Nanomaterials

Contents

1- Introduction. ----------------------------------------- 4 hr.

1-1 Nanotechnology.

1-2 Environmental implications of nanotechnology.

1-3 Nano engineering .

2- Foundamentals of nanomaterials . ---------------- 6hr.

2-1 One-dimensional nanomaterials.

2-2 Two-dimensional nanomaterials .

2-3 Three-dimensional nanomaterials .

2-4 Matrix-reinforced and layered nanocomposites .

3- Properties at the nanomaterials . --------------------6hr.

3-1 Mechanical properties .

3-2 Optical Properties .

3-3 Electrical properties .

3-4 Magnetic properties .

5- Manufacturing of nanomaterials . --------------------4hr.

4-1 Form in place .

4-2 Mechanical.

4-3 Gas phase synthesis .

4-4 Wet chemistry.

`

5 - Application of nanomaterials . --------------------6hr.

5-1Fuel cells.

5-1-1 Carbon nanotubes - Microbial fuel cell .

5-2 Catalysis.

5-3 Phosphors for High-Definition TV.

5-4 Next-Generation Computer Chips.

5-5 Elimination of Pollutants.

5-6 Sun-screen lotion.

5-7 Sensors.

Lecture 1

(nano)

Nanotechnology

make use of very small objects or artefacts.

Nanomaterials are an increasingly important product of nanotechnologies.

They contain nanoparticles, smaller than 100 nanometres in at least one

dimension. Nanotechnology is the general term for designing and making

anything whose use depends on specific structure at the nanoscale –

generally taken as being 100 nanometres (100 millionths of a millimetre

or 100 billionths of a metre) or less. It includes devices or systems made

by manipulating individual atoms or molecules, as well as materials

which contain very small structures.

Nanotechnologies involve designing and producing objects or structures

at a very small scale, on the level of 100 nanometres (100 millionth of a

millimetre) or less.

Nanomaterials

are coming into use in healthcare, electronics,

cosmetics and other areas. Their physical and chemical properties often

differ from those of bulk materials, so they call for specialised risk

assessment. This needs to cover health risks to workers and consumers,

and potential risks to the environment.

Nanomaterials

are one of the main products of nanotechnologies – as

nano-scale particles, tubes, rods, or fibres

Nanomaterials

are usually considered to be materials with at least one

external dimension that measures 100 nanometres or less or with internal

structures measuring 100 nm or less. They may be in the form of

particles, tubes, rods or fibres. The nanomaterials that have the same

composition as known materials in bulk form may have different physico-

chemical properties than the same materials in bulk form, and may

behave differently if they enter the body. They may thus pose different

potential hazards.

This is currently done on a case by case basis, but risk assessment

methods need to be kept up to date as the use of nanomaterials expands,

especially as they find their way into consumer products

.

Aggregated nanomaterials also need to be assessed in this light as they

may exhibit properties that are similar to those of the single nanoparticles,

especially when they have an unusually large surface area for a given

amount of material.

Nanoparticles

are normally defined as being smaller that 100

nanometres in at least one dimension.

The number of products produced by nanotechnology or containing

nanomaterials entering the market is increasing. Current applications

include healthcare (in targeted drug delivery, regenerative medicine, and

diagnostics), electronics, cosmetics, textiles, information technology and

environmental protection. For example, nanosilver is appearing in a range

of products, including washing machines, socks, food packaging, wound

dressings and food supplements. Food supplements need especially close

scrutiny.

Characteristics of nanomaterials .

Descriptions of nanomaterials ought to include the average particle

size, allowing for clumping and the size of the individual particles and a

description of the particle number size distribution (range from the

smallest to the largest particle present in the preparation).

Detailed assessments may include the following:

1. Physical properties:

•

Their size, shape, specific surface area, and ratio of width and

height

•

Whether they stick together

•

Size distribution

•

How smooth or bumpy their surface is

•

Structure, including crystal structure and any crystal defects

•

How well they dissolve

2. Chemical properties:

•

Molecular structure

•

Composition, including purity, and known impurities or additives

•

Whether it is held in a solid, liquid or gas

•

Surface chemistry

•

Attraction to water molecules or oils and fats

These parameters should be assessed both for the nanomaterials as they

are made, and for nanomaterials as they are used (e.g. in the formulation

in any subsequent product). Measurements need to take account of the

way properties may change when nanomaterials are mixed with or

suspended in other substances.

It is particularly important to measure how quickly nanomaterials

dissolve in any liquid they are likely to come in contact with. Their small

size means they dissolve faster than the comparable bulk (large)

particulate material.

How can exposure to nanomaterials be measured?

The measurement methods to use depend on the kind of exposure.

The most reliable methods are for particles in the air. Nanoparticles may

also be in contact with solids and liquids, especially in consumer

products.

Current techniques to assess nanoparticle exposure are suitable for

personal or area-based monitoring, continuous or discontinuous use, and

basic characterisation of samples. However, data on airborne exposures

are scarce, and there have been few if any studies outside the workplace.

exposure estimates from food and consumer products also remain

difficult. Information on the presence of manufactured nanomaterials

comes from manufacturers. There is also limited information about

product use.

Effects of nanomaterials on the health

There is experimental evidence of a range of possible interactions

with biological systems and health effects of manufactured nanoparticles.

In experimental systems in the laboratory they can affect the formation of

the fibrous protein tangles which are similar to those seen in some

diseases, including brain diseases. Airborne particles might cause effects

in the lungs but also on the heart and blood circulation similar to those

already known for particulate air pollution. There is some evidence that

nanoparticles might lead to genetic damage, either directly or by causing

inflammation.

All these effects would depend on nanoparticles’ fate in the body.

Only a minimal amount of nanoparticle doses escape the lungs or

intestine, but long-term exposure could still mean a large number are

distributed round the body. Most are held in the liver or the spleen, but

some appear to reach all tissues and organs. There may also be entry into

the brain via the membranes inside the nose.

Nanotubes or rods with similar characteristics to asbestos fibres pose a

risk of the mesothelioma (a form of cancer of the pleura).

Environment effects of nanomaterials.

Wider use of nanomaterials will lead to increases in environmental

exposure. Little is known about how they may then behave in air, water

or soil. They may be concentrated in particular “hot spots”, either by

clumping together with minerals or by interaction with organic matter.

Like other pollutants, they may pass from organism to organism, and

perhaps move up food chains. As a result of their diversity, nanomaterials

may have a wide range of effects. Some kill bacteria or viruses.

Experiments so far have also shown possible harmful effects on

invertebrates and fish, including effects on behaviour, reproduction and

development. There is less research to date on soil systems and terrestrial

species, and it is not clear whether laboratory results relate to what may

happen out in the real world.

Assessment the risks from nanomaterials.

Existing risk assessment methods are generally applicable to

nanomaterials but specific aspects related to nanomaterials need more

development. They include methods for both estimating exposure and

identifying hazards. The highest potential risks come from free, insoluble

nanoparticles either dispersed in a liquid or as dust.

Risk assessment requires a detailed examination of properties, including:

•

Particle size

•

Surface area

•

Stability

•

Surface properties

•

Solubility

•

Chemical reactivity

Comparisons with well-known existing hazards may help inform risk

assessment. They include those from airborne fine particles, and asbestos

fibres.

The recommended approach to assess the risks from nanomaterials is still

the four stage risk assessment proposed by the SCENIHR in 2007. Today,

additional details can be added to this approach in the light of recent work

on evaluating possible harmful effects of nanomaterials, especially using

controlled laboratory tests (in vitro assays). These tests are useful for

screening and for investigating mechanisms of adverse effects. However,

tests using living organisms (in vivo assays) are also needed to improve

knowledge of possible risks to people and the environment.

Improvements are sought in the determination of exposures, and there is

an urgent need for long-term exposure studies.

Full evaluation of the potential hazards of most nanomaterials is still to

come. It will include estimation of exposure in normal use, abuse, waste

and recycling of products containing nanomaterials, and detailed

measurement of physical and chemical properties.

Lecture 2

(nano

)

Classification.

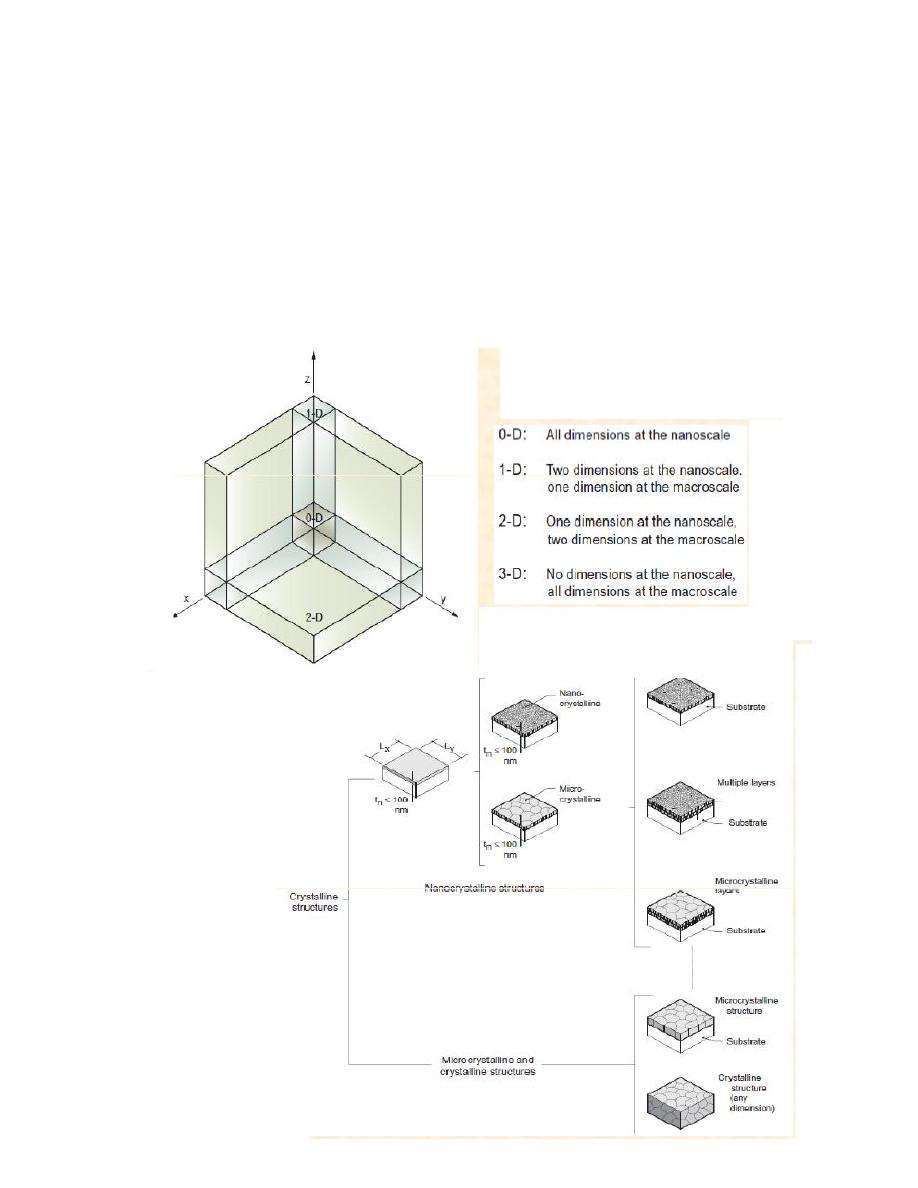

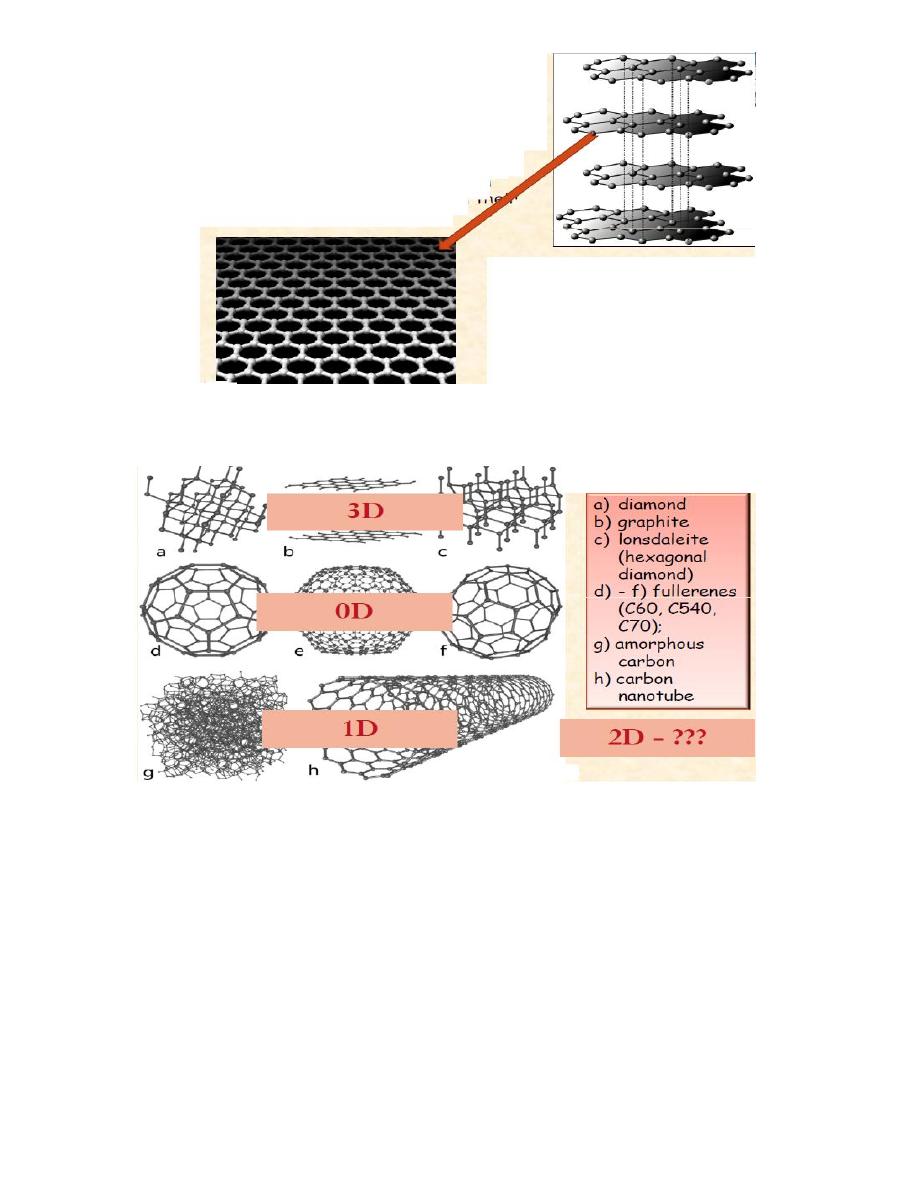

* Classification is based on the number of dimensions, which are

not confined to the nanoscale range (<100 nm).

* (1) zero-dimensional (0-D),

* (2) one-dimensional (1-D),

* (3) two-dimensional (2-D), and

* (4) three-dimensional (3-D).

Zero-dimensional nanomaterials

* Materials wherein all the dimensions are measured within the

nanoscale (no dimensions, or 0-D, are larger than 100 nm).

* The most common representation of zero-dimensional

nanomaterials are nanoparticles.

*Nanoparticles can:

* Be amorphous or crystalline

* Be single crystalline or polycrystalline

* Be composed of single or multi-chemical elements

* Exhibit various shapes and forms

* Exist individually or incorporated in a matrix

* Be metallic, ceramic, or polymeric

Fundamentals of nanmaterials.

1

- One-dimensional nanomaterials

One dimension that is outside the nanoscale.

This leads to needle like-shaped nanomaterials.

1-D materials include nanotubes, nanorods, and

nanowires.

1-D nanomaterials

can be

Amorphous or crystalline

Single crystalline or polycrystalline

Chemically pure or impure

Standalone materials or embedded in within another medium

Metallic, ceramic, or polymeric

2-Two-dimensional nanomaterials

Two of the dimensions are not confined to the nanoscale.

2-D nanomaterials exhibit plate-like shapes.

Two-dimensional nanomaterials include nanofilms,

nanolayers, and nanocoatings.

2-D nanomaterials can be:

Amorphous or crystalline

Made up of various chemical compositions

Used as a single layer or as multilayer structures

Deposited on a substrate

Integrated in a surrounding matrix material

Metallic, ceramic, or polymeric

3-

Three-dimensional nanomaterials

Bulk nanomaterials are materials that are not confined to the

nanoscale in any dimension. These materials are thus characterized

by having three arbitrarily dimensions above 100 nm.

Materials possess a nanocrystalline structure or involve the

presence of features at the nanoscale.

In terms of nanocrystalline structure, bulk nanomaterials can be

composed of a multiple arrangement of nanosize crystals,

most typically in different orientations.

With respect to the presence of features at the nanoscale, 3-D

nanomaterials can contain dispersions of nanoparticles, bundles

of nanowires, and nanotubes as well as multinanolayers.

Three-dimensional space showing the relationships

among 0-D, 1-D, 2-D, and 3-D nanomaterials.

Summary

of 2-D and

3-D

crystalline

structures

4- Matrix-reinforced and layered Nanocomposites

These materials are formed of two or more materials with very

distinctive properties that act synergistically to create properties

that cannot be achieved by each single material alone. The matrix of

the nanocomposite, which can be polymeric, metallic, or ceramic, has

dimensions larger than the nanoscale, whereas the reinforcing phase is

commonly at the nanoscale.

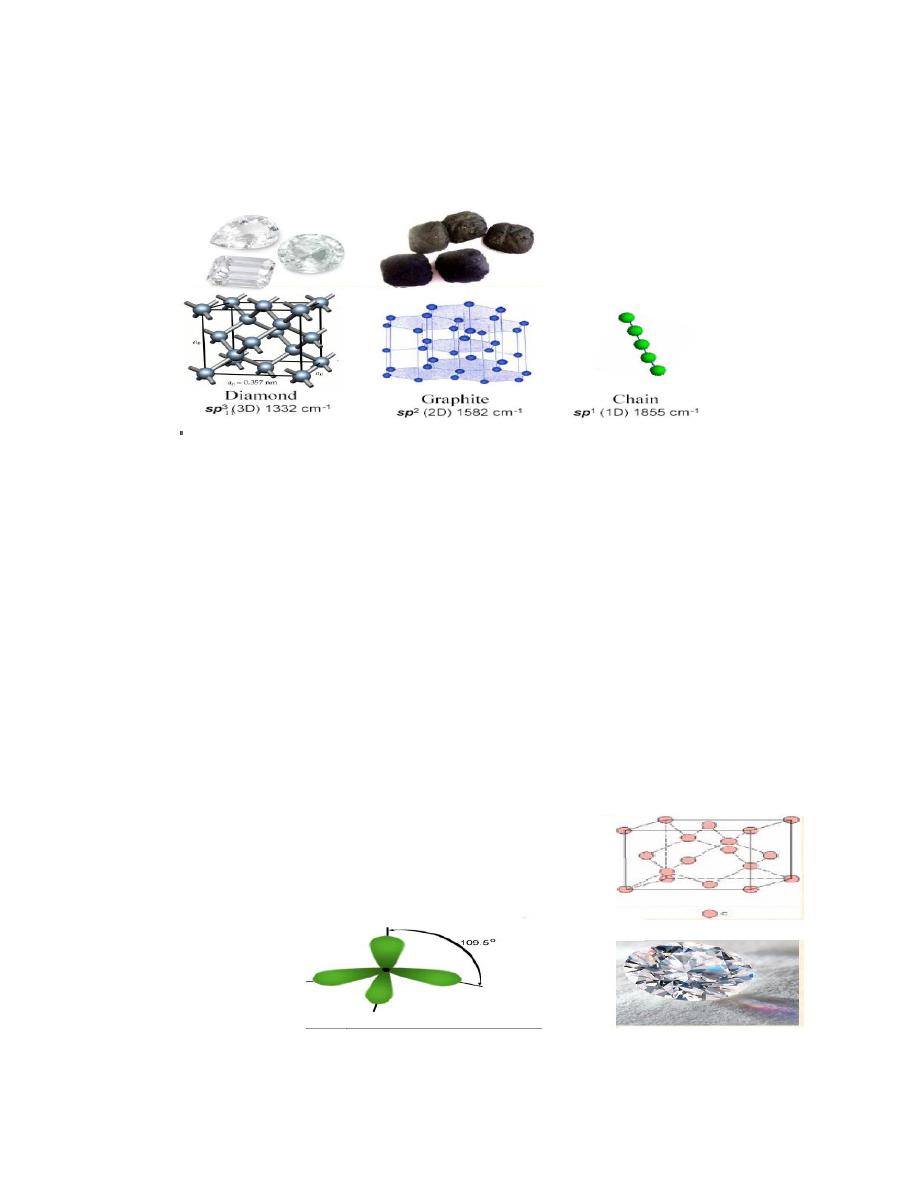

5- Carbon

*Carbon is a basic element of life

*Carbon is special because of its ability to bond to many elements in

many different ways

* It is the sixth most abundant element in the

universe

|* The most known types of carbon materials:

diamond; graphite; fullerenes; and carbon

nanotubes

Carbon materials

Diamond and graphite are two graphite are two allotropes of

carbon: pure forms of the same element that differ in structure.

2s and 2p electrons available for bonding

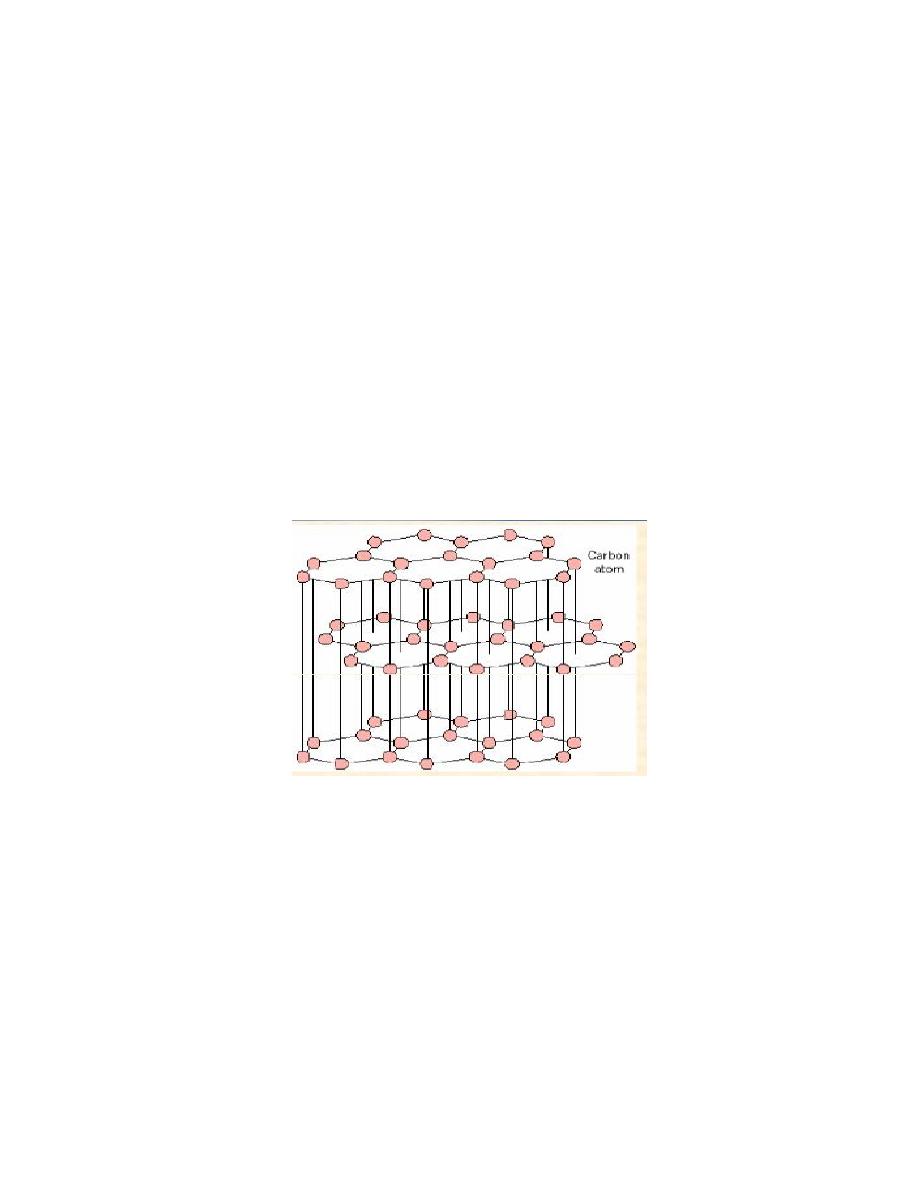

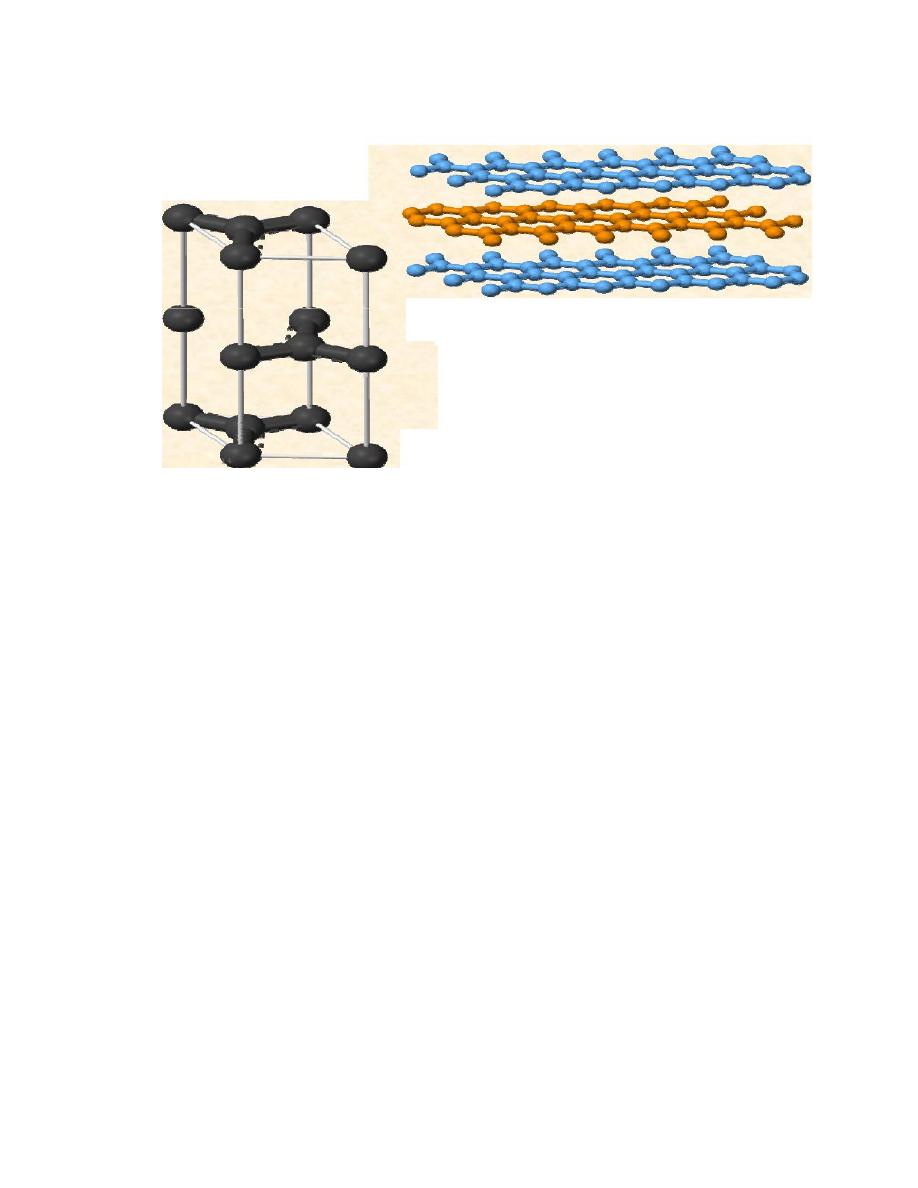

6-DIAMOND

- chemical bonding is purely covalent

- highly symmetrical unit cell

- extremely hard

- low electrical conductivity

- high thermal conductivity (superior)

- optically transparent

- used as gemstones and industrial

grinding, machining and cutting

7-GRAPHITE

•

Layered structure with strong bonding within the planar layers

and weak, van der Waals bonding between layers

• Easy interplanar cleavage,

applications as a lubricant and for writing (pencils)

• Good electrical conductor

• Chemically stable even at high

temperatures

• excellent thermal shock

Applications:

Commonly used as heating elements (in non- oxidizing atmospheres),

metallurgical crucibles, casting molds, electrical contacts, brushes and

resistors, high temperature refractories, welding electrodes, air

purification systems, etc.

-Graphite

Graphite is a layered compound. In each layer,the carbon atoms are

arranged in a hexagonal lattice with separation of 0.142 nm, and the

distance between planes is 0.335 nm.The acoustic and thermal properties

of graphite arehighly anisotropic, since phonons propagate very

quickly along the tightly-bound planes, but are

slower to travel from one plane to another.

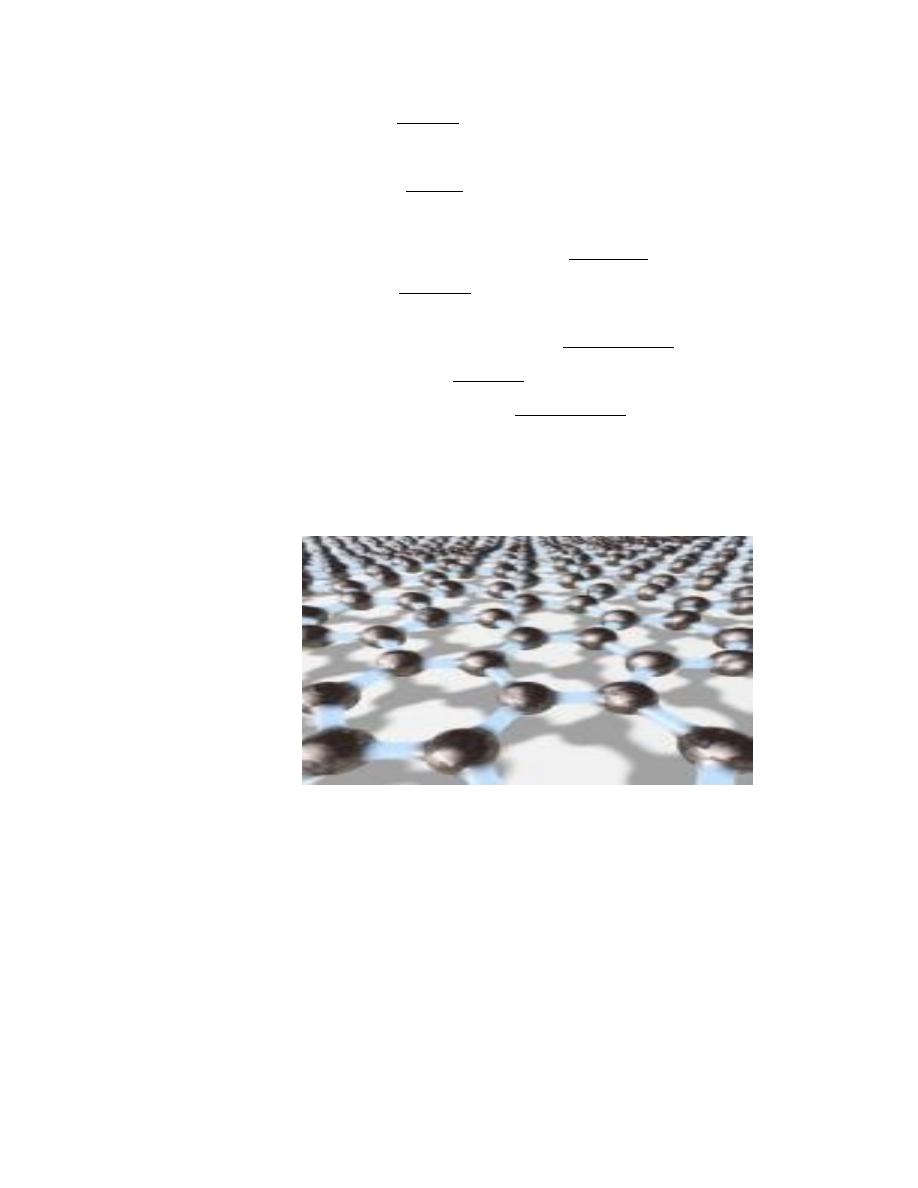

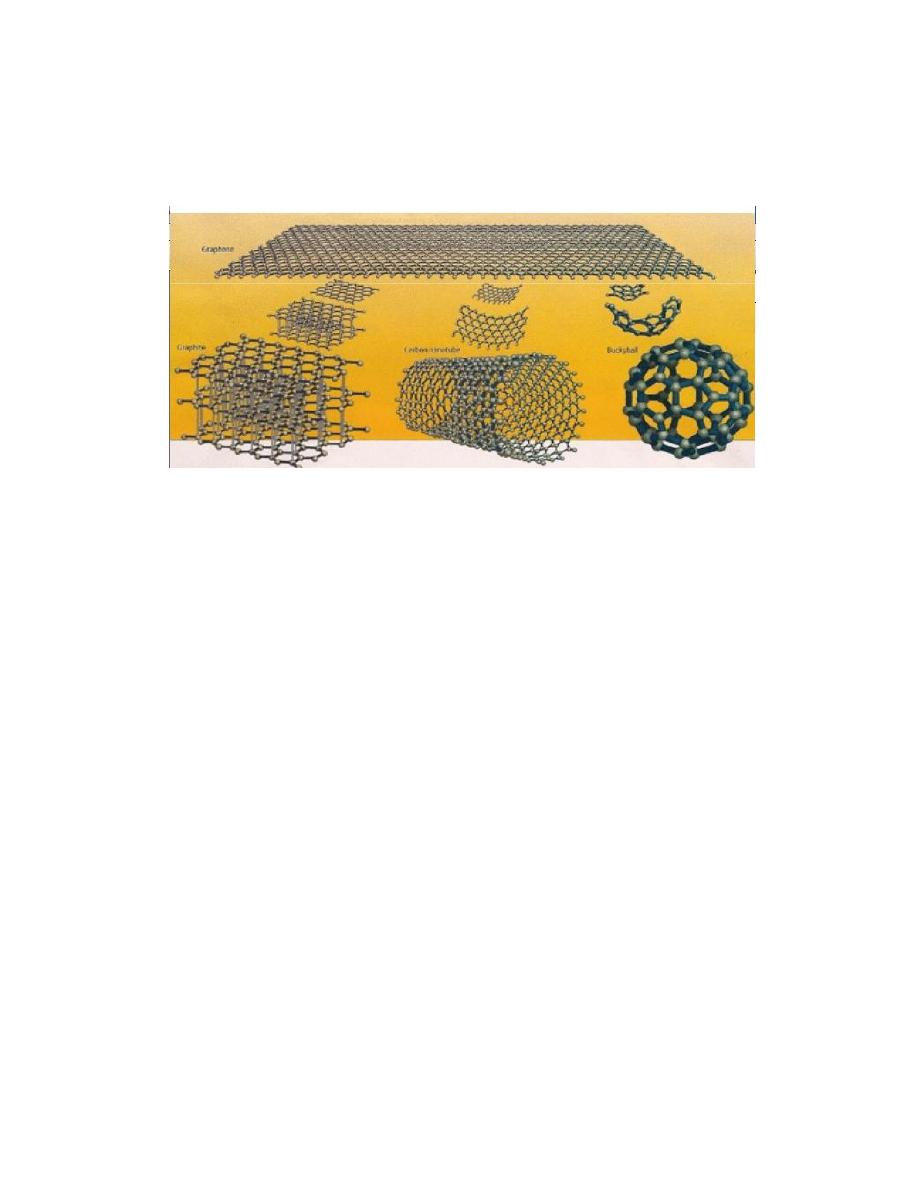

8-Graphene

Graphene is an one-atom-thick planar sheet of sp2-bonded carbon

atoms that are densely packed in a honeycomb crystal lattice. It can be

viewed as an atomic-scale chicken wire made of carbon atoms and their

bonds.

The carbon-carbon bond length in graphene is about 0.142 nm.

Graphene is the basic structural element of some carbon allotropes

including graphite, carbon nanotubes and fullerenes.

Allotropes of carbon

Graphene

The mother of all Graphites

SCIENCE, June 2010

* If there's a rock star in the world of materials, it's graphene: single-

atom–thick sheets of carbon prized for its off-the-charts ability to conduct

electrons and for being all but transparent.

* Those qualities make graphene a tantalizing alternative for use as a

transparent conductor, the sort now found in everything from computer

displays and flat panel TVs to ATM touch screens and solar cells.

* But the material has been tough to manufacture in anything larger than

flakes a few centimeters across.

* Now researchers have managed to create rectangular sheets of graphene

76 centimeters in the diagonal

direction and even use them to create a working touchscreen display

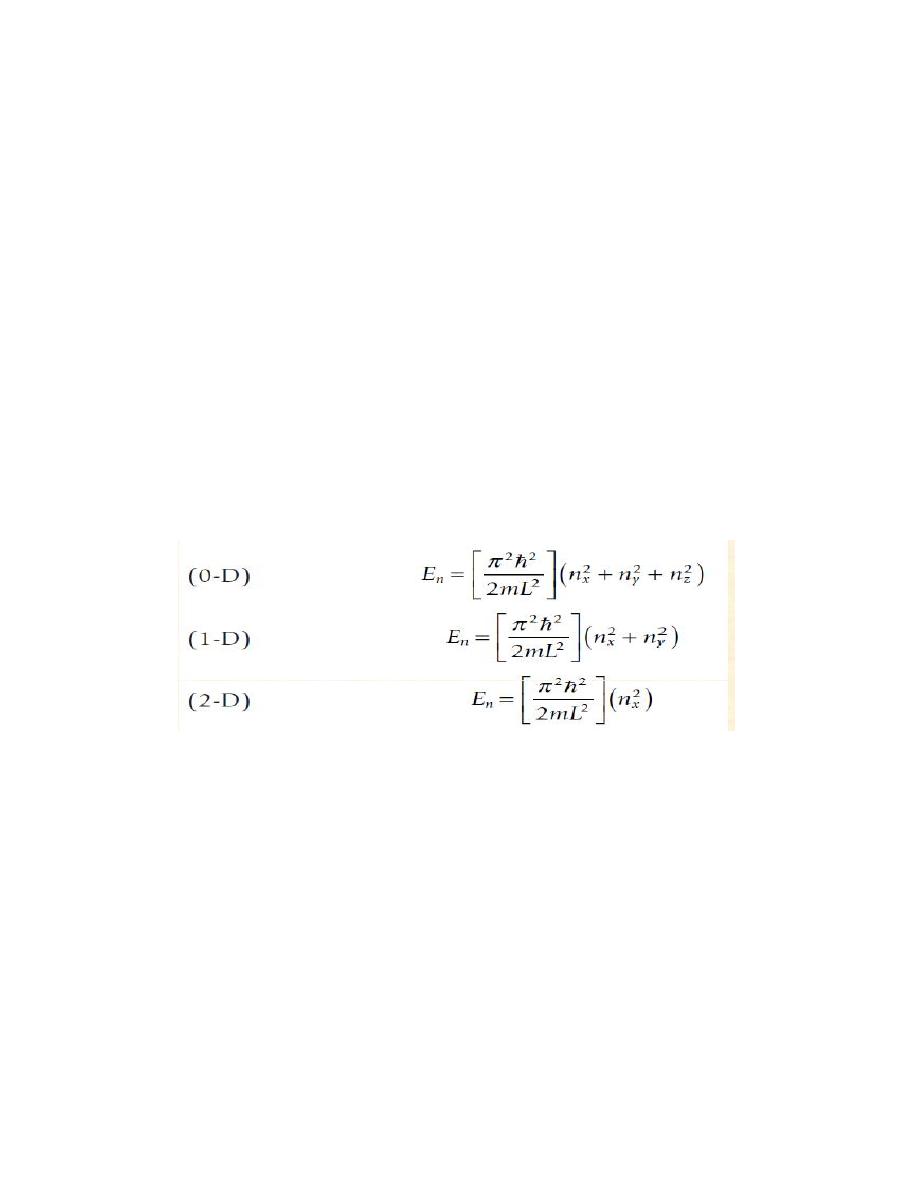

9-Quantum effects

*The overall behavior of bulk crystalline materials changes when the

dimensions are reduced to the nanoscale.

* For 0-D nanomaterials, where all the dimensions are at the nanoscale,

an electron is confined in 3-D space. No electrondelocalization (freedom

to move) occurs.

For 1-D nanomaterials, electron confinement occurs in 2-D,19 whereas

delocalization takes place along the long axis of the

nanowire/rod/tube.

* In the case of 2-D nanomaterials, the conduction electrons will

be confined across the thickness but delocalized in the plane of

the sheet.

10-Electrons confinement

*For 0-D nanomaterials the electrons are fully confined.

* For 3-D nanomaterials the electrons are fully delocalized.

* In 1-D and 2-D nanomaterials, electron confinement and delocalization

coexist.

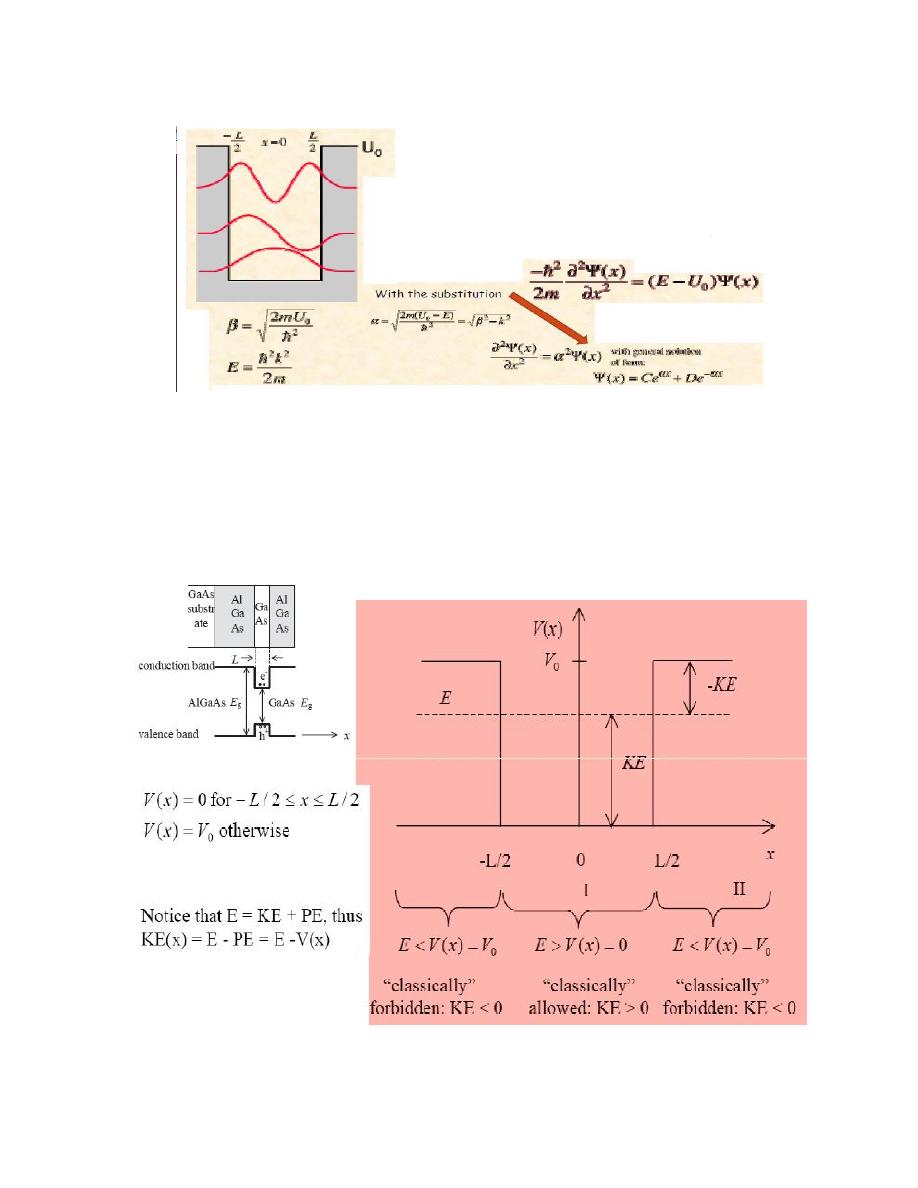

* The effect of confinement on the resulting energy states can 20

be calculated by quantum mechanics, as the “particle in the box”

problem. An electron is considered to exist inside of an infinitely deep

potential well (region of negative energies), from which it cannot escape

and is confined by the dimensions of the nanostructure.

11-Energies

where h_ _ h/2_, h is Planck’s constant, m is the mass of the electron, L is

the width(confinement) of the infinitely deep potential well, and nx, ny,

and nz are the principal quantum numbers in the three dimensions x, y,

and z.

The smaller the dimensions of the nanostructure (smaller L), the wider is

the separation between the energy levels, leading to a spectrum of

discreet energies.

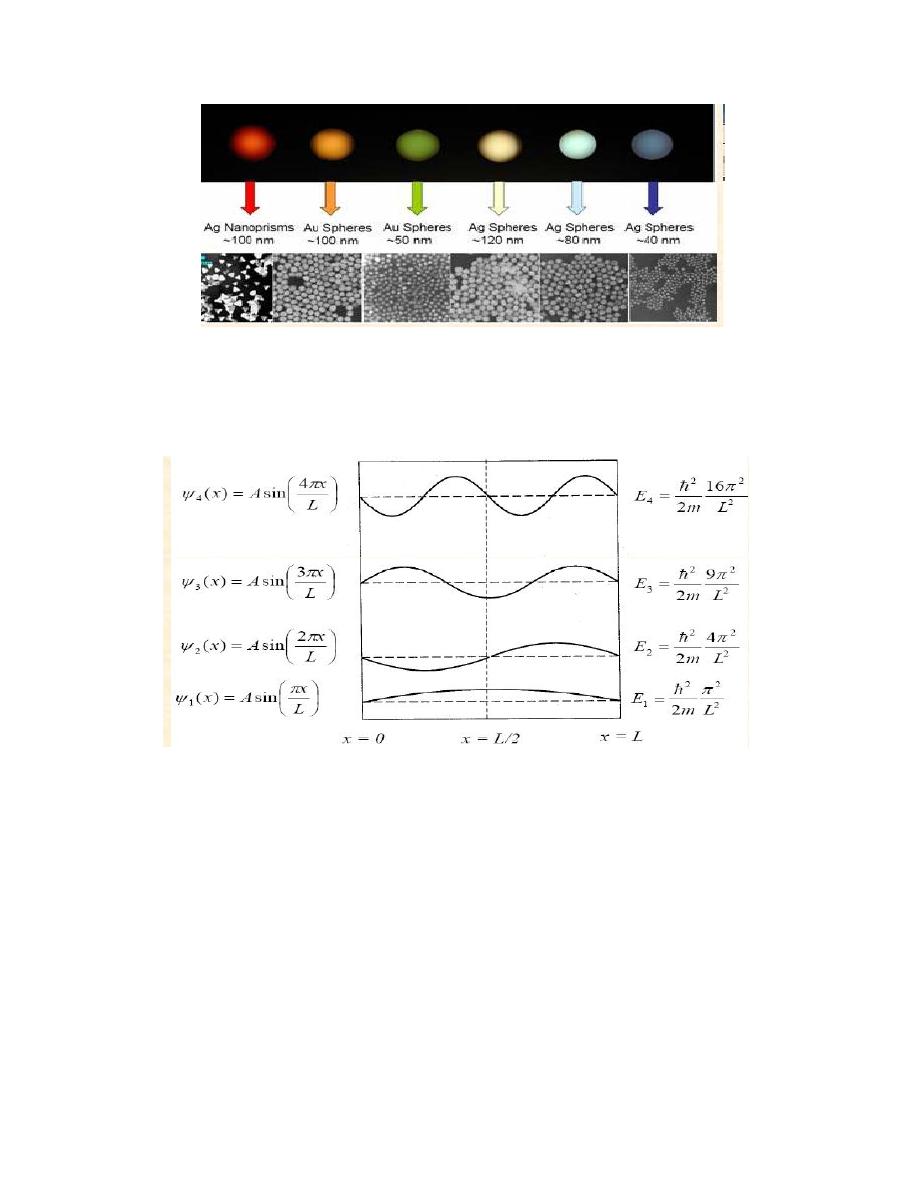

What’s different at the nanoscale?

Each of the different sized arrangement of gold atoms absorbs and

reflects light differently based on its energy levels, which are determined

by size and bonding arrangement. This is true for many materials when

the particles have a size that is less than 100 nanometers in at least one

dimension.

11-1Energy levels in infinite quantum well

11-2The finite potential well

For the finite potential well, the solution to the Schrodinger equation

gives a wavefunction with an exponentially decaying penetration into the

classically forbidden region. Confining a particle to a smaller space

requires a larger confinement energy. Since the wave function penetration

effectively "enlarges the box", the finite well energy levels are lower than

those for the infinite well. The solution for -L/2 < x < L/2 and elsewhere

must satisfy the equation .

11-3Comparison of Infinite and Finite Potential Wells

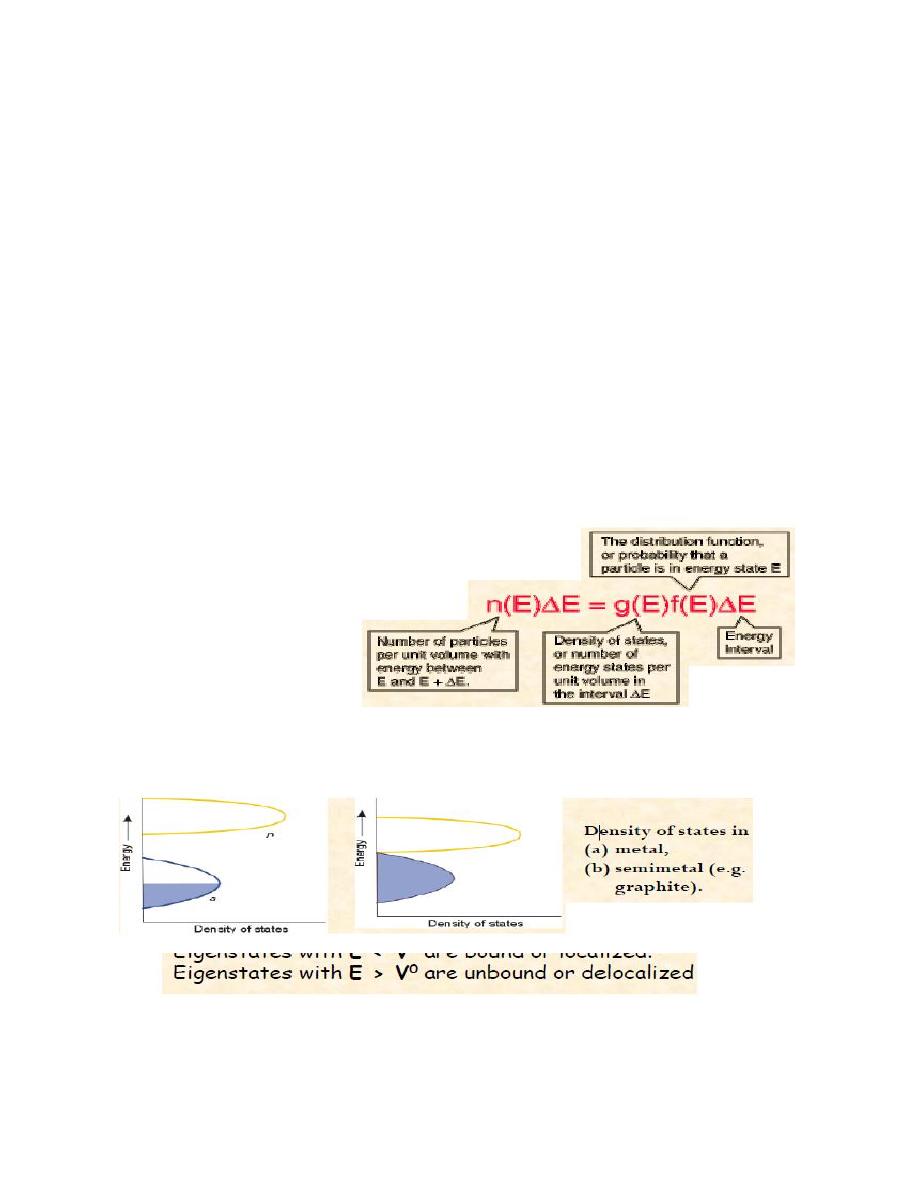

11-4Electron energy density

The behavior of electrons in solids depends upon the distribution of

energy among the electrons:

This distribution determines the probability that a given energy state will

be occupied, but must be multiplied by the density of states function to

weight the probability by the number of states available at a given energy.

Lecture 3

(nano

)

3 - Properties of Nanomaterials

Nanomaterials have the structural features in between of those of

atoms and the bulk materials. While most microstructured materials have

similar properties to the corresponding bulk materials, the properties of

materials with nanometer dimensions are significantly different from

those of atoms and bulks materials. This is mainly due to the

nanometer size of the materials which render them:

(i) large fraction of surface atoms;

(ii)high surface energy;

(iii) spatial confinement;

(iv) reduced imperfections,

which do not exist in the corresponding bulk materials. Due to their small

dimensions, nanomaterials have extremely large surface area to volume

ratio, which makes a large to be the surface or interfacial atoms, resulting

in more “surface” dependent material properties. Especially when the

sizes of nanomaterials are comparable to length, the entire material will

be affected by the surface properties of nanomaterials. This in turn may

enhance or modify the properties of the bulk materials.For example,

metallic nanoparticles can be used as very active catalysts. Chemical

sensors from nanoparticles and nanowires enhanced the sensitivity and

sensor selectivity. The nanometer feature sizes of nanomaterials also have

spatial confinement effect on the materials, which bring the quantum

effects.The energy band structure and charge carrier density in the

materials can be modified quite differently from their bulk and in turn

will modify the electronic and optical properties of the materials. For

example, lasers and light emitting diodes (LED) from both of the

quantum dots and quantum wires are very promising in the future

optoelections. High density information storage using quantum dot

devices is also a fast developing area. Reduced imperfections are also an

important factor in determination of the properties of the nanomaterials.

Nanosturctures and Nanomaterials favors of a selfpurification process in

that the impurities and intrinsic material defects will move to near

the surface upon thermal annealing. This increased materials perfection

affects the properties of nanomaterials. For example, the chemical

stability for certain nanomaterials may be enhanced, the mechanical

properties of nanomaterials will be better than the bulk materials. The

superior mechanical properties of carbon nanotubes are well known. Due

to their nanometer size, nanomaterials are already known to have many

novel properties. Many novel applications of the nanomaterials rose from

these novel properties have also been proposed. characteristics, and other

variables including doping and interaction with the surrounding

environment or other nanostructures. Likewise, shape can have dramatic

influence on optical properties of metal nanostructures.

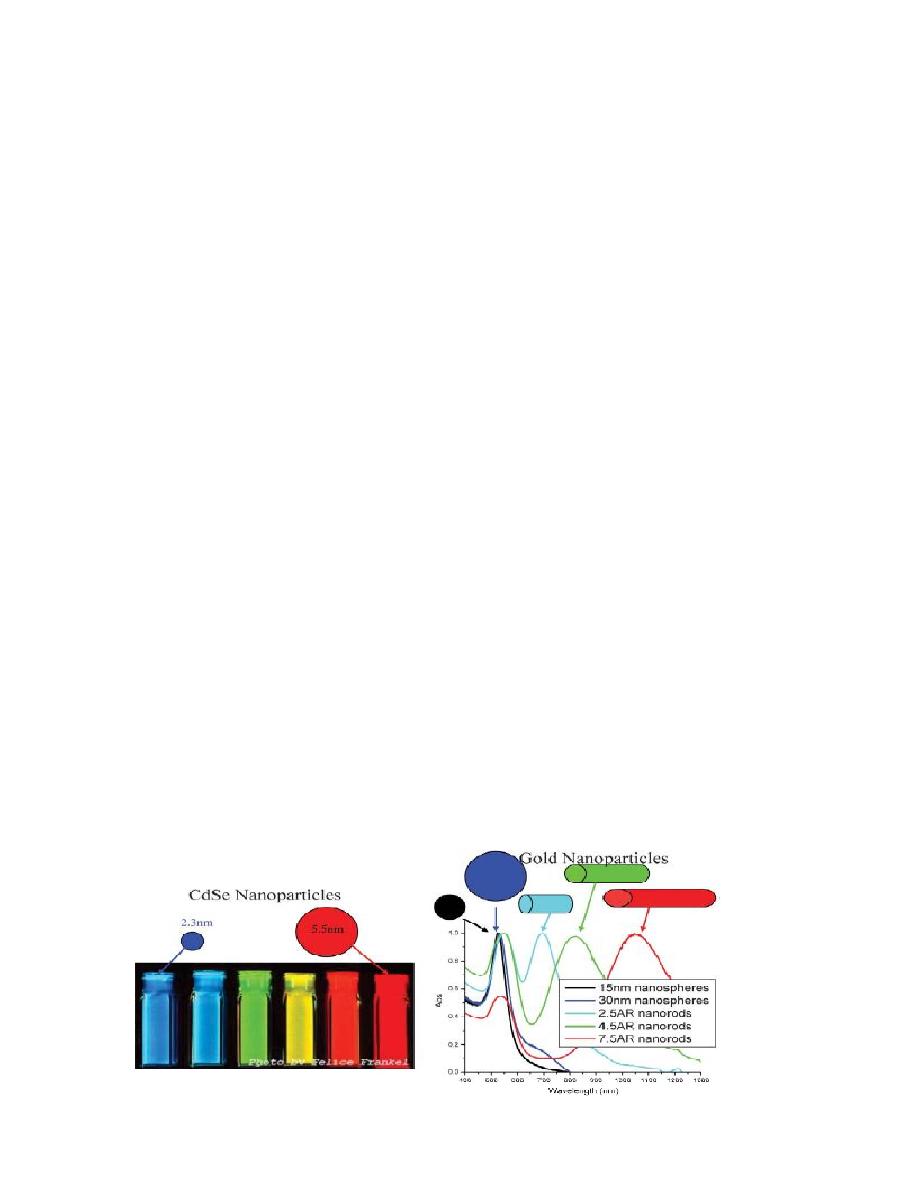

Fig. () xemplifies

the difference in the optical properties of metal and semiconductor

nanoparticles. With the CdSe semiconductor nanoparticles, a simple

change in size alters the optical properties of the

3-1 Mechanical properties

“Mechanical Properties of Nanoparticles” deals with bulk metallic

and ceramic materials, influence of porosity, influence of grain size,

superplasticity, filled polymer composites, particle-filled polymers,

polymer-based nanocomposites filled with platelets, carbon nanotube-

based composites. The discussion of mechanical properties of

anomaterials is, in to some extent, only of quite basic interest, the reason

being that it is problematic to produce macroscopic bodies with a high

density and a grain size in the range of less than 100 nm. However, two

materials, neither of which is produced by pressing and sintering,

have attracted much greater interest as they will undoubtedly achieve

industrial importance.

These materials are polymers which contain nanoparticles or

nanotubes to improve their mechanical behaviors, and severely plastic-

deformed metals, which exhibit astonishing properties. However, because

of their larger grain size, the latter are generally not accepted as

nanomaterials. Experimental studies on the mechanical properties of bulk

nanomaterials are generally impaired by major experimental problems in

producing specimens with exactly defined grain sizes and porosities.

Therefore, model calculations Book title 1.25 and molecular dynamic

studies are of major importance for an understanding of the

mechanical properties of these materials.

Filling polymers with nanoparticles or nanorods and nanotubes,

respectively, leads to significant improvements in their mechanical

properties. Such improvements depend heavily on the type of the filler

and the way in which the filling is conducted. The latter point is of

special importance, as any specific advantages of a nanoparticulate filler

may be lost if the filler forms aggregates, thereby mimicking the large

particles. Particulatefilled polymer-based nanocomposites exhibit a broad

range of failure strengths and strains. This depends on the shape of the

filler, particles or platelets, and on the degree of agglomeration. In this

class of material, polymers filled with silicate platelets exhibit the

best mechanical properties and are of the greatest economic relevance.

The larger the particles of the filler or agglomerates, the poorer are the

properties obtained. Although, potentially, the best composites are those

filled with nanofibers or nanotubes, experience teaches that sometimes

such composites have the least ductility. On the other hand, by

using carbon nanotubes it is possible to produce composite fibers with

extremely high strength and strain at rupture. Among the most exciting

nanocomposites are the polymerceramic nanocomposites, where the

ceramic phase is platelet-shaped.

This type of composite is preferred in nature, and is found in the

structure of bones, where it consists of crystallized mineral platelets of a

few nanometers thickness that are bound together with collagen as the

matrix. Composites consisting of a polymer matrix and defoliated

phyllosilicates exhibit excellent mechanical and thermal properties.

3-2

Optical properties

One of the most fascinating and useful aspects of nanomaterials is

their optical properties.Applications based on optical properties of

nanomaterials include optical detector, laser,sensor, imaging, phosphor,

display,

solar

cell,

photocatalysis,

photoelectrochemistry

and

biomedicine.The optical properties of nanomaterials depend on

parameters such as feature size,shape, surface

nanoparticles. When metal

nanoparticles are enlarged, their optical properties change only slightly as

observed for the different samples of gold nanospheres in fig.

().However, when an anisotropy is added to the nanoparticle, such as

growth of nanorods,the optical properties of the nanoparticles change

dramatically.

Fig.3-2

Fig. 4-1 Fluorescence emission of (CdSe) ZnS quantum dots of various

sizes and absorption spectra of various sizes and shapes of gold

nanoparticles .

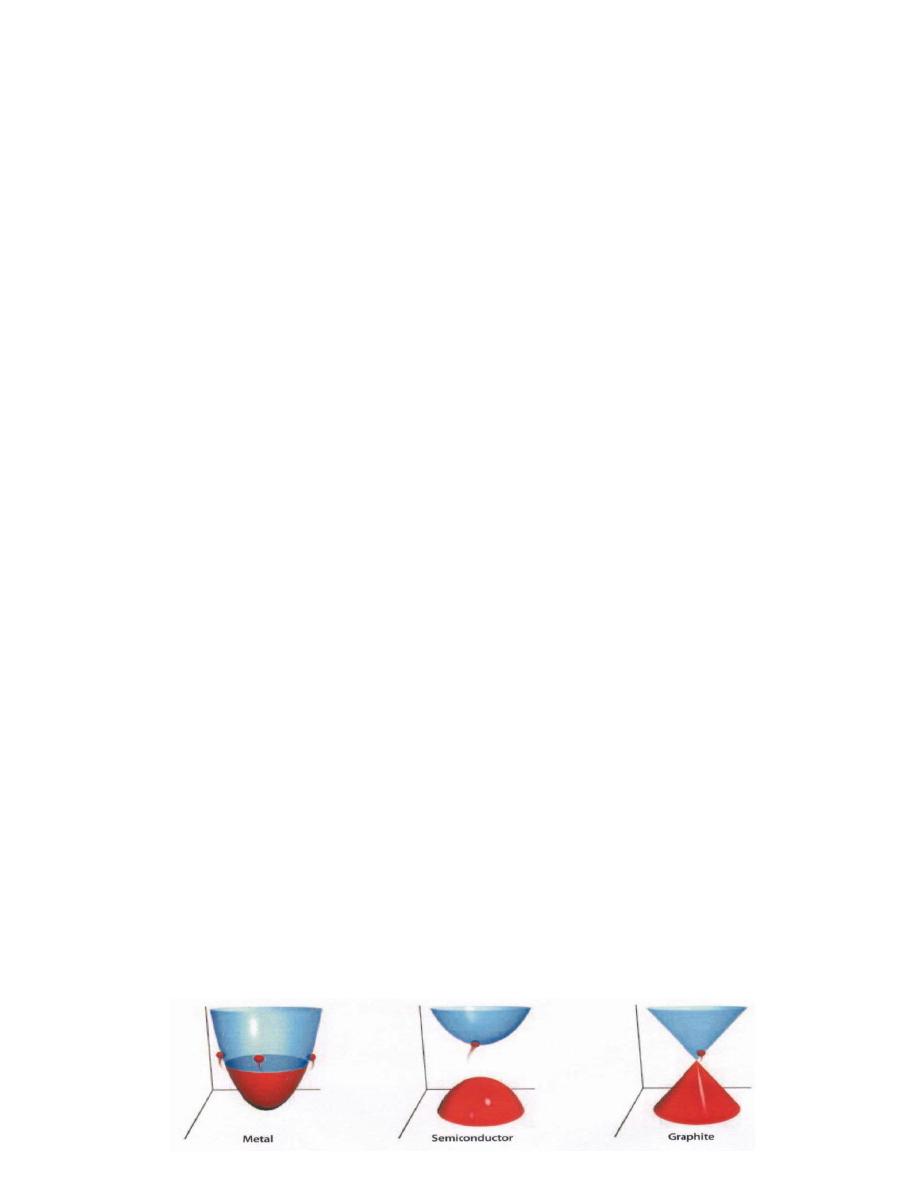

3-3Electrical properties

Electrical Properties of Nanoparticles” discuss about fundamentals

of electrical conductivity in nanotubes and nanorods, carbon nanotubes,

photoconductivity of nanorods, electrical conductivity of anocomposites.

One interesting method which can be used to demonstrate the steps in

conductance is the mechanical thinning of a nanowire and measurement

of the electrical current at a constant applied voltage. The important

point here is that, with decreasing diameter of the wire, the number of

electron wave modes contributing to the electrical conductivity is

becoming increasingly smaller by well-defined quantized steps.

In electrically conducting carbon nanotubes, only one electron wave

mode is observed which transport the electrical current. As the lengths

and orientations of the carbon nanotubes are different, they touch the

surface of the mercury at different times,which provides two sets of

information:

(i) the influence of carbon nanotube length on 1.24 Introduction to

Nanomaterials the resistance; and

(ii) the resistances of the different nanotubes. As the nanotubes have

different lengths, then with increasing protrusion of the fiber bundle an

increasing number of carbon nanotubes will touch the surface of the

mercury droplet and contribute to the electrical current transport.

Fig. 4-2 Electrical behavior of naotubes.

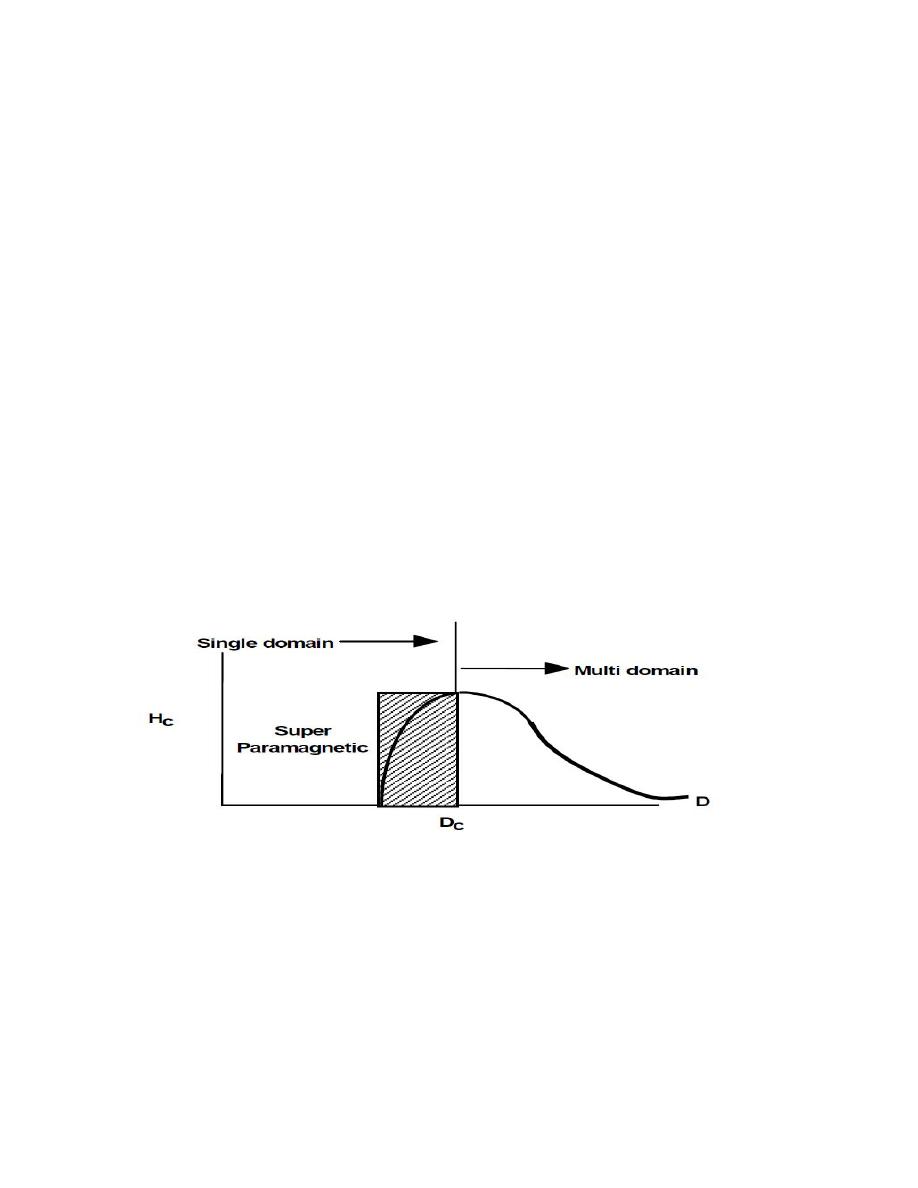

3 – 4 Magnetic properties

Bulk gold and Pt are non-magnetic, but at the nano size they are

magnetic. Surface atoms are not only different to bulk atoms, but they can

also be modified by interaction with other chemical species, that is, by

capping the nanoparticles. This phenomenon opens the possibility to

modify the physical properties of the nanoparticles by capping them with

appropriate molecules. Actually, it should be possible that non-

ferromagnetic bulk materials exhibit ferromagnetic-like behavior when

prepared in nano range. One can obtain magnetic nanoparticles of Pd, Pt

and the surprising case of Au (that is diamagnetic in bulk) from non-

magnetic bulk materials. In the case of Pt and Pd, the ferromagnetism

arises from the structural changes associated with size effects

Fig. 4-3 Magnetic properties of nanostrucutred materials.

However, gold nanoparticles become ferromagnetic when they are

capped withappropriate molecules: the charge localized at the particle

surface gives rise toferromagnetic-like behavior. Surface and the core of

Au nanoparticles with 2 nm in diameter show ferromagnetic and

paramagnetic character, respectively. The large spin-orbit coupling of

these noble metals can yield to a large anisotropy and therefore exhibit

high ordering temperatures. More surprisingly, permanent magnetism

was observed up to room temperature for thiol-capped Au nanoparticles.

For nanoparticles with sizes below 2 nm the localized carriers are in the

5d band. Bulk Au has an extremely low density of states and becomes

diamagnetic, as is also the case for bare Au nanoparticles.

This observation suggested that modification of the d band structure

by chemical bonding can induce ferromagnetic like character in metallic

clusters.

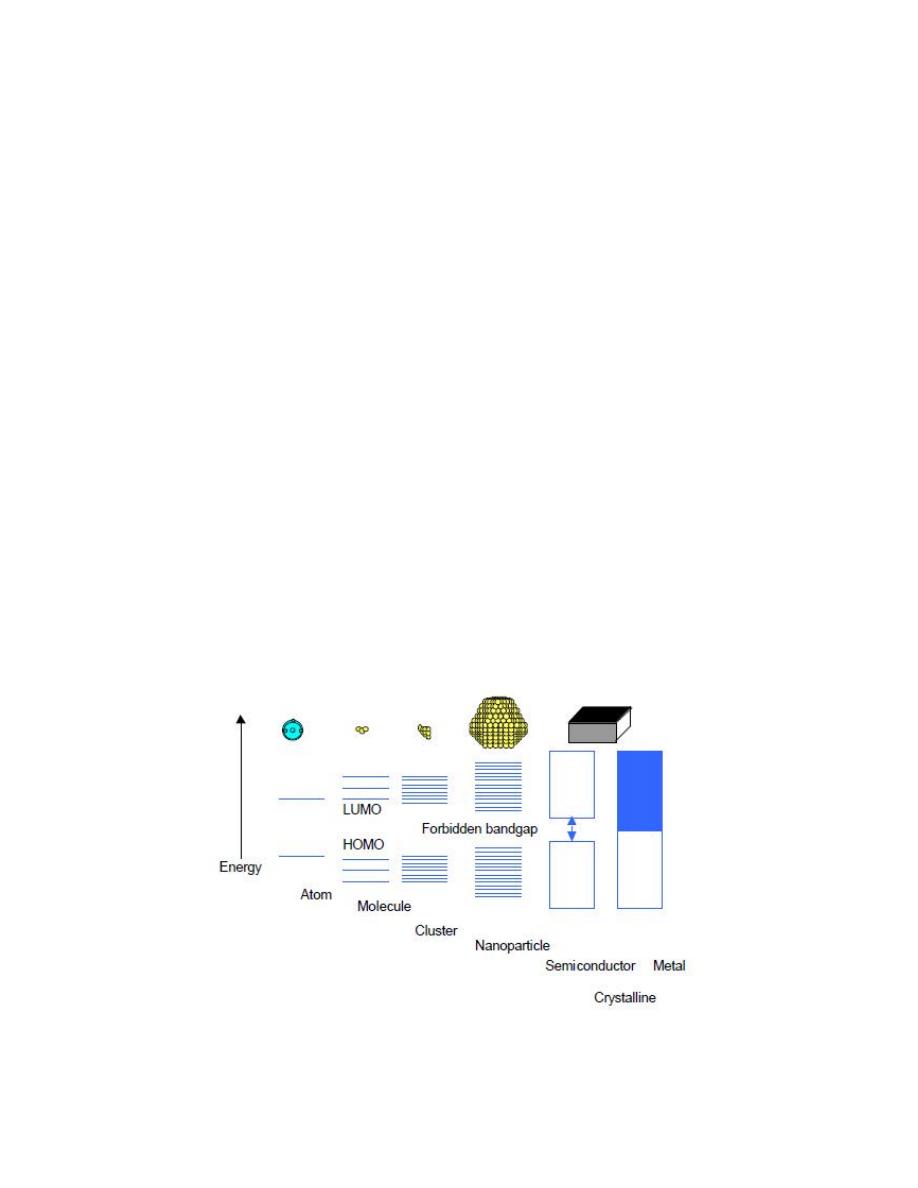

ELECTRONIC AND OPTICAL PROPERTIES OF

NANOMATERIALS

7.1 Introduction

Figure 7-1: Size quantization effect. Electronic state transition from bulk

metal/semiconductor to small cluster.

Nanocrystalline particles represent a state of matter in the transition

region between bulk solid and single molecule. As a consequence, their

physical and chemical properties gradually change from solid state to

molecular behaviour with decreasing particle size. The reasons for this

behaviour can be summarised as two basic phenomena.

First, as we have already discussed, owing to their small dimensions,

the surface-to-volume ratio increases, and the number of surface atoms

may be similar to or higher than those located in the crystalline lattice

core, and the surface properties are no longer negligible. When no other

molecules are adsorbed onto the nanocrystallites, the surface atoms are

highly unsaturated and their electronic contribution to the behaviour of

the particles is totally different from that of the inner atoms. These effects

may be even more marked when the surface atoms are ligated. This leads

to different mechanical and electronic transport properties,

which account for the catalytic properties of the nanocrystalline particles.

The second phenomenon, which only occurs in metal and semiconductor

nanoparticles, is totally an electronic effect. The band structure gradually

evolves with increasing particle size, i. e., molecular orbital convert into

delocalised band states. Figure above, shows the size quantization effect

responsible for the transition between a bulk metal or semiconductor, and

cluster species. In a metal, the quasicontinuous

density of states in the valence and the conduction bands splits into

discrete electronic levels, the spacing between these levels and the band

gap increasing with decreasing particle size.

In the case of semiconductors, the phenomenon is slightly

different, since a band gap already exists in the bulk state. However, this

band gap also increases when the particle size is decreased and the energy

bands gradually convert into discrete molecular electronic levels. If the

particle size is less than the De Broglie wavelength of the electrons, the

charge carriers may be treated quantum mechanically as "particles in a

box", where the size of the box is given by the dimensions of the

crystallites. In semiconductors, the quantization effect that

enhances the optical gap is routinely observed for clusters ranging from 1

nm to almost 10 nm. Metal particles consisting of 50 to 100 atoms with a

diameter between 1 and 2 nm start to loose their metallic behaviour and

tend to become semiconductors. Particles that show this size quantization

effect are sometimes called Q-particles or quantum dots that we will

discuss later in this chapter.Certain particle sizes, determined by the so-

called magic numbers, are more frequently observed than others. This is

not only due to the thermodynamic stability of certain structures but is

also related to the kinetics of particle growth. In semiconductor

nanoparticles such as CdS, the growth of the initially formed smallest

particles with an agglomeration number k occurs by combination of the

particles. Thus, particles so formed would have the agglomeration

number of 2k, 3k and so on.lxx Metals have a cubic or hexagonal close-

packed structure consisting of one central atom, which is surrounded in

the first shell by 12 atoms, in the second shell by 42 atoms, or in principle

by 10n2+2 atoms in the nth shell For example, one of the

Lecture 3

(nano

)

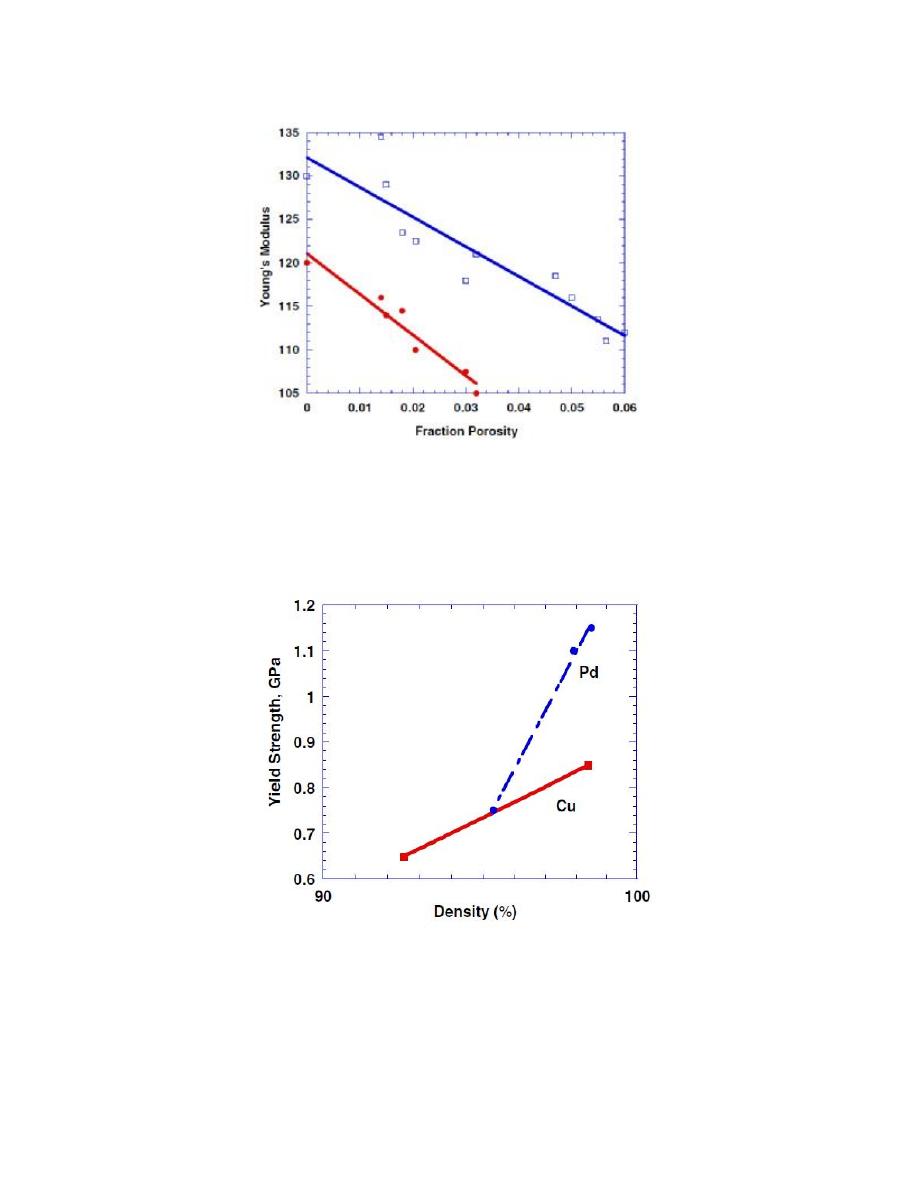

Mechanical properties of nanocrystalline metals and

alloys

In this section, we review the principal mechanical properties of

nanocrystalline metals: yield stress, ductility, strain hardening, strain-rate

sensitivity and dynamic response, creep and fatigue. At the outset, it

should be emphasized that porosity is of utmost importance and can mask

and/or distort properties. The early ‘‘bottom-up’’ synthesis methods often

resulted in porosity and incomplete bonding among the grains.

Processing flaws like porosity are known to be detrimental to the

properties of nanocrystalline materials. Fig. 11

shows the Young_s

modulus as a function of porosity for nanocrystalline Pd and Cu as shown

by Weertman et al.This decrease in Young_s modulus with porosity is

well known and is indeed expressed in many mechanics simulations.

One of the equations is Wachtman and MacKenzie

E ¼ E0ً1 _ f1p f2p2 ق

where p is the porosity and f1 and f2 are equal to 1.9 and 0.9,

respectively. For relatively low porosity, p2 can be neglected and we

have, approximately E E0 ¼ 1 _ 1:9p. The yield

stress and tensile ductility are simultaneously affected.

Fig. 12

shows as

an illustration,

Fig. 11. Young_s modulus as a function of porosity for nanocrystalline

Pd and Cu.

Fig. 12. Compressive yield strength of Cu and Pd as a function of

consolidation density.

a plot of the yield stress as a function of density for Cu and Pd. The

decrease in strength isobvious. The existing pores provide initiation sites

for failure.

3-1- Yield strength

Grain size is known to have a significant effect on the mechanical

behavior of materials,in particular, on the yield stress. The dependence of

yield stress on grain size in metals iswell established in the conventional

polycrystalline range (micrometer and larger sized grains). Yield stress,

ry, for materials with grain size d, is found to follow the Hall–Petch

relation:

ry ¼ r0 kd_1=2 ً3 ق

where r0 is the friction stress and k is a constant. This is indeed an

approximation, and a more general formulation is to use a power

expression with exponent _n, where 0.3 6 n 6 0.7.

The mechanical properties of FCC metals with nano-range grain sizes

have been estimated from uniaxial tension/compression tests and micro-

or nano-indentation. Often micro-size tensile samples are used to avoid

the influence of imperfections e.g., voids

that might adversely influence the mechanical response of the material.

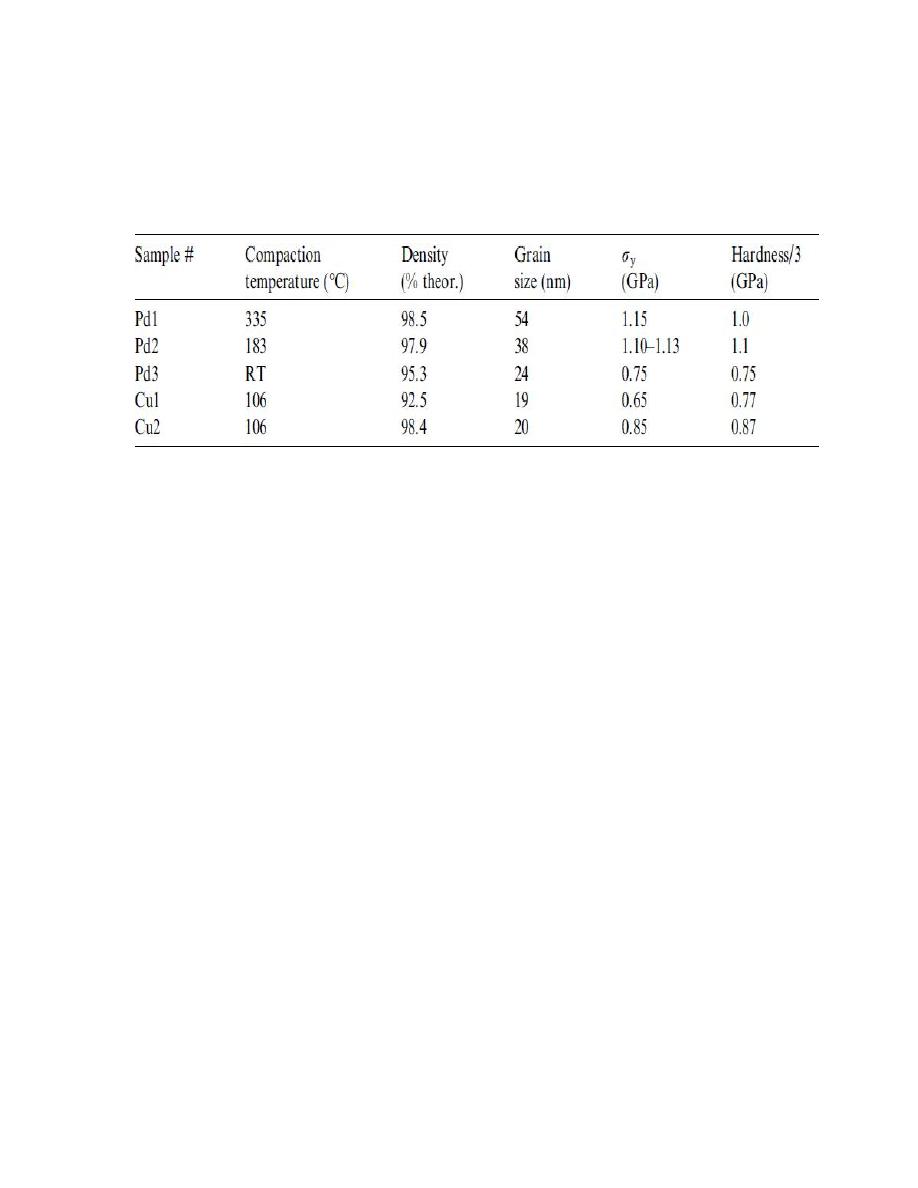

The compressive yield stresses of nanocrystalline Cu and Pd samples

synthesized by IGC are summarized in Table 2, and the plot is given in

Fig. 12. Weertman and coworkers observed that nanocrystalline Cu and

Pd samples were remarkably stronger than their coarse-grained

counterpart and this was a strong function of density. Their strain to

failure was also higher. Suryanarayana et al. reported compressive yield

strength of _500 MPa from their strongest nano Cu sample. Table 2 gives

the values of the Vickers hardness, Hv divided by 3, which approximates

to the yield strength if the work-hardening is not large. Unlike the case of

tensile yield strength, the compressive values of ry scale well with Hv/3.

Weertman et al. observed a large increase in hardness.

Table 2 Compressive yield strength of nanocrystalline Cu and Pd

synthesized by inert gas condensation method .

for the nanocrystalline Cu and Pd samples made by IGC as compared to

the annealed coarse-grained samples. It was difficult to separate the

magnitude of the strengthening effect of the small grain size from the

weakening effect due to the bulk sample defects which are inherent to the

IGC synthesis method (mainly pores).

3-2 Ductility

In the conventional grain size regime, usually a reduction in grain size

leads to an increase in ductility. Thus one should expect a ductility

increase as the grain size is reduced to nanoscale. However, the ductility

is small for most grain sizes <25 nm for metals that in the conventional

grain size have tensile ductilities of 40–60% elongation .

identified three major sources of limited ductility in nanocrystalline

materials, namely:

(1) artifacts from processing (2) tensile instability; (3) crack nucleation or

shear instability. It is difficult to process nanostructured materials free

from the artifacts that mask the inherent mechanical properties. As a

result, molecular dynamics simulation has been considered to be a

valuable tool in aiding our understanding of their deformation

mechanism . This is treated in greater detail in Section 9. The results of

the atomistic simulations have allowed several investigators to suggest

different plastic deformation mechanisms as a function of grain size .

There seems to be agreement in the existence of three regimes: (a) grain

size d > 1 lm regime in which unit dislocations and work hardening

control plasticity; (b) smallest grain size d < 10 nm regime, where limited

intragranular dislocation activity occurs and grain-boundary shear is

believed to be the mechanism of deformation. The intermediate grain size

regime (10 nm–1 lm) is less well understood. These mechanisms are

thought to affect ductility significantly.

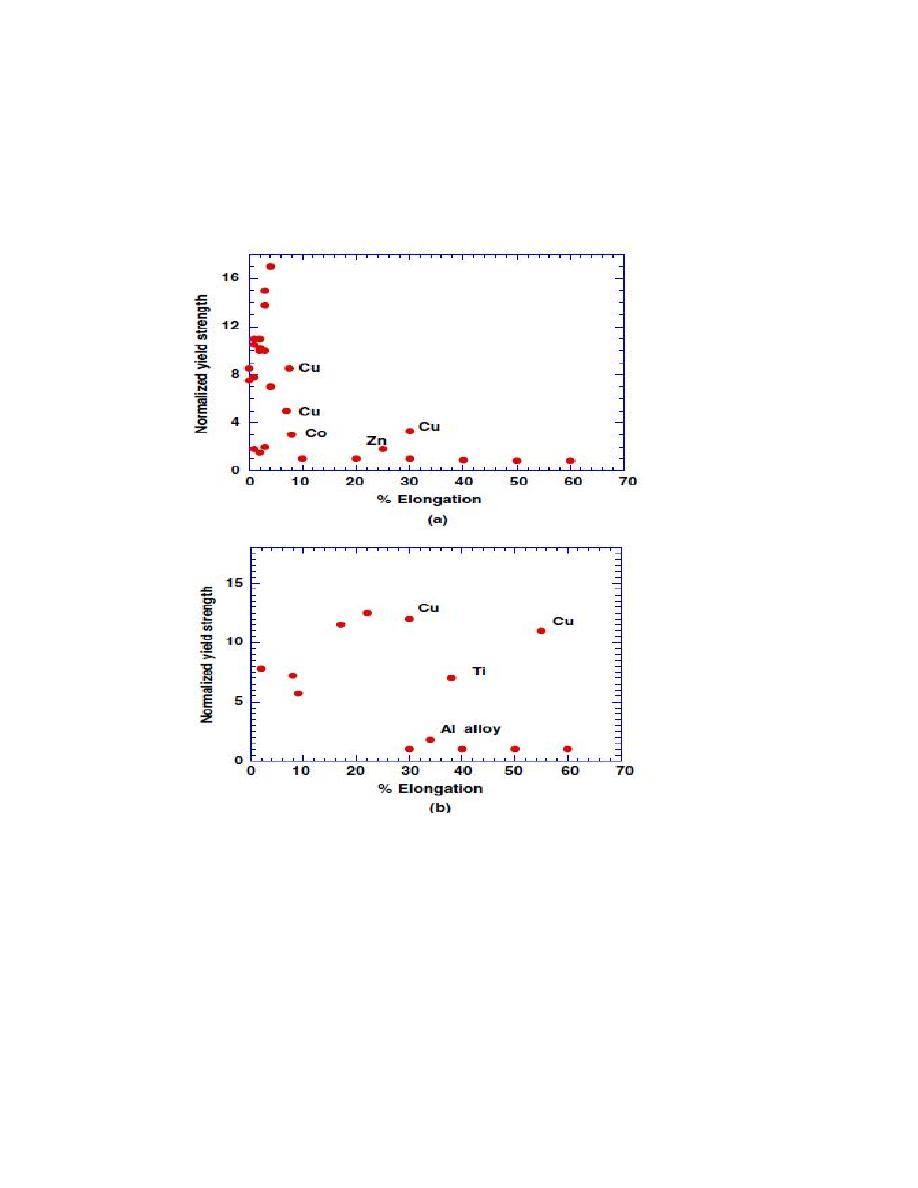

Fig. 13(a) shows data on normalized yield strength (strength/strength of

conventional polycrystalline) versus percentage elongation in tension for

metals with grain sizes in the nanocrystalline range. There is a clear

decrease in ductility as strength is increased. By comparison, ultrafine

grained materials (100–500 nm), Fig. 13(b), exhibit increased yield

strength along with good ductility in comparison to nanograined

materials. varied the microstructure of nanostructured/ultrafine grain size

of Zn by changing the milling times. A very dramatic modulated cyclic

variation of hardness was observed as a function of milling time at liquid

nitrogen temperature. The sample cryomilled for 4 h exhibited an

optimum combination of strength and ductility. The grain size

distribution in this sample contained 30% volume fraction of grains larger

than 50 nm along with the smaller nano-scale grains. This optimum

microstructure, which exhibits

Fig. 13. (a) Compilation of yield stress versus % elongation showing the

reduced ductility of nanocrystalline metals

[96]

. (b) Compilation of yield

strength versus % elongation of various ultrafine grained metals

more strain hardening than samples milled for either shorter or longer

time, combined the strengthening from the reduced grain size along with

the strain hardening provided by dislocation activity in the larger grains.

This strain hardening, in turn, provided ductility. Thus, a bimodal grain

size distribution is a possible means to increase ductility.

Nonequilibrium grain boundaries have also been proposed as a

mechanism to enhance ductility. It has been argued that such boundaries

provide a large number of excess dislocations for slip and can even

enable grains to slide or rotate at room temperature, leading to a

significant increase in the strain hardening exponent. Another way of

increasing ductility is to decrease the strain rate in order for the specimen

to sustain more plastic strain prior to necking.

Fig. 13. (a) Compilation of yield stress versus % elongation showing the

reduced ductility of nanocrystalline metals. (b) Compilation of yield

strength versus % elongation of various ultrafine grained metals.

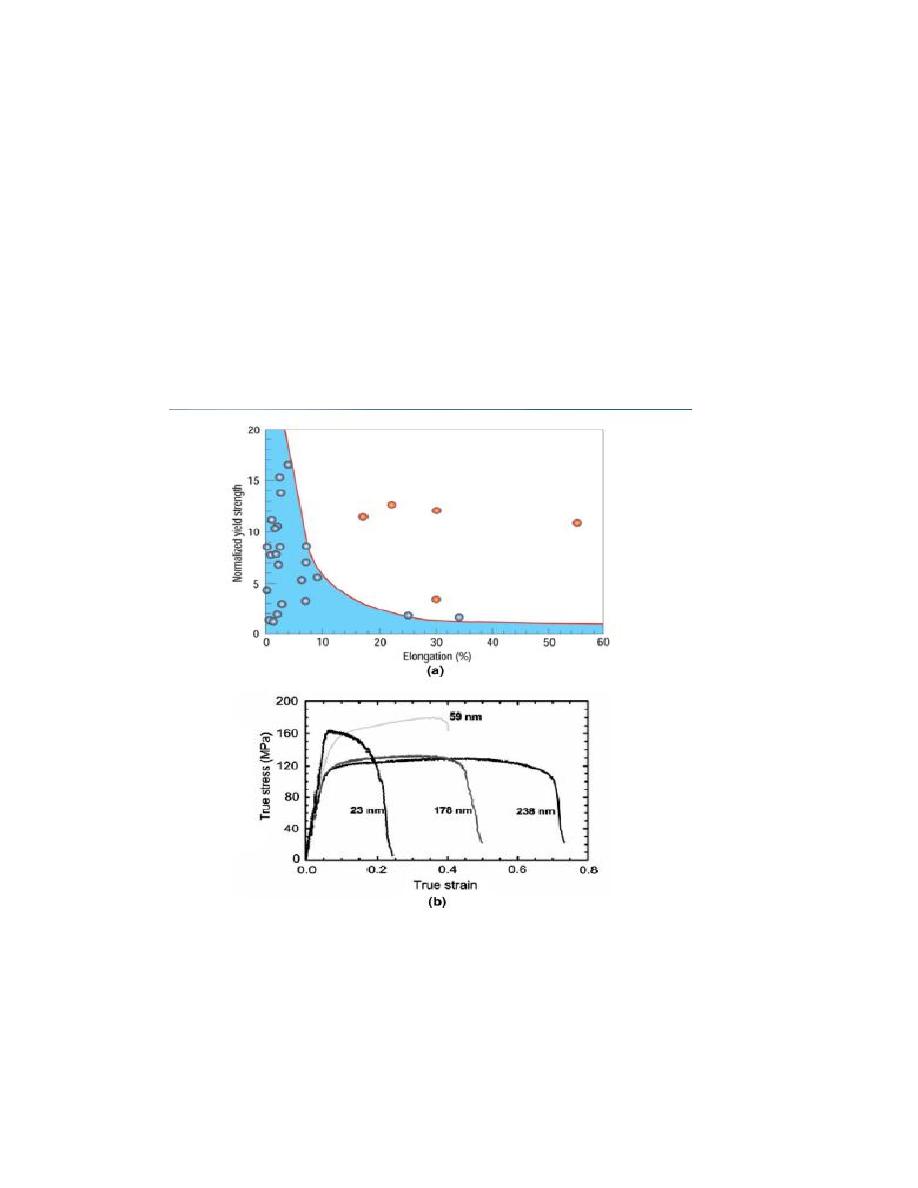

Fig. 14

(a) shows the expected ductility of metals as a function of a

normalized strength (strength in the conventional grain size domain). As

expected, as the strength increases, the ductility decreases. This defines

the grey region. However, there are five data points above this boundary.

They all apply to copper. Three factors contribute to and in fact determine

ductility: the work hardening, the strain rate sensitivity and thermal

softening. The increased ductility that is exhibited in some cases comes,

basically, from the inhibition of shear localization. The strain rate

sensitivity, m, can be expressed as:

m ¼

31=2kT

V ry

ً4 ق

where V is the activation volume for plastic deformation (which is

directly related to the physical mechanism of deformation), T is the

temperature, and ry is the yield/flow stress. The higher strain-rate

sensitivity ًm ¼ o ln r=o ln _e or 1

ry

or

o ln _e قis indicative of a smaller activation volume, as pointed out by Lu

et al.

Fig. 14. (a) Increased ductility in the nanocrystalline regime as indicated

by experimental points in right-hand side of diagram; (b) reduction of

ductility as grain size is reduced for ball milled Zn tested at a constant

strain rate of 10_4–10_3 s_1 at room temperature

This, in turn, is connected to a change in the nanostructure (presence of

twins). Thus, ductility, strain rate sensitivity, and deformation

mechanisms are connected and it is possible, through the manipulation of

the nanostructure to increase ductility. were able to increase ductility of

their nanocrystalline metals by increasing significantly the density of

growth (annealing) twins. (b) shows the mechanical response of

nanocrystalline zinc samples with different grain sizes. There is a

significant drop in ductility as the grain size goes down from 238 nm to

23 nm. Zhang et al. suggested that the reduction of elongation with the

reduction of grain size could be an inherent property of nanocrystalline

materials given that there is no porosity and bonding was complete during

synthesis. Earlier results have shown that the mechanical properties of

nanocrystalline materials can be misinterpreted because of the lack of

attention to the details of the internal structure. As mentioned earlier,

contaminates and porosity are found to be extremely detrimental to

ductility

Lecture 4

(nano

)

4 Methods for creating nanostructures

There are many different ways of creating nanostructures: of course,

macromolecules or nanoparticles or buckyballs or nanotubes and so on

can be synthesized artificially for certain specific materials. They can also

be arranged by methods based on equilibrium or near-equilibrium

thermodynamics such as methods of self-organization and self-assembly

(sometimes also called bio-mimetic processes). Using these methods,

synthesized materials can be arranged into useful shapes so that finally

the material can be applied to a certain application.

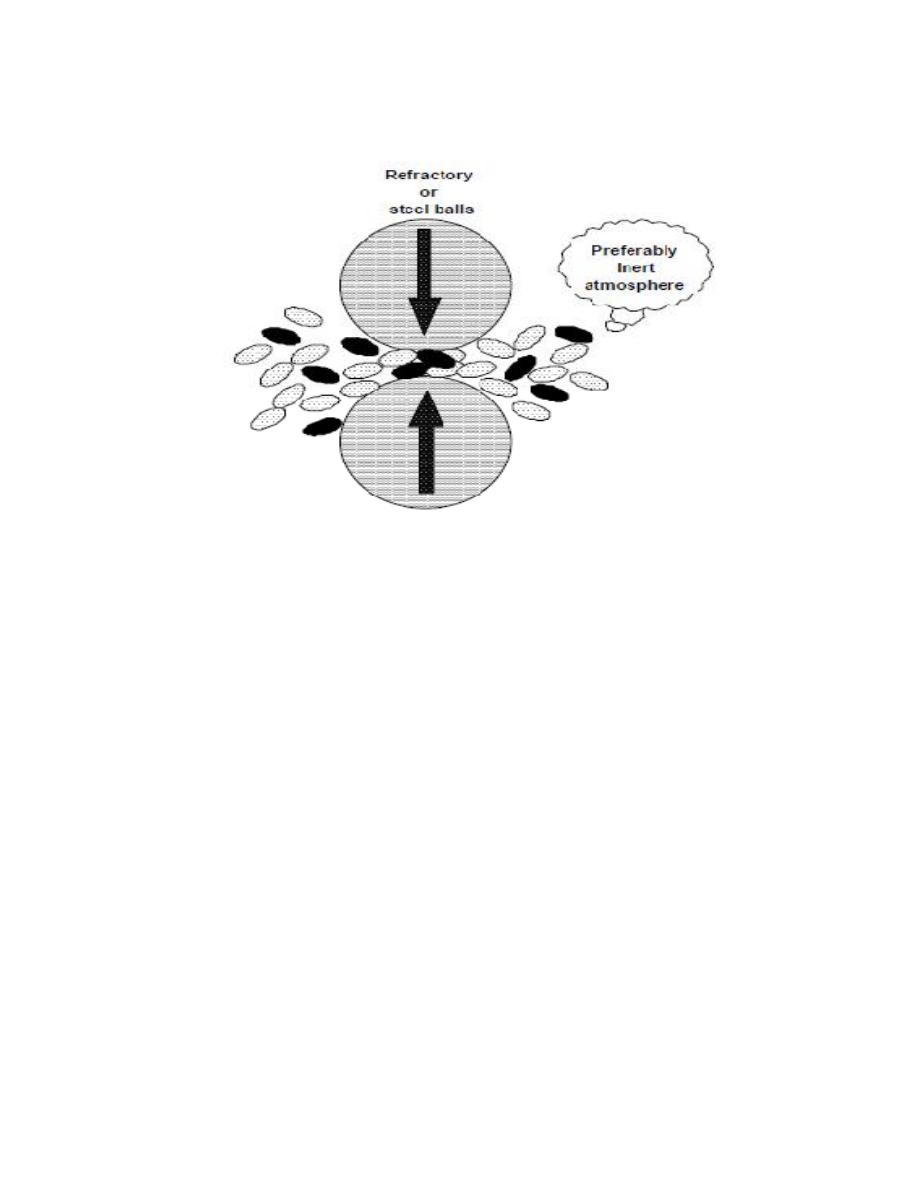

4-1 Mechanical grinding

Mechanical attrition is a typical example of ‘top down’ method of

synthesis of nanomaterials, where the material is prepared not by cluster

assembly but by the structural decomposition of coarser-grained

structures as the result of severe plastic deformation. This has become a

popular method to make nanocrystalline materials because of its

simplicity, the relatively inexpensive equipment needed, and the

applicability to essentially the synthesis of all classes of materials. The

major advantage often quoted is the possibility for easily scaling up to

tonnage quantities of material for various applications. Similarly, the

serious problems that are usually cited are;

1. contamination from milling media and/or atmosphere, and

2. to consolidate the powder product without coarsening the

nanocrystalline microstructure. In fact, the contamination problem is

often given as a reason to dismiss the method, at least for some materials.

Here we will review the mechanisms presently believed responsible for

formation of nanocrystalline structures by mechanical attrition of single

phase powders, mechanical alloying of dissimilar powders, and

mechanical

crystallisation of amorphous materials. The two important problems of

contamination and Mechanical milling is typically achieved using high

energy shaker, planetary ball, or tumbler mills. The energy transferred to

the powder from refractory or steel balls depends on the rotational

(vibrational) speed, size and number of the balls, ratio of the ball to

powder mass, the time of milling and the milling atmosphere

.

Nanoparticles are produced by the shear action during grinding.

Milling in cryogenic liquids can greatly increase the brittleness of the

powders influencing the fracture process. As with any process that

produces fine particles, an adequate step to prevent oxidation is

necessary. Hence this process is very restrictive for the production of

non-oxide materials since then it requires that the milling take place in

an inert atmosphere and that the powder particles be handled in an

appropriate vacuum system or glove box. This method of synthesis is

suitable for producing amorphous or nanocrystalline alloy particles,

elemental or compound powders. If the mechanical milling imparts

sufficient energy to the constituent powders a homogeneous alloy can be

formed. Based on the energy of the milling process and thermodynamic

properties of the constituents the alloy can be rendered amorphous by this

processing.

Fig. 6. Schematic representation of the principle of mechanical milling

4-2 Wet Chemical Synthesis of Nanomaterials

In principle we can classify the wet chemical synthesis of

nanomaterials into two broad groups:

1. The top down method: where single crystals are etched in an aqueous

solution for producing nanomaterials, For example, the synthesis of

porous silicon by electrochemical etching.

2. The bottom up method: consisting of sol-gel method, precipitation etc.

where materials containing the desired precursors are mixed in a

controlled fashion to form a colloidal solution.

4-2- 1 Sol-gel process

The sol-gel process, involves the evolution of inorganic networks

through the formation of a colloidal suspension (sol) and gelation of the

sol to form a network in a continuous liquid phase (gel). The precursors

for synthesizing these colloids consist usually of a metal or metalloid

element surrounded by various reactive ligands. The starting material

is processed to form a dispersible oxide and forms a sol in contact with

water or dilute acid. Removal of the liquid from the sol yields the gel, and

the sol/gel transition controls the particle size and shape. Calcination of

the gel produces the oxide.

Sol-gel processing refers to the hydrolysis and condensation of

alkoxide-based precursors such as Si(OEt) 4 (tetraethyl orthosilicate, or

TEOS). The reactions involved in the sol-gel chemistry based on the

hydrolysis and condensation of metal alkoxides

M(OR)z can be described as follows:

MOR + H2O → MOH + ROH (hydrolysis)

MOH + ROM → M-O-M + ROH (condensation)

Sol-gel method of synthesizing nanomaterials is very popular amongst

chemists and is widely employed to prepare oxide materials. The sol-gel

process can be characterized by a series of distinct steps.

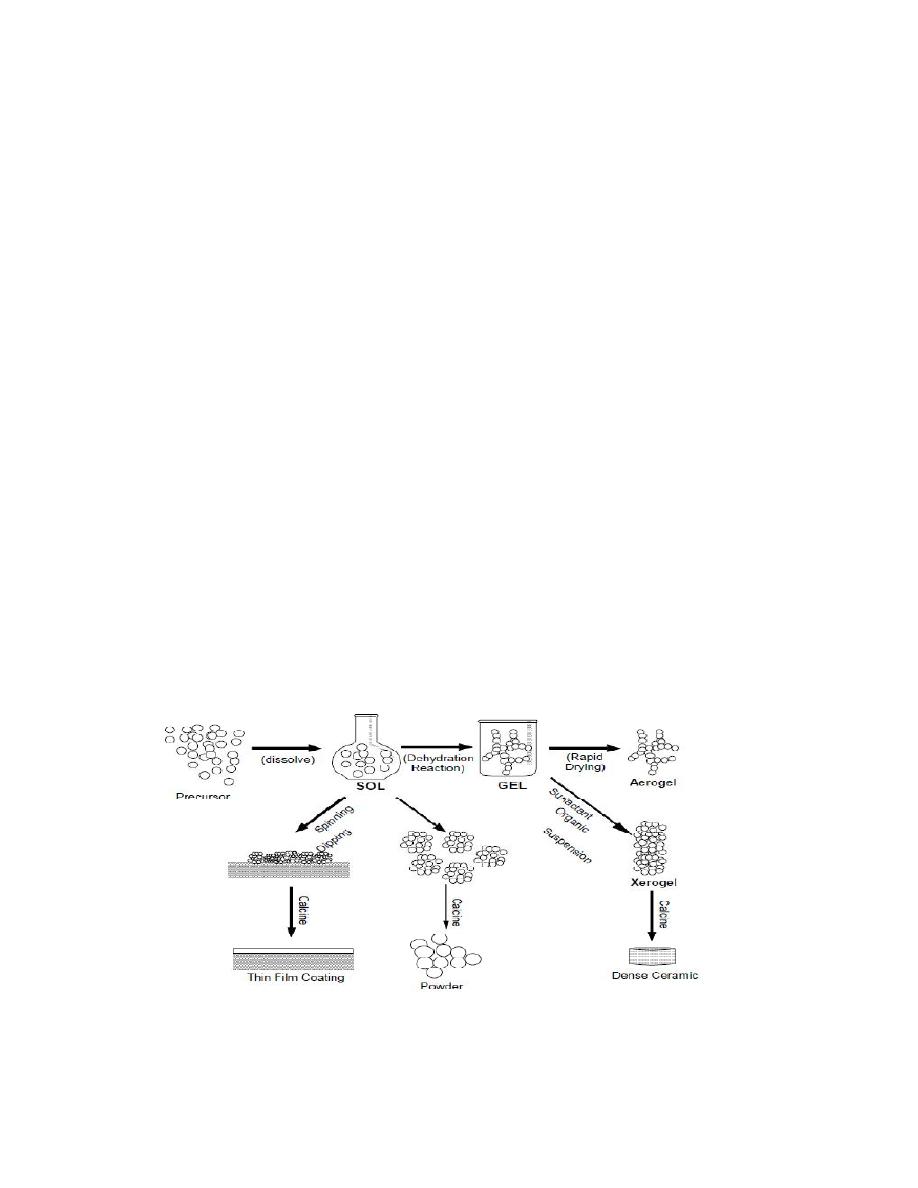

Fig. 7. Schematic representation of sol-gel process of synthesis of

nanomaterials.

1. Formation of different stable solutions of the alkoxide or solvated

metal precursor.

2. Gelation resulting from the formation of an oxide- or alcohol- bridged

network (the gel) by a polycondensation reaction that results in a

dramatic increase in the viscocity of the solution.

3. Aging of the gel (Syneresis), during which the polycondensation

reactions continue until the gel transforms into a solid mass, accompanied

by contraction of the gel network and expulsion of solvent from gel

pores. Ostwald ripening (also referred to as coarsening, is the

phenomenon by which smaller particles are consumed by larger particles

during the growth process) and phase transformations may occur

concurrently with syneresis. The aging process of gels can exceed 7 days

and is critical to the prevention of cracks in gels that have been

cast.

4. Drying of the gel, when water and other volatile liquids are removed

from the gel network. This process is complicated due to fundamental

changes in the structure of the gel. The drying process has itself been

broken into four distinct steps:

(i) the constant rate period, (ii) the critical point, (iii) the falling rate

period, (iv) the second falling rate period. If isolated by thermal

evaporation, the resulting monolith is termed a xerogel. If the solvent

(such as water) is extracted under supercritical or near super critical

conditions, the product is an aerogel.

5. Dehydration, during which surface- bound M-OH groups are removed,

there by stabilizing the gel against rehydration. This is normally achieved

by calcining the monolith at temperatures up to 8000C.

6. Densification and decomposition of the gels at high temperatures

(T>8000C). The pores of the gel network are collapsed, and remaining

organic species are volatilized. The typical steps that are involved in sol-

gel processing are shown in the schematic diagram below.

The interest in this synthesis method arises due to the possibility of

synthesizing nonmetallic inorganic materials like glasses, glass ceramics

or ceramic materials at very low temperatures compared to the high

temperature process required by melting glass or firing ceramics.

The major difficulties to overcome in developing a successful bottom-up

approach is controlling the growth of the particles and then stopping the

newly formed particles from agglomerating. Other technical issues are

ensuring the reactions are complete so that no unwanted reactant is left on

the product and completely removing any growth aids that may have been

used in the process. Also production rates of nano powders are very low

by this process. The main advantage is one can get monosized nano

particles by any bottom up approach.

4-3 Gas Phase synthesis of nanomaterials

The gas-phase synthesis methods are of increasing interest because

they allow elegant way to control process parameters in order to be able

to produce size, shape and chemical composition controlled

nanostructures. Before we discuss a few selected pathways for gas-phase

formation of nanomaterials, some general aspects of gas-phase synthesis

needs to be discussed. In conventional chemical vapour deposition

(CVD) synthesis, gaseous products either are allowed to react

homogeneously or heterogeneously depending on a particular application.

1. In homogeneous CVD, particles form in the gas phase and diffuse

towards a cold surface due to thermophoretic forces, and can either be

scrapped of from the cold surface to give nano-powders, or deposited

onto a substrate to yield what is called ‘particulate films’.

2. In heterogeneous CVD, the solid is formed on the substrate surface,

which catalyses the reaction and a dense film is formed.

In order to form nanomaterials several modified CVD methods have been

developed. Gas phase processes have inherent advantages, some of which

are noted here:

� An excellent control of size, shape, crystallinity and chemical

composition

� Highly pure materials can be obtained

� Multicomonent systems are relatively easy to form

� Easy control of the reaction mechanisms

Most of the synthesis routes are based on the production of small

clusters that can aggregate to form nano particles (condensation).

Condensation occurs only when the vapour is supersaturated and in these

processes homogeneous nucleation in the gas phase is utilised to form

particles. This can be achieved both by physical and chemical methods.

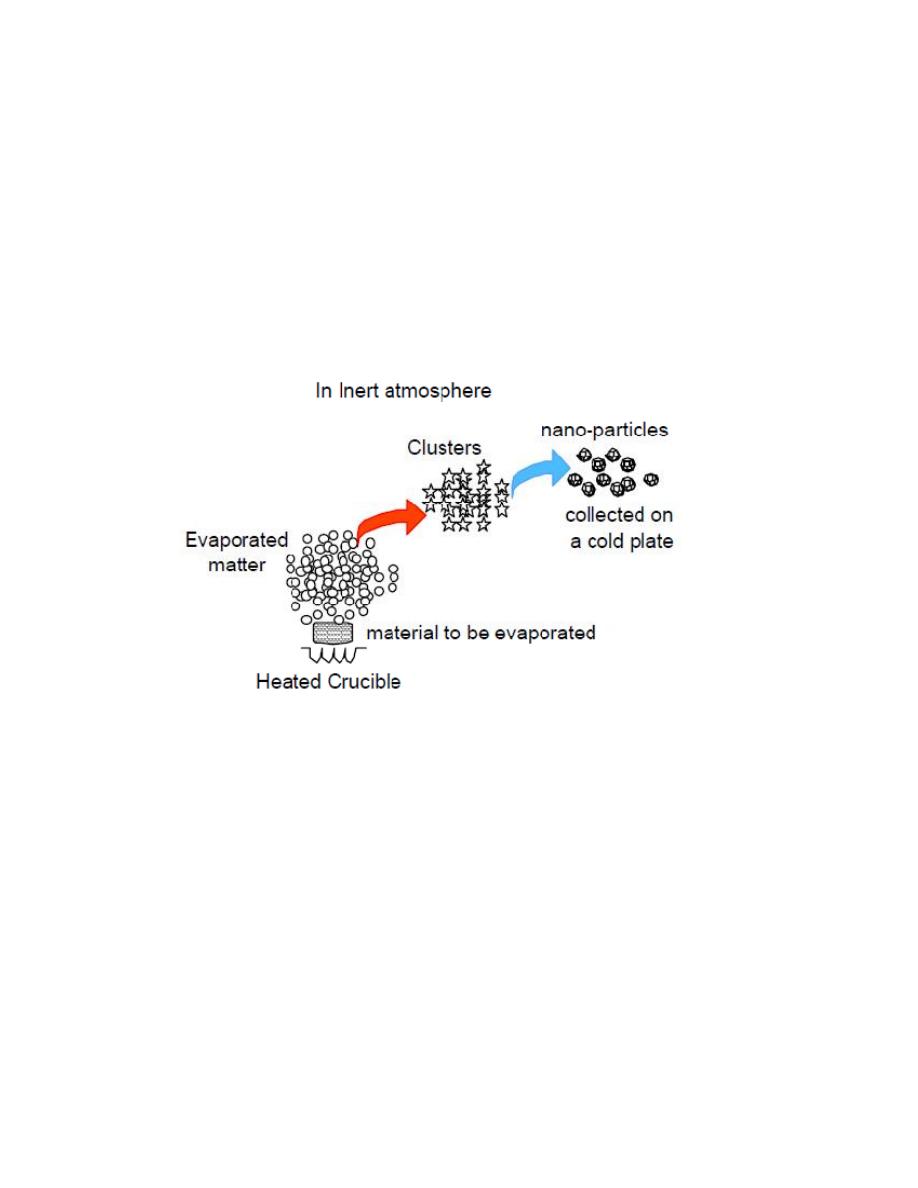

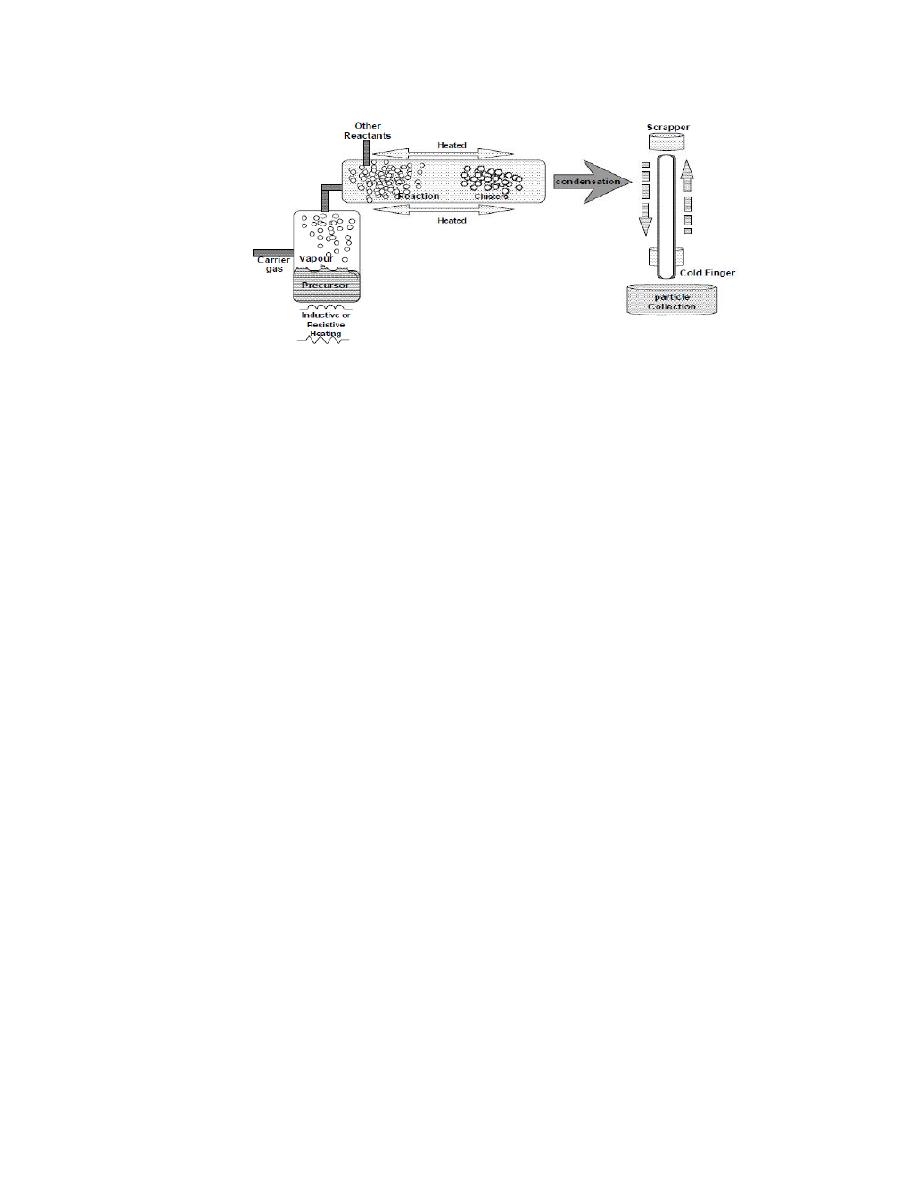

4-3-1 Furnace

The simplest fashion to produce nanoparticles is by heating the

desired material in a heatresistant crucible containing the desired

material. This method is appropriate only for materials that have a high

vapour pressure at the heated temperatures that can be as high as 2000°C.

Energy is normally introduced into the precursor by arc heating,

electronbeam heating or Joule heating. The atoms are evaporated into an

atmosphere, which is either inert (e.g. He) or reactive (so as to form a

compound). To carry out reactive synthesis, materials with very low

vapour pressure have to be fed into the furnace in the form of a suitable

precursor such as organometallics, which decompose in the furnace to

produce a condensable material. The hot atoms of the evaporated matter

lose energy by collision with the atoms of the cold gas and undergo

condensation into small clusters via homogeneous nucleation. In case a

compound is being synthesized, these precursors react in the gas phase

and form a compound with the material that is separately injected in the

reaction chamber. The clusters would continue to grow if they remain in

the supersaturated region. To control their size, they need to be rapidly

removed from the supersaturated environment by a carrier gas. The

cluster size and its distribution are controlled by only three parameters:

1) the rate of evaporation (energy input),

2) the rate of condensation (energy removal), and

3) the rate of gas flow (cluster removal).

Fig. 8. Schematic representation of gas phase process of synthesis of

single phase nanomaterials from a heated crucible.

Because of its inherent simplicity, it is possible to scale up this process

from laboratory (mg/day) to industrial scales (tons/day).

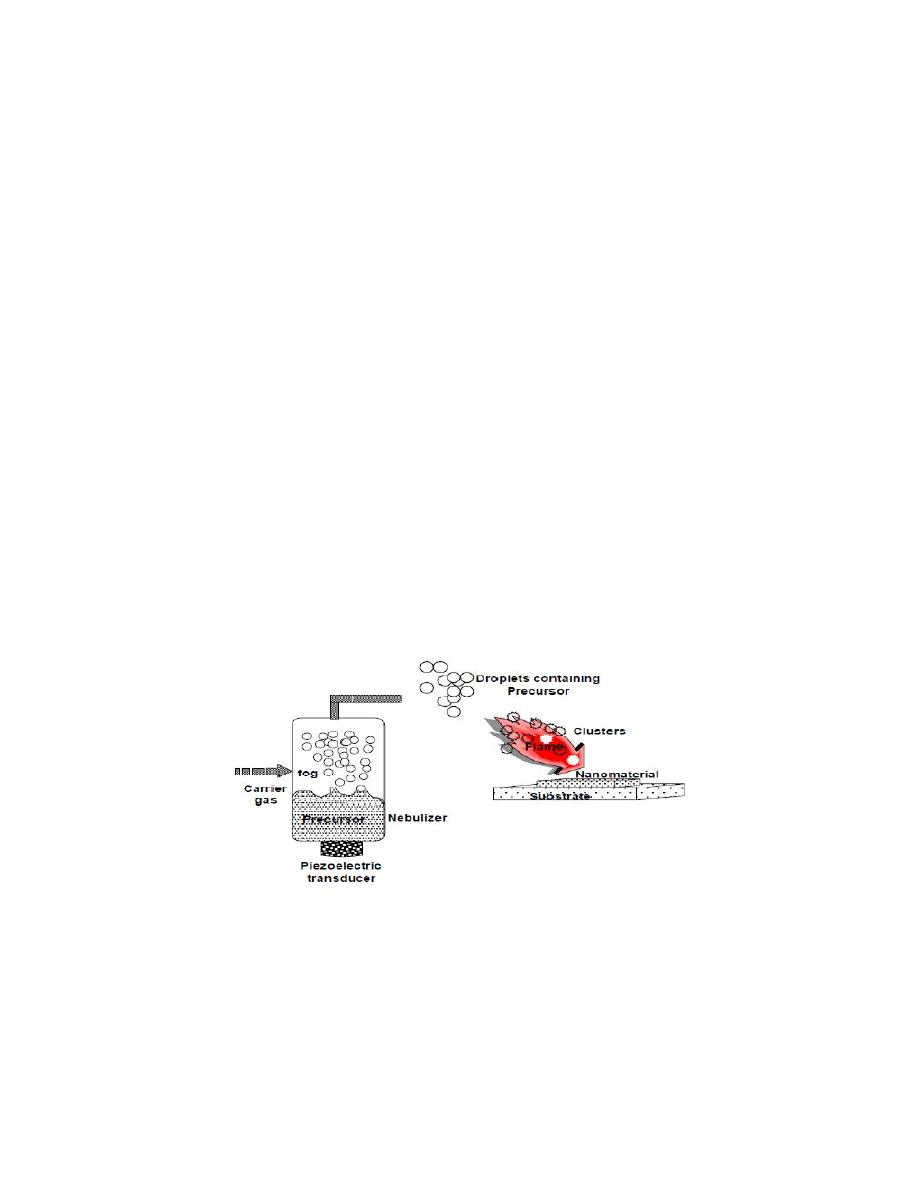

4-3-2 Flame assisted ultrasonic spray pyrolysis

In this process, precusrsors are nebulized and then unwanted

components are burnt in a flame to get the required material, eg. ZrO2

has been obtained by this method from a precursor of Zr(CH3 CH2

CH2O)4. Flame hydrolysis that is a variant of this process is

used for the manufacture of fused silica. In the process, silicon

tetrachloride is heated in an oxy-hydrogen flame to give a highly

dispersed silica. The resulting white amorphous powder consists of

spherical particles with sizes in the range 7-40 nm. The combustion

flame synthesis, in which the burning of a gas mixture, e.g. acetylene and

oxygen or hydrogen and oxygen, supplies the energy to initiate the

pyrolysis of precursor compounds, is widely used for the industrial

production of powders in large quantities, such as carbon black, fumed

silica and titanium dioxide. However, since the gas pressure

during the reaction is high, highly agglomerated powders are produced

which is disadvantageous for subsequent processing. The basic idea of

low pressure combustion flame synthesis is to extend the pressure range

to the pressures used in gas phase synthesis and thus to reduce or avoid

the agglomeration. Low pressure flames have been extensively used by

aerosol scientists to study particle formation in the flame.

Fig. 9. Flame assisted ultrasonic spray pyrolysis.

A key for the formation of nanoparticles with narrow size

distributions is the exact control of the flame in order to obtain a flat

flame front. Under these conditions the thermal history, i.e. time and

temperature, of each particle formed is identical and narrow

distributions result. However, due to the oxidative atmosphere in the

flame, this synthesis process is limited to the formation of oxides in the

reactor zone.

4-3-3 Gas Condensation Processing (GPC)

In this technique, a metallic or inorganic material, e.g. a suboxide,

is vaporised using thermal evaporation sources such as crucibles, electron

beam evaporation devices or sputtering sources in an atmosphere of 1-50

mbar He (or another inert gas like Ar, Ne, Kr). Cluster form in the

vicinity of the source by homogenous nucleation in the gas phase

and grow by coalescence and incorporation of atoms from the gas phase.

Fig. 10. Schematic representation of typical set-up for gas condensation

synthesis of nanomaterials followed by consolidation in a mechanical

press or collection in an appropriate solvent media.

The cluster or particle size depends critically on the residence time of

the particles in the growth system and can be influenced by the gas

pressure, the kind of inert gas, i.e. He, Ar or Kr, and on the evaporation

rate/vapour pressure of the evaporating material. With increasing gas

pressure, vapour pressure and mass of the inert gas used the average

particle size of the nanoparticles increases. Lognormal size distributions

have been found experimentally and have been explained theoretically by

the growth mechanisms of the particles. Even in more complex processes

such as the low pressure combustion flame synthesis where a number of

chemical reactions are involved the size distributions are determined to be

lognormal. Originally, a rotating cylindrical device cooled with liquid

nitrogen was employed for the particle collection: the nanoparticles in the

size range from 2-50 nm are extracted from the gas flow by

thermophoretic forces and deposited loosely on the surface of the

collection device as a powder of low density and no agglomeration.

Subsequenly, the nanoparticles are removed from the surface of the

cylinder by means of a scraper in the form of a metallic plate. In addition

to this cold finger device several techniques known from aerosol science

have now been implemented for the use in gas condensation

systems such as corona discharge, etc. These methods allow for the

continuous operation of the collection device and are better suited for

larger scale synthesis of nanopowders.

However, these methods can only be used in a system designed for gas

flow, i.e. a dynamic vacuum is generated by means of both continuous

pumping and gas inlet via mass flow controller. A major advantage over

convectional gas flow is the improved control of the particle sizes. It has

been found that the particle size distributions in gas flow systems, which

are also lognormal, are shifted towards smaller average values with

an appreciable reduction of the standard deviation of the distribution.

Depending on the flow rate of the He-gas, particle sizes are reduced by

80% and standard deviations by 18%.

The synthesis of nanocrystalline pure metals is relatively

straightforward as long as evaporation can be done from refractory metal

crucibles (W, Ta or Mo). If metals with high melting points or metals

which react with the crucibles, are to be prepared,sputtering, i.e. for W

and Zr, or laser or electron beam evaporation has to be used.

Synthesis of alloys or intermetallic compounds by thermal evaporation

can only be done in the exceptional cases that the vapour pressures of the

elements are similar. As an alternative, sputtering from an alloy or mixed

target can be employed. Composite materials such as Cu/Bi or W/Ga

have been synthesised by simultaneous evaporation from two separate

crucibles onto a rotating collection device. It has been found that

excellent intermixing on the scale of the particle size can be obtained.

However, control of the composition of the elements has been difficult

and reproducibility is poor. Nanocrystalline oxide powders are formed by

controlled postoxidation of primary nanoparticles of a pure metal (e.g. Ti

to TiO2) or a suboxide (e.g. ZrO to ZrO2). Although the gas

condensation method including the variations have been widely employed

to prepared a variety of metallic and ceramic materials, quantities

have so far been limited to a laboratory scale. The quantities of metals are

below 1 g/day, while quantities of oxides can be as high as 20 g/day for

simple oxides such as CeO2 or ZrO2. These quantities are sufficient for

materials testing but not for industrial production. However, it should be

mentioned that the scale-up of the gas condensation method for industrial

production of nanocrystalline oxides by a company called nanophase

technologies has been successful.

4-3-4 Chemical Vapour Condensation (CVC)

As shown schematically in Figure, the evaporative source used in

GPC is replaced by a hot wall reactor in the Chemical Vapour

Condensation or the CVC process. Depending on the processing

parameters nucleation of nanoparticles is observed during chemical

vapour deposition (CVC) of thin films and poses a major problem in

obtaining good film qualities. The original idea of the novel CVC process

which is schematically shown below where, it was intended to adjust the

parameter field during the synthesis in order to suppress film formation

and enhance homogeneous nucleation of particles in the gas flow. It is

readily found that the residence time of the precursor in the reactor

determines if films or particles are formed. In a certain range of residence

time both particle and formation can be obtained.

Adjusting the residence time of the precursor molecules by changing the

gas flow rate, the pressure difference between the precursor delivery

system and the main chamber occurs. Then the temperature of the hot

wall reactor results in the fertile production of nanosized particles of

metals and ceramics instead of thin films as in CVD processing. In

the simplest form a metal organic precursor is introduced into the hot

zone of the reactor using mass flow controller. Besides the increased

quantities in this continuous processcompared to GPC has been

demonstrated that a wider range of ceramics including nitrides and

carbides can be synthesised. Additionally, more complex oxides such as

BaTiO3 or composite structures can be formed as well. Appropriate

precursor compounds can be readily found in the CVD literature. The

extension to production of nanoparticles requires the determination of a

modified parameter field in order to promote particle formation instead of

film formation. In addition to the formation of single phase nanoparticles

by CVC of a single precursor the reactor allows the synthesis of

1. mixtures of nanoparticles of two phases or doped nanoparticles by

supplying two precursors at the front end of the reactor, and

2. coated nanoparticles, i.e., n-ZrO2 coated with n-Al2O3 or vice

versa, by supplying a second precursor at a second stage of the reactor. In

this case nanoparticles which have been formed by homogeneous

nucleation are coated by heterogeneous nucleation in a second stage of

the reactor.

Fig. 11. A schematic of a typical CVC reactor.

Because CVC processing is continuous, the production capabilities

are much larger than in GPC processing. Quantities in excess of 20 g/hr

have been readily produced with a small scale laboratory reactor. A

further expansion can be envisaged by simply enlarging the diameter of

the hot wall reactor and the mass flow through the reactor.

4-4 Sputtered Plasma Processing:

In this method is yet again a variation of the gas-condensation

method excepting the fact that the source material is a sputtering target

and this target is sputtered using rare gases and the constituents are

allowed to agglomerate to produce nanomaterial. Both dc (direct

current) and rf (radio-frequency) sputtering has been used to synthesize

nanoparticles.

Again reactive sputtering or multitarget sputtering has been used to

make alloys and/or oxides, carbides, nitrides of materials. This method is

specifically suitable for the preparation of ultrapure and non-

agglomerated nanoparticles of metal.

5-6 Microwave Plasma Processing

This technique is similar to the previously discussed CVC

method but employs plasma instead of high temperature for

decomposition of the metal organic precursors. The method uses

microwave plasma in a 50 mm diameter reaction vessel made of quartz

placed in a cavity connected to a microwave generator. A precursor such

as a chloride compound is introduced into the front end of the reactor.

Generally, the microwave cavity is designed as a single mode cavity

using the TE10 mode in a WR975 waveguide with a frequency of 0.915

GHz. The major advantage of the plasma assisted pyrolysis in contrast to

the thermal activation is the low temperature reaction which reduces the

tendency for agglomeration of the primary particles. This is also true in

the case of plasma-CVD processes. Additionally, it has been shown that

by introducing another precursor into a second reaction zone of the

tubular reactor, e.g. by splitting the microwave guide tubes, the primary

particles can be coated with a second phase. For example, it has been

demonstrated that ZrO2 nanoparticles can be coated by Al2O3. In

this case the inner ZrO2 core is crystalline, while the Al2O3 coating is

amorphous. The reaction sequence can be reversed with the result that an

amorphous Al2O3 core is coated with crystalline ZrO2. While the

formation of the primary particles occurs by homogeneous nucleation, it

can be easily estimated using gas reaction kinetics that the coating on the

primary particles grows heterogeneously and that homogeneous

nucleation of nanoparticles originating from the second compound has a

very low probability. A schematic representation of the particle growth in

plasma’s is given below:

5-7 Particle precipitation aided CVD:

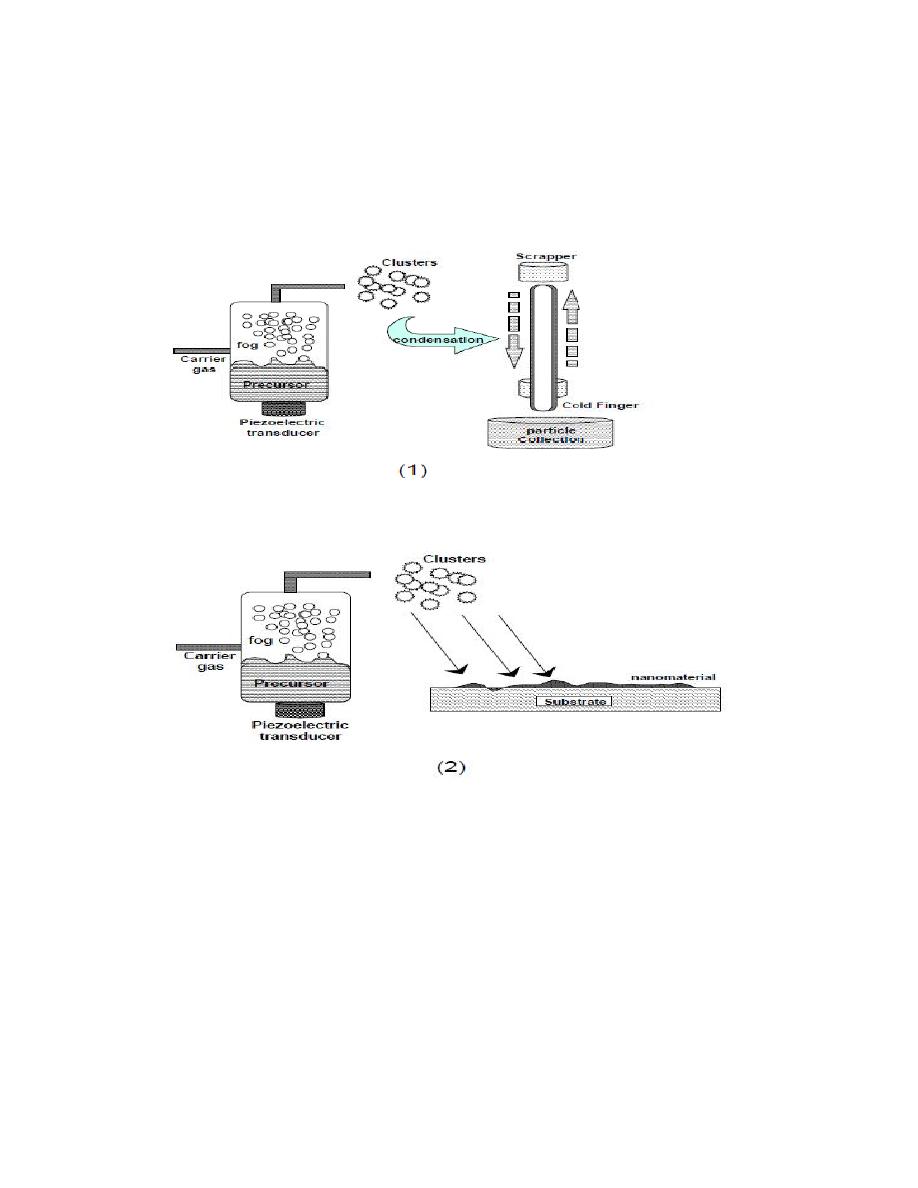

Fig. 12. Schematic representation of (1) nanoparticle, and (2) particulate

film formation .

In another variation of this process, colloidal clusters of materials

are used to prepare nanoparticles. The CVD reaction conditions are so set

that particles form by condensation in the gas phase and collect onto a

substrate, which is kept under a different condition that allows

heterogeneous nucleation. By this method both nanoparticles and

particulate films can be prepared. An example of this method has been

used to form nanomaterials eg. SnO2, by a method called pyrosol

deposition process, where clusters of tin hydroxide are transformed into

small aerosol droplets, following which they are reacted onto a

heated glass substrate.

5-8 Laser ablation

Laser ablation has been extensively used for the preparation of

nanoparticles and particulate films. In this process a laser beam is used as

the primary excitation source of ablation for generating clusters directly

from a solid sample in a wide variety of applications. The small

dimensions of the particles and the possibility to form thick films

make this method quite an efficient tool for the production of ceramic

particles and coatings and also an ablation source for analytical

applications such as the coupling to induced coupled plasma emission

spectrometry, ICP, the formation of the nanoparticles has been explained

following a liquefaction process which generates an aerosol, followed

by the cooling/solidification of the droplets which results in the formation

of fog. The general dynamics of both the aerosol and the fog favours the

aggregation process and micrometer-sized fractal-like particles are

formed. The laser spark atomizer can be used

to produce highly mesoporous thick films and the porosity can be

modified by the carrier gas flow rate. ZrO2 and SnO2 nanoparticulate

thick films were also synthesized successfully using this process with

quite identical microstructure. Synthesis of other materials such as

lithium manganate, silicon and carbon has also been carried out by this

technique.

Lecture 5

(nano

)

Application of nanomaterials

Nanomaterials having wide range of applications in the field of

electronics, fuel cells, batteries, agriculture, food industry, and medicines,

etc... It is evident that nanomaterials split their conventional counterparts

because of their superior chemical, physical, and mechanical properties

and of their exceptional formability.

5-1 Fuel cells.

A fuel cell is an electrochemical energy conversion device that

converts the chemical energy from fuel (on the anode side) and oxidant

(on the cathode side) directly into electricity. The heart of fuel cell is the

electrodes. The performance of a fuel cell electrode can be optimized in

two ways; by improving the physical structure and by using

more active electro catalyst. A good structure of electrode must provide

ample surface area, provide maximum contact of catalyst, reactant gas

and electrolyte, facilitate gas transport and provide good electronic

conductance. In this fashion the structure should be able to minimize

losses.

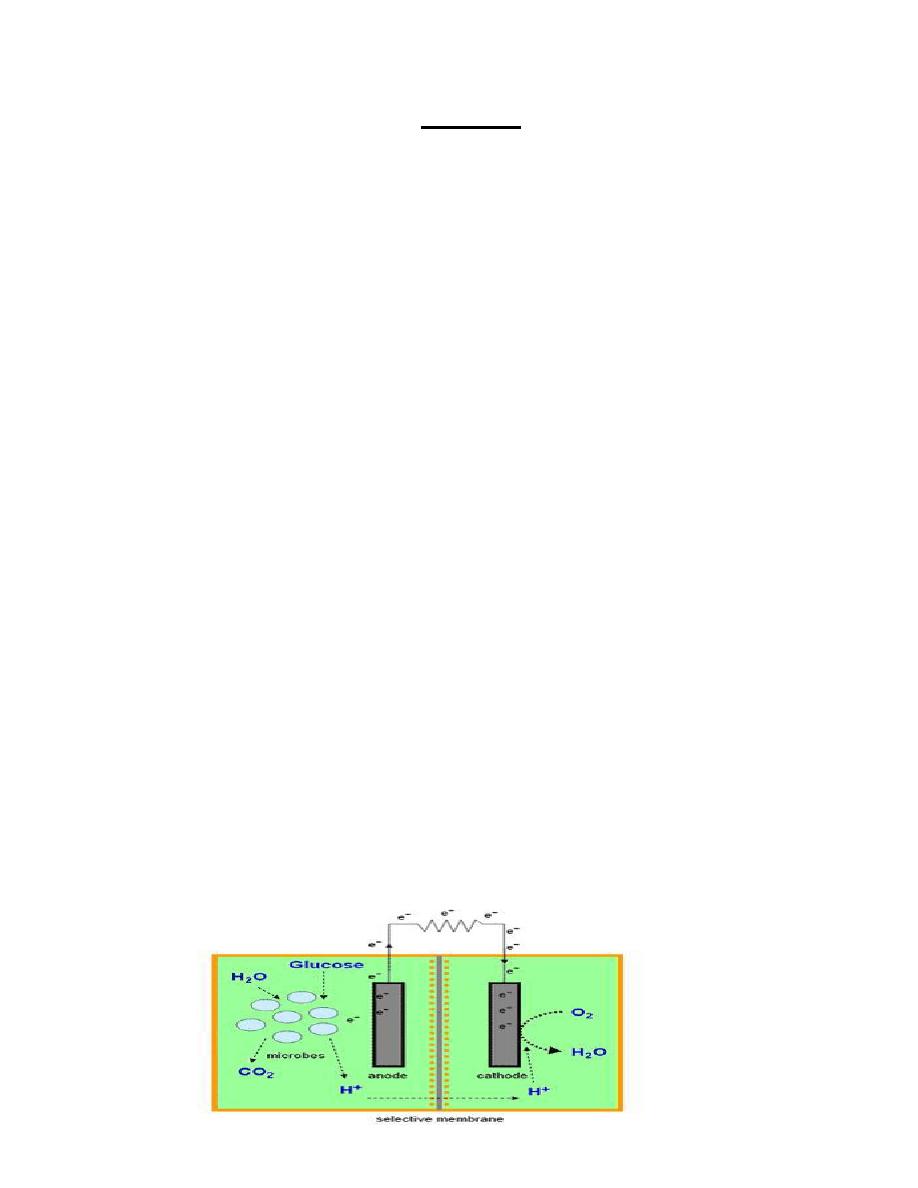

5-1-1 Carbon nanotubes - Microbial fuel cell .

Fig. 6-1 Schematic representation of microbial fuel cell

Microbial fuel cell is a device in which bacteria consume water-

soluble waste such as sugar, starch and alcohols and produces electricity

plus clean water. This technology will make it possible to generate

electricity while treating domestic or industrial wastewater.

Microbial fuel cell can turn different carbohydrates and complex

substrates present in wastewaters into a source of electricity. The efficient

electron transfer between the microorganism and the anode of the

microbial fuel cell plays a major role in the performance of the fuel cell.

The organic molecules present in the wastewater posses a certain amount

of chemical energy, which is released when converting them to simpler

molecules like CO2. The microbial fuel cell is thus a device that converts

the chemical energy present in water-soluble waste into electrical energy

by the catalytic reaction of microorganisms.Carbon nanotubes (CNTs)

have chemical stability, good mechanical properties and high surface

area, making them ideal for the design of sensors and provide very high

surface area due to its structural network. Since carbon nanotubes are also

suitable.supports for cell growth, electrodes of microbial fuel cells can be

built using of CNT.Due to three-dimensional architectures and enlarged

electrode surface area for the entry of growth medium, bacteria can grow

and proliferate and get immobilized. Multi walled CNT scaffolds could

offer self-supported structure with large surface area through

whichhydrogen producing bacteria (e.g., E. coli) can eventually grow and

proliferate. Also CNTs and MWCNTs have been reported to be

biocompatible for different eukaryotic cells. The efficient proliferation of

hydrogen producing bacteria throughout an electron conducting scaffold

of CNT can form the basis for the potential application as electrodes in

MFCs leading to efficient performance.

5-2 Catalysis.

Higher surface area available with the nanomaterial counterparts, nano-

catalysts tend to have exceptional surface activity. For example, reaction

rate at nano-aluminum can go sohigh, that it is utilized as a solid-fuel in

rocket propulsion, whereas the bulk aluminum is widely used in utensils.

Nano-aluminum becomes highly reactive and supplies the required thrust

to send off pay loads in space. Similarly, catalysts assisting or retarding

the reaction rates are dependent on the surface activity, and can very well

be utilized in manipulating the rate-controlling step.

5 -3 Phosphors for High-Definition TV.

The resolution of a television, or a monitor, depends greatly on the

size of the pixel. These pixels are essentially made of materials called

"phosphors," which glow whenstruck by a stream of electrons inside the

cathode ray tube (CRT). The resolution improves with a reduction in the

size of the pixel, or the phosphors. Nanocrystalline zinc selenide, zinc

sulfide, cadmium sulfide, and lead telluride synthesized by the sol-gel

techniques are candidates for improving the resolution of monitors. The

use of nanophosphors is envisioned to reduce the cost of these displays

so as to render highdefinition televisions (HDTVs) and personal

computers affordable to be purchase.

5 -4 Next-Generation Computer Chips.

The

microelectronics

industry

has

been

emphasizing

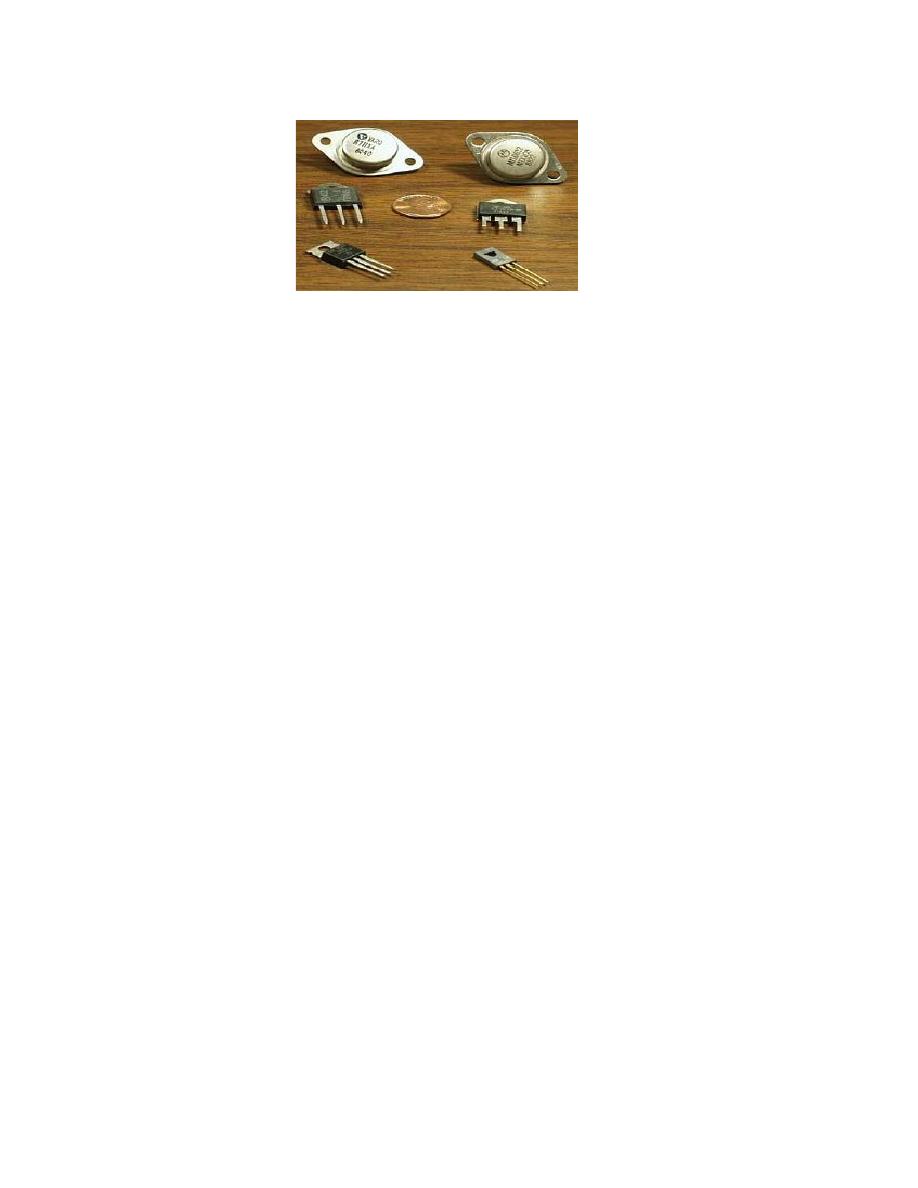

miniaturization, whereby the circuits, such as transistors, resistors, and

capacitors, are reduced in size. By achieving a significant reduction in

their size, the microprocessors, which contain these components,can run

much faster, thereby enabling computations at far greater speeds.

However, there are several technological impediments to these

advancements, including lack of the ultrafine precursors to manufacture

these components; poor dissipation of tremendous amount of heat

generated by these microprocessors due to faster speeds; short mean time

to failures (poor reliability), etc. Nanomaterials help the industry break

these barriers down by providing the manufacturers with nanocrystalline

starting materials, ultra-high purity materials, materials with better

thermal conductivity, and longer-lasting, durable interconnections

(connections between various components in the microprocessors).

Example: Nanowires for junctionless transistors

Transistors are made so tiny to reduce the size of sub assemblies of

electronic systems and make smaller and smaller devices, but it is

difficult to create high-quality junctions.

In particular, it is very difficult to change the doping concentration

of a material over distances shorter than about 10 nm. Researchers have

succeeded in making the junctionless transistor having nearly ideal

electrical properties. It could potentially operate faster and use less power

than any conventional transistor on the market today.

The device consists of a silicon nanowire in which current flow is

perfectly controlled by a silicon gate that is separated from the nanowire

by a thin insulating layer. The entire silicon nanowire is heavily n-doped,

making it an excellent conductor. However, the gate is p-doped and its

presence has the effect of depleting the number of electrons in the