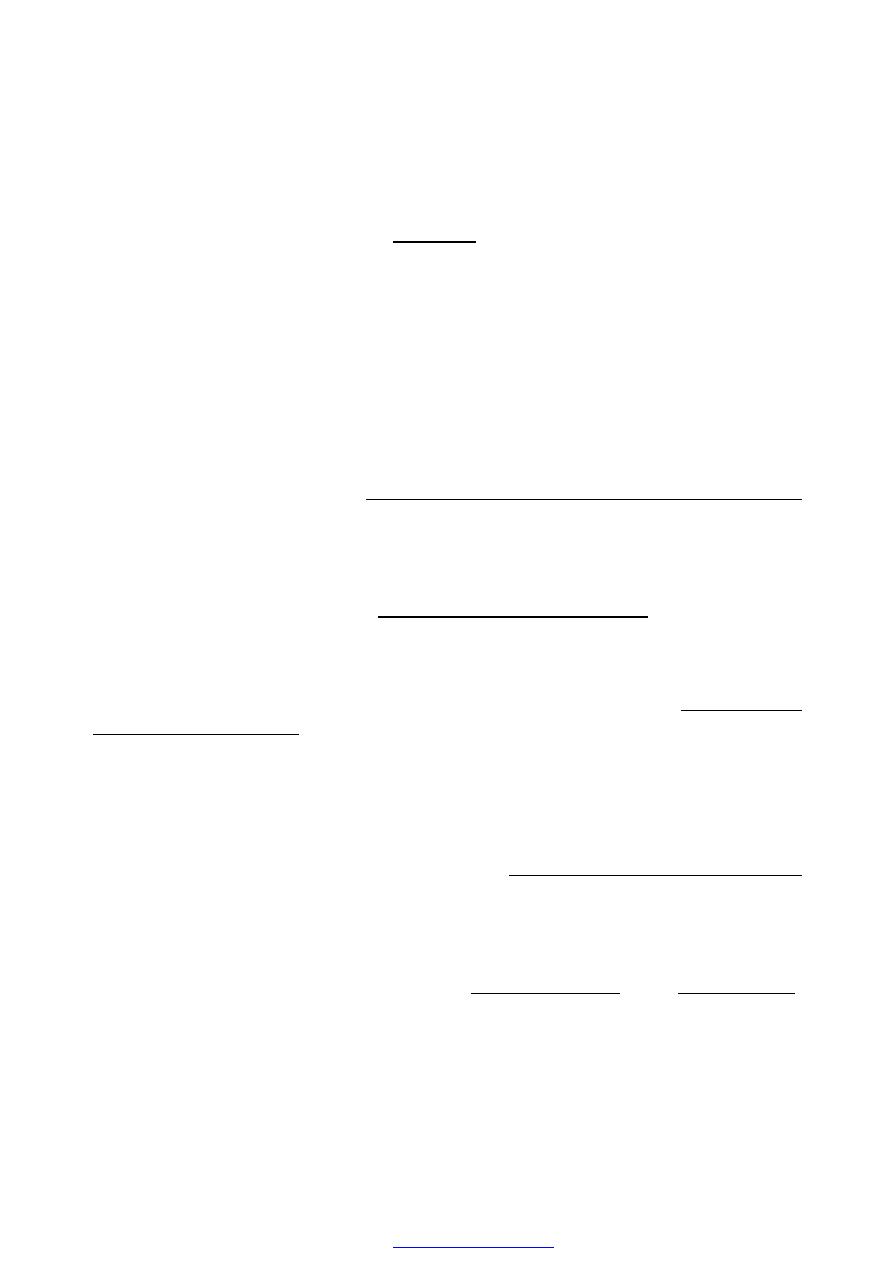

When a uniform circular shaft is subjected to a torque it can be shown that every section

of the shaft is subjected to a state of pure shear Figure (1), the moment of resistance

developed by the shear stresses being everywhere equal to the magnitude, and opposite in

sense, to the applied torque. For the purposes of deriving a simple theory, to make the

following basic assumptions:

(1) The material is homogeneous, i.e. of uniform elastic properties throughout.

(2) The material is elastic, following Hooke's law with shear stress proportional to shear

strain.

(3) The stress does not exceed the elastic limit or limit of proportionality.

(4) Circular Sections remain circular.

(5) Cross-sections remain plane. (This is certainly not the case with the torsion of non

circular Sections.)

(6) Cross-sections rotate as if rigid, i.e. every diameter rotates through the same angle.

Practical tests carried out on circular shafts have shown that the theory developed below

on the basis of these assumptions shows excellent correlation with experimental results.

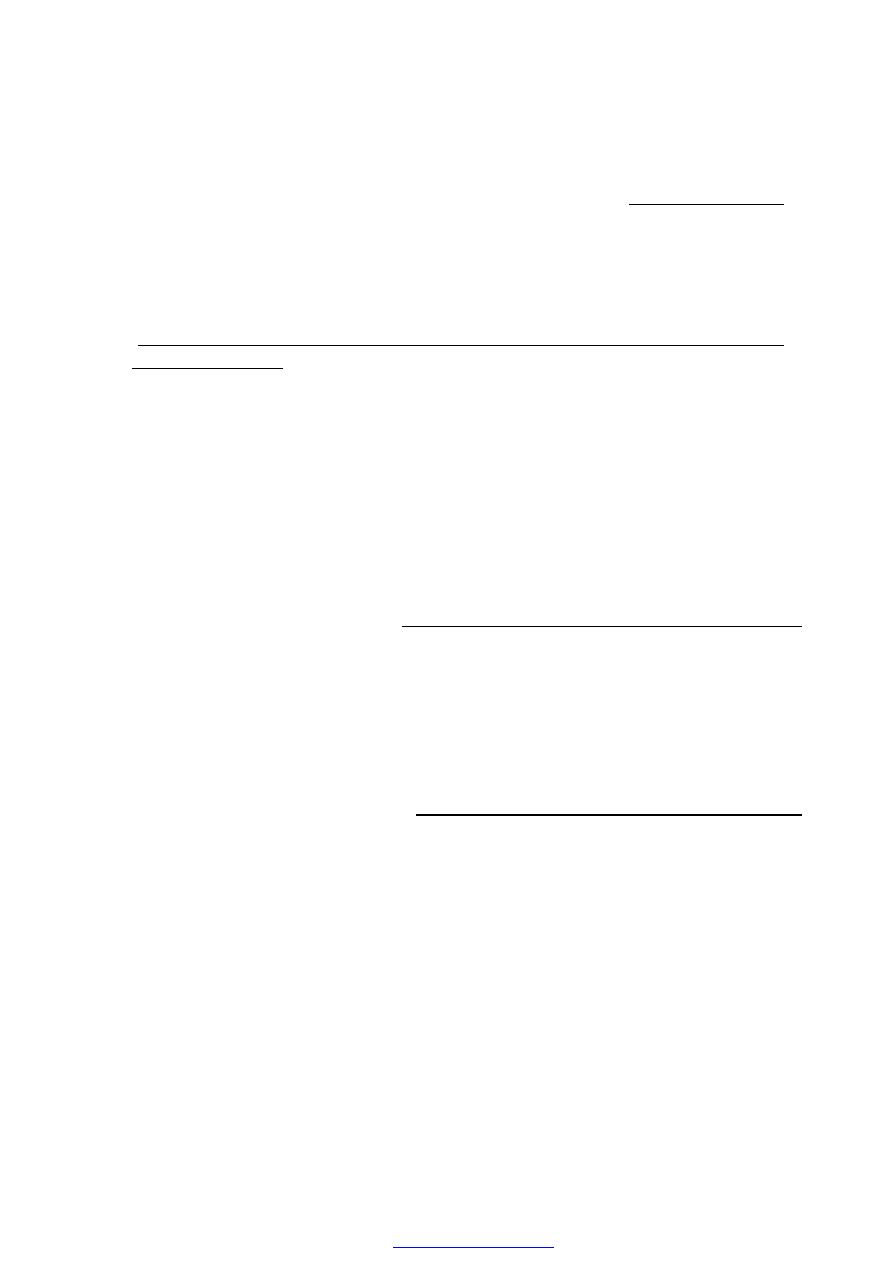

(a) Angle of twist

Consider now the solid circular shaft of radius (R) subjected to a torque (T) at one

end, the other end being fixed Figure (2). Under the action of this torque a radial

line at the free end of the shaft twists through an angle (

θ)

, point A moves to B, and AB

subtends an angle (

γ)

at the fixed end. This is then the angle of distortion of the shaft, i.e.

the shear strain.

PDF created with pdfFactory Pro trial version

59

Figure (2)

(b) Stresses

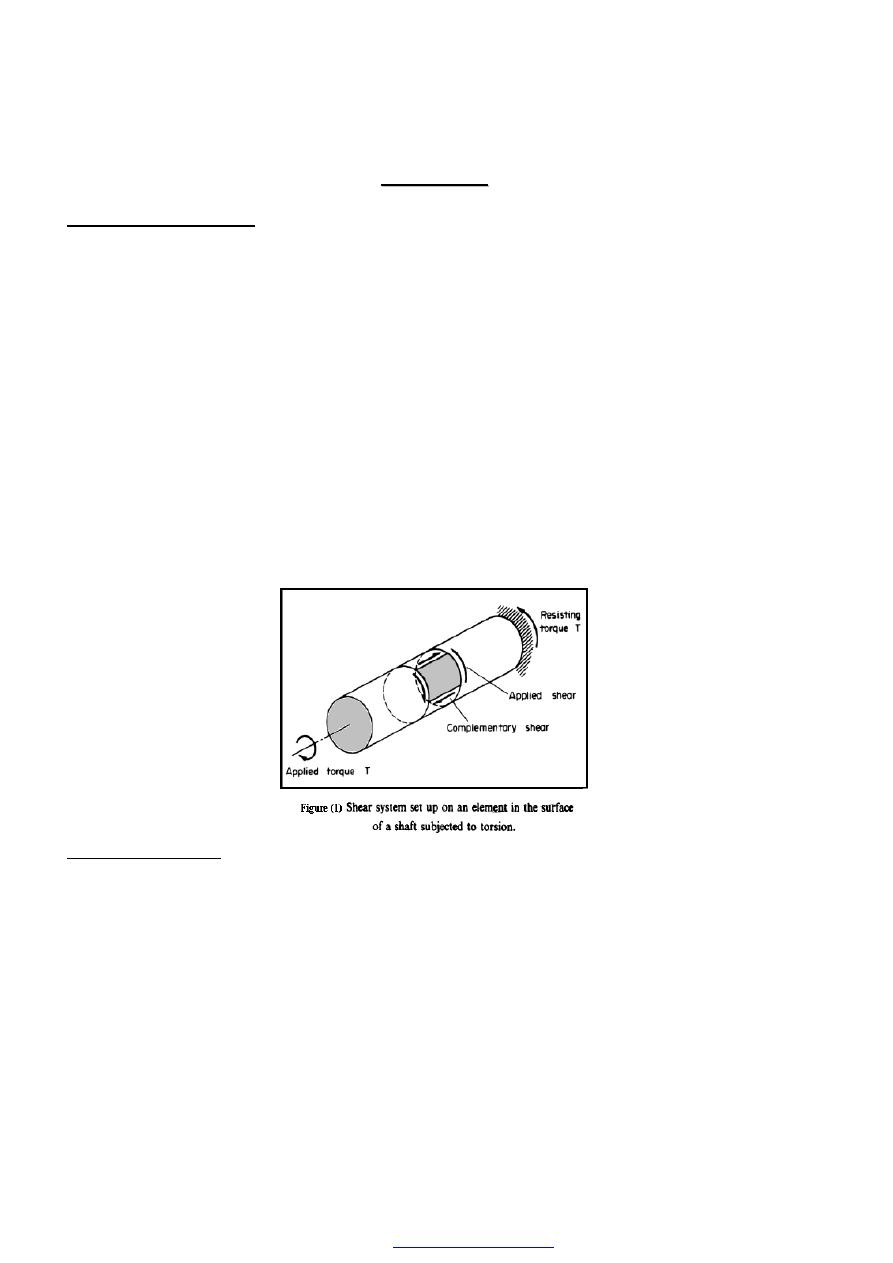

Let the cross-section of the shaft be considered as divided into elements of radius r

and thickness (dr) as shown in Figure (3) each subjected to a shear stress (

τ

').

PDF created with pdfFactory Pro trial version

60

The force set up on each element,

= stress x area=

τ

' x 2.

π.r dr (approximately)

This force will produce a moment about the centre axis of the shaft, providing a

contribution to the torque

=

(τ

' x 2.

π.r dr

)

.r=

τ

' x 2.

π.r

2

dr

The total torque on the section (T) will then be the sum of all such contributions across

the section,

Now the shear stress (

τ') will vary with the radius rand must therefore be replaced in

terms of r before the integral is evaluated. From eqnuation (3)

The integral

∫

R

dr

r

0

3

.

.

.

2

π

is called the polar second moment of area (J), and may be

evaluated as a

standard form for solid and hollow shafts .

PDF created with pdfFactory Pro trial version

61

Combining eqns. (3) and (4) produces the so-called simple theory of torsion:

Polar second moment of area

As

stated above the polar second moment

of

area J

is

defined as

For a solid shaft,

For

a

hollow shaft

of internal radius r,

For thin-walled hollow shafts the values of (D) and (d) may be nearly equal, and in such

cases there can be considerable errors in using the above equation involving the

difference of two large quantities of similar value. It is therefore convenient to obtain an

alternative form of expression for the polar moment of area.

Now

PDF created with pdfFactory Pro trial version

62

Where; A = 2

π

r dr is the area of each small element of Figure (3).

If a thin hollow cylinder is therefore considered as just one of these small elements with

its wall thickness t = dr, then

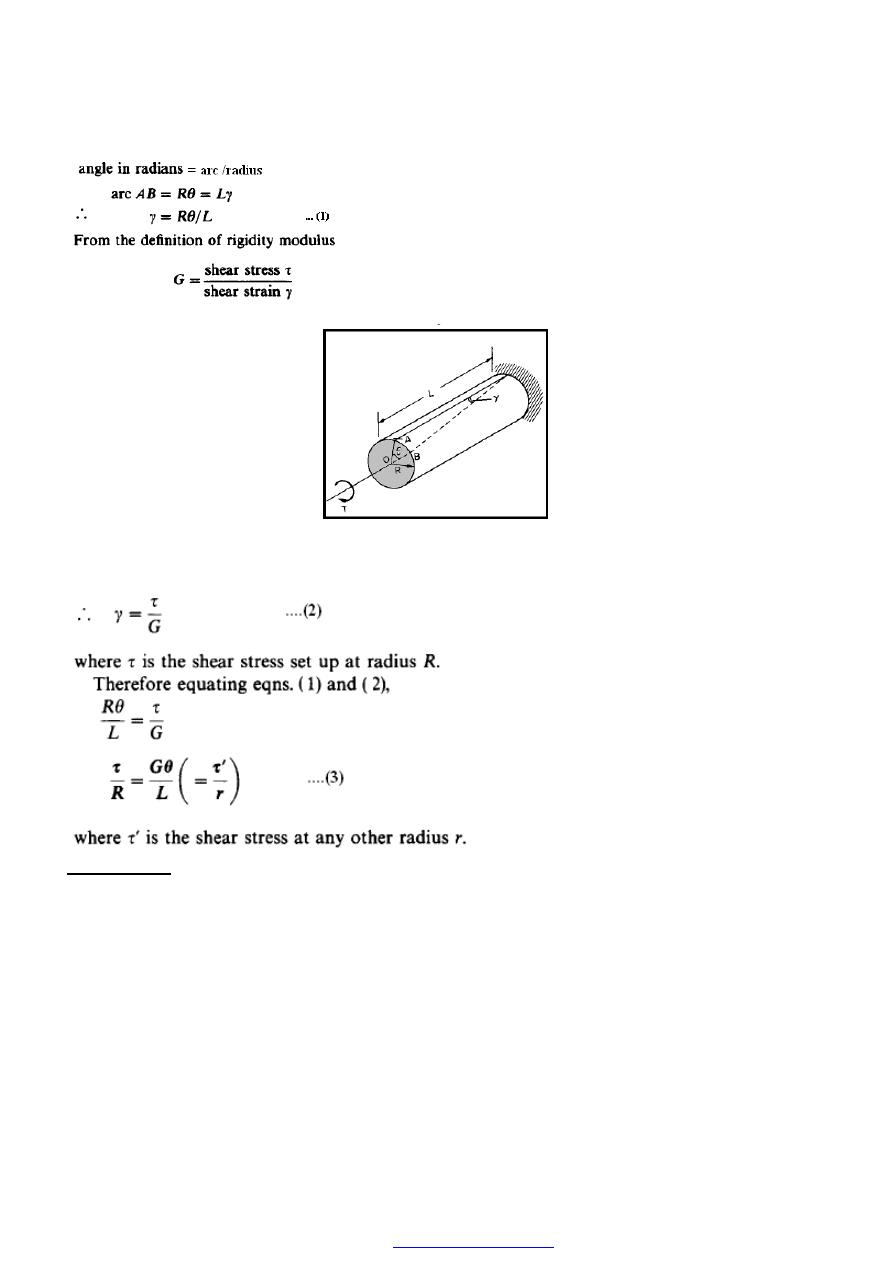

Shear stress and shear strain in shafts

The shear stresses which are developed in a shaft subjected to pure torsion are indicated

in Figure (1),their values being given by the simple torsion theory as

Now from the definition of the shear or rigidity modulus (G),

It therefore follows that the two equations may be combined to relate the shear stress and

strain in the shaft to the angle of twist per unit length, thus

or, in terms of some internal radius r,

These equations indicate that the shear stress and shear strain vary linearly with radius

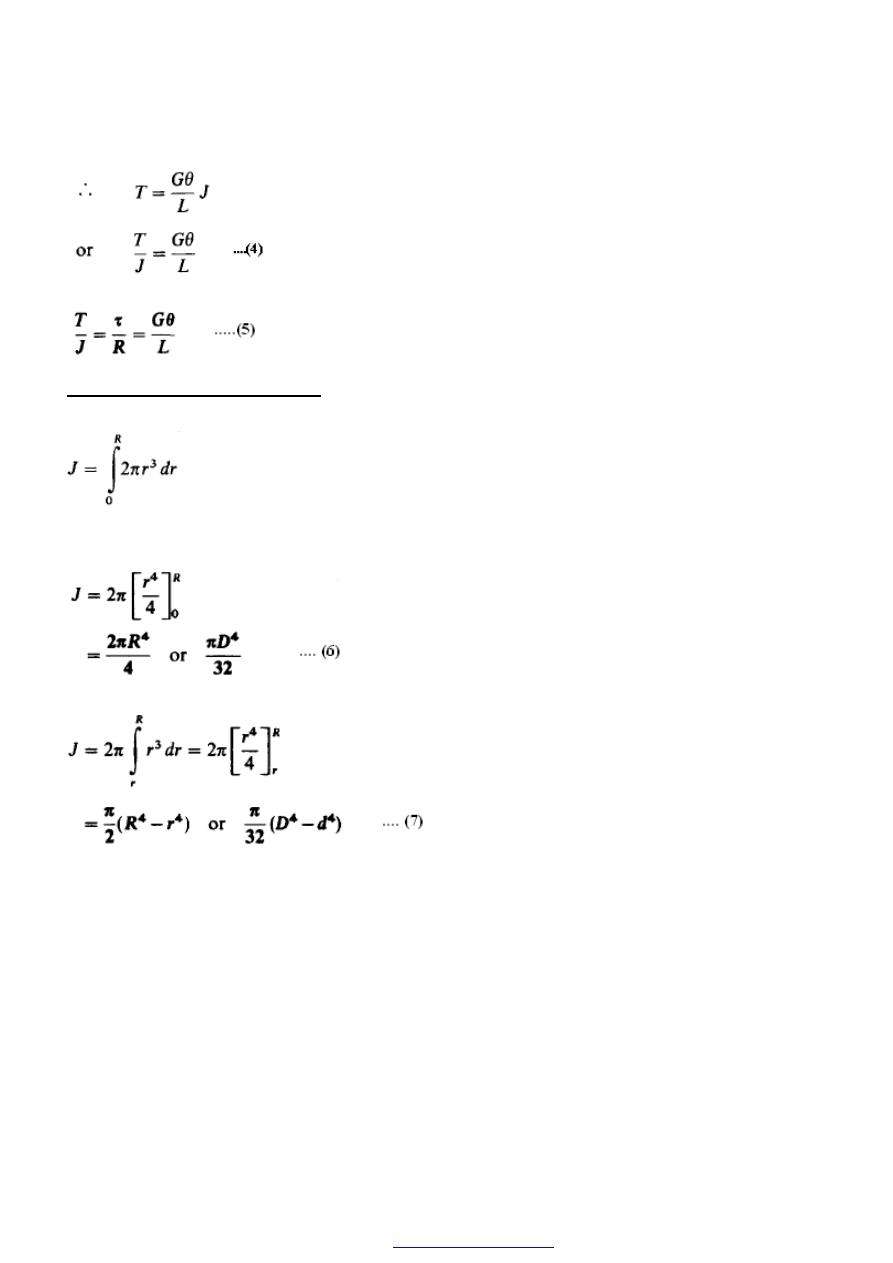

and have their maximum value at the outside radius Figure (4) .

PDF created with pdfFactory Pro trial version

63

Section modulus

It is sometimes convenient to re-write part of the torsion theory formula to obtain the

maximum shear stress in shafts as follows:

With (R) the outside radius of the shaft the above equation yields the greatest value

possible for T, Figure (4).

Where; z = J/R is termed the polar section modulus. It will be seen from the preceding

section that:

Torsional rigidity

The angle of twist per unit length of shafts is given by the torsion theory as

The quantity (GJ) is termed the torsional rigidity of the shaft and is thus given by

i.e. the torsional rigidity is the torque divided by the angle of twist (in radians) per unit

length

.

Torsion of hollow shafts

It has been shown above that the maximum shear stress in a solid shaft is developed in

the outer surface, values at other radii decreasing linearly to zero at the centre. In

applications where weight reduction is of prime importance as in the aerospace industry,

for instance, it is often found advisable to use hollow shafts.

PDF created with pdfFactory Pro trial version

64

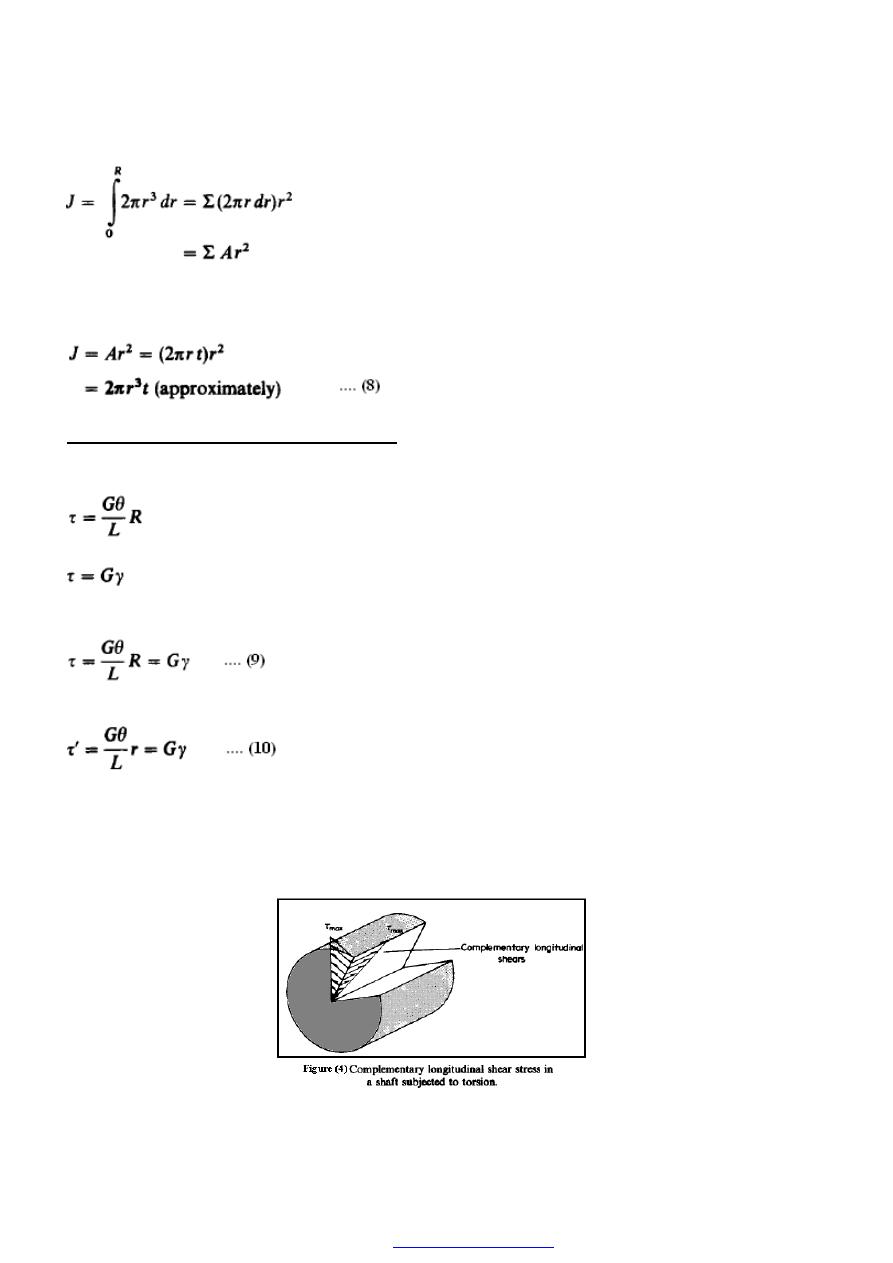

Composite shafts - series connection

If two or more shafts of different material, diameter or basic form are connected

together in such a way that each carries the same torque, then the shafts are said to be

connected in series and the composite shaft so produced is therefore termed series-

connected Figure (5) .

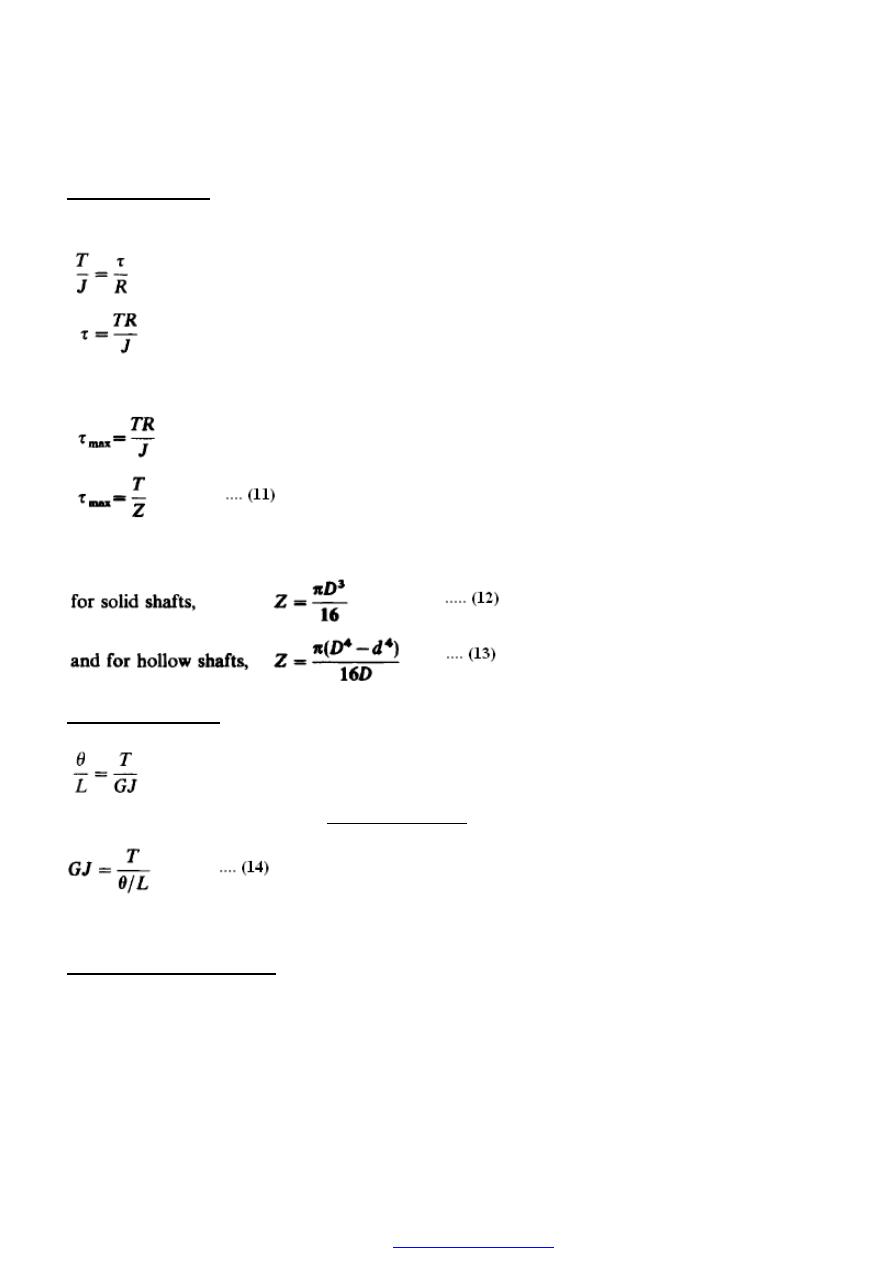

Composite shafts - parallel connection

If two or more materials are rigidly fixed together such that the applied torque is shared

between them then the composite shaft so formed is said to be connected in parallel

Figure (6).

PDF created with pdfFactory Pro trial version

65

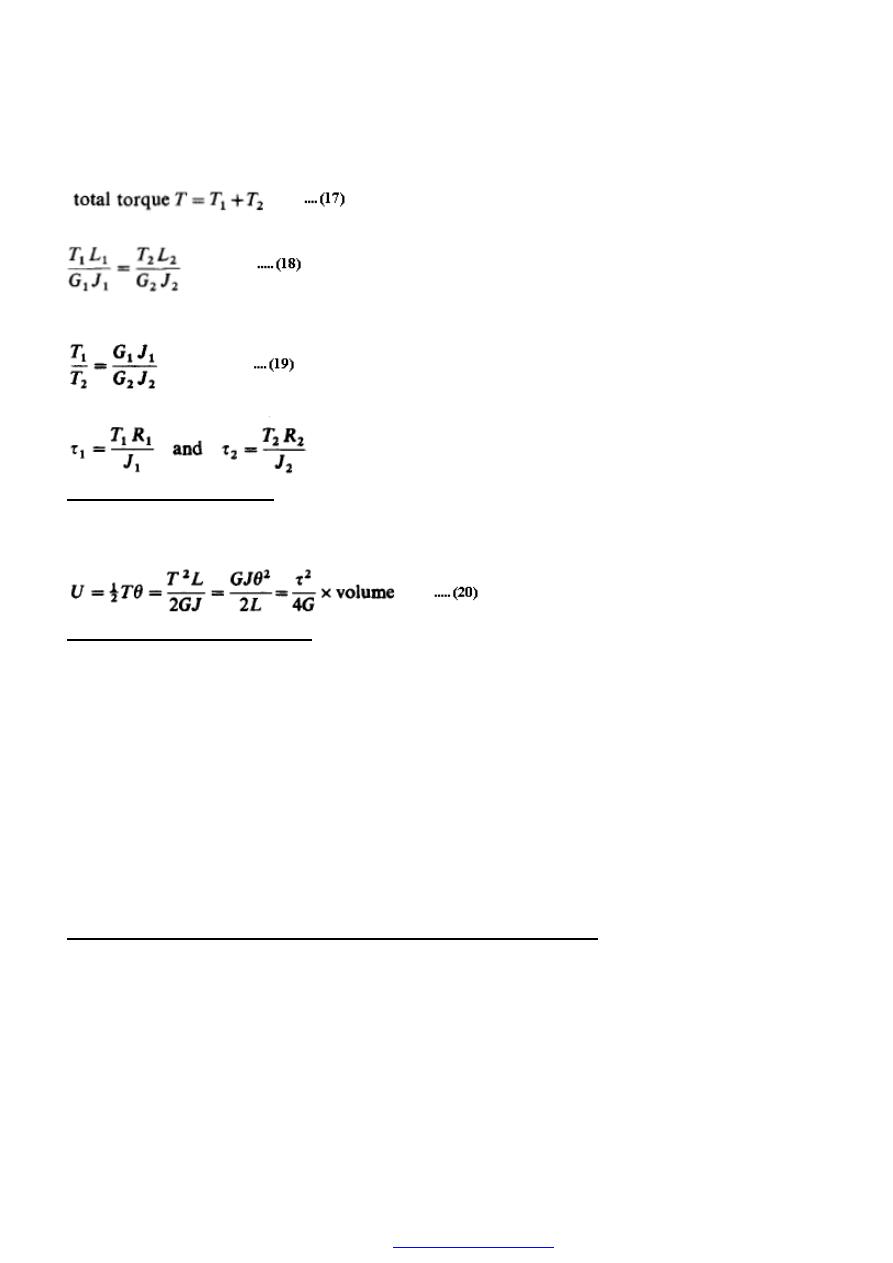

For parallel connection,

In this case the angles of twist of each portion are equal and

i.e. for equal lengths (as is normally the case for parallel shafts)

The maximum stresses in each part can then be found from

Strain energy in torsion

The strain energy stored in a solid circular bar or shaft subjected to a torque (T) is given

by the alternative expressions.

Power transmitted by shafts

If a shaft carries a torque T Newton metres and rotates at o rad/s it will do work at the

rate of;

T.

ω

Nm/s (or joule/s).

Now the rate at which a system works is defined as its power, the basic unit of power

being the

Watt (1 Watt = 1 N.m/s).

Thus, the power transmitted by the shaft:

=

T.

ω

Watts.

Since the Watt is a very small unit of power in engineering terms use is normally made of

SI. multiples, i.e. kilowatts (kW) or megawatts (MW).

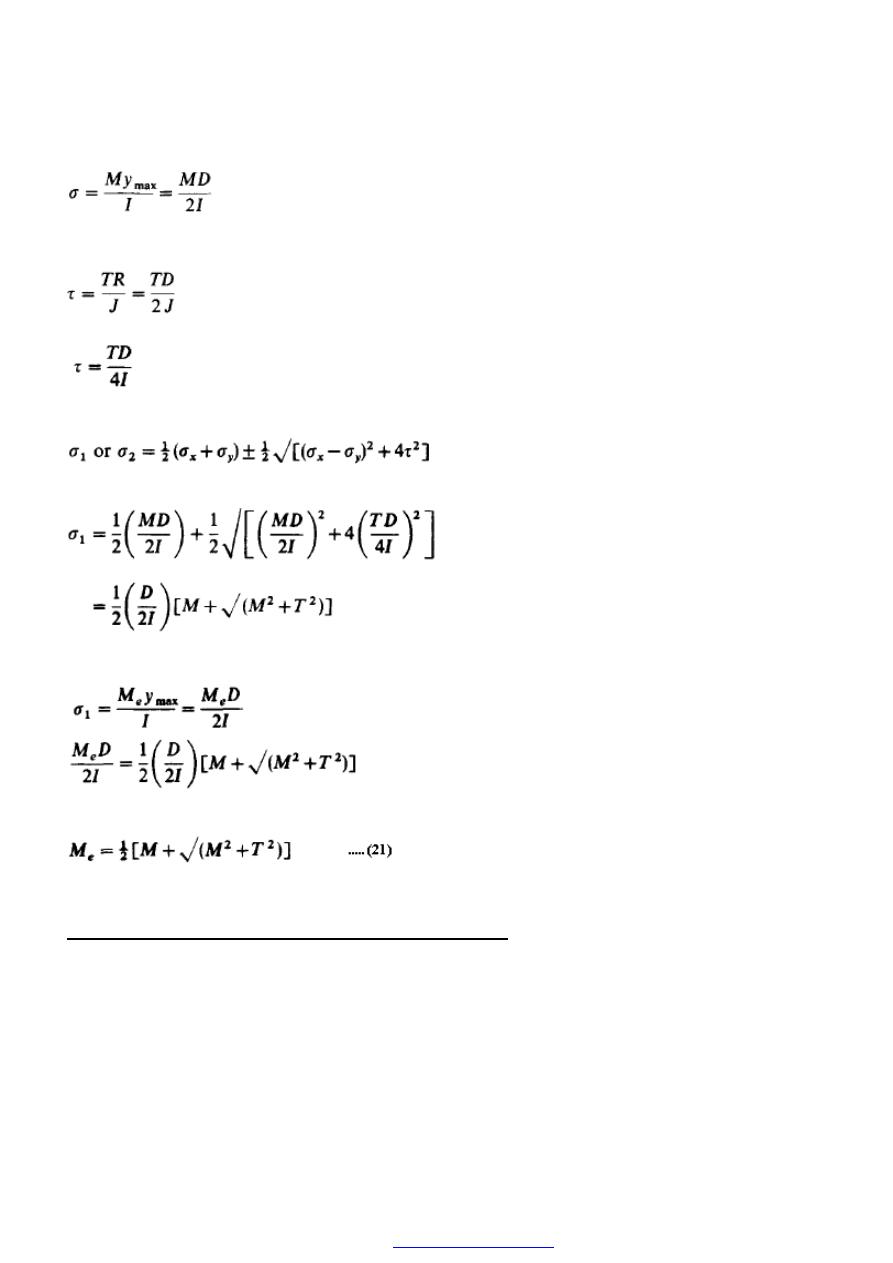

Combined bending and torsion - equivalent bending moment

For shafts subjected to the simultaneous application of a bending moment (M) and torque

(T) the principal stresses set up in the shaft can be shown to be equal to those produced

by an equivalent bending moment, of a certain value (M

e

) acting alone.

From the simple bending theory the maximum direct stresses set up at the outside surface

of the shaft owing to the bending moment (M) are given by

PDF created with pdfFactory Pro trial version

66

Similarly, from the torsion theory, the maximum shear stress in the surface of the shaft is

given by

But for a circular shaft J = 2I,

The principal stresses for this system can now be obtained by applying the formula

derived in

and, with

σ

y

= 0, the maximum principal stress (

σ

1

) is given by

Now if (M

e

) is the bending moment which, acting alone, will produce the same

maximum stress, then

i.e. the equivalent bending moment is given by

and it will produce the same maximum direct stress as the combined bending and torsion

effects.

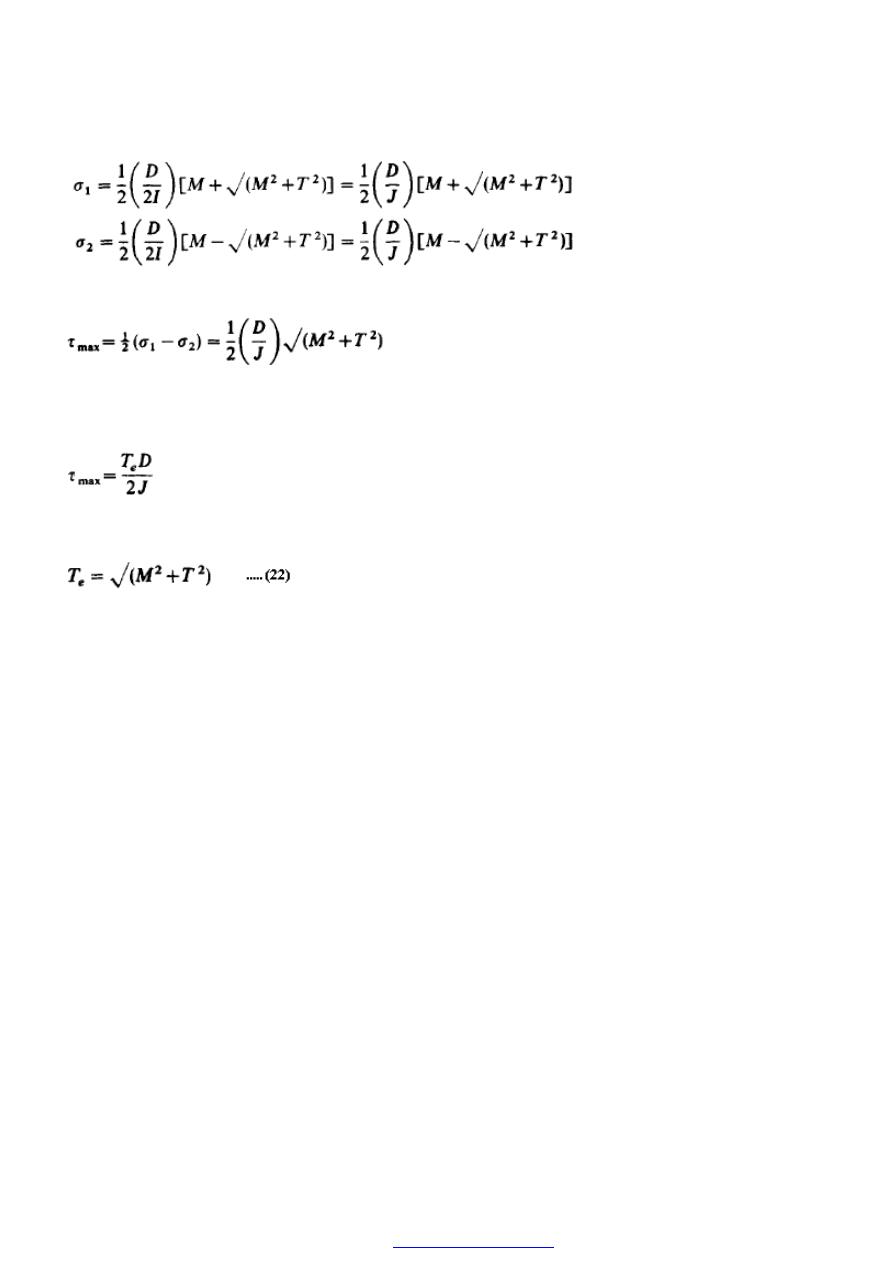

Combined bending and torsion - equivalent torque

Again considering shafts subjected to the simultaneous application of a bending moment

(M) and a torque (T) the maximum shear stress set up in the shaft may be determined

by the application of an equivalent torque of value (T

e

) acting alone. From the preceding

section the principal stresses in the shaft are given by

PDF created with pdfFactory Pro trial version

67

Now the maximum shear stress is given by equation (12)

But, from the torsion theory, the equivalent torque T

e ,

will set up a maximum shear

stress of

Thus if these maximum shear stresses are to be equal,

PDF created with pdfFactory Pro trial version

68

Examples

Example 1

(a) A solid shaft, 100 mm diameter, transmits 75 kW at 150 rev/min. Determine the value

of the maximum shear stress set up in the shaft and the angle of twist per metre of the

shaft length if G = 80 GN/m

2

.

(b) If the shaft were now bored in order to reduce weight to produce a tube of 100 mm

outside diameter and 60mm inside diameter, what torque could be carried if the same

maximum shear stress is not to be exceeded? What is the percentage increase in

power/weight ratio effected by this modification?

Solution

PDF created with pdfFactory Pro trial version

69

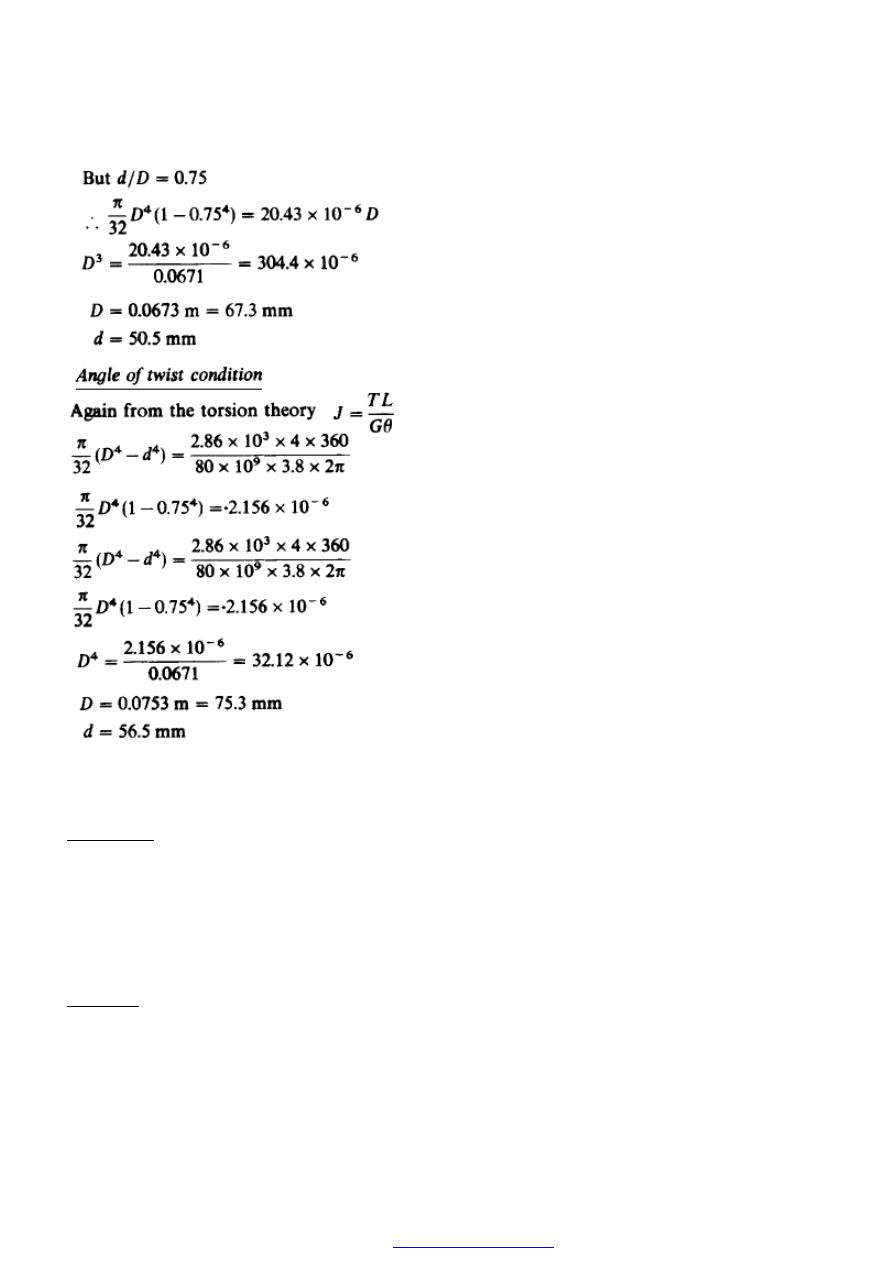

Example 2

Determine the dimensions of a hollow shaft with a diameter ratio of 3:4 which is to

transmit 60 kW at 200 rev/min. The maximum shear stress in the shaft is limited to

70 MN/m

2

and the angle of twist to 3.8

o

in a length of 4 m. For the shaft material G =

80 GN/m

2

.

Solution

PDF created with pdfFactory Pro trial version

70

Thus the dimensions required for the shaft to satisfy both conditions are outer diameter

75.3mm; inner diameter 56.5 mm.

Example 3

(a) A steel transmission shaft is 510 mm long and 50 mm external diameter. For part of

its length it is bored to a diameter of 25 mm and for the rest to 38 mm diameter. Find the

maximum power that may be transmitted at a speed of 210 rev/min if the shear

stress is not to exceed 70 MN/m

2

.

(b) If the angle of twist in the length of 25 mm bore is equal to that in the length of 38

mm bore, find the length bored to the latter diameter.

Solution

(a) This is, in effect, a question on shafts in series since each part is subjected to the same

torque. From the torsion theory ;

PDF created with pdfFactory Pro trial version

71

and as the maximum stress and the radius at which it occurs (the outside radius) are the

same for both shafts the torque allowable for a known value of shear stress is dependent

only on the value of (J). This will be least where the internal diameter is greatest since

(

b)

Let suffix 1 refer to the 38 mm diameter bore portion and suffix 2 to the other part. Now

for shafts in series, equation (16) applies

,

PDF created with pdfFactory Pro trial version

72

PROBLEMS

1 - A solid steel shaft (A) of 50 mm diameter rotates at 250 rev/min. Find the greatest power that can be

transmitted for a limiting shearing stress of 60 MN/m

2

in the steel.

It is proposed to replace (A) by a hollow shaft ( B), of the Same external diameter but with

a limiting shearing stress of 75 MN/m

2

. Determine the internal diameter of (B) to transmit the same

power at the same speed.

A

A

n

n

s

s

.

.

[

[

3

3

8

8

.

.

6

6

k

k

W

W

,

,

3

3

3

3

.

.

4

4

m

m

m

m

]

]

2 - Calculate the dimensions of a hollow steel shaft which is required to transmit 750 kW at a speed of

400 rev/min if the maximum torque exceeds the mean by 20 % and the greatest intensity of shear

stress is limited to75 MN/m

2

. The internal diameter of the shaft is to be 80 % of the external

diameter. (The mean torque is that derived from the horsepower equation.)

A

A

n

n

s

s

.

.

[

[

1

1

3

3

5

5

.

.

2

2

m

m

m

m

,

,

1

1

0

0

8

8

.

.

2

2

m

m

m

m

.

.

]

]

3 - A steel shaft 3 m long is transmitting 1 MW at 240 rev/min. The working conditions to be satisfied

by the

shaft are:

(a) that the shaft must not twist more than 0.02 radian on a length of 10 diameters;

(b) that the working stress must not exceed 60 MN/m

2

.

If the modulus of rigidity of steel is 80 GN/m

2

what is

(i) the diameter of the shaft required

(ii) the actual working stress;

(iii) the angle of twist of the 3 m length?

A

A

n

n

s

s

.

.

[

[

l

l

5

5

0

0

m

m

m

m

;

;

6

6

0

0

M

M

N

N

/

/

m

m

2

2

;

;

0

0

.

.

0

0

3

3

0

0

r

r

a

a

d

d

.

.

]

]

4 - A hollow shaft has to transmit 6MW at 150 rev/min. The maximum allowable stress is not to exceed

60 MN/m

2

and the angle of twist 0.3

o

per metre length of shafting. If the outside diameter of the

shaft is 300 mm find the minimum thickness of the hollow shaft to satisfy the above conditions. G =

80 GN/m

2

.

A

A

n

n

s

s

.

.

[

[

6

6

1

1

.

.

5

5

m

m

m

m

.

.

]

]

5 - A flanged coupling having six bolts placed at a pitch circle diameter of 180 mm connects two lengths

of solid steel shafting of the same diameter. The shaft is required to transmit 80 kW at 240 rev/min.

Assuming the allowable intensities of shearing stresses in the shaft and bolts are 75 MN/m

2

and 55

MN/m

2

respectively, and the maximum torque is 1.4 times the mean torque, calculate:

(a) the diameter of the shaft;

(b) the diameter of the bolts.

A

A

n

n

s

s

.

.

[

[

6

6

7

7

.

.

2

2

m

m

m

m

,

,

1

1

3

3

.

.

8

8

m

m

m

m

.

.

]

]

6 - A hollow low carbon steel shaft is subjected to a torque of 0.25 MN. m. If the ratio of internal to

external diameter is 1 to 3 and the shear stress due to torque has to be limited to 70 MN/m

2

determine the required diameters and the angle of twist in degrees per metre length of shaft.

G = 80GN/m

2

.

A

A

n

n

s

s

.

.

[

[

2

2

6

6

4

4

m

m

m

m

,

,

8

8

8

8

m

m

m

m

;

;

0

0

.

.

3

3

8

8

o

o

]

]

PDF created with pdfFactory Pro trial version

73

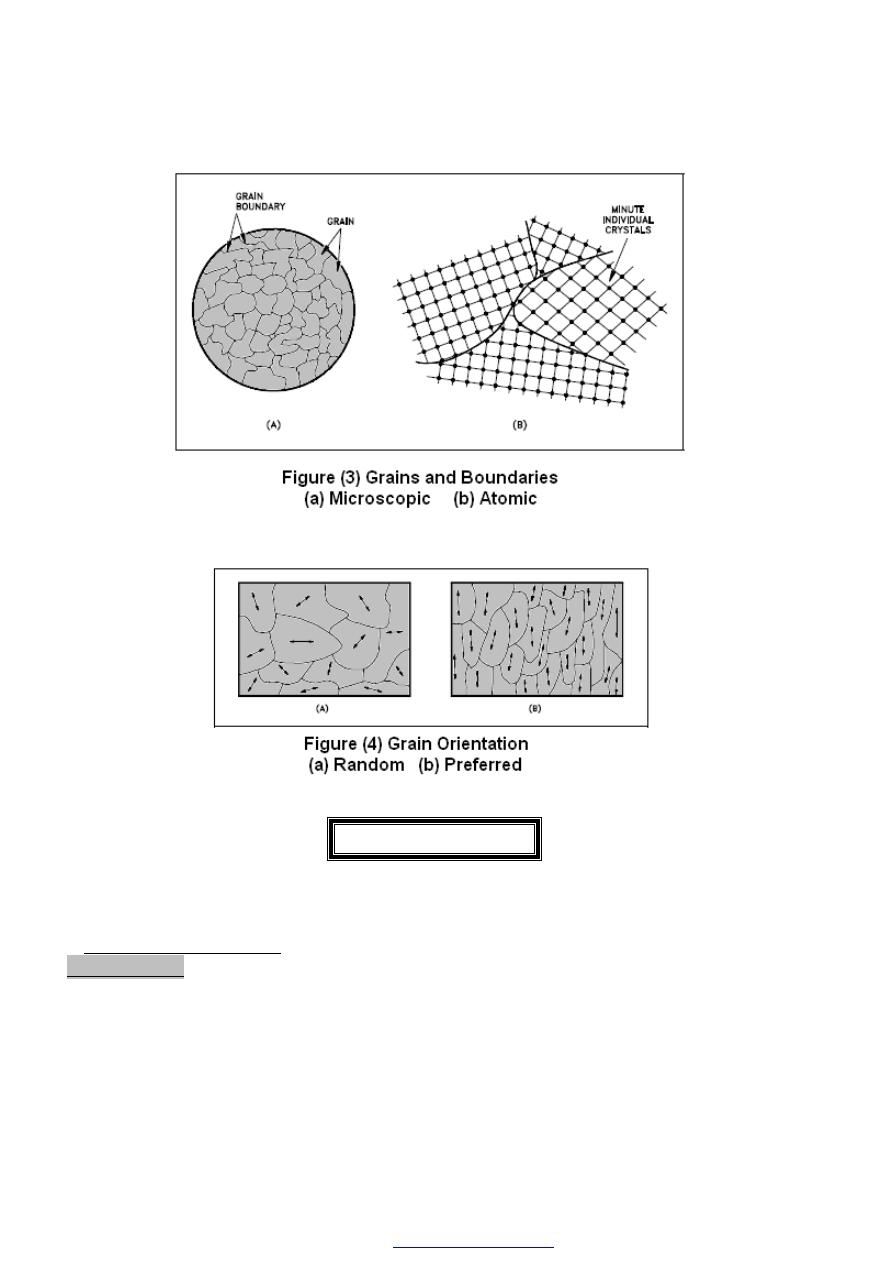

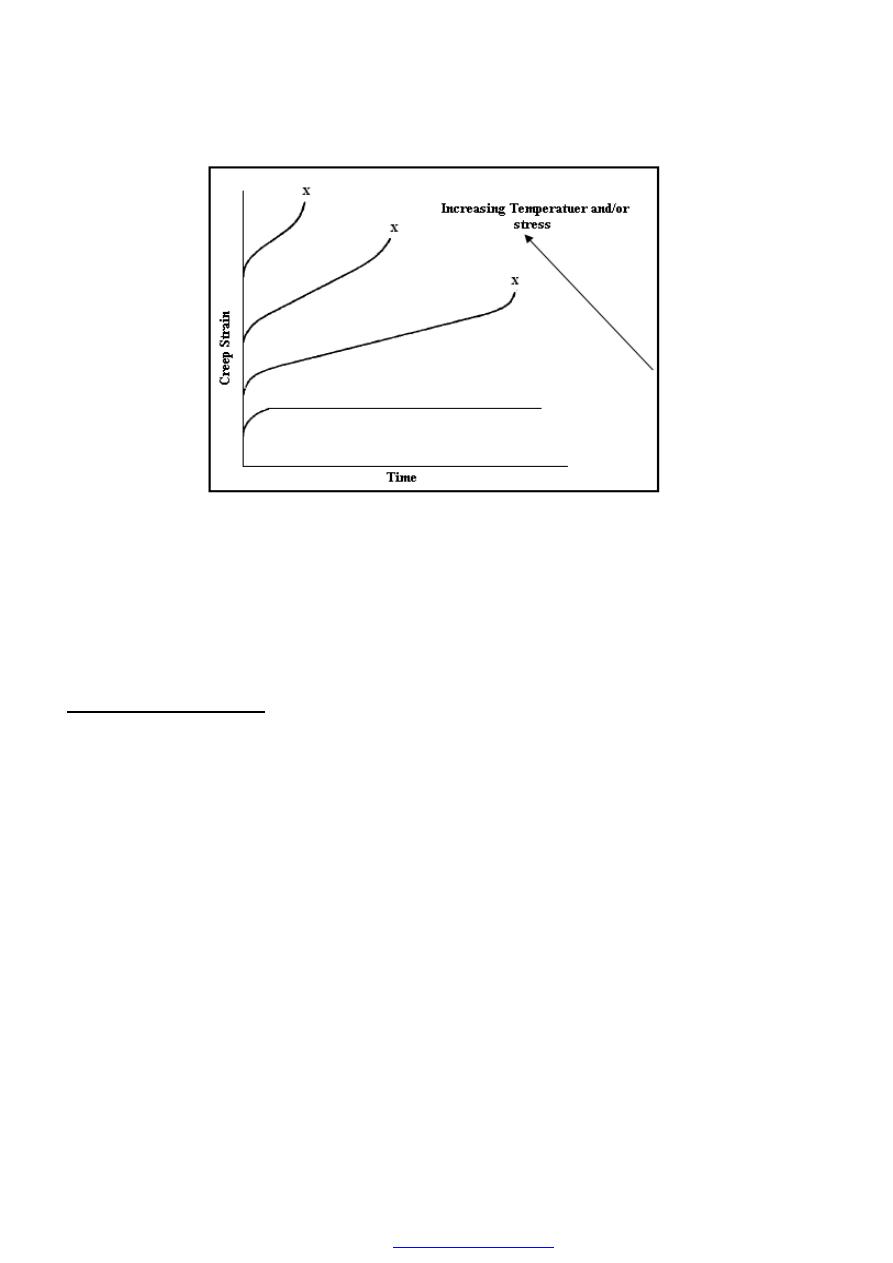

CRYSTALLINE STRUCTURE OF METALS

The arrangement of atoms in a material determines the behavior and properties of that

material. Most of the materials used in the construction of a nuclear reactor facility are

metals. In this chapter, we will discuss the various types of bonding that occurs in

material selected for use in a reactor facility.

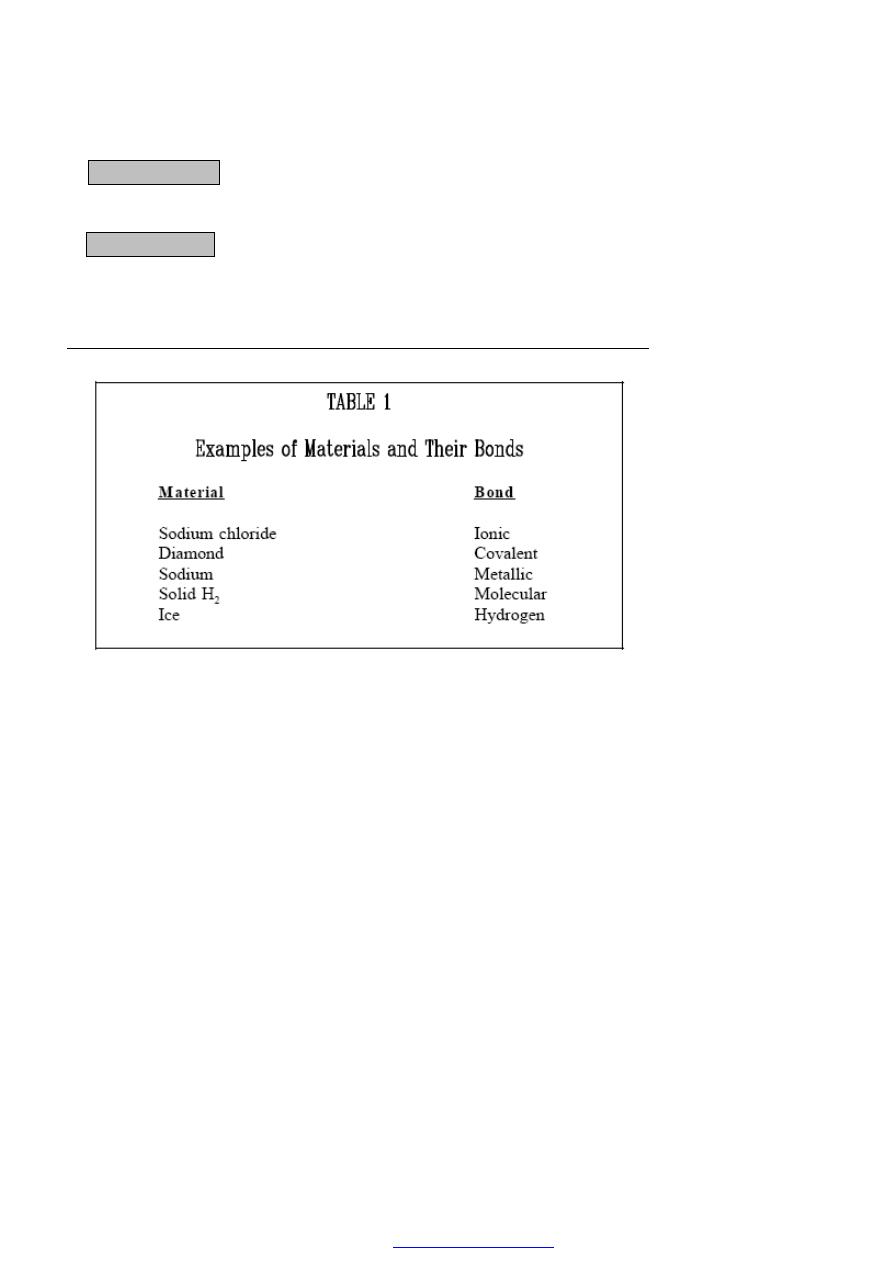

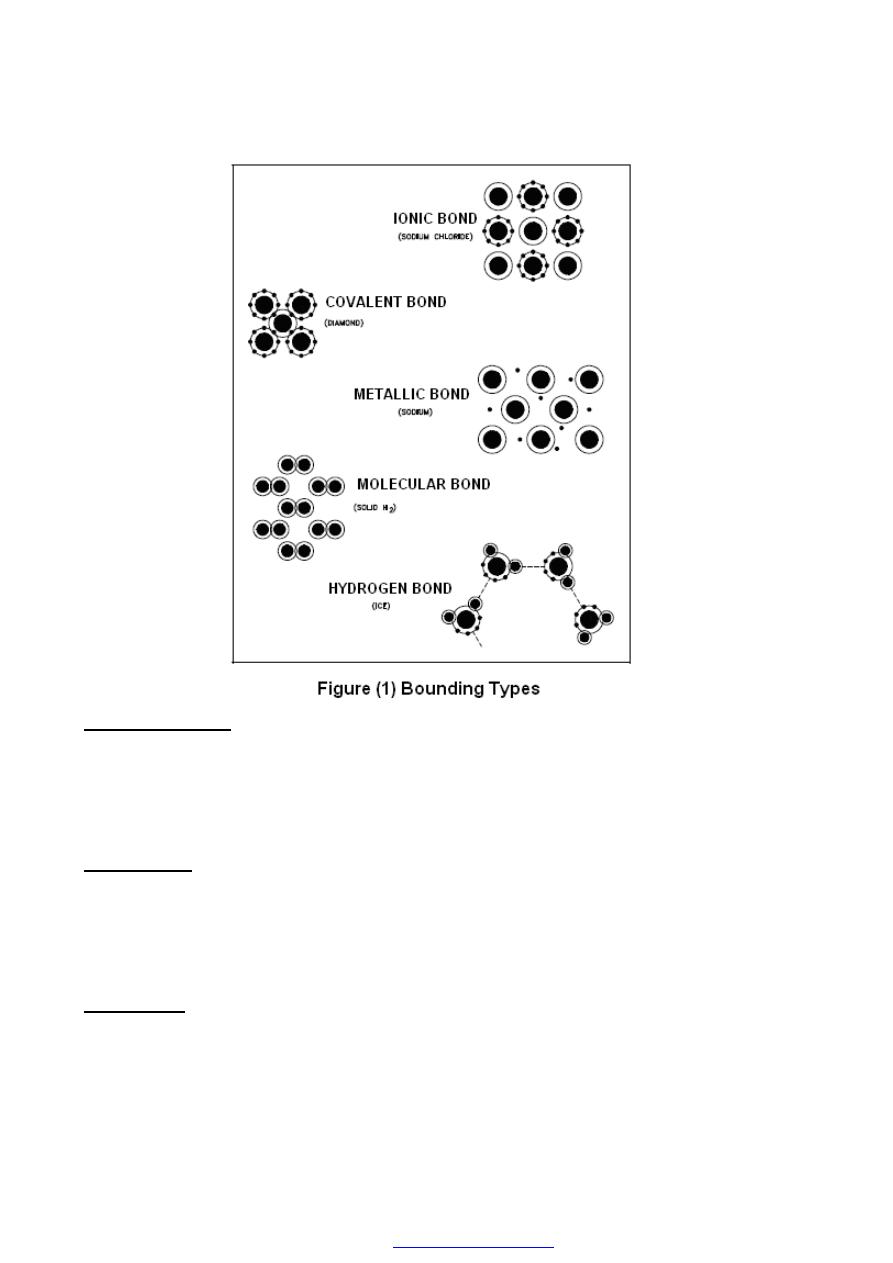

1- Atomic Bonding

There are three common states, these three states are solid, liquid, and gas. The

atomic or molecular interactions that occur within a substance determine its state. In this

chapter, we will deal primarily with solids because solids are of the most concern in

engineering applications of materials. Liquids and gases will be mentioned for

comparative purposes only. Solid matter is held together by forces originating between

neighboring atoms or molecules. These forces arise because of differences in the electron

clouds of atoms. In other words, the valence electrons, or those in the outer shell, of

atoms determine their attraction for their neighbors. When physical attraction between

molecules or atoms of a material is great, the material is held tightly together. Molecules

in solids are bound tightly together. When the attractions are weaker, the substance may

be in a liquid form and free to flow. Gases exhibit virtually no attractive forces between

atoms or molecules, and their particles are free to move independently of each other. The

types of bonds in a material are determined by the manner in which forces hold matter

together. Figure (1) illustrates several types of bonds and their characteristics

are listed below.